三通接頭是不(bu)銹鋼管件的一種,它的連接形式就是直接將不銹(xiu)鋼三(san)通與鋼管對焊,三通接頭的主要制造標準一般是GB/T 12459《鋼制無縫焊接管件》、GB/T 13401《鋼板制對焊管件》、ASME B16.9《工廠制造的鍛軋制對焊管配件》、SH/T 3408《鋼制對焊無縫管件》、SH/T3409《鋼板制對焊管件》、HG/T 21635《碳鋼、低合金鋼無縫對焊管件》、HG/T 21631《鋼制有縫對焊管件》、SY/T 0510《鋼制對焊管件》。

①. 按照(zhao)管件口徑(jing)分一般有等(deng)徑(jing)三通(straight tee),異徑(jing)三通(reducing tee)等(deng)。

②. 按照支管方向分有正(zheng)(zheng)三(san)通(tong)和(he)斜三(san)通(tong)(Y形三(san)通(tong)),斜三(san)通(tong)常常代替一般正(zheng)(zheng)三(san)通(tong),用(yong)于輸送有固(gu)體(ti)顆粒(li)或沖刷腐蝕(shi)較(jiao)嚴重的管道上。

③. 按(an)照材料(liao)分有碳鋼、合(he)金鋼、不(bu)銹(xiu)鋼、銅、PVC等三(san)通。

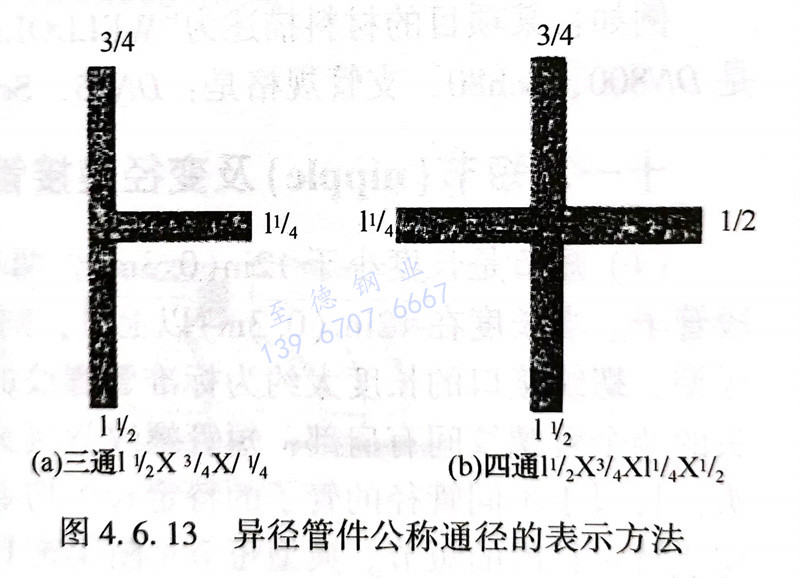

④. 按照連(lian)接方式分有普通三(san)通、螺紋三(san)通、卡(ka)套三(san)通、承插三(san)通。典型三(san)通及連(lian)接見圖4.6.11。

不(bu)(bu)銹鋼(gang)三(san)通(tong)(tong)接頭成(cheng)(cheng)形(xing)(xing)(xing)是將(jiang)大于三(san)通(tong)(tong)直(zhi)徑(jing)(jing)的(de)(de)管(guan)(guan)(guan)坯(pi),壓(ya)(ya)扁約(yue)至三(san)通(tong)(tong)直(zhi)徑(jing)(jing)的(de)(de)尺寸,在(zai)(zai)(zai)拉(la)伸支管(guan)(guan)(guan)的(de)(de)部位開一個(ge)孔;管(guan)(guan)(guan)坯(pi)經加熱(re),放入(ru)成(cheng)(cheng)形(xing)(xing)(xing)模中,并在(zai)(zai)(zai)管(guan)(guan)(guan)坯(pi)內裝入(ru)拉(la)伸支管(guan)(guan)(guan)的(de)(de)沖(chong)模;在(zai)(zai)(zai)壓(ya)(ya)力的(de)(de)作用(yong)(yong)(yong)下管(guan)(guan)(guan)坯(pi)被徑(jing)(jing)向(xiang)(xiang)壓(ya)(ya)縮,在(zai)(zai)(zai)徑(jing)(jing)向(xiang)(xiang)壓(ya)(ya)縮的(de)(de)過(guo)(guo)程中金屬(shu)向(xiang)(xiang)支管(guan)(guan)(guan)方向(xiang)(xiang)流動(dong)并在(zai)(zai)(zai)沖(chong)模的(de)(de)拉(la)伸下形(xing)(xing)(xing)成(cheng)(cheng)支管(guan)(guan)(guan)。整個(ge)過(guo)(guo)程是通(tong)(tong)過(guo)(guo)管(guan)(guan)(guan)坯(pi)的(de)(de)徑(jing)(jing)向(xiang)(xiang)壓(ya)(ya)縮和(he)支管(guan)(guan)(guan)部位的(de)(de)拉(la)伸過(guo)(guo)程而成(cheng)(cheng)形(xing)(xing)(xing)。與液壓(ya)(ya)脹形(xing)(xing)(xing)三(san)通(tong)(tong)不(bu)(bu)同的(de)(de)是,三(san)通(tong)(tong)接頭支管(guan)(guan)(guan)的(de)(de)金屬(shu)是由管(guan)(guan)(guan)坯(pi)的(de)(de)徑(jing)(jing)向(xiang)(xiang)運動(dong)進行補償(chang)的(de)(de),所以也稱(cheng)為徑(jing)(jing)向(xiang)(xiang)補償(chang)工藝。由于采(cai)用(yong)(yong)(yong)加熱(re)后壓(ya)(ya)制三(san)通(tong)(tong),材(cai)料成(cheng)(cheng)形(xing)(xing)(xing)所需要的(de)(de)設備噸(dun)位降低(di)。熱(re)壓(ya)(ya)三(san)通(tong)(tong)對材(cai)料的(de)(de)適(shi)應性較(jiao)寬,適(shi)用(yong)(yong)(yong)于低(di)碳鋼(gang)、合金鋼(gang)、不(bu)(bu)銹鋼(gang)的(de)(de)材(cai)料;特別是大直(zhi)徑(jing)(jing)和(he)管(guan)(guan)(guan)壁偏厚的(de)(de)三(san)通(tong)(tong),通(tong)(tong)常(chang)采(cai)用(yong)(yong)(yong)這種成(cheng)(cheng)形(xing)(xing)(xing)工藝。

不銹(xiu)鋼四通為管件、管道連接件,用在主管道要分支管處,又稱管件四通、四通管件、四通接頭。四通有等徑和異徑之分,等徑四通的接管端部均為相同的尺寸;異徑的四通的主管接管尺寸相同,而支管的接管尺寸小于主管的接管尺寸。對于采用無縫管制造四通來講,目前通常所采用的工藝有液壓脹形和熱壓成形兩種。四通以制作方法劃分可分為頂制、壓制、鍛制、鑄造等。制造標準有GB/T 12459,GB/T 13401,ASME B16.9,SH/T 3408,SH/T 3409,HG/T 21635,DL/T 695,SY/T 0510,DIN 2615等。典型四通見圖4.6.12。

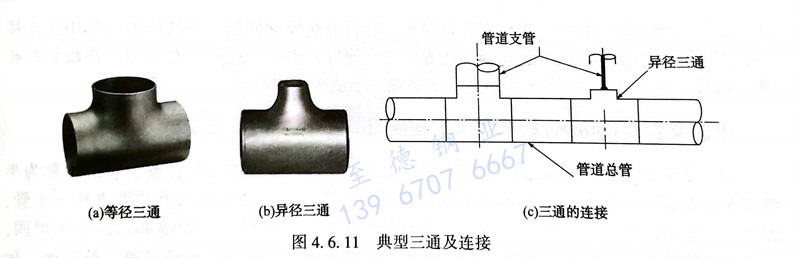

對于(yu)(yu)異(yi)徑(jing)(jing)(jing)三通(tong)(tong)(tong),首(shou)先給(gei)出(chu)(chu)(chu)最大(da)(da)端(duan)(duan)(duan)的(de)(de)公稱(cheng)通(tong)(tong)(tong)徑(jing)(jing)(jing),然后是與(yu)最大(da)(da)端(duan)(duan)(duan)相(xiang)對應的(de)(de)那(nei)一(yi)端(duan)(duan)(duan)的(de)(de)公稱(cheng)通(tong)(tong)(tong)徑(jing)(jing)(jing),最后給(gei)出(chu)(chu)(chu)支管(guan)瑞(rui)的(de)(de)公稱(cheng)通(tong)(tong)(tong)徑(jing)(jing)(jing);對于(yu)(yu)異(yi)徑(jing)(jing)(jing)四(si)通(tong)(tong)(tong),首(shou)先給(gei)出(chu)(chu)(chu)最大(da)(da)端(duan)(duan)(duan)的(de)(de)公稱(cheng)通(tong)(tong)(tong)徑(jing)(jing)(jing),其次是與(yu)最大(da)(da)端(duan)(duan)(duan)相(xiang)對應的(de)(de)另一(yi)端(duan)(duan)(duan)的(de)(de)公稱(cheng)通(tong)(tong)(tong)徑(jing)(jing)(jing),第三個(ge)給(gei)出(chu)(chu)(chu)的(de)(de)是另外(wai)兩端(duan)(duan)(duan)中的(de)(de)較大(da)(da)端(duan)(duan)(duan)的(de)(de)公稱(cheng)通(tong)(tong)(tong)徑(jing)(jing)(jing),最后給(gei)出(chu)(chu)(chu)剩余一(yi)端(duan)(duan)(duan)的(de)(de)公稱(cheng)通(tong)(tong)(tong)徑(jing)(jing)(jing)(見圖4.6.13)。