反(fan)應(ying)(ying)(ying)(ying)過(guo)程的(de)基本(ben)特征決定(ding)了適宜的(de)反(fan)應(ying)(ying)(ying)(ying)器(qi)形式(shi)。例(li)如氣(qi)固(gu)相(xiang)反(fan)應(ying)(ying)(ying)(ying)過(guo)程大致是(shi)(shi)用固(gu)定(ding)床(chuang)反(fan)應(ying)(ying)(ying)(ying)器(qi)、流(liu)化床(chuang)反(fan)應(ying)(ying)(ying)(ying)器(qi)或(huo)移動床(chuang)反(fan)應(ying)(ying)(ying)(ying)器(qi)。但(dan)是(shi)(shi)適宜的(de)選型則(ze)需(xu)考(kao)慮反(fan)應(ying)(ying)(ying)(ying)的(de)熱效應(ying)(ying)(ying)(ying)、對反(fan)應(ying)(ying)(ying)(ying)轉化率和選擇率的(de)要(yao)求、催化劑物理(li)化學性態和失活等(deng)多種因素。

不(bu)銹鋼反應(ying)(ying)器(qi)(qi)的操作方式(shi)和加(jia)料(liao)方式(shi)也需(xu)考慮。例如,對于(yu)(yu)有串聯或(huo)平行副反應(ying)(ying)的過程,分段(duan)進(jin)料(liao)可(ke)能優于(yu)(yu)一(yi)次進(jin)料(liao)。溫(wen)度(du)序列(lie)也是反應(ying)(ying)器(qi)(qi)選型的一(yi)個重要因素。例如,對于(yu)(yu)放熱的可(ke)逆反應(ying)(ying),應(ying)(ying)采用先高后低的溫(wen)度(du)序列(lie),多(duo)級、級間(jian)換熱式(shi)反應(ying)(ying)器(qi)(qi)可(ke)使反應(ying)(ying)器(qi)(qi)的溫(wen)度(du)序列(lie)趨(qu)于(yu)(yu)合(he)理。

下面(mian)主要介紹釜式(shi)反(fan)(fan)應器(qi)、管式(shi)反(fan)(fan)應器(qi)、塔式(shi)反(fan)(fan)應器(qi)、固(gu)定床反(fan)(fan)應器(qi)、流化床反(fan)(fan)應器(qi)。

①. 釜式(shi)反應器

釜(fu)(fu)式(shi)(shi)反(fan)(fan)應(ying)(ying)器也(ye)(ye)稱槽式(shi)(shi)、鍋式(shi)(shi)反(fan)(fan)應(ying)(ying)器,它是各類反(fan)(fan)應(ying)(ying)器中結(jie)構較(jiao)為簡單且應(ying)(ying)用(yong)較(jiao)廣(guang)的(de)一(yi)種(zhong)。主(zhu)要應(ying)(ying)用(yong)于(yu)液-液均相反(fan)(fan)應(ying)(ying)過程,在(zai)(zai)氣(qi)-液、液-液非均相反(fan)(fan)應(ying)(ying)過程中也(ye)(ye)有(you)應(ying)(ying)用(yong)。在(zai)(zai)化工生產中,既適(shi)用(yong)于(yu)間(jian)(jian)歇(xie)操(cao)(cao)作過程,又可單釜(fu)(fu)或多釜(fu)(fu)串聯用(yong)于(yu)連續操(cao)(cao)作過程,但在(zai)(zai)間(jian)(jian)歇(xie)生產過程中應(ying)(ying)用(yong)最多。釜(fu)(fu)式(shi)(shi)反(fan)(fan)應(ying)(ying)器具有(you)適(shi)用(yong)的(de)溫(wen)度(du)和(he)壓力范圍(wei)寬、適(shi)應(ying)(ying)性強、操(cao)(cao)作彈性大(da)、連續操(cao)(cao)作時溫(wen)度(du)濃度(du)容(rong)易控制、產品質(zhi)量均一(yi)等特(te)點(dian)。但用(yong)在(zai)(zai)較(jiao)高轉化率工藝要求時,需要較(jiao)大(da)容(rong)積。通常在(zai)(zai)操(cao)(cao)作條件比較(jiao)緩和(he)的(de)情況(kuang)下使用(yong),如(ru)常壓、溫(wen)度(du)較(jiao)低(di)且低(di)于(yu)物(wu)料(liao)沸點(dian)時,應(ying)(ying)用(yong)此類反(fan)(fan)應(ying)(ying)器最為普遍。

②. 管式反應器

管式(shi)反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)主要(yao)用于(yu)(yu)氣(qi)相(xiang)(xiang)、液相(xiang)(xiang)、氣(qi)-液相(xiang)(xiang)連(lian)續(xu)反(fan)(fan)應(ying)(ying)過程,由(you)單(dan)根(直(zhi)管或(huo)(huo)盤管)連(lian)續(xu)或(huo)(huo)多(duo)(duo)根平行(xing)排列的(de)管子(zi)(zi)組成,一般設有(you)套(tao)管或(huo)(huo)殼管式(shi)換熱(re)裝置。操(cao)作時(shi),物(wu)料自一端連(lian)續(xu)加入(ru),在(zai)(zai)管中連(lian)續(xu)反(fan)(fan)應(ying)(ying),從另一端連(lian)續(xu)流出,便達到了要(yao)求的(de)轉化(hua)(hua)率。由(you)于(yu)(yu)管式(shi)反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)能承受(shou)較(jiao)高(gao)的(de)壓力,故(gu)用于(yu)(yu)加壓反(fan)(fan)應(ying)(ying)尤為(wei)合適(shi),例如油脂(zhi)或(huo)(huo)脂(zhi)肪(fang)酸加氫生產高(gao)碳(tan)醇、裂(lie)解反(fan)(fan)應(ying)(ying)用的(de)管式(shi)爐便是管式(shi)反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)。此種反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)具有(you)容積小、比表面大(da)、返混少、反(fan)(fan)應(ying)(ying)混合物(wu)連(lian)續(xu)性變化(hua)(hua)、易于(yu)(yu)控制等(deng)優點。但(dan)若反(fan)(fan)應(ying)(ying)速(su)度較(jiao)慢時(shi),則有(you)所(suo)需管子(zi)(zi)長、壓降(jiang)較(jiao)大(da)等(deng)不足(zu)。隨著化(hua)(hua)工(gong)生產越來越趨于(yu)(yu)大(da)型化(hua)(hua)、連(lian)續(xu)化(hua)(hua)、自動化(hua)(hua),連(lian)續(xu)操(cao)作的(de)管式(shi)反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)在(zai)(zai)生產中使用越來越多(duo)(duo),某些傳統上(shang)一直(zhi)使用間歇攪(jiao)拌釜的(de)高(gao)分子(zi)(zi)聚合反(fan)(fan)應(ying)(ying),目前也開始改用連(lian)續(xu)操(cao)作的(de)管式(shi)反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)。管式(shi)反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)的(de)長徑比較(jiao)大(da),與釜式(shi)反(fan)(fan)應(ying)(ying)器(qi)(qi)(qi)(qi)相(xiang)(xiang)比在(zai)(zai)結構上(shang)差異較(jiao)大(da),有(you)直(zhi)管式(shi)、盤管式(shi)、多(duo)(duo)管式(shi)等(deng)。

③. 塔式反應(ying)器

塔(ta)(ta)(ta)式(shi)(shi)反應(ying)器(qi)(qi)的(de)長徑比介于釜式(shi)(shi)和管(guan)式(shi)(shi)之間。主要用(yong)(yong)于氣-液(ye)(ye)反應(ying),常用(yong)(yong)的(de)有(you)(you)鼓(gu)泡塔(ta)(ta)(ta)、填料塔(ta)(ta)(ta)、板(ban)式(shi)(shi)塔(ta)(ta)(ta)。最(zui)常用(yong)(yong)的(de)是鼓(gu)泡塔(ta)(ta)(ta)式(shi)(shi)反應(ying)器(qi)(qi),底部(bu)裝(zhuang)有(you)(you)氣體(ti)(ti)(ti)(ti)(ti)分(fen)布器(qi)(qi),殼外裝(zhuang)有(you)(you)夾套或(huo)(huo)其他形式(shi)(shi)換(huan)熱(re)器(qi)(qi)或(huo)(huo)設(she)有(you)(you)擴大(da)(da)(da)段、液(ye)(ye)滴捕(bu)集器(qi)(qi)等。反應(ying)氣體(ti)(ti)(ti)(ti)(ti)通(tong)過分(fen)布器(qi)(qi)上(shang)的(de)小孔以鼓(gu)泡形式(shi)(shi)通(tong)過液(ye)(ye)層進(jin)行(xing)化學反應(ying),液(ye)(ye)體(ti)(ti)(ti)(ti)(ti)間歇或(huo)(huo)連(lian)續加入,連(lian)續加入的(de)液(ye)(ye)體(ti)(ti)(ti)(ti)(ti)可以和氣體(ti)(ti)(ti)(ti)(ti)并流或(huo)(huo)逆流,一般采用(yong)(yong)并流形式(shi)(shi)較多。氣體(ti)(ti)(ti)(ti)(ti)在(zai)(zai)塔(ta)(ta)(ta)內為分(fen)散相,液(ye)(ye)體(ti)(ti)(ti)(ti)(ti)為連(lian)續相,液(ye)(ye)體(ti)(ti)(ti)(ti)(ti)返混程(cheng)(cheng)度較大(da)(da)(da)。為了提高氣體(ti)(ti)(ti)(ti)(ti)分(fen)散程(cheng)(cheng)度和減少液(ye)(ye)體(ti)(ti)(ti)(ti)(ti)軸向(xiang)循環,可以在(zai)(zai)塔(ta)(ta)(ta)內安置(zhi)水平多孔隔板(ban)。當吸收(shou)或(huo)(huo)反應(ying)過程(cheng)(cheng)熱(re)效(xiao)應(ying)不(bu)大(da)(da)(da)時,可采用(yong)(yong)夾套換(huan)熱(re)裝(zhuang)置(zhi),熱(re)效(xiao)應(ying)較大(da)(da)(da)時,可在(zai)(zai)塔(ta)(ta)(ta)內增設(she)換(huan)熱(re)蛇管(guan)或(huo)(huo)采用(yong)(yong)塔(ta)(ta)(ta)外換(huan)熱(re)裝(zhuang)置(zhi),也可以利(li)用(yong)(yong)反應(ying)液(ye)(ye)蒸發的(de)方法帶(dai)走熱(re)量(liang)。

④. 固(gu)定床(chuang)反應器(qi)

固定床(chuang)(chuang)(chuang)板反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)(qi)是(shi)(shi)指流體通過靜(jing)止(zhi)不(bu)動(dong)的固體物料(liao)所形成的床(chuang)(chuang)(chuang)層(ceng)而(er)進(jin)行化學(xue)反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)的設(she)備。以氣(qi)-固反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)的固定床(chuang)(chuang)(chuang)反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)(qi)最常見。固定床(chuang)(chuang)(chuang)反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)(qi)根據床(chuang)(chuang)(chuang)層(ceng)數的多(duo)(duo)少又可分為單(dan)段(duan)(duan)式(shi)(shi)和多(duo)(duo)段(duan)(duan)式(shi)(shi)兩種(zhong)類型。單(dan)段(duan)(duan)式(shi)(shi)一般為高徑比不(bu)大的圓筒體,在圓筒體下(xia)部裝有柵板等板件,其上為催(cui)(cui)化劑床(chuang)(chuang)(chuang)層(ceng),均勻地(di)堆置(zhi)一定厚(hou)度的催(cui)(cui)化劑固體顆粒。單(dan)段(duan)(duan)式(shi)(shi)固定床(chuang)(chuang)(chuang)反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)(qi)結構簡單(dan)、造價便宜、反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)(qi)體積利用(yong)率高。多(duo)(duo)段(duan)(duan)式(shi)(shi)是(shi)(shi)在圓筒體反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)(qi)內設(she)有多(duo)(duo)個催(cui)(cui)化劑床(chuang)(chuang)(chuang)層(ceng),在各(ge)床(chuang)(chuang)(chuang)層(ceng)之間可采用(yong)多(duo)(duo)種(zhong)方式(shi)(shi)進(jin)行反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)物料(liao)的換熱。其特點是(shi)(shi)便于控制調節反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)溫(wen)度,防(fang)止(zhi)反(fan)(fan)(fan)應(ying)(ying)(ying)(ying)溫(wen)度超出(chu)允許范圍。

⑤. 流化床反應器

細小(xiao)的(de)固(gu)(gu)體(ti)(ti)顆(ke)粒被(bei)流(liu)(liu)動著的(de)流(liu)(liu)體(ti)(ti)攜帶(dai),具有流(liu)(liu)體(ti)(ti)一(yi)(yi)(yi)樣自由流(liu)(liu)動的(de)性質,此種現(xian)象稱為(wei)固(gu)(gu)體(ti)(ti)的(de)流(liu)(liu)態化(hua)(hua)。一(yi)(yi)(yi)般(ban)把(ba)反(fan)應器和(he)在其中呈流(liu)(liu)態化(hua)(hua)的(de)固(gu)(gu)體(ti)(ti)催(cui)化(hua)(hua)劑(ji)(ji)顆(ke)粒合在一(yi)(yi)(yi)起,稱為(wei)流(liu)(liu)化(hua)(hua)床(chuang)(chuang)(chuang)(chuang)反(fan)應器。流(liu)(liu)化(hua)(hua)床(chuang)(chuang)(chuang)(chuang)反(fan)應器多用(yong)(yong)于氣(qi)-固(gu)(gu)反(fan)應過(guo)程。當原料氣(qi)通過(guo)反(fan)應器催(cui)化(hua)(hua)劑(ji)(ji)床(chuang)(chuang)(chuang)(chuang)層(ceng)時,催(cui)化(hua)(hua)劑(ji)(ji)顆(ke)粒受氣(qi)流(liu)(liu)作用(yong)(yong)而懸浮起來呈翻滾沸(fei)騰(teng)狀,原料氣(qi)在處(chu)于流(liu)(liu)態化(hua)(hua)的(de)催(cui)化(hua)(hua)劑(ji)(ji)表(biao)面進行化(hua)(hua)學反(fan)應,此時的(de)催(cui)化(hua)(hua)劑(ji)(ji)床(chuang)(chuang)(chuang)(chuang)層(ceng)即為(wei)流(liu)(liu)化(hua)(hua)床(chuang)(chuang)(chuang)(chuang),也叫沸(fei)騰(teng)床(chuang)(chuang)(chuang)(chuang)。流(liu)(liu)化(hua)(hua)床(chuang)(chuang)(chuang)(chuang)反(fan)應器的(de)形式很多,但一(yi)(yi)(yi)般(ban)都由殼(ke)體(ti)(ti)、內部構(gou)件、固(gu)(gu)體(ti)(ti)顆(ke)粒裝卸設(she)備及氣(qi)體(ti)(ti)分(fen)布(bu)、傳熱(re)、氣(qi)固(gu)(gu)分(fen)離裝置等(deng)構(gou)成(cheng)。流(liu)(liu)化(hua)(hua)床(chuang)(chuang)(chuang)(chuang)反(fan)應器也可(ke)根據床(chuang)(chuang)(chuang)(chuang)層(ceng)結構(gou)分(fen)為(wei)圓筒式、圓錐(zhui)式和(he)多管式等(deng)類(lei)型。

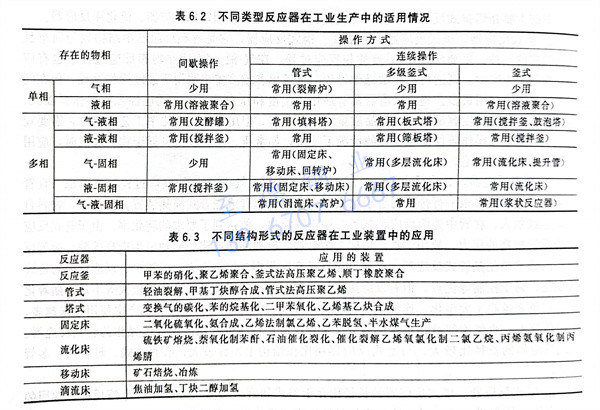

不(bu)同類型(xing)反(fan)應(ying)器在工業生(sheng)產中的(de)適用情況見表6.2。不(bu)同結構形式(shi)的(de)反(fan)應(ying)器在工業裝置中的(de)應(ying)用舉例見表6.3。