1. 基本(ben)條件及要求

①. 試(shi)件材質(zhi):15CrMo.

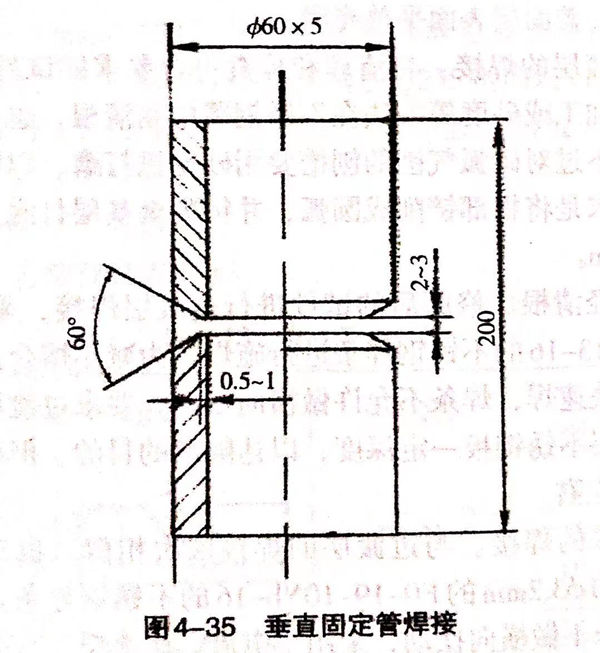

②. 試件尺(chi)寸及(ji)坡(po)口角度(du):如(ru)圖(tu)4-35所示(shi)。

③. 焊(han)接材(cai)料:E5503-B2(R302)或E5515-B2(R307),焊(han)條直徑(jing)Φ2.5mm,焊(han)條使用(yong)前(qian)要求(qiu)烘干(gan)。

④. 焊機:ZX7-400S.

2. 試件清理及裝配

①. 清(qing)除坡口及其(qi)兩側外表面20mm范(fan)圍(wei)內的油、銹(xiu)及其(qi)他(ta)污(wu)物、直至露(lu)出金屬光(guang)澤。

②. 裝配:采(cai)用(yong)(yong)兩(liang)點(dian)(dian)(dian)(dian)定位焊(han)接(jie)(jie)固(gu)定,點(dian)(dian)(dian)(dian)固(gu)點(dian)(dian)(dian)(dian)在時鐘2點(dian)(dian)(dian)(dian)與10點(dian)(dian)(dian)(dian)位置,所用(yong)(yong)材料(liao)與焊(han)接(jie)(jie)試(shi)件時相同,且點(dian)(dian)(dian)(dian)焊(han)處(chu)的裝配間(jian)隙(xi)起焊(han)處(chu)為(wei)2.0mm(另一(yi)邊(bian)間(jian)隙(xi)為(wei)3.0mm).焊(han)點(dian)(dian)(dian)(dian)長度為(wei)10~15mm,要求焊(han)透(tou)并不得(de)有焊(han)接(jie)(jie)缺陷,焊(han)點(dian)(dian)(dian)(dian)兩(liang)端(duan)用(yong)(yong)砂輪機打磨出斜坡(po),以利于接(jie)(jie)頭。試(shi)件的錯邊(bian)量應(ying)不大于0.5mm,保證管與管同心。將(jiang)試(shi)件垂直固(gu)定于焊(han)接(jie)(jie)架(jia)上,接(jie)(jie)頭與操作者(zhe)視線相適應(ying)為(wei)宜。

3. 焊接工藝參數

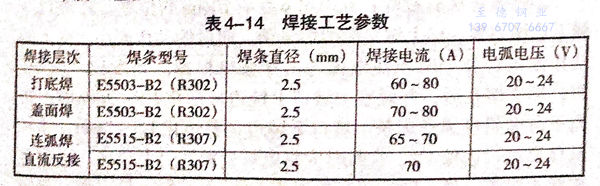

焊接工藝參(can)數見表4-14.

4. 操(cao)作要點及注意事項

采用(yong)三層四道(dao)焊(han)(han),可(ke)分前后兩(liang)個半圈進(jin)行施(shi)焊(han)(han),也可(ke)整圈進(jin)行施(shi)焊(han)(han)。

①. 斷弧焊法打底焊

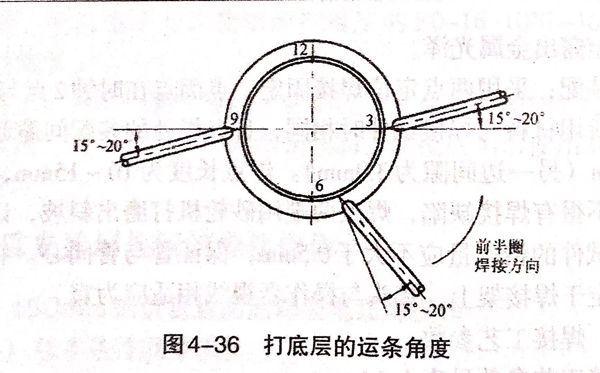

引(yin)弧(hu)在(zai)時(shi)鐘(zhong)6點前10mm的(de)(de)位置坡(po)(po)口(kou)面的(de)(de)一側上邊(bian)(bian)緣。然(ran)后(hou)(hou)(hou)(hou)把電(dian)弧(hu)移至鈍邊(bian)(bian)間隙處,當(dang)鈍邊(bian)(bian)熔化后(hou)(hou)(hou)(hou),焊(han)(han)條(tiao)向下(xia)壓一下(xia),當(dang)聽到“噗噗”聲后(hou)(hou)(hou)(hou),立(li)即把電(dian)弧(hu)移至坡(po)(po)口(kou)下(xia)邊(bian)(bian)緣,形成(cheng)第一個(ge)熔池后(hou)(hou)(hou)(hou)再(zai)(zai)采(cai)用短弧(hu)以(yi)兩點擊(ji)穿(chuan)法,向坡(po)(po)口(kou)上邊(bian)(bian)緣及下(xia)邊(bian)(bian)緣根部分別給送熔滴,依(yi)次循環。在(zai)施焊(han)(han)過程中,要首先擊(ji)穿(chuan)坡(po)(po)口(kou)的(de)(de)下(xia)緣,再(zai)(zai)擊(ji)穿(chuan)坡(po)(po)口(kou)的(de)(de)上邊(bian)(bian)緣,并使下(xia)熔孔(kong)在(zai)前、上熔孔(kong)在(zai)后(hou)(hou)(hou)(hou),坡(po)(po)口(kou)的(de)(de)上、下(xia)邊(bian)(bian)緣鈍邊(bian)(bian)處各要熔化1.5~2mm.弧(hu)柱(zhu)長度應透過內壁(bi)1/3左右。焊(han)(han)接(jie)打底層時(shi)的(de)(de)焊(han)(han)條(tiao)水平(ping)方向角度,如圖4-36所示。焊(han)(han)條(tiao)的(de)(de)下(xia)傾(qing)角為10°~15°,以(yi)控(kong)制熔渣(zha)和形成(cheng)熔池,并盡可(ke)能將熔池形狀控(kong)制成(cheng)為斜橢圓形,避免出現凸圓形焊(han)(han)縫,因(yin)為凸圓形焊(han)(han)縫容(rong)易形成(cheng)層間夾渣(zha)及熔合不良等缺陷。

后半圈操作方法與(yu)前半圈相同。

②. 連弧(hu)焊法打底焊

在時鐘6點前10mm的位置,在坡(po)(po)口一(yi)側下邊緣引(yin)弧(hu)(hu),向(xiang)(xiang)(xiang)上做斜橢(tuo)圓(yuan)形(xing)運條(tiao),向(xiang)(xiang)(xiang)后(hou)(hou)(hou)的動作要(yao)(yao)小,向(xiang)(xiang)(xiang)上的動作要(yao)(yao)大,并同(tong)時壓(ya)住電(dian)弧(hu)(hu),擊穿坡(po)(po)口根部。當(dang)(dang)發出“噗噗”聲(sheng),形(xing)成熔(rong)(rong)孔(kong)后(hou)(hou)(hou),并觀察當(dang)(dang)坡(po)(po)口上鈍邊被熔(rong)(rong)化(hua)1.5~2mm時,再向(xiang)(xiang)(xiang)下方做斜橢(tuo)圓(yuan)形(xing)運條(tiao)。坡(po)(po)口下鈍邊也(ye)要(yao)(yao)熔(rong)(rong)化(hua)1.5~2mm,弧(hu)(hu)柱長(chang)度要(yao)(yao)透(tou)過內壁(bi)1/2,收弧(hu)(hu)時應將(jiang)電(dian)弧(hu)(hu)帶(dai)到坡(po)(po)口上邊緣,向(xiang)(xiang)(xiang)后(hou)(hou)(hou)方提(ti)起再熄弧(hu)(hu)。接頭時,應在距焊道末端10~15mm處引(yin)弧(hu)(hu),并做斜橢(tuo)圓(yuan)運條(tiao),當(dang)(dang)運到原(yuan)熔(rong)(rong)池的1/2處時,將(jiang)電(dian)弧(hu)(hu)向(xiang)(xiang)(xiang)管(guan)內壓(ya)、擊穿,然(ran)后(hou)(hou)(hou)再以斜橢(tuo)圓(yuan)形(xing)運條(tiao)法施焊。

③. 填充及(ji)蓋面焊(han)

首先(xian)清理打底焊(han)(han)的(de)熔(rong)(rong)渣,修平焊(han)(han)縫的(de)凸(tu)處,焊(han)(han)接(jie)第(di)二(er)層(ceng)及蓋面(mian)焊(han)(han)時,要由下向(xiang)上排列焊(han)(han)接(jie)的(de)多道焊(han)(han),采用(yong)直線運條法,焊(han)(han)接(jie)時電流(liu)應(ying)略大一些,熔(rong)(rong)池形狀應(ying)盡可能控制為斜橢圓(yuan)形。如果運條時熔(rong)(rong)渣和液態(tai)金屬(shu)混(hun)合在一起,可將電弧略為拉(la)長并向(xiang)后(與焊(han)(han)接(jie)方向(xiang)相反)帶(dai)一下,熔(rong)(rong)渣就會(hui)被吹向(xiang)后方,與液態(tai)金屬(shu)分離(li),使熔(rong)(rong)池保持清晰,焊(han)(han)縫平整。

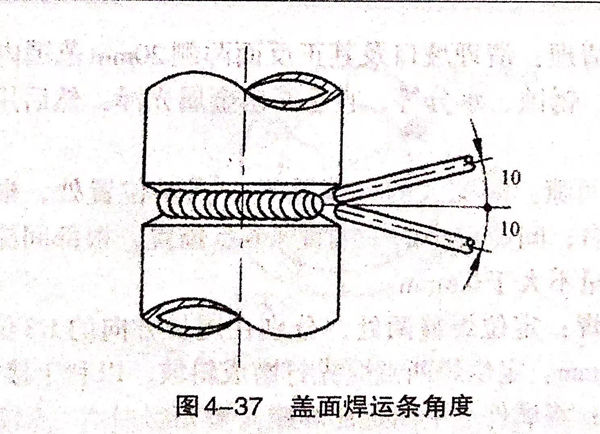

施(shi)焊(han)時(shi)焊(han)條(tiao)的角度,填充時(shi),焊(han)條(tiao)要基本保持水(shui)平位置,焊(han)條(tiao)與水(shui)平軸線成90°夾角。蓋面層時(shi),焊(han)條(tiao)應與水(shui)平軸成15°傾角。下面的焊(han)縫焊(han)條(tiao)向(xiang)(xiang)下傾,上(shang)面的焊(han)縫焊(han)條(tiao)向(xiang)(xiang)上(shang)傾,如圖4-37所(suo)示。這樣可防止(zhi)產生(sheng)咬邊(bian),并(bing)有利于焊(han)道與母材金屬的圓滑過渡。