某DN 1000熱(re)力管(guan)(guan)道(dao),設(she)(she)計溫度120℃,設(she)(she)計壓力1.6MPa,鋼管(guan)(guan)材質為(wei)Q235B 碳(tan)素(su)結(jie)構鋼,聚乙烯外保護殼保溫管(guan)(guan),閥(fa)門(men)采用(yong)(yong)金屬硬密封(feng)焊接(jie)蝶閥(fa),閥(fa)體、閥(fa)桿材質為(wei)碳(tan)鋼,密封(feng)材料為(wei)不銹鋼。采用(yong)(yong)直埋敷(fu)設(she)(she)。管(guan)(guan)道(dao)是按(an)照直埋無(wu)補償敷(fu)設(she)(she)設(she)(she)計的(de),這種無(wu)補償設(she)(she)計需(xu)要管(guan)(guan)道(dao)施(shi)工(gong)時采用(yong)(yong)預(yu)(yu)熱(re),從而降低管(guan)(guan)道(dao)的(de)應力幅度,經濟、安全與可靠。管(guan)(guan)道(dao)常見的(de)預(yu)(yu)熱(re)方式(shi)有三種,即熱(re)水預(yu)(yu)熱(re)、熱(re)風預(yu)(yu)熱(re)和電預(yu)(yu)熱(re)。下(xia)面結(jie)合工(gong)程實際對直埋供熱(re)管(guan)(guan)道(dao)的(de)電預(yu)(yu)熱(re)做簡單講述。

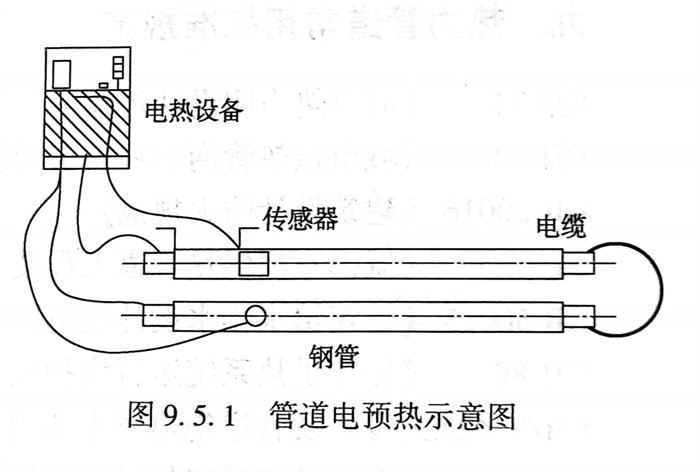

電(dian)(dian)(dian)(dian)預(yu)熱(re)的(de)(de)目的(de)(de)是將管(guan)道受熱(re)后產生的(de)(de)熱(re)應力提前釋放,見圖9.5.1設備的(de)(de)輸(shu)入口處(chu)接(jie)(jie)(jie)低電(dian)(dian)(dian)(dian)流(liu),高電(dian)(dian)(dian)(dian)壓,在輸(shu)出口處(chu)接(jie)(jie)(jie)高電(dian)(dian)(dian)(dian)流(liu)、低電(dian)(dian)(dian)(dian)壓,一般輸(shu)出電(dian)(dian)(dian)(dian)壓不(bu)高于(yu)60V,輸(shu)出電(dian)(dian)(dian)(dian)流(liu)在3000~5000A。開機(ji)通電(dian)(dian)(dian)(dian)后,電(dian)(dian)(dian)(dian)流(liu)越大,時(shi)間越長,產生的(de)(de)熱(re)量(liang)就越多,使管(guan)道不(bu)斷(duan)伸長,當伸長量(liang)達到設計預(yu)熱(re)伸長量(liang)時(shi)即可(ke)(ke)進行(xing)補償器焊接(jie)(jie)(jie)固(gu)定和管(guan)溝回(hui)填。如果管(guan)子較長可(ke)(ke)以分段(duan)(duan)預(yu)熱(re),有的(de)(de)工程(cheng)預(yu)熱(re)段(duan)(duan)在350~900m左右。施工之前將預(yu)熱(re)管(guan)段(duan)(duan)兩端管(guan)道口用端帽(mao)密(mi)封,防止氣(qi)體流(liu)通。為了使回(hui)填過程(cheng)中管(guan)道的(de)(de)伸長量(liang)不(bu)回(hui)縮(suo),需繼續(xu)預(yu)熱(re)保(bao)持恒溫,直(zhi)到焊接(jie)(jie)(jie)完(wan)成、回(hui)填結(jie)束(shu)后方可(ke)(ke)停止預(yu)熱(re)。

預(yu)(yu)熱(re)(re)(re)安(an)裝的基本原理是(shi)在(zai)管(guan)道(dao)的最(zui)低溫(wen)(wen)度(du)(du)(du)和最(zui)高溫(wen)(wen)度(du)(du)(du)之間(jian)選取(qu)一個溫(wen)(wen)度(du)(du)(du)點tm,在(zai)該溫(wen)(wen)度(du)(du)(du)下,使管(guan)道(dao)內應力為(wei)0.一般情況下,t值選取(qu)中(zhong)間(jian)溫(wen)(wen)度(du)(du)(du),即(ji)最(zui)低溫(wen)(wen)度(du)(du)(du)和最(zui)高溫(wen)(wen)度(du)(du)(du)的平均值。在(zai)實際預(yu)(yu)熱(re)(re)(re)安(an)裝中(zhong),無論采用局部回填還是(shi)敞口預(yu)(yu)熱(re)(re)(re),管(guan)段因加熱(re)(re)(re)發生伸(shen)(shen)長(chang)時(shi),土(tu)壤與管(guan)道(dao)外壁的摩擦力是(shi)不(bu)可避免的,它將阻礙管(guan)道(dao)的自由伸(shen)(shen)長(chang)。因此實際預(yu)(yu)熱(re)(re)(re)溫(wen)(wen)度(du)(du)(du)比(bi)中(zhong)間(jian)溫(wen)(wen)度(du)(du)(du)t略高5℃.在(zai)該工(gong)程中(zhong)預(yu)(yu)熱(re)(re)(re)溫(wen)(wen)度(du)(du)(du)設定為(wei)65℃,預(yu)(yu)處理管(guan)段的伸(shen)(shen)長(chang)量為(wei):

按(an)要(yao)求(qiu)對管(guan)道(dao)進行回(hui)(hui)填,回(hui)(hui)填土為均勻的密石土,要(yao)求(qiu)分(fen)層碾(nian)壓(ya),一般要(yao)求(qiu)回(hui)(hui)填至(zhi)管(guan)道(dao)上(shang)端(duan)200~300mm。

在預熱管(guan)道管(guan)網兩(liang)端設(she)置標尺,以便預熱伸(shen)長(chang)后計算管(guan)道伸(shen)長(chang)量。其設(she)計計算伸(shen)長(chang)量應該等于管(guan)道兩(liang)端伸(shen)長(chang)量之和。

在指(zhi)定的時間(jian)內對管溝進行回(hui)填。回(hui)填時要嚴格控(kong)制管道的回(hui)縮量(liang)(liang),對回(hui)填土每200~300mm就(jiu)要分層夯實與碾壓(ya)一次(ci),回(hui)填時要按照從預熱管道的兩(liang)端向中間(jian)的順序進行回(hui)填。目的是要在管網中形(xing)成錨固段,產生預應力,從而使管路的軸向應力降低到冷安裝(zhuang)時的一半。回(hui)填土回(hui)填質量(liang)(liang)對后續施工質量(liang)(liang)起到很(hen)大制約作用。

管(guan)道電(dian)(dian)預熱(re)無補償配(pei)管(guan)施工(gong)(gong)(gong)簡單方便(bian),施工(gong)(gong)(gong)速度快,預熱(re)均勻,預熱(re)時間(jian)短,熱(re)消耗量較小(xiao),有效提(ti)高(gao)管(guan)網(wang)的(de)安全性(xing)和可靠性(xing)及(ji)使(shi)用(yong)壽(shou)命,電(dian)(dian)預熱(re)設(she)備(bei)體積小(xiao)、易(yi)操作、無噪聲,自動監(jian)控(kong)。管(guan)道的(de)軸(zhou)向應力可以降低(di)到冷安裝時的(de)一半,取消了(le)一次性(xing)補償器安裝中大(da)量使(shi)用(yong)的(de)一次性(xing)補償,施工(gong)(gong)(gong)費用(yong)相對較低(di)。

在石油化工裝(zhuang)置配管(guan)設(she)計(ji)過(guo)程中,筆者也(ye)采用了類(lei)似(si)的(de)無補償(chang)配管(guan)設(she)計(ji),具有較好的(de)效(xiao)果(guo)。