尿素,英文名稱為Urea,化學名稱為脲或碳酰胺。結構式為CO(NH2或NH2CONH2,分子式為CH4ON2,相對分子質量為60.056。純尿素含氮46.65%(質量分數),是含氮量最高的氮肥。

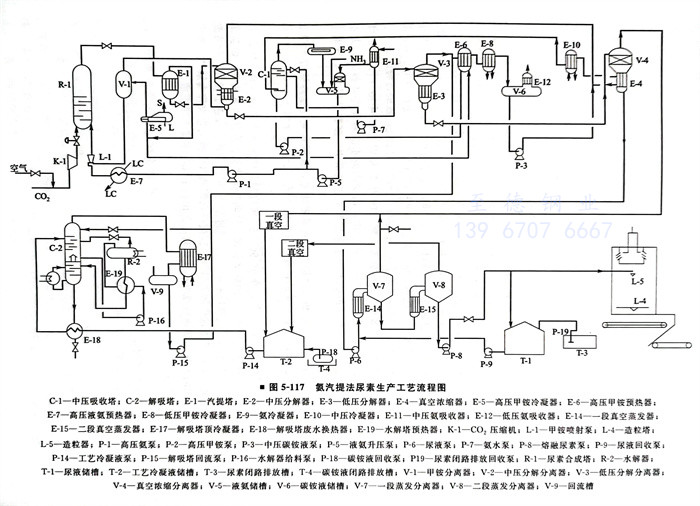

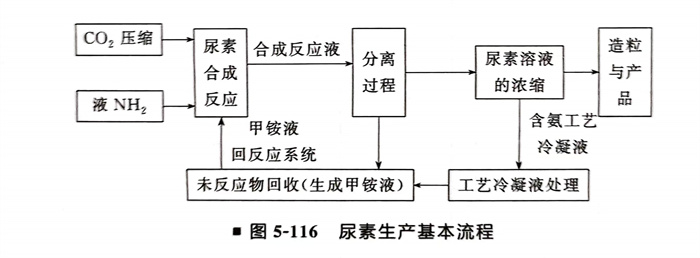

尿(niao)素(su)(su)生產工(gong)(gong)(gong)(gong)藝流程(cheng)基(ji)本由6個(ge)工(gong)(gong)(gong)(gong)藝單(dan)(dan)元(yuan),即原料供應(ying)、尿(niao)素(su)(su)的(de)(de)高(gao)(gao)壓合(he)成(cheng)(cheng)、含(han)尿(niao)素(su)(su)溶(rong)(rong)液(ye)的(de)(de)分離過(guo)(guo)程(cheng)、未反(fan)應(ying)氨和(he)(he)二(er)氧(yang)(yang)化(hua)碳的(de)(de)回(hui)收(shou)、尿(niao)素(su)(su)溶(rong)(rong)液(ye)的(de)(de)濃縮、造粒與產品(pin)(pin)輸送和(he)(he)工(gong)(gong)(gong)(gong)藝冷凝液(ye)處(chu)理,其基(ji)本過(guo)(guo)程(cheng)如(ru)圖5-116所示。原料CO2和(he)(he)NH3被(bei)加壓送到高(gao)(gao)壓合(he)成(cheng)(cheng)圈,反(fan)應(ying)生成(cheng)(cheng)尿(niao)素(su)(su),二(er)氧(yang)(yang)化(hua)碳轉(zhuan)化(hua)率在(zai)50%~75%,此(ci)過(guo)(guo)程(cheng)被(bei)稱(cheng)為(wei)(wei)(wei)(wei)合(he)成(cheng)(cheng)工(gong)(gong)(gong)(gong)序;分離過(guo)(guo)程(cheng)與未反(fan)應(ying)物回(hui)收(shou)單(dan)(dan)元(yuan)承擔著把(ba)未轉(zhuan)化(hua)為(wei)(wei)(wei)(wei)尿(niao)素(su)(su)的(de)(de)氨和(he)(he)二(er)氧(yang)(yang)化(hua)碳從溶(rong)(rong)液(ye)中分離出(chu)來,并(bing)回(hui)收(shou)返回(hui)合(he)成(cheng)(cheng)工(gong)(gong)(gong)(gong)序,因(yin)此(ci)這兩個(ge)單(dan)(dan)元(yuan)被(bei)統稱(cheng)為(wei)(wei)(wei)(wei)循環工(gong)(gong)(gong)(gong)序;最后在(zai)真空蒸發(fa)和(he)(he)造粒設備中把(ba)70%~75%的(de)(de)尿(niao)素(su)(su)溶(rong)(rong)液(ye)經濃縮加工(gong)(gong)(gong)(gong)為(wei)(wei)(wei)(wei)固體產品(pin)(pin),稱(cheng)為(wei)(wei)(wei)(wei)最終加工(gong)(gong)(gong)(gong)工(gong)(gong)(gong)(gong)序。

盡(jin)管尿(niao)素(su)(su)生(sheng)產(chan)的(de)(de)(de)基(ji)本過程(cheng)(cheng)(cheng)相似,但(dan)在具體的(de)(de)(de)流程(cheng)(cheng)(cheng)、工(gong)(gong)(gong)(gong)藝條件、設(she)備(bei)結構等(deng)方面,不同工(gong)(gong)(gong)(gong)藝存(cun)在一定的(de)(de)(de)差(cha)異。迄今世界(jie)各地的(de)(de)(de)尿(niao)素(su)(su)工(gong)(gong)(gong)(gong)廠(chang),絕大(da)多數(shu)都是(shi)由幾(ji)家工(gong)(gong)(gong)(gong)程(cheng)(cheng)(cheng)設(she)計公(gong)(gong)司所開發(fa)設(she)計的(de)(de)(de),已形成幾(ji)種典型的(de)(de)(de)工(gong)(gong)(gong)(gong)藝流程(cheng)(cheng)(cheng),典型的(de)(de)(de)有荷蘭斯太米卡邦(bang)(Stamicarbon)公(gong)(gong)司的(de)(de)(de)水溶(rong)液全循環CO2氣提法、意大(da)利斯納姆(Snamprogetti)公(gong)(gong)司的(de)(de)(de)氨汽提法和蒙特愛(ai)迪(di)生(sheng)集團公(gong)(gong)司的(de)(de)(de)等(deng)壓雙循環工(gong)(gong)(gong)(gong)藝(IDR)、日本三(san)井東亞-東洋工(gong)(gong)(gong)(gong)程(cheng)(cheng)(cheng)公(gong)(gong)司的(de)(de)(de)全循環改良C法和改良D法及ACES法、美(mei)國尿(niao)素(su)(su)技術公(gong)(gong)司UTI的(de)(de)(de)熱(re)循環法尿(niao)素(su)(su)工(gong)(gong)(gong)(gong)藝(HR)等(deng)。但(dan)不論(lun)是(shi)哪種工(gong)(gong)(gong)(gong)藝流程(cheng)(cheng)(cheng),生(sheng)產(chan)過程(cheng)(cheng)(cheng)中(zhong)主(zhu)要(yao)原料NH3和CO2的(de)(de)(de)消耗(hao)基(ji)本上是(shi)相同的(de)(de)(de),其流程(cheng)(cheng)(cheng)的(de)(de)(de)先進(jin)與(yu)否主(zhu)要(yao)表(biao)現在公(gong)(gong)用工(gong)(gong)(gong)(gong)程(cheng)(cheng)(cheng),即(ji)水、電、汽的(de)(de)(de)消耗(hao)上。尿(niao)素(su)(su)生(sheng)產(chan)流程(cheng)(cheng)(cheng)的(de)(de)(de)改進(jin)過程(cheng)(cheng)(cheng),實質(zhi)就是(shi)公(gong)(gong)用工(gong)(gong)(gong)(gong)程(cheng)(cheng)(cheng)消耗(hao)降低的(de)(de)(de)過程(cheng)(cheng)(cheng)。

目前國內建有尿素裝置200多套,規模分為大型(48萬噸/年以上)、中型(11萬噸/年以上)、小型(4萬噸/年以上)。中、小型尿素裝置均采用國內的水溶液全循環技術,大型裝置多采用國外引進工藝技術。在國內的大型尿素裝置工藝技術中,多數采用CO2汽提工藝和氨汽提工藝。

目前設計的采用(yong)CO2汽(qi)提工(gong)藝(yi)(yi)和氨(an)(an)汽(qi)提工(gong)藝(yi)(yi)的尿素(su)(su)裝(zhuang)置,其(qi)尿素(su)(su)氨(an)(an)耗基本接近于理論(lun)水平,公用(yong)工(gong)程消耗更(geng)(geng)低(di),相對于傳統的設計,其(qi)投資更(geng)(geng)低(di)。下面僅介紹 Snamprogetti 氨(an)(an)汽(qi)提法尿素(su)(su)工(gong)藝(yi)(yi)。

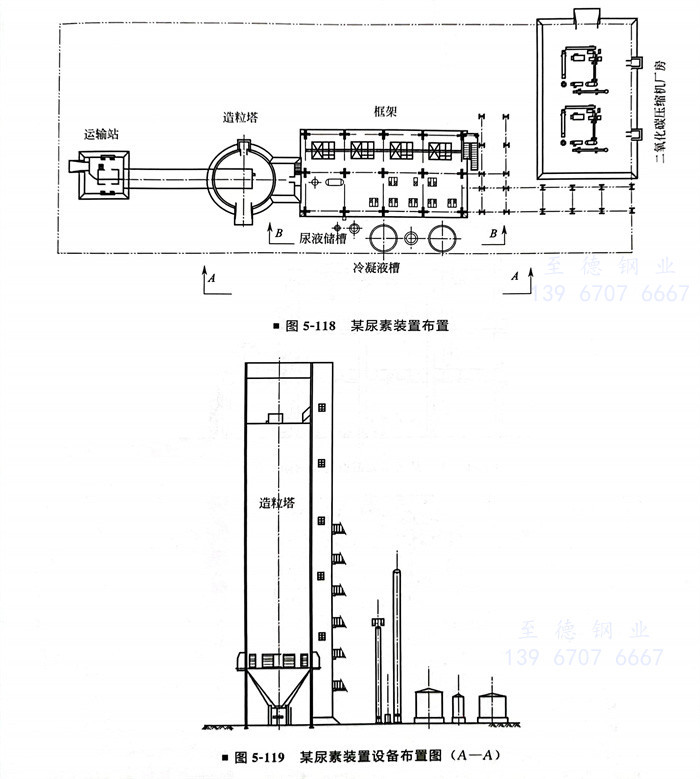

意大利(li)斯(si)納姆(mu)公司創立于1956年(nian),在20世(shi)紀(ji)60年(nian)代初(chu)開始尿(niao)素生產(chan)的研究。1966年(nian)第一個(ge)建(jian)成(cheng)以氨(an)(an)作為汽(qi)(qi)提氣(qi)的日(ri)產(chan)70t的尿(niao)素裝(zhuang)置。早期(qi)第一代氨(an)(an)汽(qi)(qi)提法(fa)尿(niao)素裝(zhuang)置,設(she)(she)備采用(yong)框架式立體布置,氨(an)(an)直接加(jia)入(ru)汽(qi)(qi)提塔底(di)部(bu)。在20世(shi)紀(ji)70年(nian)代中期(qi),改進了設(she)(she)計,設(she)(she)備改為平(ping)面布置,而且(qie)也(ye)不向汽(qi)(qi)提塔直接加(jia)入(ru)氨(an)(an)氣(qi),這(zhe)就是(shi)所謂的自汽(qi)(qi)提工(gong)藝(yi)或(huo)稱(cheng)為第二代氨(an)(an)汽(qi)(qi)提工(gong)藝(yi),是(shi)目(mu)前采用(yong)的方法(fa)。斯(si)納姆(mu)氨(an)(an)汽(qi)(qi)提法(fa)尿(niao)素工(gong)藝(yi)由以下幾個(ge)主(zhu)要工(gong)序(xu)組成(cheng)。

①. CO2氣體的壓縮。

②. 液氨的加壓。

③. 高壓合(he)成與氨汽提回收。

④. 中(zhong)壓分解與(yu)循環(huan)回收。

⑤. 低(di)壓分解(jie)與(yu)循環回收。

⑥. 中、低壓分解與循(xun)環(huan)回收。

⑦. 真(zhen)空蒸發(fa)與造粒(li)。

⑧. 解吸與水(shui)解系統。

氨(an)汽提法尿(niao)素生產工藝流程、如圖5-117所示(shi)。