不(bu)銹(xiu)鋼管(guan)道分支(zhi)處補強(qiang)方(fang)式(shi)的(de)(de)選(xuan)擇,一般(ban)是通過定性分析(xi)和定量計算相結合的(de)(de)方(fang)式(shi)來(lai)確定。定量計算的(de)(de)詳細(xi)講述見(jian)本(ben)書第三章(zhang)中支(zhi)管(guan)連接形式(shi)的(de)(de)選(xuan)用與強(qiang)度(du)計算工程應用。

1. 分(fen)支(zhi)(zhi)(zhi)管(guan)連接(jie)方式(shi)的(de)選用,主要根據管(guan)道(dao)的(de)設計溫度、設計壓力、腐蝕余量等設計條件確定。分(fen)支(zhi)(zhi)(zhi)的(de)方法基本為兩(liang)種,對于低壓大直(zhi)徑(jing)管(guan)則(ze)直(zhi)接(jie)把分(fen)支(zhi)(zhi)(zhi)管(guan)焊(han)于主管(guan)上(shang);其他多數是利用分(fen)支(zhi)(zhi)(zhi)管(guan)件進行分(fen)支(zhi)(zhi)(zhi)。

①. 當從主(zhu)(zhu)管(guan)引(yin)出支(zhi)(zhi)管(guan),支(zhi)(zhi)管(guan)直徑(jing)與主(zhu)(zhu)管(guan)直徑(jing)的比值(zhi)大(da)(da)于(yu)(yu)等于(yu)(yu)0.5時,采(cai)用(yong)異徑(jing)三(san)(san)通(tong)或(huo)(huo)等徑(jing)三(san)(san)通(tong);當主(zhu)(zhu)支(zhi)(zhi)管(guan)為等徑(jing)時,應采(cai)用(yong)三(san)(san)通(tong)。GB 50316規定:公稱壓(ya)力(li)大(da)(da)于(yu)(yu)或(huo)(huo)等于(yu)(yu)10MPa的管(guan)道,主(zhu)(zhu)支(zhi)(zhi)管(guan)為異徑(jing)時,不(bu)宜采(cai)用(yong)焊接(jie)支(zhi)(zhi)管(guan),宜采(cai)用(yong)三(san)(san)通(tong)或(huo)(huo)在主(zhu)(zhu)管(guan)上開孔(kong)并焊接(jie)支(zhi)(zhi)管(guan)臺。當主(zhu)(zhu)管(guan)直徑(jing)大(da)(da)于(yu)(yu)DN65而支(zhi)(zhi)管(guan)直徑(jing)為DN40和以下時,根據設計壓(ya)力(li)的大(da)(da)小,采(cai)用(yong)支(zhi)(zhi)管(guan)臺或(huo)(huo)半管(guan)接(jie)頭。

有的規范規定,一般主管(guan)尺寸的一半并降低(di)(di)兩個尺寸系列,就沒(mei)有三通可供(gong)使用(yong)了(le),如(ru)主管(guan)為12”,標準三通一般可做到5"(不常用(yong)的口徑),再低(di)(di)就沒(mei)有三通可供(gong)選用(yong)了(le)。

②. 普(pu)通無腐蝕性的低溫介質(如LNG),在(zai)中、低壓(ya)條件(jian)下(一般不大于(yu)(yu)9MPa),小尺(chi)(chi)寸(cun)的分支(zhi)(≤2”),選用半(ban)管接(jie)頭(half coupling),在(zai)高壓(ya)條件(jian)下(一般大于(yu)(yu)9MPa),小尺(chi)(chi)寸(cun)的分支(zhi)(≤2")選用對(dui)焊支(zhi)管座(weldolet)。

③. 普(pu)通(tong)無腐蝕性的低(di)溫介質(如LNG),在(zai)中、低(di)壓(ya)條件(jian)下(一般<6MPa),大(da)(da)尺(chi)(chi)寸的分支(zhi)(>2”),選用補強板連接(reinforcing pad);在(zai)高壓(ya)條件(jian)下(一般大(da)(da)于6MPa),大(da)(da)尺(chi)(chi)寸的分支(zhi)(>2”)選用對焊(han)支(zhi)管座(zuo)(Weldolet)。

④. 等級表中低(di)溫管道的(de)分(fen)支形(xing)式(shi)主要(yao)包括標準三(san)通、半管接(jie)頭、對焊支管座、補強板(ban)連接(jie)、直接(jie)開口(較少)等形(xing)式(shi)。

⑤. 其他工況支管連接方式的選用(yong):

a. 主管直徑(jing)(jing)小于DN50時(shi),支管小于主管,則用異徑(jing)(jing)三通或等徑(jing)(jing)三通加(jia)異徑(jing)(jing)短管。

b. 設(she)(she)計(ji)壓力等(deng)于(yu)(yu)或(huo)(huo)大(da)于(yu)(yu)2.0MPa、設(she)(she)計(ji)溫度(du)超過250℃以及(ji)支(zhi)管與主管公稱(cheng)(cheng)直(zhi)徑之(zhi)比大(da)于(yu)(yu)0.8,或(huo)(huo)承受機械振動、壓力脈(mo)動和溫度(du)急劇變化的管道(dao)分支(zhi),應(ying)(ying)采(cai)用(yong)等(deng)徑異徑三(san)通;公稱(cheng)(cheng)直(zhi)徑小于(yu)(yu)或(huo)(huo)等(deng)于(yu)(yu)40mm的管道(dao),應(ying)(ying)采(cai)用(yong)承插焊(或(huo)(huo)螺(luo)紋)鍛(duan)制三(san)通;公稱(cheng)(cheng)直(zhi)徑等(deng)于(yu)(yu)或(huo)(huo)大(da)于(yu)(yu)50mm的管道(dao),應(ying)(ying)采(cai)用(yong)對(dui)焊三(san)通、對(dui)焊加強管接頭(對(dui)焊支(zhi)管臺(tai))或(huo)(huo)嵌(qian)入式(鞍形)支(zhi)管接頭。

c. 支(zhi)管通過加強管接頭(支(zhi)管臺)與主管連接是指將一個螺(luo)紋(wen)、承(cheng)插(cha)焊(han)或對焊(han)的(de)(de)管接頭或半管接頭(支(zhi)管臺)直接焊(han)于(yu)主管上(shang)而制(zhi)成,螺(luo)紋(wen)、承(cheng)插(cha)焊(han)支(zhi)管臺用于(yu)直徑≤DN40(NPS1 1/2)的(de)(de)支(zhi)管連接。螺(luo)紋(wen)、承(cheng)插(cha)焊(han)支(zhi)管臺在任何情況下(xia)其(qi)額定等(deng)級應(ying)大于(yu)等(deng)于(yu)2000lb。

d. 其他支管連(lian)接可(ke)用(yong)直(zhi)接焊接,但必須經校核后明確是(shi)否增加補(bu)強(qiang)。直(zhi)接焊接在主管上的(de)支管連(lian)接,不宜用(yong)于(yu)有機械振動、壓力脈動和溫度急劇變(bian)(bian)化(hua)的(de)部位及設(she)計(ji)溫度超過425℃的(de)管道,當支管連(lian)接處承受由于(yu)支管熱變(bian)(bian)形(xing),外荷載及支架(jia)位移等引起(qi)的(de)應力時,應對附加荷載在支管連(lian)接處產生的(de)影響進(jin)行分(fen)析并采取必要的(de)加強(qiang)措施。

⑥. 依(yi)據管(guan)(guan)道等級中已經(jing)確定的法(fa)蘭壓(ya)力等級或公稱壓(ya)力來選用支管(guan)(guan)連接件。

一(yi)般,當(dang)法蘭的(de)公稱壓(ya)力公稱壓(ya)力≤2.5MPa(磅(bang)級系列(lie)≤150lb)時,綜合考慮(lv)其他工(gong)況(kuang)后,支管(guan)可直(zhi)(zhi)接(jie)焊(han)接(jie)在主(zhu)管(guan)上;當(dang)公稱壓(ya)力≥4.0MPa(磅(bang)級系列(lie)公稱壓(ya)力≥300lb)時,則根據主(zhu)管(guan)支管(guan)公稱直(zhi)(zhi)徑的(de)不同按對(dui)焊(han)三通(tong)、對(dui)焊(han)加(jia)(jia)強管(guan)接(jie)頭、承(cheng)插焊(han)或螺紋(wen)連接(jie)三通(tong)、承(cheng)插焊(han)或螺紋(wen)加(jia)(jia)強管(guan)接(jie)頭的(de)順序選用。

2. 管(guan)件壁厚

在確定支管(guan)(guan)(guan)(guan)(guan)連(lian)接(jie)件(jian)(jian)(jian)(jian)(jian)的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)時(shi),應根據管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)與管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)等(deng)強度的(de)(de)(de)原則(ze)以及管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)與管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)連(lian)接(jie)方式而(er)定。例如,當(dang)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)與管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)采用(yong)對焊連(lian)接(jie)時(shi),管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)與管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)應一致;而(er)當(dang)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)與管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)采用(yong)承插(cha)焊或(huo)(huo)螺(luo)紋連(lian)接(jie)時(shi),標準的(de)(de)(de)承插(cha)焊和螺(luo)紋管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)只有Sch80、Sch60、XXS,最(zui)低的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)就(jiu)(jiu)(jiu)是(shi)Sch80,也就(jiu)(jiu)(jiu)是(shi)說只要當(dang)承插(cha)焊或(huo)(huo)螺(luo)紋管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)所(suo)連(lian)接(jie)的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)不大于(yu)Sch80時(shi),承插(cha)焊或(huo)(huo)螺(luo)紋管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)就(jiu)(jiu)(jiu)選Sch80。而(er)當(dang)所(suo)連(lian)接(jie)的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)大于(yu)Sch80時(shi),承插(cha)焊或(huo)(huo)螺(luo)紋管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(jian)(jian)的(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)子(zi)(zi)(zi)表(biao)(biao)(biao)(biao)(biao)號(hao)(hao)(hao)就(jiu)(jiu)(jiu)選Sch60或(huo)(huo)XXS。

當對(dui)焊三通(tong)主(zhu)(zhu)管(guan)(guan)、支(zhi)(zhi)管(guan)(guan)所連(lian)接的(de)(de)管(guan)(guan)子的(de)(de)管(guan)(guan)子表號(hao)不同時,應注意三通(tong)主(zhu)(zhu)管(guan)(guan)、支(zhi)(zhi)管(guan)(guan)端部的(de)(de)管(guan)(guan)子表號(hao)應分別(bie)與其所連(lian)接的(de)(de)管(guan)(guan)子的(de)(de)管(guan)(guan)子表號(hao)相同,這樣就非常(chang)方(fang)便管(guan)(guan)道施工,管(guan)(guan)件不必現場再打坡口。

3. 支管直接(jie)焊(han)于主管的補強計算

GB/T 20801、SH/T 3059、GB 50316 等規范與ASME B31.3關于(yu)面積補強(qiang)法的計算基本相(xiang)同(tong)。

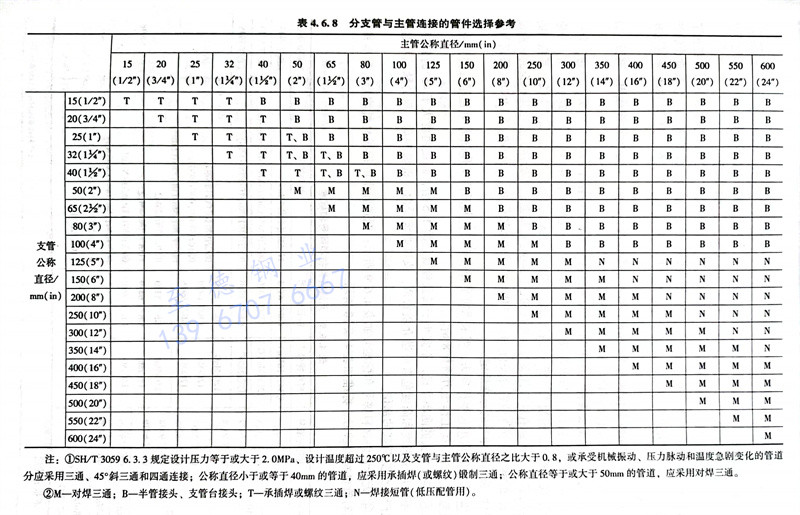

4. 分(fen)支管與(yu)主管連接(jie)的管件選擇參(can)見(jian)表4.6.8。