常有(you)(you)(you)管(guan)(guan)(guan)道(dao)設計人員(yuan)向筆者咨詢Pipe與Tube管(guan)(guan)(guan)道(dao)的(de)(de)(de)區(qu)別。在ASME B31.1(動(dong)力(li)管(guan)(guan)(guan)道(dao))第100.2節中有(you)(you)(you)詳(xiang)細(xi)的(de)(de)(de)定義。Pipe是有(you)(you)(you)圓形(xing)截(jie)面的(de)(de)(de)空心(xin)制品(pin);Tube是具(ju)有(you)(you)(you)連續(xu)周圓形(xing)或(huo)任何(he)其截(jie)面形(xing)狀的(de)(de)(de)空心(xin)制品(pin)。在規(gui)(gui)(gui)格(ge)表(biao)(biao)示(shi)(shi)上,Tube的(de)(de)(de)外徑(jing)、內(nei)徑(jing)和(he)壁(bi)厚可用(yong)兩個獨立參數表(biao)(biao)示(shi)(shi),即國內(nei)常用(yong)的(de)(de)(de)外徑(jing)x壁(bi)厚(Φφdxt)),內(nei)徑(jing)可推算出。Pipe規(gui)(gui)(gui)格(ge)則用(yong)公(gong)稱(cheng)管(guan)(guan)(guan)道(dao)規(gui)(gui)(gui)格(ge)NPSx表(biao)(biao)示(shi)(shi),更完善的(de)(de)(de)表(biao)(biao)示(shi)(shi)應(ying)是:NPSxSchy,其中x表(biao)(biao)示(shi)(shi)直徑(jing),y表(biao)(biao)示(shi)(shi)壁(bi)厚,它(ta)們(men)僅(jin)是規(gui)(gui)(gui)格(ge)型號而非實(shi)際尺寸(cun)(cun)。當(dang)壁(bi)厚是標準(zhun)規(gui)(gui)(gui)格(ge)sch40時(shi),可省略(lve)。具(ju)體內(nei)、外徑(jing)及壁(bi)厚尺寸(cun)(cun)數值要查(cha)表(biao)(biao)(ASME B36.10表(biao)(biao)2、A4及ASME B36.19表(biao)(biao)1)。相應(ying)的(de)(de)(de)翻譯方法還有(you)(you)(you) pipe:管(guan)(guan)(guan)道(dao)或(huo)配管(guan)(guan)(guan);Tube:管(guan)(guan)(guan)子(zi)。在不區(qu)分時(shi),統稱(cheng)管(guan)(guan)(guan)材(cai)。

Pipe管(guan)的(de)(de)通用技(ji)術條件(jian)為(wei)(wei)A530,Tube管(guan)的(de)(de)通用技(ji)術條件(jian)為(wei)(wei)A450,它們的(de)(de)主要(yao)差(cha)(cha)(cha)別如(ru)(ru)(ru)下:A530:壁(bi)(bi)(bi)厚用公(gong)稱壁(bi)(bi)(bi)厚表示,壁(bi)(bi)(bi)厚的(de)(de)允許(xu)(xu)偏(pian)差(cha)(cha)(cha)±12.5%,外徑(jing)的(de)(de)允許(xu)(xu)偏(pian)差(cha)(cha)(cha)控制較松(如(ru)(ru)(ru)上(shang)偏(pian)差(cha)(cha)(cha)最(zui)(zui)小(xiao)為(wei)(wei)0.4mm),對于擴口(kou)試(shi)(shi)驗、卷邊(bian)試(shi)(shi)驗、硬度(du)均沒有要(yao)求。A450:壁(bi)(bi)(bi)厚用最(zui)(zui)小(xiao)壁(bi)(bi)(bi)厚表示,壁(bi)(bi)(bi)厚的(de)(de)允許(xu)(xu)偏(pian)差(cha)(cha)(cha)負公(gong)差(cha)(cha)(cha)位零,外徑(jing)的(de)(de)允許(xu)(xu)偏(pian)差(cha)(cha)(cha)控制較嚴(如(ru)(ru)(ru)上(shang)偏(pian)差(cha)(cha)(cha)最(zui)(zui)大(da)為(wei)(wei)0.4mm),對于擴口(kou)試(shi)(shi)驗、卷邊(bian)試(shi)(shi)驗、硬度(du)均有要(yao)求。

Pipe管(guan)和Tube管(guan)的(de)規范中(zhong)有(you)自己(ji)的(de)技術(shu)要(yao)求。對于(yu)一(yi)般(ban)管(guan)線(xian)具體用(yong)Tube 管(guan)還是用(yong)Pipe管(guan),很難給出明確的(de)界限,但對于(yu)脹接的(de)換熱(re)器管(guan)、爐管(guan)、儀(yi)表的(de)卡套連接管(guan)必須用(yong)Tube管(guan),對于(yu)焊(han)接的(de)管(guan)子(zi)用(yong)Tube 管(guan)和Pipe管(guan)一(yi)般(ban)都可以,由于(yu)Tube管(guan)的(de)制造檢(jian)驗要(yao)求更(geng)為嚴格(ge),可以用(yong)在壓力溫(wen)度更(geng)為苛刻的(de)工況,價格(ge)也較(jiao)貴。

ASME在制定這段規則時,著(zhu)眼于(yu)(yu)Pipe管和Tube管用(yong)途(tu)的(de)性(xing)質(zhi)。在鍋爐(lu)和壓力(li)容器范圍內,Tube主要著(zhu)眼于(yu)(yu)內外傳導熱量、熱交換(huan)用(yong)途(tu),而Pipe則主要立足于(yu)(yu)將受壓介質(zhi)從一個(ge)(ge)地(di)方(fang)輸(shu)送到(dao)另一個(ge)(ge)地(di)方(fang)的(de)功能。

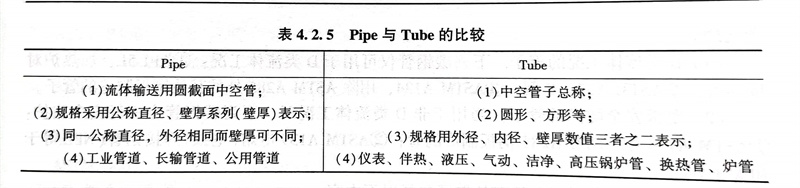

Tube可(ke)(ke)以(yi)(yi)是任(ren)何截面形狀,Pipe要是圓的截面。Pipe是以(yi)(yi)公(gong)稱直徑定義,Tube是以(yi)(yi)外徑和(he)壁厚(hou)定義,Pipe可(ke)(ke)以(yi)(yi)焊接(jie)(jie)、車(che)螺紋,Tube只能(neng)用(yong)壓緊接(jie)(jie)頭(compress joint type)的管件(jian)(fitting)連接(jie)(jie)。Pipe與Tube的比較(jiao)見表4.2.5。