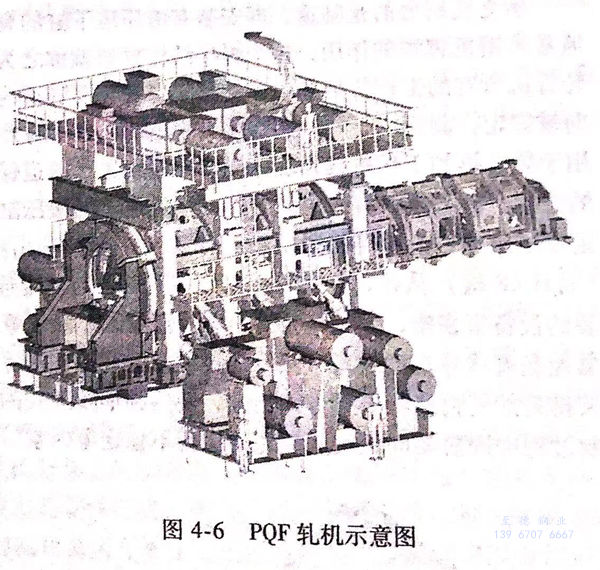

三輥限動芯棒連續軋管機PQF(Premium Quality Finishing)是意大利 INNSE公司為克服二輥連續軋管機的固有局限性而研制開發的。如圖4-6所示,PQF軋管機由4~7架三輥可調式機架組成,采用限動芯棒方式操作,其中ф168mm PQF機組由于采用了獨特的芯棒運行方式,使其軋制節奏達到24s/支。代表性機組為我國天津不銹鋼(gang)管廠的ф168mm機組。

從軋(ya)(ya)(ya)鋼工(gong)藝上講(jiang)三輥(gun)連(lian)續(xu)(xu)軋(ya)(ya)(ya)管(guan)機比二輥(gun)連(lian)續(xu)(xu)軋(ya)(ya)(ya)管(guan)機有(you)(you)明(ming)顯的優點,但(dan)多(duo)了一(yi)個(ge)軋(ya)(ya)(ya)輥(gun)使得軋(ya)(ya)(ya)機結構(gou)有(you)(you)了明(ming)顯的差異,用(yong)什么樣的結構(gou)形式(shi)才能滿(man)足新機型(xing)的要求,使其(qi)發(fa)揮優勢,實現高效生(sheng)產,達到理(li)想的效果,一(yi)直(zhi)是人們探索的目標,多(duo)年來全世(shi)(shi)界一(yi)直(zhi)沒有(you)(you)哪(na)家企業開發(fa)采用(yong)這項技(ji)術。進入21世(shi)(shi)紀,天(tian)津(jin)不銹鋼管(guan)廠(chang)和(he)米爾/因西(xi)公司共(gong)同成(cheng)功(gong)開發(fa)了Φ168mm PQF限動芯(xin)棒(bang)連(lian)續(xu)(xu)軋(ya)(ya)(ya)管(guan)機,于2003年8月在(zai)天(tian)津(jin)不銹鋼管(guan)廠(chang)建(jian)成(cheng)投(tou)產,并在(zai)當年12月就(jiu)達到了設計產量(liang)。PQF一(yi)經問世(shi)(shi),就(jiu)引起了國內外同行的高度(du)重視,現對(dui)其(qi)工(gong)藝、結構(gou)和(he)傳動等特點作一(yi)簡要介(jie)紹。

一、工藝特點

三輥連續軋管機簡稱PQF,是由因西公司開發推出的。軋管時芯棒是限動的、速度是可控的,芯棒的速度應高于第一架的咬入速度,屬于限動芯棒連續軋管機,每個機架由三個軋輥組成孔型,采用三輥設計的孔型比傳統的兩輥設計的孔型圓度好,且孔型的半徑差小,有利于軋件的均勻變形,也使軋輥的磨損均勻。軋槽底部和軋槽頂部之間的圓周速度差較小,從而能在穩定的條件下使軋制的金屬變形更加均勻,使所軋制的荒管徑壁比達到45以上。凸緣面積(不與軋輥或芯棒接觸的管子面積,也就是輥縫處壁厚/外徑的凸起面積,見圖4-2)有所減小,即流向凸緣的金屬量減少了,這一優點在軋制不受外端及其他機架約束的鋼管尾端時尤為重要。事實上鋼管尾端在三輥式軋管機上軋制時受控是由于凸緣面積較小(比二輥式的小30%左右)以及軋槽底部與軋槽頂部間的圓周速度差較小的緣故,因此可以避免或大大減少管端折疊和飛翅的形成。由于圓周壓應力較高,從而能在軋制時使輥縫處產生的縱向拉應力的危險性大大降低。孔型中芯棒的穩定性較高,PQF機組可以生產高強度(P110以上)特殊鋼級油井用管、高壓鍋爐管及13Cr、304L等不銹鋼管。POF最大的優勢是,由于三輥孔型的半徑差小于兩輥,軋件變形更加均勻、平穩,使產品的壁厚精度和表面質量高于MPM,軋制的荒管直徑越大,優勢越明顯。

二、結構(gou)特點

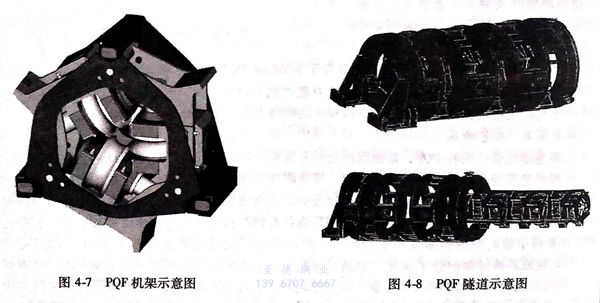

工(gong)作(zuo)(zuo)機(ji)(ji)(ji)架(jia)(jia)(jia)是由(you)三(san)個(ge)(ge)軋(ya)(ya)(ya)輥(gun)(gun)組成(cheng)一(yi)(yi)體相對獨(du)立的(de)(de)軋(ya)(ya)(ya)制(zhi)單元。天津鋼管公司的(de)(de)PQF連(lian)續軋(ya)(ya)(ya)管機(ji)(ji)(ji)由(you)6個(ge)(ge)工(gong)作(zuo)(zuo)機(ji)(ji)(ji)架(jia)(jia)(jia)(包括第1架(jia)(jia)(jia)空減(jian)機(ji)(ji)(ji)架(jia)(jia)(jia)即VRS)組成(cheng)。工(gong)作(zuo)(zuo)機(ji)(ji)(ji)架(jia)(jia)(jia)不承(cheng)(cheng)受(shou)軋(ya)(ya)(ya)制(zhi)力,只承(cheng)(cheng)受(shou)限(xian)動(dong)力。工(gong)作(zuo)(zuo)機(ji)(ji)(ji)架(jia)(jia)(jia)內的(de)(de)三(san)個(ge)(ge)軋(ya)(ya)(ya)輥(gun)(gun)在(zai)壓下機(ji)(ji)(ji)構和(he)平衡裝(zhuang)置(zhi)的(de)(de)控(kong)制(zhi)下構成(cheng)一(yi)(yi)個(ge)(ge)孔型(xing)(xing),并(bing)可對孔型(xing)(xing)進行(xing)調整(zheng)(zheng)。每(mei)個(ge)(ge)軋(ya)(ya)(ya)輥(gun)(gun)(包括軸承(cheng)(cheng)座(zuo))安裝(zhuang)在(zai)一(yi)(yi)個(ge)(ge)杠(gang)桿臂上(shang),杠(gang)桿臂通過銷(xiao)軸安裝(zhuang)在(zai)工(gong)作(zuo)(zuo)機(ji)(ji)(ji)架(jia)(jia)(jia)上(shang),孔型(xing)(xing)調整(zheng)(zheng)時杠(gang)桿以(yi)銷(xiao)軸為支(zhi)點擺動(dong)。每(mei)個(ge)(ge)軋(ya)(ya)(ya)輥(gun)(gun)軸承(cheng)(cheng)座(zuo)的(de)(de)兩(liang)側(ce),工(gong)作(zuo)(zuo)機(ji)(ji)(ji)架(jia)(jia)(jia)上(shang)都有導向滑板,用來保(bao)持軋(ya)(ya)(ya)輥(gun)(gun)調整(zheng)(zheng)時的(de)(de)位置(zhi),并(bing)承(cheng)(cheng)受(shou)限(xian)動(dong)力。工(gong)作(zuo)(zuo)機(ji)(ji)(ji)架(jia)(jia)(jia)上(shang)有一(yi)(yi)套軋(ya)(ya)(ya)輥(gun)(gun)軸承(cheng)(cheng)甘油潤滑管線系統和(he)一(yi)(yi)套軋(ya)(ya)(ya)輥(gun)(gun)冷卻水系統,由(you)液壓缸操作(zuo)(zuo)的(de)(de)快速接頭將這兩(liang)個(ge)(ge)系統連(lian)接到外管網上(shang)。PQF機(ji)(ji)(ji)架(jia)(jia)(jia)示意圖(tu)參見(jian)圖(tu)4-7。

承受軋(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)(zhi)力(li)的(de)(de)(de)(de)是(shi)(shi)隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao),即安(an)裝(zhuang)有液(ye)壓(ya)壓(ya)下(xia)缸的(de)(de)(de)(de)高(gao)強度、高(gao)剛(gang)度的(de)(de)(de)(de)焊(han)接(jie)結構框架,它(ta)起到(dao)了(le)通常(chang)軋(ya)(ya)(ya)(ya)鋼機(ji)(ji)(ji)(ji)(ji)(ji)牌坊的(de)(de)(de)(de)作(zuo)用,這個焊(han)接(jie)結構框架就稱之為“隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)”,其示意圖參見圖4-8。PQF連(lian)續(xu)軋(ya)(ya)(ya)(ya)管機(ji)(ji)(ji)(ji)(ji)(ji)所有的(de)(de)(de)(de)工(gong)作(zuo)機(ji)(ji)(ji)(ji)(ji)(ji)架和(he)(he)(he)(he)芯棒支撐架都安(an)裝(zhuang)在(zai)(zai)隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)內,它(ta)們通過液(ye)壓(ya)缸從(cong)(cong)垂方(fang)向和(he)(he)(he)(he)軋(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)(zhi)線方(fang)向被固定(ding)在(zai)(zai)隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)內,與(yu)軋(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)(zhi)線相吻(wen)合。PQF的(de)(de)(de)(de)軋(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)(zhi)力(li)和(he)(he)(he)(he)限動(dong)力(li)都是(shi)(shi)由(you)(you)隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)來(lai)承受的(de)(de)(de)(de)。隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)內有用于裝(zhuang)、拆卸工(gong)作(zuo)機(ji)(ji)(ji)(ji)(ji)(ji)架和(he)(he)(he)(he)芯棒支撐架的(de)(de)(de)(de)軌道(dao)(dao)(dao)(dao)(dao)(dao),軌道(dao)(dao)(dao)(dao)(dao)(dao)保(bao)證(zheng)換輥(gun)時(shi)工(gong)作(zuo)機(ji)(ji)(ji)(ji)(ji)(ji)架和(he)(he)(he)(he)芯棒支撐架達到(dao)正(zheng)確(que)的(de)(de)(de)(de)位(wei)置(zhi)。隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)出口有一個鎖緊門,用隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)上(shang)的(de)(de)(de)(de)液(ye)壓(ya)缸沿軋(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)(zhi)線方(fang)向將工(gong)作(zuo)機(ji)(ji)(ji)(ji)(ji)(ji)架和(he)(he)(he)(he)芯棒支撐架固定(ding)在(zai)(zai)隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)內,換輥(gun)時(shi)鎖緊門隨(sui)工(gong)作(zuo)機(ji)(ji)(ji)(ji)(ji)(ji)架一起被移出隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)到(dao)換輥(gun)位(wei)置(zhi)。驅動(dong)每個軋(ya)(ya)(ya)(ya)輥(gun)的(de)(de)(de)(de)傳動(dong)軸(共計(ji)18根)從(cong)(cong)各自的(de)(de)(de)(de)位(wei)置(zhi)由(you)(you)外(wai)面伸入(ru)隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)與(yu)軋(ya)(ya)(ya)(ya)輥(gun)連(lian)接(jie)。PQF軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)(ji)(ji)(ji)設計(ji)非(fei)常(chang)緊湊,在(zai)(zai)隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)上(shang)安(an)裝(zhuang)的(de)(de)(de)(de)設備很密集,其中包括有100個液(ye)壓(ya)缸、液(ye)壓(ya)管、潤(run)滑管、冷(leng)卻水管、沖渣(zha)水管和(he)(he)(he)(he)各種電器(qi)控制(zhi)(zhi)(zhi)(zhi)管線等輔助設備,只有通過統籌合理地安(an)排才能安(an)裝(zhuang)恰當。與(yu)傳統的(de)(de)(de)(de)兩(liang)輥(gun)式連(lian)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)交(jiao)叉排列的(de)(de)(de)(de)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)(ji)(ji)(ji)機(ji)(ji)(ji)(ji)(ji)(ji)架布(bu)置(zhi)方(fang)式比較,使(shi)用圓形隧(sui)(sui)道(dao)(dao)(dao)(dao)(dao)(dao)式的(de)(de)(de)(de)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)(ji)(ji)(ji)牌坊的(de)(de)(de)(de)機(ji)(ji)(ji)(ji)(ji)(ji)架間距縮短了(le),減少了(le)在(zai)(zai)軋(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)(zhi)過程中因機(ji)(ji)(ji)(ji)(ji)(ji)架間距大而使(shi)軋(ya)(ya)(ya)(ya)件運行不穩定(ding)等因素(su)。

三、傳(chuan)動(dong)系統

PQF每個工(gong)作(zuo)(zuo)機架(jia)(jia)上的(de)三個軋(ya)(ya)輥(gun)互(hu)成(cheng)120°,驅動這(zhe)三個軋(ya)(ya)輥(gun)的(de)傳動系(xi)統(tong)在(zai)隧(sui)道(dao)外(wai)也要分(fen)布(bu)(bu)在(zai)互(hu)呈120°的(de)位置上。同一(yi)工(gong)作(zuo)(zuo)機架(jia)(jia)上的(de)三個軋(ya)(ya)輥(gun)的(de)轉(zhuan)速(su)和(he)加速(su)度必須完(wan)全一(yi)致,因此(ci),三個減速(su)箱(xiang)的(de)速(su)比必須完(wan)全相(xiang)(xiang)同,減速(su)箱(xiang)和(he)傳動軸的(de)轉(zhuan)動慣(guan)量必須基本(ben)一(yi)致,電動機的(de)特(te)性和(he)控制(zhi)變形保(bao)持一(yi)致。相(xiang)(xiang)鄰POF連(lian)續(xu)軋(ya)(ya)管(guan)機工(gong)作(zuo)(zuo)機架(jia)(jia)之間(jian)布(bu)(bu)置非常緊湊,間(jian)距(ju)很(hen)小,相(xiang)(xiang)鄰的(de)傳動系(xi)統(tong)的(de)間(jian)距(ju)因此(ci)同樣也很(hen)小,給設計減速(su)機和(he)選擇電動機提出了苛(ke)刻的(de)要求(qiu)。傳動軸是可伸縮的(de),在(zai)換(huan)輥(gun)時傳動軸回縮脫離和(he)軋(ya)(ya)輥(gun)的(de)連(lian)接(jie),新工(gong)作(zuo)(zuo)機架(jia)(jia)換(huan)入(ru)后傳動軸伸出并和(he)軋(ya)(ya)輥(gun)連(lian)接(jie),伸縮的(de)動作(zuo)(zuo)由液壓缸來執行。

四、軋輥更換系統

已經投產的(de)最初(chu)兩(liang)套PQF連(lian)續(xu)軋(ya)管機(ji)(ji),在(zai)(zai)設計時三(san)個互呈120°的(de)傳動系統占據了軋(ya)機(ji)(ji)四周的(de)空間(jian)、傳統(MPM式(shi))的(de)換(huan)輥(gun)(gun),即(ji)從(cong)側向換(huan)輥(gun)(gun)方(fang)式(shi)已不可能,只(zhi)有采用從(cong)軸向,即(ji)軋(ya)制線方(fang)向來換(huan)輥(gun)(gun)。在(zai)(zai)PQF 連(lian)續(xu)軋(ya)管機(ji)(ji)和脫管機(ji)(ji)之間(jian)布置一個換(huan)輥(gun)(gun)區,這(zhe)個換(huan)輥(gun)(gun)區應滿足以下要求:

1. 軋機(ji)出口(kou)到(dao)脫管(guan)機(ji)的(de)輸送輥道(dao)在(zai)換輥時要能移開,換輥結束(shu)后,輸送輥道(dao)要及(ji)時復位并可(ke)靠(kao)地和軋制(zhi)線對中(zhong);

2. 換輥區要布置兩列換輥小車,分別放置待換人的工作(zuo)機(ji)架(jia)(jia)和承(cheng)接從隧道中拉出(chu)的需要換掉的工作(zuo)機(ji)架(jia)(jia);

3. 每列(lie)換(huan)(huan)(huan)輥小車由(you)可單(dan)獨(du)(du)橫移的換(huan)(huan)(huan)輥單(dan)元組成,其數量與工作機(ji)架和芯(xin)棒(bang)支撐(cheng)架的數量相一致,兩列(lie)換(huan)(huan)(huan)輥小車也可整(zheng)列(lie)橫移,并(bing)能和軋制(zhi)線正確對(dui)中以達到整(zheng)列(lie)更(geng)(geng)換(huan)(huan)(huan)和個別任意(yi)一架單(dan)獨(du)(du)更(geng)(geng)換(huan)(huan)(huan)的目的。

五、芯棒的運行方(fang)式

限(xian)動(dong)芯(xin)棒(bang)(bang)(bang)連續(xu)軋(ya)管(guan)(guan)機(ji)的(de)(de)(de)芯(xin)棒(bang)(bang)(bang)運(yun)(yun)(yun)行(xing)有(you)兩(liang)種(zhong)(zhong)方(fang)(fang)式(shi)(shi):1. 軋(ya)制(zhi)(zhi)(zhi)結(jie)束(shu)時,芯(xin)棒(bang)(bang)(bang)停止運(yun)(yun)(yun)動(dong),待荒(huang)(huang)管(guan)(guan)從(cong)芯(xin)棒(bang)(bang)(bang)中脫(tuo)出(chu)(chu)后(hou),芯(xin)棒(bang)(bang)(bang)快(kuai)(kuai)速(su)返回,移(yi)出(chu)(chu)軋(ya)制(zhi)(zhi)(zhi)線,冷(leng)卻、潤滑后(hou)循(xun)(xun)(xun)環使(shi)用(yong),傳統(tong)的(de)(de)(de)MPM均采用(yong)此種(zhong)(zhong)運(yun)(yun)(yun)行(xing)方(fang)(fang)式(shi)(shi);2. 軋(ya)制(zhi)(zhi)(zhi)結(jie)束(shu)時,芯(xin)棒(bang)(bang)(bang)停止運(yun)(yun)(yun)動(dong),待荒(huang)(huang)管(guan)(guan)由脫(tuo)管(guan)(guan)機(ji)從(cong)芯(xin)棒(bang)(bang)(bang)中脫(tuo)出(chu)(chu)后(hou),芯(xin)棒(bang)(bang)(bang)不是(shi)(shi)回送,而(er)是(shi)(shi)向(xiang)前(qian)快(kuai)(kuai)速(su)運(yun)(yun)(yun)行(xing)跟隨荒(huang)(huang)管(guan)(guan)之后(hou)依次通(tong)過(guo)脫(tuo)管(guan)(guan)機(ji),芯(xin)棒(bang)(bang)(bang)穿(chuan)過(guo)脫(tuo)管(guan)(guan)機(ji)后(hou),移(yi)出(chu)(chu)軋(ya)線再回送、冷(leng)卻、潤滑循(xun)(xun)(xun)環使(shi)用(yong),該方(fang)(fang)法減(jian)少了芯(xin)棒(bang)(bang)(bang)的(de)(de)(de)在(zai)線待軋(ya)時間,從(cong)而(er)有(you)效地縮短了軋(ya)制(zhi)(zhi)(zhi)周期,加(jia)快(kuai)(kuai)了軋(ya)制(zhi)(zhi)(zhi)節(jie)奏,Φ168mm的(de)(de)(de)PQF機(ji)組采用(yong)此種(zhong)(zhong)運(yun)(yun)(yun)行(xing)方(fang)(fang)式(shi)(shi)。兩(liang)種(zhong)(zhong)運(yun)(yun)(yun)行(xing)方(fang)(fang)式(shi)(shi)的(de)(de)(de)主(zhu)要區別是(shi)(shi)脫(tuo)管(guan)(guan)完成后(hou),芯(xin)棒(bang)(bang)(bang)是(shi)(shi)與荒(huang)(huang)管(guan)(guan)反(fan)向(xiang)運(yun)(yun)(yun)行(xing)回退(tui),離開軋(ya)機(ji)后(hou)移(yi)出(chu)(chu)軋(ya)制(zhi)(zhi)(zhi)線冷(leng)卻、潤滑、循(xun)(xun)(xun)環使(shi)用(yong);還(huan)是(shi)(shi)同向(xiang)運(yun)(yun)(yun)行(xing)芯(xin)棒(bang)(bang)(bang)前(qian)行(xing)離開軋(ya)機(ji)后(hou)、穿(chuan)過(guo)脫(tuo)管(guan)(guan)機(ji)后(hou)撥出(chu)(chu)軋(ya)制(zhi)(zhi)(zhi)線冷(leng)卻、潤滑、循(xun)(xun)(xun)環使(shi)用(yong)。第(di)二(er)種(zhong)(zhong)方(fang)(fang)法因芯(xin)棒(bang)(bang)(bang)要通(tong)過(guo)脫(tuo)管(guan)(guan)機(ji),在(zai)軋(ya)制(zhi)(zhi)(zhi)薄壁管(guan)(guan)(脫(tuo)管(guan)(guan)機(ji)的(de)(de)(de)減(jian)徑量大于等于2倍的(de)(de)(de)荒(huang)(huang)管(guan)(guan)壁厚)時要求脫(tuo)管(guan)(guan)機(ji)軋(ya)輥必須具備快(kuai)(kuai)開快(kuai)(kuai)合功能,以免芯(xin)棒(bang)(bang)(bang)撞損脫(tuo)管(guan)(guan)機(ji)軋(ya)輥。