不銹鋼無縫鋼管因其制造工藝不同,又分為熱軋(擠壓)不銹鋼無(wu)縫(feng)管和冷拔(軋)不銹鋼無縫管兩種。冷拔(軋)管又分為圓形管和異形管兩種。

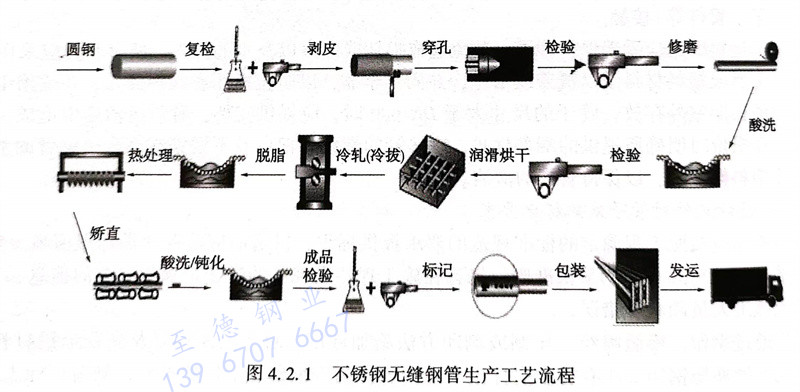

工藝流程(cheng):①. 熱軋(ya)(擠壓)無縫鋼(gang)管生(sheng)(sheng)產工藝:生(sheng)(sheng)產圓管坯→加熱→穿孔→三輥斜軋(ya)、連軋(ya)或擠壓→脫(tuo)管→定徑(或減徑)→冷(leng)卻→矯(jiao)(jiao)直(zhi)→水壓試(shi)驗(yan)(或探(tan)傷)→標記→入(ru)庫(ku)。②. 冷(leng)拔(ba)(軋(ya))無縫鋼(gang)管生(sheng)(sheng)產工藝:圓管坯→加熱→穿孔→打頭→退火→酸洗→涂油(鍍銅(tong))→多道(dao)次(ci)冷(leng)拔(ba)(冷(leng)軋(ya))→坯管→熱處理→矯(jiao)(jiao)直(zhi)→水壓試(shi)驗(yan)(探(tan)傷)→標記→入(ru)庫(ku)。無縫鋼(gang)管生(sheng)(sheng)產工藝流程(cheng)參見圖4.2.1和圖4.2.2。

筆者到浙江(jiang)至(zhi)德鋼業有限公司不銹鋼無(wu)縫(feng)鋼管廠調研,僅在生產(chan)圓管坯煉爐(lu)內(nei)加入其他(ta)金屬(shu)元素(su)環(huan)節是半人工操作,各生產(chan)過程基本是計算機自動(dong)化操作,質量、安全、效率全面(mian)提升(sheng)。