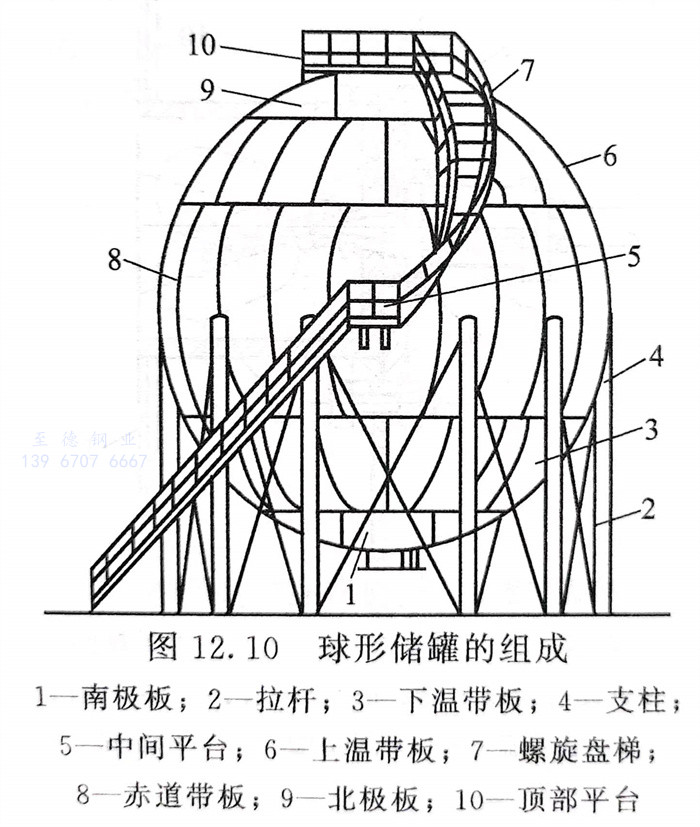

球(qiu)罐(guan)(球(qiu)形儲罐(guan))由球(qiu)罐(guan)本體(ti)、支座及附(fu)件組成(cheng),如圖12.10所示(shi)。

1. 球(qiu)罐本體

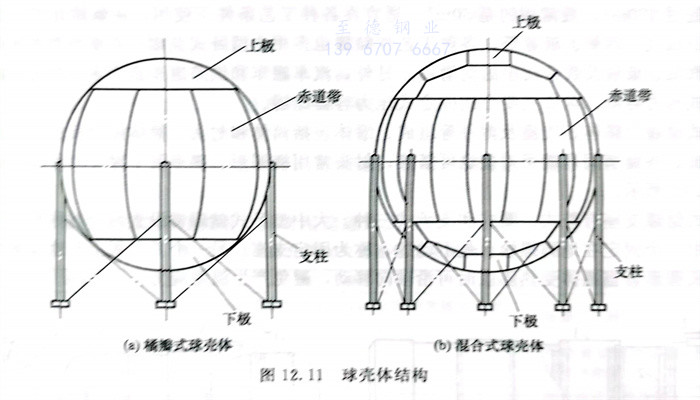

球(qiu)罐(guan)本體(ti)是球(qiu)罐(guan)結構(gou)的(de)(de)主體(ti),它是球(qiu)罐(guan)儲存物料并承受物料工作壓力和液體(ti)靜壓力的(de)(de)構(gou)件(jian)。球(qiu)罐(guan)本體(ti)是由(you)許多(duo)塊球(qiu)殼板(ban)拼焊而成的(de)(de)一(yi)個球(qiu)形(xing)容器。由(you)于(yu)球(qiu)罐(guan)直徑(jing)大小不同,球(qiu)殼板(ban)的(de)(de)數量也不一(yi)樣。球(qiu)殼體(ti)常用的(de)(de)有橘瓣(ban)式和混(hun)合式兩種結構(gou),見圖12.11。

球殼板(ban)為標準(zhun)球形,一般由(you)容器(qi)制造(zao)廠根據(ju)設計圖紙進行壓(ya)(ya)(ya)制。壓(ya)(ya)(ya)制方法(fa)有熱(re)壓(ya)(ya)(ya)和(he)冷壓(ya)(ya)(ya)兩種。熱(re)壓(ya)(ya)(ya)是將鋼板(ban)置于加(jia)熱(re)爐中加(jia)熱(re)至750~800℃,然后放在模具上進行壓(ya)(ya)(ya)制。對(dui)于調質(zhi)和(he)正(zheng)火供貨(huo)的鋼板(ban),為保持鋼板(ban)原

有(you)的(de)力學性能(neng),應進(jin)行冷(leng)壓成形。冷(leng)壓是將鋼板(ban)(ban)(ban)(ban)置于(yu)模(mo)具上用壓力機通(tong)過模(mo)頭對(dui)鋼板(ban)(ban)(ban)(ban)施(shi)以壓力使鋼板(ban)(ban)(ban)(ban)應力超過屈服強度極限而變(bian)形。不論是熱(re)壓和冷(leng)壓,球殼板(ban)(ban)(ban)(ban)周邊均應留有(you)余量,便(bian)于(yu)檢驗尺寸、劃線切割和開(kai)坡(po)口。球殼板(ban)(ban)(ban)(ban)經檢查(cha)合格后,在制造廠還應進(jin)行預(yu)組(zu)裝,然(ran)后對(dui)每塊(kuai)球殼板(ban)(ban)(ban)(ban)編號,發送施(shi)工(gong)現場。

2. 支座

支(zhi)(zhi)座(zuo)是用于支(zhi)(zhi)承(cheng)球(qiu)罐(guan)本(ben)體、附件、儲存物(wu)料重量及承(cheng)受(shou)風載、地(di)震力(li)等自然力(li)的結構(gou)部件。支(zhi)(zhi)座(zuo)多(duo)采(cai)用與(yu)球(qiu)罐(guan)赤道板(ban)(ban)正切的柱(zhu)式(shi)(shi)支(zhi)(zhi)座(zuo),也稱球(qiu)罐(guan)支(zhi)(zhi)柱(zhu)。球(qiu)罐(guan)支(zhi)(zhi)柱(zhu)一(yi)(yi)般用鋼管制成(cheng),支(zhi)(zhi)柱(zhu)數量通常為赤道板(ban)(ban)數量的一(yi)(yi)半(ban)。支(zhi)(zhi)柱(zhu)間有(you)拉桿(gan),使其支(zhi)(zhi)承(cheng)連成(cheng)整體。支(zhi)(zhi)柱(zhu)通過柱(zhu)腳板(ban)(ban)用地(di)腳螺栓(shuan)固定在基礎上。除赤道正切式(shi)(shi)支(zhi)(zhi)座(zuo)外(wai),還有(you)V形(xing)柱(zhu)式(shi)(shi)支(zhi)(zhi)座(zuo)、裙(qun)式(shi)(shi)支(zhi)(zhi)座(zuo)、半(ban)埋式(shi)(shi)支(zhi)(zhi)座(zuo)等,但用得較少。

3. 附件

①. 梯子平臺

為了(le)檢(jian)查、維護和操(cao)作(zuo),球(qiu)(qiu)罐(guan)(guan)上(shang)均設置(zhi)有(you)(you)頂(ding)部(bu)平(ping)(ping)(ping)臺(tai)(tai)和中間平(ping)(ping)(ping)臺(tai)(tai)。頂(ding)部(bu)平(ping)(ping)(ping)臺(tai)(tai)是工藝(yi)操(cao)作(zuo)平(ping)(ping)(ping)臺(tai)(tai),球(qiu)(qiu)罐(guan)(guan)上(shang)的(de)(de)工藝(yi)接管、人(ren)孔(kong)、儀表等大部(bu)分設置(zhi)在(zai)球(qiu)(qiu)罐(guan)(guan)頂(ding)部(bu)的(de)(de)極板上(shang)。中間平(ping)(ping)(ping)臺(tai)(tai)是為了(le)操(cao)作(zuo)人(ren)員上(shang)下頂(ding)部(bu)平(ping)(ping)(ping)臺(tai)(tai)時中間休(xiu)息(xi)或作(zuo)為檢(jian)查球(qiu)(qiu)罐(guan)(guan)赤道部(bu)位而設置(zhi)的(de)(de),很多工程僅(jin)設置(zhi)小的(de)(de)中間休(xiu)息(xi)平(ping)(ping)(ping)臺(tai)(tai),而不設置(zhi)環繞球(qiu)(qiu)罐(guan)(guan)赤道的(de)(de)大平(ping)(ping)(ping)臺(tai)(tai)。有(you)(you)的(de)(de)球(qiu)(qiu)罐(guan)(guan)為便于(yu)內部(bu)檢(jian)查和維護,設置(zhi)有(you)(you)內部(bu)轉(zhuan)梯(ti),該轉(zhuan)梯(ti)可以旋轉(zhuan),可轉(zhuan)到球(qiu)(qiu)罐(guan)(guan)內部(bu)的(de)(de)任何部(bu)位。

②. 人孔和接管

人(ren)孔是為了(le)檢修(xiu)人(ren)員進(jin)出球罐(guan)進(jin)行檢查(cha)和維修(xiu)而設置(zhi)的,同時(shi)也用(yong)于現場(chang)組裝焊接(jie)球罐(guan)時(shi)通風、進(jin)行熱處理、安(an)裝燃燒(shao)器和煙氣排(pai)出等用(yong),人(ren)孔大(da)小一般(ban)選用(yong)DN500。根據需要,球罐(guan)還裝有各種(zhong)接(jie)管。

③. 噴淋裝置

噴(pen)淋裝置的作用(yong)如(ru)下:

a. 對(dui)球(qiu)罐起(qi)(qi)冷卻作(zuo)(zuo)用(yong)(yong)。噴(pen)淋裝置裝在球(qiu)罐的(de)上(shang)部,通水時,冷卻水從環管或堰流出,沿球(qiu)罐壁流下,起(qi)(qi)到冷卻介質的(de)作(zuo)(zuo)用(yong)(yong)。

b. 消(xiao)防作用。在(zai)球罐不同高(gao)(gao)度,離球罐外壁一(yi)(yi)定距(ju)離裝環形(xing)(xing)(xing)管,環形(xing)(xing)(xing)管每隔(ge)一(yi)(yi)段(duan)距(ju)離裝一(yi)(yi)個噴頭(tou),當球罐失(shi)火(huo)(huo)(自身或(huo)相鄰)時,即可通(tong)過(guo)噴頭(tou)噴灑滅火(huo)(huo)介(jie)質(一(yi)(yi)般為高(gao)(gao)壓水(shui),通(tong)過(guo)噴頭(tou)后(hou)形(xing)(xing)(xing)成霧狀)進行滅火(huo)(huo)或(huo)隔(ge)熱。

④. 隔(ge)熱和保(bao)(bao)冷設施。隔(ge)熱和保(bao)(bao)冷是為了保(bao)(bao)證介(jie)(jie)質(zhi)的(de)一定(ding)溫度,根據不同的(de)介(jie)(jie)質(zhi)和要求(qiu)而定(ding)。

⑤. 液位計。用于觀測球(qiu)罐內液位。

⑥. 壓(ya)力表。為了測量球(qiu)罐內的壓(ya)力,一般在球(qiu)罐的上部(bu)和下部(bu)各裝(zhuang)一塊壓(ya)力表。