一、概況

山東磐金鋼(gang)管(guan)制造(zao)有(you)限公(gong)司(si)(以下(xia)簡稱磐金鋼(gang)管(guan))是魯(lu)麗集團(tuan)的子(zi)公(gong)司(si),成(cheng)立于(yu)(yu)2017年(nian),占地(di)面(mian)(mian)(mian)積(ji)約38萬平方米,總(zong)建(jian)筑面(mian)(mian)(mian)積(ji)計(ji)23.4萬平方米,主廠房建(jian)筑面(mian)(mian)(mian)積(ji)21.4萬平方米。共建(jian)設(she)(she)6條(tiao)(tiao)現(xian)代化連(lian)軋管(guan)生(sheng)(sheng)產(chan)(chan)(chan)(chan)(chan)線,其中Φ159mm連(lian)軋管(guan)生(sheng)(sheng)產(chan)(chan)(chan)(chan)(chan)線兩(liang)(liang)條(tiao)(tiao),Φ180mm連(lian)軋管(guan)生(sheng)(sheng)產(chan)(chan)(chan)(chan)(chan)線兩(liang)(liang)條(tiao)(tiao),φ273mm連(lian)軋管(guan)生(sheng)(sheng)產(chan)(chan)(chan)(chan)(chan)線兩(liang)(liang)條(tiao)(tiao),設(she)(she)備分別由太(tai)原通澤重工、太(tai)原重工設(she)(she)計(ji)制造(zao),產(chan)(chan)(chan)(chan)(chan)品規格(Φ32mm)φ60~φ356mmx3.5~40mm,6條(tiao)(tiao)生(sheng)(sheng)產(chan)(chan)(chan)(chan)(chan)線設(she)(she)計(ji)產(chan)(chan)(chan)(chan)(chan)量300萬噸/年(nian)。目前φ159mm兩(liang)(liang)條(tiao)(tiao)連(lian)軋機組已分別于(yu)(yu)2018年(nian)7月初、8月底建(jian)成(cheng)投產(chan)(chan)(chan)(chan)(chan),φ180mm、φ273mm生(sheng)(sheng)產(chan)(chan)(chan)(chan)(chan)線預(yu)計(ji)2019年(nian)上半年(nian)陸(lu)續建(jian)成(cheng)投產(chan)(chan)(chan)(chan)(chan)。

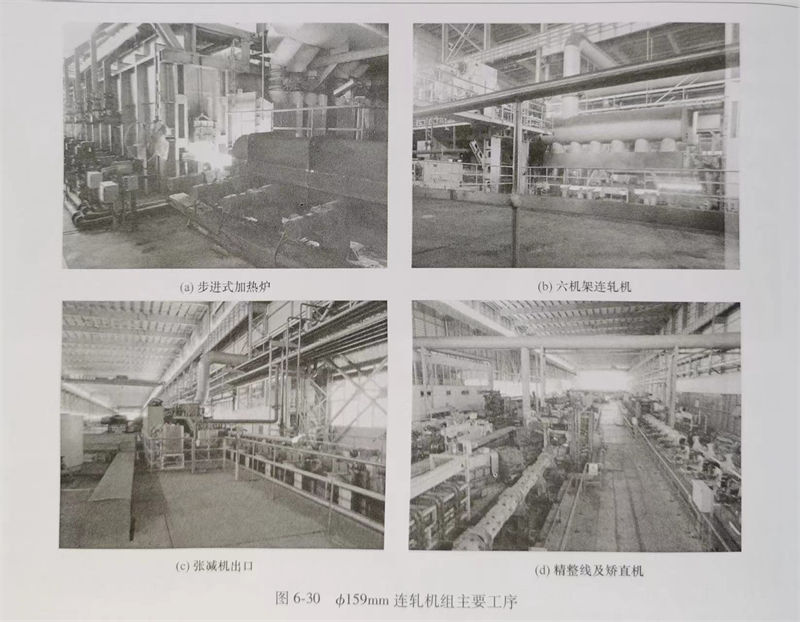

兩(liang)(liang)條ф159mm連(lian)軋(ya)(ya)(ya)管(guan)(guan)(guan)(guan)生(sheng)產(chan)線(xian)(xian)(xian),配(pei)有(you)一座步(bu)進式(shi)加熱(re)爐(lu)(配(pei)有(you)管(guan)(guan)(guan)(guan)坯(pi)熱(re)送通道),采用(yong)(yong)倍尺(chi)坯(pi)裝(zhuang)爐(lu),管(guan)(guan)(guan)(guan)坯(pi)出爐(lu)后,利用(yong)(yong)熱(re)鋸將倍尺(chi)管(guan)(guan)(guan)(guan)坯(pi)切成單倍尺(chi),分別(bie)供給兩(liang)(liang)條連(lian)軋(ya)(ya)(ya)管(guan)(guan)(guan)(guan)生(sheng)產(chan)線(xian)(xian)(xian),這種工(gong)藝(yi)流程模式(shi)在全球屬(shu)于首創。連(lian)軋(ya)(ya)(ya)管(guan)(guan)(guan)(guan)生(sheng)產(chan)線(xian)(xian)(xian)配(pei)有(you)基礎自動化、過(guo)程自動化和生(sheng)產(chan)管(guan)(guan)(guan)(guan)理(li)系(xi)統。通過(guo)配(pei)置的(de)線(xian)(xian)(xian)性位移(yi)傳感器(qi)、壓(ya)力傳感器(qi)、位置編碼(ma)器(qi)、旋轉編碼(ma)器(qi)、熱(re)金屬(shu)檢測(ce)器(qi)等元器(qi)件,可實現從坯(pi)料出料、穿孔(kong)、連(lian)軋(ya)(ya)(ya)到(dao)張減的(de)熱(re)軋(ya)(ya)(ya)產(chan)線(xian)(xian)(xian)自動化生(sheng)產(chan)。主軋(ya)(ya)(ya)線(xian)(xian)(xian)(穿孔(kong)機、連(lian)軋(ya)(ya)(ya)管(guan)(guan)(guan)(guan)機、張減機)配(pei)備(bei)工(gong)藝(yi)控(kong)制模型,能實現工(gong)藝(yi)與工(gong)具的(de)設計(ji)與計(ji)算、仿真、生(sheng)產(chan)參數的(de)自動記錄、顯示、貯存、調用(yong)(yong)。配(pei)有(you)輥(gun)縫液壓(ya)壓(ya)下系(xi)統HCCS、頭尾(wei)削尖FTS系(xi)統;張力頭尾(wei)控(kong)制CEC系(xi)統;另外,熱(re)軋(ya)(ya)(ya)線(xian)(xian)(xian)主傳動全部采用(yong)(yong)了ABB控(kong)制系(xi)統,全線(xian)(xian)(xian)裝(zhuang)備(bei)水平(ping)達到(dao)國(guo)內外先進水平(ping)。

二、生產規模(mo)及產品規格

1. φ159mm機組兩(liang)條(tiao),兩(liang)輥連軋(ya)管機,兩(liang)條(tiao)線設(she)計產量70萬噸(dun)/年(nian),設(she)備由太原通澤設(she)計制(zhi)造。其產品規(gui)格:

外徑:(φ32mm)φ60~159mm;

壁(bi)厚(hou):3.5~22mm。

2. ф180mm機(ji)組兩條,三(san)輥連軋管(guan)機(ji),兩條線設(she)計產(chan)量100萬(wan)噸/年,設(she)備由太原(yuan)重工(gong)設(she)計制(zhi)造。其產(chan)品(pin)規格(ge):

外徑:φ60~180mm;

壁厚:4.0~25mm。

3. Φ273mm機組兩條,三輥連(lian)軋管機,兩條線設計產(chan)量130萬(wan)噸/年,設備由太(tai)原(yuan)通(tong)澤設計制造。其產(chan)品規格:

外徑:φ~356mm;

壁厚:5.0~40m

三、主要品(pin)種

結構管、流體管、管線管、低中壓鍋爐管和石油裂化管等。

四、ф159mm連軋管機組主要設備技術參數

1. 加熱(re)爐的形(xing)式(shi)為步進式(shi)

爐長:30m;

爐寬:12m;

最大產量:180t/h;

管坯直徑(jing):φ180mm,φ140mm。

2. 穿孔(kong)機的(de)形式(shi)為(wei)錐形輥導板式(shi)垂直布置

軋輥直(zhi)徑:800~900mm;

軋輥長度:730mm;

軋輥轉(zhuan)速:100~150r/min;

主電機:2500kW×2臺。

3. 連軋機為兩輥連軋管機,軋輥平立交叉布置

軋輥名義直(zhi)徑:520~620mm;

1~4機架(jia)電(dian)機功(gong)率:1800kW,750~1200r/min;

5~6機(ji)架電機(ji)功率:1000kW,750~1200r/min。

4. 脫管機

軋(ya)輥直徑:480mm;

主電機功(gong)率:600kW。

5. 張(zhang)力減徑機(ji)為(wei)28架減徑機(ji)

軋(ya)輥直徑:360mm;

主電機功率(lv):28×250kW,750~1300r/min。

6. 冷床為(wei)步(bu)進式

寬度:100m;

長度(du):20.5m。