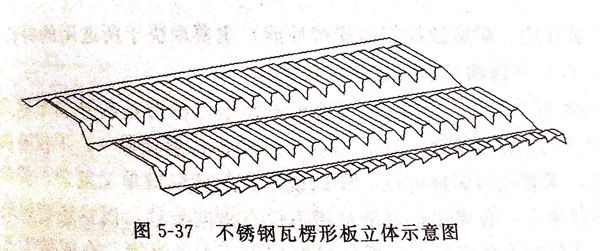

不(bu)銹(xiu)鋼(gang)瓦楞形板是不(bu)銹(xiu)鋼(gang)寬幅(fu)型鋼(gang)的(de)一種,由于其形狀如(ru)同頂(ding)上用瓦片鋪成的(de)行列隆起(qi)部分(fen),故稱(cheng)為在線亞洲日產一區二區:不銹鋼瓦楞形板(ban),如圖5-37所示。

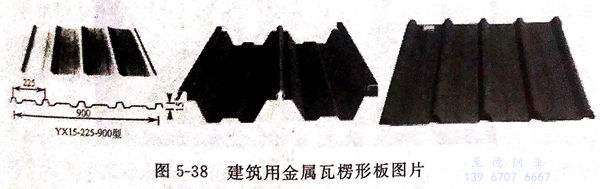

人們過去常(chang)見的(de)(de)“瓦(wa)(wa)楞(leng)(形(xing))板(ban)(ban)”大(da)都是用普通低(di)碳鋼(gang),也(ye)就(jiu)是非合金鋼(gang)材料(liao)制(zhi)成(cheng)(cheng)的(de)(de)(見圖5-38),還有用非金屬材料(liao)如(ru)石棉(mian)、塑(su)料(liao)、紙板(ban)(ban)等制(zhi)成(cheng)(cheng)的(de)(de)瓦(wa)(wa)楞(leng)形(xing)板(ban)(ban)。這(zhe)些瓦(wa)(wa)楞(leng)形(xing)板(ban)(ban)主要(yao)用于建筑領域的(de)(de)屋頂材料(liao)、外(wai)(wai)墻材料(liao)和各種包裝箱體的(de)(de)外(wai)(wai)形(xing)材料(liao)和產品包裝箱、盒等,之所以(yi)做成(cheng)(cheng)瓦(wa)(wa)楞(leng)形(xing)狀(zhuang),主要(yao)目的(de)(de)是增加結構(gou)剛度和穩(wen)定性。因(yin)此(ci),其尺寸精度和表面(mian)質量要(yao)求及(ji)材質要(yao)求都不是很高(gao)。

此處介紹(shao)的不(bu)銹(xiu)鋼瓦(wa)(wa)(wa)(wa)楞(leng)形(xing)(xing)(xing)板(ban)(ban)(ban)與普(pu)通(tong)的“瓦(wa)(wa)(wa)(wa)楞(leng)(形(xing)(xing)(xing))板(ban)(ban)(ban)”有(you)著(zhu)本質的不(bu)同,首(shou)先材料是不(bu)銹(xiu)鋼,無疑要(yao)(yao)比(bi)普(pu)通(tong)的“瓦(wa)(wa)(wa)(wa)楞(leng)(形(xing)(xing)(xing))板(ban)(ban)(ban)”具有(you)更高(gao)(gao)的強度、良好的耐(nai)腐(fu)蝕(shi)性(xing)能(neng)和(he)極好的裝飾效果,另外在結構上也大(da)不(bu)相(xiang)同。這些都賦予了不(bu)銹(xiu)鋼瓦(wa)(wa)(wa)(wa)楞(leng)形(xing)(xing)(xing)板(ban)(ban)(ban)不(bu)僅具有(you)普(pu)通(tong)“瓦(wa)(wa)(wa)(wa)楞(leng)形(xing)(xing)(xing)板(ban)(ban)(ban)”的各(ge)種功(gong)能(neng)與作(zuo)用,而且具有(you)普(pu)通(tong)“瓦(wa)(wa)(wa)(wa)楞(leng)(形(xing)(xing)(xing))板(ban)(ban)(ban)”沒有(you)的功(gong)能(neng),即不(bu)銹(xiu)鋼瓦(wa)(wa)(wa)(wa)楞(leng)形(xing)(xing)(xing)板(ban)(ban)(ban)可以(yi)作(zuo)為傳熱(re)元件使用。作(zuo)為傳熱(re)元件,對其(qi)各(ge)方(fang)面的要(yao)(yao)求(qiu)(qiu)就比(bi)普(pu)通(tong)“瓦(wa)(wa)(wa)(wa)楞(leng)(形(xing)(xing)(xing))板(ban)(ban)(ban)”高(gao)(gao)得多,特別是對瓦(wa)(wa)(wa)(wa)楞(leng)形(xing)(xing)(xing)板(ban)(ban)(ban)表觀的要(yao)(yao)求(qiu)(qiu)。對瓦(wa)(wa)(wa)(wa)楞(leng)形(xing)(xing)(xing)板(ban)(ban)(ban)表觀的要(yao)(yao)求(qiu)(qiu)主(zhu)要(yao)(yao)體現在對外形(xing)(xing)(xing)尺寸(cun)和(he)表面質量的要(yao)(yao)求(qiu)(qiu)上。因此,采用何種方(fang)式(shi)、何種工藝加工生產(chan)不(bu)銹(xiu)鋼瓦(wa)(wa)(wa)(wa)楞(leng)形(xing)(xing)(xing)板(ban)(ban)(ban)就成為保(bao)證其(qi)外形(xing)(xing)(xing)尺寸(cun)和(he)質量的關鍵。其(qi)他(ta)性(xing)能(neng)(機械性(xing)能(neng)、耐(nai)腐(fu)蝕(shi)性(xing)能(neng)和(he)焊(han)接性(xing)能(neng))主(zhu)要(yao)(yao)取決于所選用的材料。

1. 不銹(xiu)鋼瓦楞形板外(wai)形尺(chi)寸

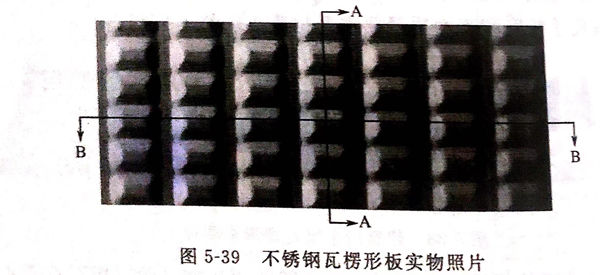

從圖5-37和(he)圖5-39可以看出不(bu)銹鋼瓦楞(leng)形(xing)板的(de)外表(biao)形(xing)狀(zhuang)是有(you)規(gui)律、周期性變化的(de),而且彎曲深度較小、形(xing)狀(zhuang)單一(yi),不(bu)僅有(you)橫向(xiang)波(bo)紋(wen),而且還有(you)縱(zong)向(xiang)波(bo)紋(wen)。所以說(shuo),其形(xing)狀(zhuang)既(ji)簡單又(you)復雜,簡單是指(zhi)形(xing)狀(zhuang)單一(yi),有(you)規(gui)律;復雜是指(zhi)不(bu)僅有(you)橫向(xiang)波(bo)紋(wen),而且還有(you)縱(zong)向(xiang)波(bo)紋(wen)。這就(jiu)給不(bu)銹鋼瓦楞(leng)形(xing)板的(de)成(cheng)型(xing)帶來不(bu)小的(de)難度,在成(cheng)型(xing)工藝(yi)上(shang)必須采(cai)取(qu)相(xiang)應的(de)工藝(yi)措施和(he)手段,方能保證獲得要求的(de)外形(xing)尺寸和(he)成(cheng)型(xing)質量。

圖5-39是不(bu)銹鋼瓦楞形板的(de)實物照片,從圖片可以看出,不(bu)銹鋼瓦楞形板的(de)外表(biao)和形狀是非常美(mei)觀、漂亮(liang)的(de),具(ju)有較高的(de)觀賞(shang)性,如同(tong)工藝品、裝飾品。

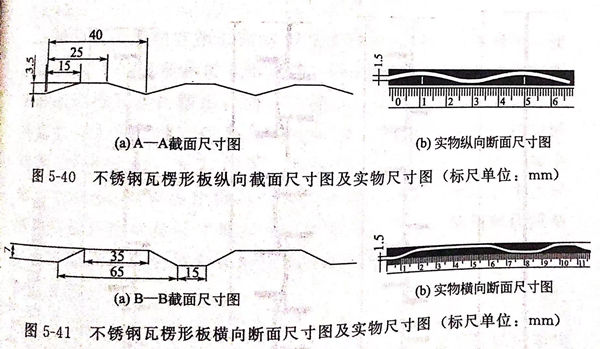

圖(tu)5-39不(bu)銹鋼瓦(wa)楞(leng)形板(ban)A-A截(jie)面尺(chi)寸,見圖(tu)5-40,B-B截(jie)面尺(chi)寸,見圖(tu)5-41。

不銹(xiu)鋼瓦楞形(xing)板成品實物斷(duan)面圖(tu)(tu)片,見圖(tu)(tu)5-40(b)和圖(tu)(tu)5-41(b)。

從(cong)圖5-40和圖5-41可以看出,不銹(xiu)鋼瓦(wa)楞形板的(de)(de)斷面(mian)變(bian)化的(de)(de)規(gui)律是(shi)周期(qi)性(xing)的(de)(de),斷面(mian)形狀是(shi)關于縱向(xiang)中心線(xian)為對(dui)稱的(de)(de)型鋼,彎曲(qu)深度(du)較淺,深度(du)僅有(you)7mm。

不銹(xiu)鋼瓦楞形板外(wai)形尺寸精度:截面最(zui)大(da)邊長誤差≤0.3mm;圓角最(zui)大(da)直徑:≤2.0mm;縱(zong)向、橫向彎曲度:每米(mi)≤1mm; 扭轉(zhuan):每米(mi)≤1°。

2. 瓦楞形板橫(heng)向波紋(wen)的成(cheng)型(xing)

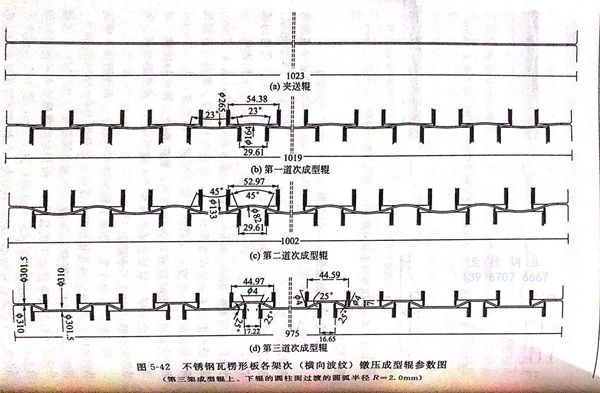

不(bu)(bu)銹鋼(gang)瓦楞形(xing)(xing)板輥(gun)式冷彎(wan)成(cheng)型時,首先將不(bu)(bu)銹鋼(gang)冷軋(ya)平板預彎(wan)曲鐓(dui)壓成(cheng)弧形(xing)(xing)波紋,如圖5-42所示的(de)(de)第一架成(cheng)型輥(gun)孔形(xing)(xing)的(de)(de)形(xing)(xing)狀(zhuang)。輥(gun)形(xing)(xing)的(de)(de)形(xing)(xing)狀(zhuang)為(wei)(wei)(wei)(wei)(wei),向下彎(wan)曲的(de)(de)弧形(xing)(xing)直徑為(wei)(wei)(wei)(wei)(wei)Φ=265mm,向上(shang)彎(wan)曲的(de)(de)弧形(xing)(xing)直徑為(wei)(wei)(wei)(wei)(wei)Φ=164mm,帶鋼(gang)進入(ru)并通過如此(ci)輥(gun)型是(shi)毫不(bu)(bu)困(kun)難的(de)(de),一個波長(chang)(周期(qi))為(wei)(wei)(wei)(wei)(wei)83.40mm,弧深(shen)度(垂直位(wei)移(yi)(yi))為(wei)(wei)(wei)(wei)(wei)4.12mm,這(zhe)個成(cheng)型形(xing)(xing)狀(zhuang)無論是(shi)在變形(xing)(xing)寬(kuan)(kuan)(kuan)度上(shang),還是(shi)變形(xing)(xing)深(shen)度上(shang)都是(shi)可行的(de)(de)和(he)(he)符合要(yao)求的(de)(de)。一個波長(chang)(周期(qi))橫向位(wei)移(yi)(yi)(減(jian)寬(kuan)(kuan)(kuan)量)為(wei)(wei)(wei)(wei)(wei)0.60mm,相對減(jian)寬(kuan)(kuan)(kuan)率(橫向位(wei)移(yi)(yi))為(wei)(wei)(wei)(wei)(wei)0.71%,見圖5-42,如此(ci)的(de)(de)位(wei)移(yi)(yi)(減(jian)寬(kuan)(kuan)(kuan)量)不(bu)(bu)會對鐓(dui)壓成(cheng)型造成(cheng)困(kun)難和(he)(he)產(chan)生成(cheng)型缺陷,這(zhe)些都為(wei)(wei)(wei)(wei)(wei)第二架成(cheng)型輥(gun)再鐓(dui)壓創造了條件。

第(di)二(er)架成(cheng)(cheng)型(xing)(xing)(xing)輥(gun)(gun)(gun)在(zai)第(di)一架成(cheng)(cheng)型(xing)(xing)(xing)輥(gun)(gun)(gun)的(de)(de)(de)鐓壓(ya)(ya)基礎上(shang),再(zai)(zai)次鐓壓(ya)(ya),使(shi)(shi)其(qi)達到(dao)如(ru)圖5-42所示(shi)的(de)(de)(de)孔(kong)形(xing)(xing)(xing)(xing)形(xing)(xing)(xing)(xing)狀(zhuang),弧度(du)直徑分(fen)別為(wei)(wei)(wei)(wei)(wei)Φ=133mm和(he)(he)p=82mm,一個波長(周期(qi))為(wei)(wei)(wei)(wei)(wei)81.70mm、弧深(shen)度(du)為(wei)(wei)(wei)(wei)(wei)8.18mm,這就是說寬度(du)和(he)(he)深(shen)度(du)更接(jie)近于成(cheng)(cheng)品(pin)形(xing)(xing)(xing)(xing)狀(zhuang),而(er)相(xiang)對減(jian)寬量(水(shui)平位(wei)移)僅為(wei)(wei)(wei)(wei)(wei)1.42mm,相(xiang)對減(jian)寬率(水(shui)平方(fang)(fang)向)為(wei)(wei)(wei)(wei)(wei)1.7%,要比(bi)第(di)一道次大了許(xu)多,這是符合開始小一些(xie)、中間大一些(xie)的(de)(de)(de)成(cheng)(cheng)型(xing)(xing)(xing)規律要求(qiu)的(de)(de)(de),見(jian)第(di)三架成(cheng)(cheng)型(xing)(xing)(xing)輥(gun)(gun)(gun)在(zai)第(di)二(er)架成(cheng)(cheng)型(xing)(xing)(xing)輥(gun)(gun)(gun)的(de)(de)(de)鐓壓(ya)(ya)基礎上(shang),再(zai)(zai)鐓壓(ya)(ya),使(shi)(shi)其(qi)達到(dao)如(ru)圖5-42所示(shi)的(de)(de)(de)孔(kong)形(xing)(xing)(xing)(xing)形(xing)(xing)(xing)(xing)狀(zhuang),這時將已經成(cheng)(cheng)型(xing)(xing)(xing)的(de)(de)(de)弧形(xing)(xing)(xing)(xing)瓦楞(leng)形(xing)(xing)(xing)(xing)鐓壓(ya)(ya)成(cheng)(cheng)梯(ti)形(xing)(xing)(xing)(xing)狀(zhuang)瓦楞(leng)形(xing)(xing)(xing)(xing),而(er)一個波長(周期(qi))為(wei)(wei)(wei)(wei)(wei)80mm,相(xiang)對減(jian)寬量(水(shui)平位(wei)移)僅為(wei)(wei)(wei)(wei)(wei)2.28mm,一個波長(周期(qi))相(xiang)對減(jian)寬率(水(shui)平方(fang)(fang)向)為(wei)(wei)(wei)(wei)(wei)2.79%.通(tong)過鐓壓(ya)(ya)使(shi)(shi)弧深(shen)由(you)8.18mm減(jian)小為(wei)(wei)(wei)(wei)(wei)7.00mm,這樣可使(shi)(shi)梯(ti)形(xing)(xing)(xing)(xing)成(cheng)(cheng)型(xing)(xing)(xing)更加精(jing)確(que)到(dao)位(wei),為(wei)(wei)(wei)(wei)(wei)最(zui)后沖壓(ya)(ya)成(cheng)(cheng)型(xing)(xing)(xing)達到(dao)成(cheng)(cheng)品(pin)形(xing)(xing)(xing)(xing)狀(zhuang)及(ji)尺寸奠定良好的(de)(de)(de)基礎,此時,橫(heng)向鐓壓(ya)(ya)成(cheng)(cheng)型(xing)(xing)(xing)已全部完(wan)成(cheng)(cheng),隨(sui)后將采用沖壓(ya)(ya)成(cheng)(cheng)型(xing)(xing)(xing)輥(gun)(gun)(gun)在(zai)已成(cheng)(cheng)型(xing)(xing)(xing)橫(heng)向波紋上(shang)完(wan)成(cheng)(cheng)最(zui)終(zhong)成(cheng)(cheng)型(xing)(xing)(xing)。

圖(tu)5-42是各架次成型輥(gun)輥(gun)形尺寸圖(tu)。

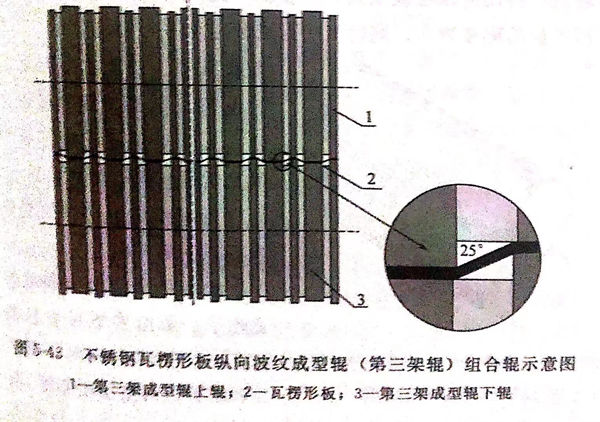

第三(san)架(jia)成(cheng)型(xing)輥(gun)(gun)輥(gun)(gun)形(xing)圖(tu)和(he)孔(kong)形(xing)圖(tu),見(jian)圖(tu)5-43.第三(san)架(jia)成(cheng)型(xing)輥(gun)(gun)應是(shi)由(you)多片輥(gun)(gun)片疊加組(zu)合而成(cheng)的(de)(de)(de)組(zu)合輥(gun)(gun),輥(gun)(gun)片的(de)(de)(de)水平(ping)段和(he)圓(yuan)弧(hu)(hu)(hu)段采取(qu)與板材(cai)接(jie)觸(chu)(chu)的(de)(de)(de)方式,而傾斜段則(ze)采取(qu)與板材(cai)不接(jie)觸(chu)(chu)的(de)(de)(de)方式,為的(de)(de)(de)是(shi)減少成(cheng)型(xing)表(biao)面的(de)(de)(de)擦劃傷,此(ci)外(wai),如此(ci)結(jie)構(gou)也將便于成(cheng)型(xing)輥(gun)(gun)的(de)(de)(de)加工和(he)隨后的(de)(de)(de)使用與維護(hu)等。上(shang)、下(xia)輥(gun)(gun)斜角采取(qu)圓(yuan)弧(hu)(hu)(hu)過渡,一(yi)般(ban)情況下(xia),圓(yuan)弧(hu)(hu)(hu)的(de)(de)(de)直(zhi)徑(jing)應大(da)于板厚,所以圖(tu)5-43所示的(de)(de)(de)第三(san)架(jia)上(shang)、下(xia)輥(gun)(gun)斜角的(de)(de)(de)圓(yuan)弧(hu)(hu)(hu)過渡直(zhi)徑(jing)為2.0mm,見(jian)圖(tu)5-43局部(bu)放大(da)圖(tu)。

3. 縱向波(bo)紋的成型

縱向(xiang)波紋(wen)的(de)成(cheng)型(xing)(xing)是(shi)在橫向(xiang)波紋(wen)成(cheng)型(xing)(xing)之后的(de)橫向(xiang)波紋(wen)上(shang)成(cheng)型(xing)(xing)的(de)。所以在已成(cheng)型(xing)(xing)的(de)波紋(wen)上(shang)再(zai)成(cheng)型(xing)(xing)縱向(xiang)波紋(wen)是(shi)有難度的(de)。其難度主要表(biao)現為,可能破壞已成(cheng)型(xing)(xing)的(de)橫向(xiang)波紋(wen),而且縱向(xiang)波紋(wen)也成(cheng)型(xing)(xing)不好。選用(yong)何種方式成(cheng)型(xing)(xing)就(jiu)成(cheng)為縱向(xiang)波紋(wen)成(cheng)型(xing)(xing)的(de)關鍵。

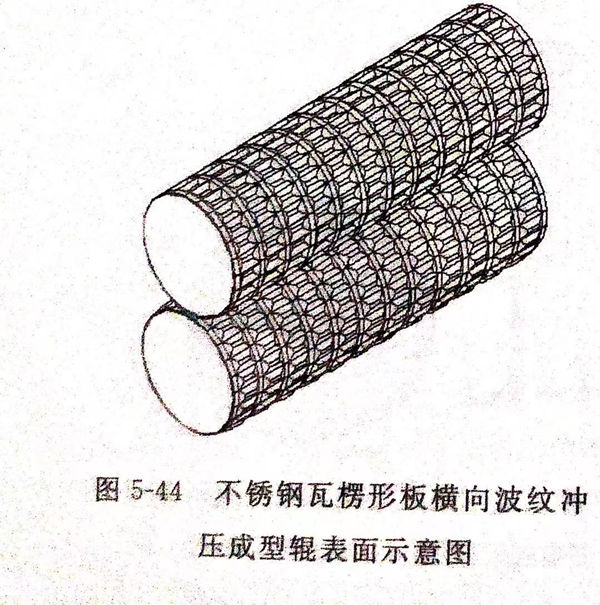

沖(chong)壓(ya)(ya)(ya)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)輥(gun)(gun)(gun)(gun)(gun)就是在(zai)(zai)一對成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)輥(gun)(gun)(gun)(gun)(gun)上,按工(gong)藝和(he)產品(pin)的(de)(de)(de)要求(qiu),在(zai)(zai)要面上間(jian)隙(xi)分布著凸起(qi)(qi)和(he)凹陷的(de)(de)(de)部(bu)分,用于壓(ya)(ya)(ya)制成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)瓦(wa)(wa)楞(leng)(leng)形(xing)(xing)板(ban)的(de)(de)(de)縱(zong)向(xiang)(xiang)波紋(wen),同時又不能損壞已成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)的(de)(de)(de)橫向(xiang)(xiang)梯形(xing)(xing)波紋(wen),縱(zong)向(xiang)(xiang)波紋(wen)尺(chi)寸圖(tu)及實物圖(tu)片,見圖(tu)5-40和(he)圖(tu)5-41。之所以將沖(chong)壓(ya)(ya)(ya)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)輥(gun)(gun)(gun)(gun)(gun)置于橫向(xiang)(xiang)波紋(wen)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)輥(gun)(gun)(gun)(gun)(gun)后(hou)、平(ping)整(zheng)輥(gun)(gun)(gun)(gun)(gun)前,是為了(le)保(bao)證瓦(wa)(wa)楞(leng)(leng)形(xing)(xing)板(ban)的(de)(de)(de)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)過程(cheng)的(de)(de)(de)穩定(ding)和(he)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)質(zhi)(zhi)量(liang)。可以想象,在(zai)(zai)沒有橫向(xiang)(xiang)波紋(wen)的(de)(de)(de)平(ping)板(ban)帶(dai)材(cai)上沖(chong)壓(ya)(ya)(ya)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)凸起(qi)(qi)和(he)凹陷型(xing)(xing)(xing)(xing)材(cai),由于自由度(du)(du)大(da)沒有約(yue)束力,沖(chong)壓(ya)(ya)(ya)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)會造成(cheng)(cheng)(cheng)(cheng)坯料(liao)(liao)局部(bu)收縮,產生皺折及其(qi)他缺(que)陷,影響(xiang)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)質(zhi)(zhi)量(liang)和(he)成(cheng)(cheng)(cheng)(cheng)品(pin)的(de)(de)(de)尺(chi)寸。另外,瓦(wa)(wa)楞(leng)(leng)形(xing)(xing)板(ban)型(xing)(xing)(xing)(xing)鋼截面受(shou)材(cai)料(liao)(liao)內部(bu)殘余應力作(zuo)用,很容易產生扭(niu)轉,這也會影響(xiang)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)過程(cheng)的(de)(de)(de)穩定(ding)性。但在(zai)(zai)瓦(wa)(wa)楞(leng)(leng)形(xing)(xing)板(ban)橫向(xiang)(xiang)波紋(wen)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)輥(gun)(gun)(gun)(gun)(gun)后(hou)、平(ping)整(zheng)輥(gun)(gun)(gun)(gun)(gun)前,再用沖(chong)壓(ya)(ya)(ya)輥(gun)(gun)(gun)(gun)(gun)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)其(qi)縱(zong)向(xiang)(xiang)波紋(wen),此時,已成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)的(de)(de)(de)橫向(xiang)(xiang)波紋(wen)使瓦(wa)(wa)楞(leng)(leng)形(xing)(xing)板(ban)的(de)(de)(de)剛度(du)(du)增大(da),同時又受(shou)到(dao)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)輥(gun)(gun)(gun)(gun)(gun)和(he)平(ping)整(zheng)輥(gun)(gun)(gun)(gun)(gun)的(de)(de)(de)約(yue)束,其(qi)自由度(du)(du)就減小。以上這些(xie)都可以有效(xiao)地防(fang)止(zhi)局部(bu)收縮和(he)型(xing)(xing)(xing)(xing)鋼的(de)(de)(de)扭(niu)轉,從而對保(bao)證瓦(wa)(wa)楞(leng)(leng)形(xing)(xing)板(ban)的(de)(de)(de)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)及質(zhi)(zhi)量(liang)起(qi)(qi)到(dao)有效(xiao)的(de)(de)(de)保(bao)障(zhang)作(zuo)用。瓦(wa)(wa)楞(leng)(leng)形(xing)(xing)板(ban)橫向(xiang)(xiang)波紋(wen)沖(chong)壓(ya)(ya)(ya)輥(gun)(gun)(gun)(gun)(gun)的(de)(de)(de)示意(yi)圖(tu),見圖(tu)5-44。

沖(chong)壓成(cheng)型輥也應做成(cheng)組(zu)合式輥子,即由多輥片(pian)疊加組(zu)合而成(cheng)。這(zhe)種形式的輥子便(bian)于(yu)加工和(he)維護,調整使用方(fang)便(bian)。