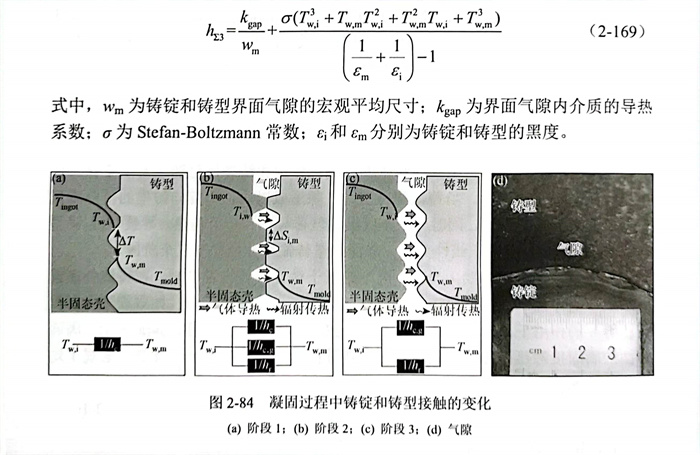

受(shou)鑄(zhu)(zhu)錠(ding)凝(ning)固收縮和(he)鑄(zhu)(zhu)型(xing)受(shou)熱(re)(re)膨脹(zhang)的影響(xiang),鑄(zhu)(zhu)錠(ding)和(he)鑄(zhu)(zhu)型(xing)接觸隨之發生(sheng)(sheng)變化(hua),即形成氣隙,如下(xia)圖(tu)所示。當鑄(zhu)(zhu)錠(ding)和(he)鑄(zhu)(zhu)型(xing)間(jian)氣隙形成以后,鑄(zhu)(zhu)錠(ding)向(xiang)鑄(zhu)(zhu)型(xing)的傳熱(re)(re)方式不只(zhi)是簡單的傳導(dao)傳熱(re)(re),同時存在小區域的氣體導(dao)熱(re)(re)和(he)輻射(she)傳熱(re)(re),導(dao)致鑄(zhu)(zhu)錠(ding)-鑄(zhu)(zhu)型(xing)界面熱(re)(re)阻(1/hz)發生(sheng)(sheng)非線(xian)性變化(hua)。界面熱(re)(re)量傳輸可分為如下(xia)三個(ge)階段。

階段1: 在(zai)凝(ning)(ning)固(gu)初期,當表面(mian)(mian)(mian)溫度略低于鑄(zhu)錠(ding)(ding)液相線溫度時,在(zai)鑄(zhu)錠(ding)(ding)外表面(mian)(mian)(mian)會形成(cheng)一定厚度的半固(gu)態殼;此時,在(zai)液體靜壓(ya)(ya)力(li)(li)(li)和(he)外界(jie)壓(ya)(ya)力(li)(li)(li)(如(ru)凝(ning)(ning)固(gu)壓(ya)(ya)力(li)(li)(li)和(he)大(da)氣壓(ya)(ya)等(deng))的作(zuo)用下(xia),鑄(zhu)錠(ding)(ding)和(he)鑄(zhu)型界(jie)面(mian)(mian)(mian)處于完全接觸(chu)狀態,如(ru)圖2-84(a)所示,因而界(jie)面(mian)(mian)(mian)的固(gu)固(gu)接觸(chu)熱(re)量傳(chuan)輸方式在(zai)界(jie)面(mian)(mian)(mian)傳(chuan)熱(re)過程(cheng)中起主導(dao)作(zuo)用, 此界(jie)面(mian)(mian)(mian)宏觀平均換熱(re)系數hz1可表示為(wei)

h21=a+b·(P1+P3) (2-167)

式中,a和b為(wei)常量;Ph為(wei)液(ye)體靜壓(ya)力;Ps為(wei)外界壓(ya)力。

階(jie)段2: 在(zai)給(gei)定(ding)外界(jie)(jie)壓力(li)和(he)(he)液(ye)體靜壓力(li)條(tiao)件下,半(ban)(ban)固(gu)(gu)(gu)態(tai)殼(ke)的(de)(de)強(qiang)度存在(zai)一個臨(lin)界(jie)(jie)值(zhi)σm;隨(sui)著(zhu)凝固(gu)(gu)(gu)過(guo)程的(de)(de)進(jin)行,半(ban)(ban)固(gu)(gu)(gu)態(tai)殼(ke)的(de)(de)強(qiang)度不斷增大;當強(qiang)度大于(yu)臨(lin)界(jie)(jie)值(zhi)時,半(ban)(ban)固(gu)(gu)(gu)態(tai)殼(ke)定(ding)型;隨(sui)后鑄(zhu)(zhu)錠(ding)半(ban)(ban)固(gu)(gu)(gu)態(tai)殼(ke)逐(zhu)漸與鑄(zhu)(zhu)型分離,固(gu)(gu)(gu)固(gu)(gu)(gu)接觸(chu)積逐(zhu)漸減(jian)小,氣隙在(zai)界(jie)(jie)面(mian)某些位置形成且其(qi)尺寸逐(zhu)漸增大,導致鑄(zhu)(zhu)錠(ding)和(he)(he)鑄(zhu)(zhu)型界(jie)(jie)面(mian)處于(yu)半(ban)(ban)完全接觸(chu)狀態(tai),如圖2-84(b)所示(shi)。在(zai)此(ci)階(jie)段,氣隙的(de)(de)尺寸主(zhu)要受由液(ye)相(xiang)變固(gu)(gu)(gu)相(xiang)發生(sheng)的(de)(de)凝固(gu)(gu)(gu)收縮影響。盡管(guan)界(jie)(jie)面(mian)還(huan)存在(zai)部分固(gu)(gu)(gu)固(gu)(gu)(gu)接觸(chu),但界(jie)(jie)面(mian)熱(re)(re)阻隨(sui)著(zhu)凝固(gu)(gu)(gu)的(de)(de)進(jin)行不斷增大,由于(yu)鑄(zhu)(zhu)錠(ding)和(he)(he)鑄(zhu)(zhu)型界(jie)(jie)面(mian)接觸(chu)方式的(de)(de)變化,界(jie)(jie)面(mian)熱(re)(re)量傳輸主(zhu)要由固(gu)(gu)(gu)固(gu)(gu)(gu)接觸(chu)傳熱(re)(re)、輻射換(huan)(huan)熱(re)(re)以(yi)及氣相(xiang)導熱(re)(re)傳熱(re)(re)三分構成,其(qi)中,固(gu)(gu)(gu)固(gu)(gu)(gu)接觸(chu)傳熱(re)(re)仍(reng)然占(zhan)據界(jie)(jie)面(mian)熱(re)(re)量傳輸的(de)(de)主(zhu)導地位。此(ci)階(jie)段界(jie)(jie)面(mian)宏觀平均換(huan)(huan)熱(re)(re)系數hz2可(ke)表示(shi)為

此外,隨著凝(ning)(ning)固(gu)(gu)的進行,鑄(zhu)(zhu)錠(ding)和鑄(zhu)(zhu)型界(jie)(jie)(jie)面上固(gu)(gu)固(gu)(gu)接觸(chu)面積逐漸(jian)(jian)減(jian)小,因而階段(duan)1界(jie)(jie)(jie)面宏(hong)觀(guan)平均換(huan)熱(re)(re)系(xi)數(shu)(shu)hz1最大,階段(duan)2界(jie)(jie)(jie)面宏(hong)觀(guan)平均換(huan)熱(re)(re)系(xi)數(shu)(shu)hz2值次之,階段(duan)3界(jie)(jie)(jie)面宏(hong)觀(guan)平均換(huan)熱(re)(re)系(xi)數(shu)(shu)hz3值最小,這(zhe)與(yu)實際凝(ning)(ning)固(gu)(gu)過(guo)程中界(jie)(jie)(jie)面換(huan)熱(re)(re)系(xi)數(shu)(shu)逐漸(jian)(jian)減(jian)小的規(gui)律相(xiang)互印證。同(tong)時,在(zai)鑄(zhu)(zhu)錠(ding)自身重力的作用(yong)下(xia),在(zai)鑄(zhu)(zhu)錠(ding)底部位置,界(jie)(jie)(jie)面半完全接觸(chu)狀態始終貫穿整個凝(ning)(ning)固(gu)(gu)過(guo)程,這(zhe)與(yu)鑄(zhu)(zhu)錠(ding)頂端界(jie)(jie)(jie)面固(gu)(gu)固(gu)(gu)接觸(chu)完全消失有所(suo)不(bu)同(tong),如圖2-84(d)所(suo)示(shi)。

凝固壓(ya)力在氣隙的形成(cheng)過程中扮演(yan)了十分重要(yao)的角色。研究表明(ming),增加(jia)凝固壓(ya)力(兆帕級)具有明(ming)顯的強化冷卻(que)效(xiao)果(guo),但在界面熱(re)量傳輸變(bian)化的三(san)個(ge)階段,加(jia)壓(ya)強化冷卻(que)的程度大有不同。

階段1:當(dang)壓力(li)(li)在幾兆帕下變(bian)化時,由于物性(xing)參數(shu)(如強度、密度和導熱系數(shu)等(deng))的變(bian)化量可(ke)以忽略不(bu)計,壓力(li)(li)對(dui)鑄錠和鑄型界面完(wan)全接(jie)觸狀態影(ying)響(xiang)較小,根據式(2-166)可(ke)知,壓力(li)(li)對(dui)界面宏(hong)觀平均(jun)換(huan)熱系數(shu)的影(ying)響(xiang)可(ke)以忽略不(bu)計,因此增加(jia)壓力(li)(li)對(dui)階段1的界面換(huan)熱影(ying)響(xiang)很小。

階(jie)段(duan)2:在此(ci)階(jie)段(duan),鑄(zhu)錠和鑄(zhu)型(xing)界面(mian)非(fei)完全接觸狀態主要(yao)由凝固收(shou)縮控制。

隨(sui)著(zhu)壓(ya)力(li)的(de)增(zeng)加(jia),半固(gu)態殼抵抗變(bian)形所需臨界(jie)(jie)強(qiang)(qiang)度增(zeng)大(da),因(yin)而(er)加(jia)壓(ya)能(neng)(neng)夠抑制(zhi)(zhi)界(jie)(jie)面(mian)(mian)(mian)(mian)非完全接(jie)觸狀態的(de)形成(cheng),有助于將(jiang)界(jie)(jie)面(mian)(mian)(mian)(mian)在整(zheng)個凝(ning)固(gu)過程中實現保持固(gu)固(gu)接(jie)觸的(de)狀態。例如,隨(sui)著(zhu)壓(ya)力(li)的(de)增(zeng)加(jia),H13表(biao)面(mian)(mian)(mian)(mian)上的(de)坑變(bian)得淺平(ping),且數(shu)量逐(zhu)漸減少(shao),意(yi)味著(zhu)鑄(zhu)錠(ding)表(biao)面(mian)(mian)(mian)(mian)越來(lai)越光滑,粗糙度減小,鑄(zhu)錠(ding)鑄(zhu)型界(jie)(jie)面(mian)(mian)(mian)(mian)處(chu)的(de)固(gu)固(gu)接(jie)觸面(mian)(mian)(mian)(mian)積增(zeng)大(da)。根據式(2-168)可知,界(jie)(jie)面(mian)(mian)(mian)(mian)宏(hong)觀(guan)(guan)平(ping)均傳熱系數(shu)與(yu)壓(ya)力(li)趨于正(zheng)比關系,加(jia)壓(ya)能(neng)(neng)夠顯著(zhu)提升此階段界(jie)(jie)面(mian)(mian)(mian)(mian)宏(hong)觀(guan)(guan)平(ping)均換熱系數(shu)。因(yin)此,增(zeng)加(jia)壓(ya)力(li)能(neng)(neng)夠強(qiang)(qiang)化(hua)鑄(zhu)錠(ding)鑄(zhu)型間界(jie)(jie)面(mian)(mian)(mian)(mian)固(gu)固(gu)接(jie)觸狀態,抑制(zhi)(zhi)由(you)凝(ning)固(gu)收縮導致界(jie)(jie)面(mian)(mian)(mian)(mian)氣隙的(de)形成(cheng),加(jia)快鑄(zhu)錠(ding)鑄(zhu)型界(jie)(jie)面(mian)(mian)(mian)(mian)傳遞,強(qiang)(qiang)化(hua)冷卻效果明顯。

階段3:界(jie)(jie)(jie)(jie)面(mian)(mian)氣(qi)(qi)隙(xi)的(de)長大(da)主要受控于固態收縮。隨著界(jie)(jie)(jie)(jie)面(mian)(mian)氣(qi)(qi)隙(xi)尺寸的(de)變大(da),外(wai)界(jie)(jie)(jie)(jie)逐步與(yu)界(jie)(jie)(jie)(jie)面(mian)(mian)氣(qi)(qi)隙(xi)連通,在壓(ya)力的(de)作(zuo)用下(xia),氣(qi)(qi)體逐漸進(jin)入(ru)界(jie)(jie)(jie)(jie)面(mian)(mian)氣(qi)(qi)隙(xi)內(nei),進(jin)而導(dao)致界(jie)(jie)(jie)(jie)面(mian)(mian)氣(qi)(qi)隙(xi)與(yu)外(wai)界(jie)(jie)(jie)(jie)之間的(de)壓(ya)差(cha)趨于零,壓(ya)力對(dui)界(jie)(jie)(jie)(jie)面(mian)(mian)氣(qi)(qi)隙(xi)的(de)影響逐漸消失。此階段,氣(qi)(qi)體導(dao)熱換(huan)熱與(yu)輻射換(huan)熱為界(jie)(jie)(jie)(jie)面(mian)(mian)換(huan)熱的(de)主要方式。其(qi)中氣(qi)(qi)體導(dao)熱換(huan)熱系數(hc,g)主要由氣(qi)(qi)隙(xi)內(nei)氣(qi)(qi)體導(dao)熱系數(kgap)和界(jie)(jie)(jie)(jie)面(mian)(mian)氣(qi)(qi)隙(xi)尺寸(wgap)決定,作(zuo)為計算氣(qi)(qi)體導(dao)熱換(huan)熱系數的(de)重要參數,在給定壓(ya)力下(xia)氣(qi)(qi)體導(dao)熱系數(kgap)可由下(xia)列(lie)公式進(jin)行(xing)計算:

綜(zong)上所(suo)述,在(zai)通過(guo)(guo)氣體(ti)維持壓力(li)的(de)加(jia)(jia)壓條(tiao)件(jian)下(xia),壓力(li)對界面換熱系數(shu)的(de)影(ying)響主要集中在(zai)界面氣隙形成(cheng)的(de)第(di)二階段(duan),即在(zai)鑄錠殼凝(ning)固收縮階段(duan)加(jia)(jia)壓通過(guo)(guo)增大(da)鑄錠殼抵抗變形所(suo)需臨(lin)界強度從而改(gai)善界面換熱,起到強化(hua)冷(leng)卻的(de)作用。

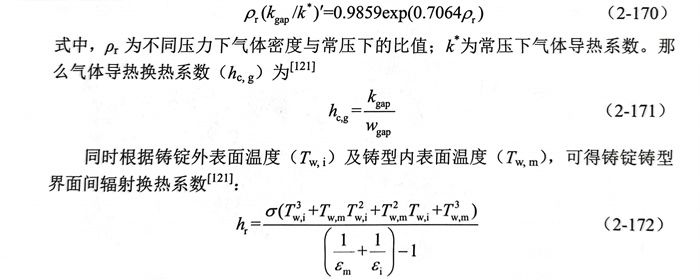

以H13在0.1MPa、1MPa和(he)2MPa壓力下凝(ning)固(gu)為(wei)(wei)例,其(qi)凝(ning)固(gu)壓力通過(guo)充(chong)入(ru)(ru)氬氣獲得(de)。為(wei)(wei)了分(fen)(fen)析(xi)加壓對界(jie)面(mian)氣隙尺寸和(he)換熱(re)方式的(de)影(ying)響(xiang)規律,采用埋設熱(re)電(dian)偶以及(ji)位(wei)(wei)(wei)移傳感(gan)器實驗(yan),同時測(ce)量凝(ning)固(gu)過(guo)程(cheng)中(zhong)鑄(zhu)錠和(he)鑄(zhu)型溫度(du)變化(hua)曲線以及(ji)其(qi)位(wei)(wei)(wei)移變化(hua)曲線,其(qi)中(zhong),1#和(he)2#熱(re)電(dian)偶分(fen)(fen)別(bie)測(ce)量離鑄(zhu)錠外(wai)表面(mian)10mm和(he)15mm位(wei)(wei)(wei)置(zhi)處(chu)鑄(zhu)錠溫度(du)變化(hua)曲線;3#和(he)4#熱(re)電(dian)偶分(fen)(fen)別(bie)測(ce)量鑄(zhu)型內表面(mian)5mm和(he)10mm位(wei)(wei)(wei)置(zhi)處(chu)鑄(zhu)型的(de)溫度(du)變化(hua)曲線;位(wei)(wei)(wei)移傳感(gan)器LVDT1和(he)LVDT2的(de)探頭位(wei)(wei)(wei)置(zhi)離鑄(zhu)型內表面(mian)徑向距離均為(wei)(wei)5mm,分(fen)(fen)別(bie)插入(ru)(ru)鑄(zhu)錠和(he)鑄(zhu)型中(zhong)測(ce)量凝(ning)固(gu)過(guo)程(cheng)中(zhong)其(qi)位(wei)(wei)(wei)移變化(hua)曲線。測(ce)量溫度(du)和(he)位(wei)(wei)(wei)移變化(hua)曲線的(de)裝(zhuang)置(zhi)如圖(tu)2-85所示。

溫度(du)測(ce)(ce)量曲(qu)線(xian)如圖2-86所示,對于鑄錠(ding)溫度(du)測(ce)(ce)量曲(qu)線(xian),存(cun)在(zai)“陡升(sheng)”和“振蕩”區域(yu),這主要由熱電偶預熱和澆(jiao)注引起(qi)鋼液湍流(liu)分(fen)別造(zao)成。隨著(zhu)凝固過程(cheng)的(de)進行,鑄型溫度(du)升(sheng)高,鑄錠(ding)溫度(du)不斷降低。

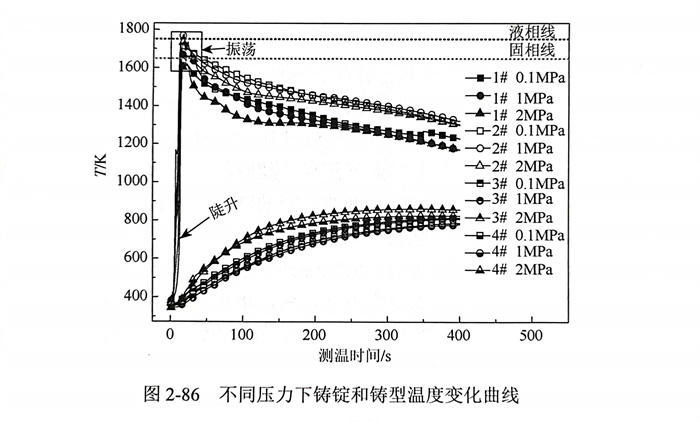

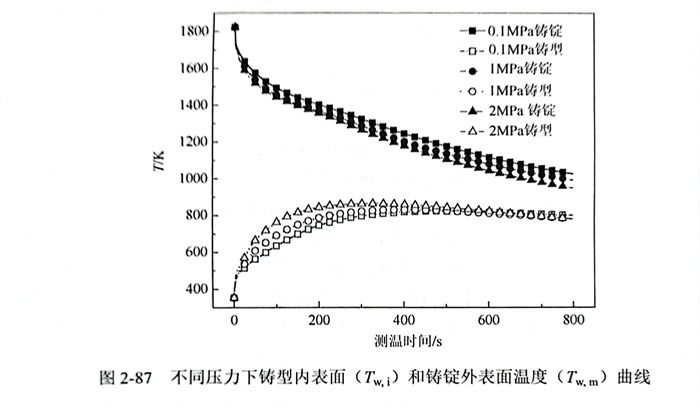

因(yin)鑄(zhu)型(xing)(xing)(xing)內表(biao)面(mian)(mian)(mian)(mian)(mian)和(he)(he)鑄(zhu)錠外(wai)(wai)表(biao)面(mian)(mian)(mian)(mian)(mian)溫(wen)度(du)(du)幾(ji)乎難以通過(guo)實驗進(jin)行準確測(ce)量(liang)(liang),因(yin)而可通過(guo)數(shu)值計算的(de)方式獲得,即(ji)以測(ce)量(liang)(liang)的(de)鑄(zhu)錠和(he)(he)鑄(zhu)型(xing)(xing)(xing)溫(wen)度(du)(du)變(bian)化曲線作(zuo)為輸入(ru)量(liang)(liang),采用Beck 非線性(xing)求解法,計算鑄(zhu)型(xing)(xing)(xing)內表(biao)面(mian)(mian)(mian)(mian)(mian)(Tw,i)和(he)(he)鑄(zhu)錠外(wai)(wai)表(biao)面(mian)(mian)(mian)(mian)(mian)溫(wen)度(du)(du)(Twm),由于鑄(zhu)錠和(he)(he)鑄(zhu)型(xing)(xing)(xing)表(biao)面(mian)(mian)(mian)(mian)(mian)非鏡面(mian)(mian)(mian)(mian)(mian),有一(yi)定粗糙(cao)度(du)(du),因(yin)而計算所(suo)得鑄(zhu)型(xing)(xing)(xing)內表(biao)面(mian)(mian)(mian)(mian)(mian)(Tw,i)和(he)(he)鑄(zhu)錠外(wai)(wai)表(biao)面(mian)(mian)(mian)(mian)(mian)溫(wen)度(du)(du)(Tw,m)均(jun)為宏觀平(ping)均(jun)表(biao)面(mian)(mian)(mian)(mian)(mian)溫(wen)度(du)(du),計算結果如圖(tu)2-87所(suo)示。當(dang)壓力(li)一(yi)定時,在(zai)鑄(zhu)錠鑄(zhu)型(xing)(xing)(xing)界面(mian)(mian)(mian)(mian)(mian)換熱(re)以及(ji)鑄(zhu)型(xing)(xing)(xing)外(wai)(wai)表(biao)面(mian)(mian)(mian)(mian)(mian)散(san)熱(re)的(de)影響下(xia),鑄(zhu)錠外(wai)(wai)表(biao)面(mian)(mian)(mian)(mian)(mian)溫(wen)度(du)(du)(Tw,i)在(zai)整(zheng)個凝(ning)固過(guo)程中持(chi)續降(jiang)低(di)(di),鑄(zhu)型(xing)(xing)(xing)內表(biao)面(mian)(mian)(mian)(mian)(mian)(Tw,m)先增加而后逐(zhu)漸降(jiang)低(di)(di)。隨著壓力(li)從0.1MPa增加至2MPa,鑄(zhu)錠外(wai)(wai)表(biao)面(mian)(mian)(mian)(mian)(mian)降(jiang)溫(wen)速(su)率(lv)和(he)(he)鑄(zhu)型(xing)(xing)(xing)內表(biao)面(mian)(mian)(mian)(mian)(mian)升溫(wen)速(su)率(lv)明顯加快(kuai),表(biao)明加壓對鑄(zhu)錠和(he)(he)鑄(zhu)型(xing)(xing)(xing)界面(mian)(mian)(mian)(mian)(mian)間換熱(re)速(su)率(lv)影響顯著。

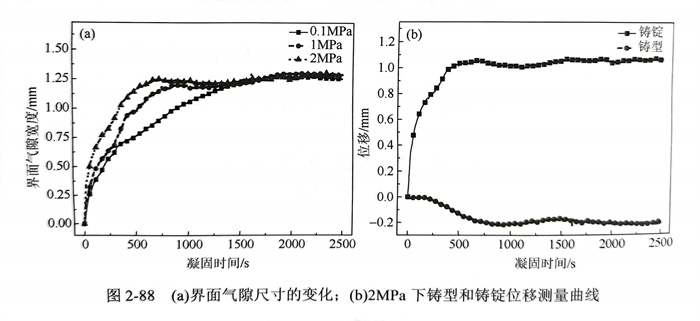

當壓力(li)一定時(shi)(shi),界(jie)面氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)寬度(du)隨(sui)時(shi)(shi)間的(de)(de)(de)(de)變(bian)(bian)化關系可通過(guo)凝(ning)固(gu)過(guo)程中鑄(zhu)(zhu)錠和鑄(zhu)(zhu)型(xing)位(wei)(wei)(wei)移(yi)變(bian)(bian)化曲(qu)線獲得。基于位(wei)(wei)(wei)移(yi)傳(chuan)(chuan)(chuan)感(gan)器(qi)(qi)的(de)(de)(de)(de)位(wei)(wei)(wei)移(yi)測(ce)量(liang)(liang)結果,所得界(jie)面氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)寬度(du)隨(sui)時(shi)(shi)間的(de)(de)(de)(de)變(bian)(bian)化關系如(ru)圖2-88(a)所示,在(zai)0.1MPa、1MPa和2MPa下(xia),界(jie)面氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)寬度(du)隨(sui)時(shi)(shi)間變(bian)(bian)化規律基本相似。以(yi)(yi)2MPa為例,在(zai)凝(ning)固(gu)初(chu)(chu)期,鑄(zhu)(zhu)錠、鑄(zhu)(zhu)型(xing)和位(wei)(wei)(wei)移(yi)傳(chuan)(chuan)(chuan)感(gan)器(qi)(qi)之(zhi)間存(cun)在(zai)巨(ju)大(da)溫差(cha),使得位(wei)(wei)(wei)移(yi)傳(chuan)(chuan)(chuan)感(gan)器(qi)(qi)附(fu)近的(de)(de)(de)(de)鋼液迅速(su)凝(ning)固(gu),以(yi)(yi)至(zhi)于無法測(ce)量(liang)(liang)階段2 中凝(ning)固(gu)收(shou)縮(suo)導(dao)致(zhi)(zhi)的(de)(de)(de)(de)氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)寬度(du);同時(shi)(shi),鑄(zhu)(zhu)錠和鑄(zhu)(zhu)型(xing)初(chu)(chu)期溫差(cha)巨(ju)大(da),加(jia)速(su)了鑄(zhu)(zhu)型(xing)升(sheng)溫膨脹和鑄(zhu)(zhu)錠冷卻收(shou)縮(suo),因(yin)(yin)而(er)在(zai)界(jie)面氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)尺(chi)(chi)(chi)寸隨(sui)時(shi)(shi)間變(bian)(bian)化曲(qu)線前(qian)段不(bu)存(cun)氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)尺(chi)(chi)(chi)寸緩慢增長(chang)部(bu)分,取而(er)代之(zhi)的(de)(de)(de)(de)是氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)寬度(du)隨(sui)時(shi)(shi)間的(de)(de)(de)(de)陡升(sheng),而(er)且氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)寬度(du)的(de)(de)(de)(de)陡升(sheng)很大(da)程度(du)由鑄(zhu)(zhu)錠固(gu)態(tai)收(shou)縮(suo)所致(zhi)(zhi)。因(yin)(yin)此,位(wei)(wei)(wei)移(yi)傳(chuan)(chuan)(chuan)感(gan)器(qi)(qi)所測(ce)氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)尺(chi)(chi)(chi)寸僅包(bao)含了固(gu)態(tai)收(shou)縮(suo)導(dao)致(zhi)(zhi)氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)形(xing)成(cheng)部(bu)分,無因(yin)(yin)凝(ning)固(gu)收(shou)縮(suo)形(xing)成(cheng)氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)部(bu)分。在(zai)低壓下(xia),增加(jia)壓力(li)對鑄(zhu)(zhu)型(xing)和鑄(zhu)(zhu)錠的(de)(de)(de)(de)密度(du)影(ying)響(xiang)很小,幾(ji)乎(hu)(hu)可以(yi)(yi)忽略不(bu)計(ji),所以(yi)(yi)增加(jia)壓力(li)對鑄(zhu)(zhu)型(xing)固(gu)態(tai)收(shou)縮(suo)導(dao)致(zhi)(zhi)氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)的(de)(de)(de)(de)尺(chi)(chi)(chi)寸影(ying)響(xiang)非(fei)常(chang)小,所以(yi)(yi)在(zai)0.1MPa、1MPa和2MPa下(xia),界(jie)面氣(qi)(qi)(qi)(qi)隙(xi)(xi)(xi)(xi)(xi)(xi)尺(chi)(chi)(chi)寸傳(chuan)(chuan)(chuan)感(gan)器(qi)(qi)量(liang)(liang)的(de)(de)(de)(de)最大(da)值幾(ji)乎(hu)(hu)相同,約為1.27mm。

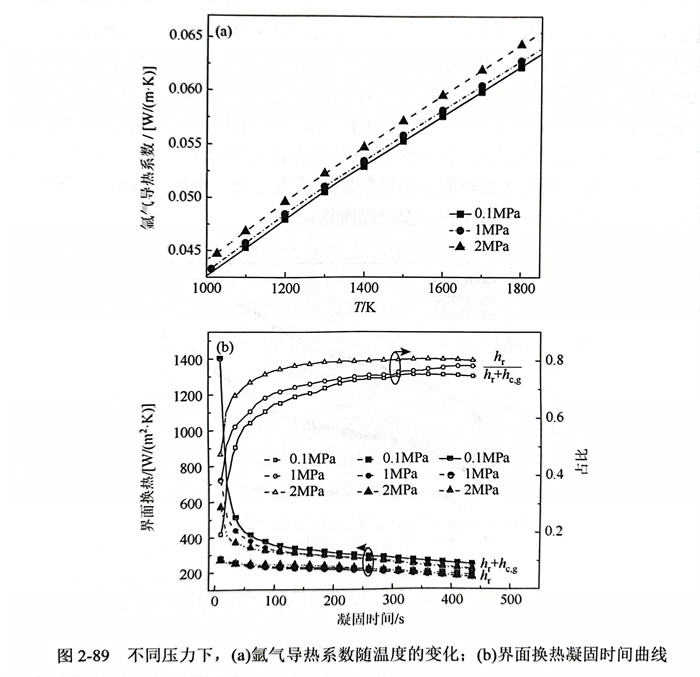

根據氬氣(qi)(qi)(qi)導熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)隨(sui)(sui)壓(ya)(ya)力(li)的變(bian)(bian)化(hua)情況[圖(tu)2-89(a)]、凝(ning)固過(guo)程(cheng)中(zhong)界(jie)面(mian)(mian)氣(qi)(qi)(qi)隙(xi)測量曲(qu)(qu)線和(he)(he)鑄錠外表(biao)(biao)面(mian)(mian)以(yi)及(ji)鑄型內表(biao)(biao)溫(wen)度(du)的變(bian)(bian)化(hua)曲(qu)(qu)線,利用式(shi)(2-171)和(he)(he)式(shi)(2-172)可獲得氣(qi)(qi)(qi)隙(xi)形成(cheng)階段(duan)3中(zhong)界(jie)面(mian)(mian)氣(qi)(qi)(qi)體(ti)導熱(re)換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)hc,g和(he)(he)輻射(she)(she)換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)hr,以(yi)及(ji)換熱(re)方式(shi)比(bi)(bi)例關系(xi)(xi)(xi)(xi),結果如圖(tu)2-89(b)所示(shi)。輻射(she)(she)換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)不(bu)受(shou)界(jie)面(mian)(mian)氣(qi)(qi)(qi)隙(xi)尺(chi)寸(cun)的影響,在整個凝(ning)固過(guo)程(cheng)中(zhong),基本保持不(bu)變(bian)(bian);相比(bi)(bi)之下,氣(qi)(qi)(qi)體(ti)導熱(re)換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)主(zhu)要(yao)由氣(qi)(qi)(qi)體(ti)導熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)和(he)(he)面(mian)(mian)氣(qi)(qi)(qi)隙(xi)尺(chi)寸(cun)共(gong)同決定,與(yu)(yu)氣(qi)(qi)(qi)體(ti)導熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)成(cheng)正比(bi)(bi),與(yu)(yu)界(jie)面(mian)(mian)氣(qi)(qi)(qi)隙(xi)尺(chi)寸(cun)成(cheng)反比(bi)(bi),因而在凝(ning)固過(guo)程(cheng)中(zhong)氣(qi)(qi)(qi)體(ti)導熱(re)換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)變(bian)(bian)化(hua)規(gui)律與(yu)(yu)界(jie)面(mian)(mian)氣(qi)(qi)(qi)隙(xi)尺(chi)寸(cun)的變(bian)(bian)化(hua)過(guo)程(cheng)截然(ran)(ran)(ran)相反,呈現先迅速減(jian)小,然(ran)(ran)(ran)后(hou)趨于(yu)定值。在各個壓(ya)(ya)力(li)條件下,隨(sui)(sui)著凝(ning)固的進行(xing),界(jie)面(mian)(mian)總換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(hc,g+h,)迅速減(jian)小,然(ran)(ran)(ran)后(hou)趨于(yu)穩定,其中(zhong)輻射(she)(she)換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)h1在總換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)中(zhong)的占比(bi)(bi)為60%~80%[120],且(qie)在凝(ning)固中(zhong)后(hou)期(qi),0.1MPa、1MPa和(he)(he)2MPa壓(ya)(ya)力(li)下,總界(jie)面(mian)(mian)換熱(re)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)基本相等。由此可知,低(di)壓(ya)(ya)下,加(jia)壓(ya)(ya)對由固態收(shou)縮(suo)形成(cheng)界(jie)面(mian)(mian)氣(qi)(qi)(qi)隙(xi)的尺(chi)寸(cun)影響幾乎可以(yi)忽略不(bu)計。

根據以(yi)上討論可知(zhi)(zhi),凝固(gu)(gu)(gu)結束(shu)后,界(jie)(jie)(jie)面(mian)(mian)(mian)換(huan)(huan)(huan)熱(re)(re)(re)主要(yao)(yao)通(tong)(tong)過氣(qi)(qi)(qi)體(ti)導(dao)(dao)(dao)(dao)熱(re)(re)(re)換(huan)(huan)(huan)熱(re)(re)(re)和(he)輻射(she)換(huan)(huan)(huan)熱(re)(re)(re)兩種(zhong)方式進行(xing),因加壓(ya)(ya)對(dui)輻射(she)換(huan)(huan)(huan)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu)的(de)(de)影響(xiang)(xiang)很小,那(nei)(nei)么加壓(ya)(ya)主要(yao)(yao)通(tong)(tong)過改變界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)體(ti)導(dao)(dao)(dao)(dao)熱(re)(re)(re)換(huan)(huan)(huan)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu),從(cong)而(er)(er)起(qi)到強化(hua)冷卻(que)的(de)(de)效果(guo)。同時,界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)體(ti)導(dao)(dao)(dao)(dao)熱(re)(re)(re)換(huan)(huan)(huan)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu)主要(yao)(yao)由(you)氣(qi)(qi)(qi)體(ti)導(dao)(dao)(dao)(dao)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu)和(he)界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)體(ti)尺(chi)寸(cun)(cun)決定,因壓(ya)(ya)力(li)(li)從(cong)0.1MPa增加至2MPa,氬氣(qi)(qi)(qi)導(dao)(dao)(dao)(dao)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu)變化(hua)很小,進一步可知(zhi)(zhi)壓(ya)(ya)力(li)(li)主要(yao)(yao)通(tong)(tong)過改變界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)隙(xi)宏觀平(ping)均(jun)尺(chi)寸(cun)(cun)影響(xiang)(xiang)界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)體(ti)導(dao)(dao)(dao)(dao)熱(re)(re)(re)換(huan)(huan)(huan)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu),進而(er)(er)改變界(jie)(jie)(jie)面(mian)(mian)(mian)總換(huan)(huan)(huan)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu)。此外,壓(ya)(ya)力(li)(li)對(dui)固(gu)(gu)(gu)態收縮導(dao)(dao)(dao)(dao)致的(de)(de)界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)隙(xi)尺(chi)寸(cun)(cun)影響(xiang)(xiang)幾乎可以(yi)忽略(lve)不計(ji),那(nei)(nei)么壓(ya)(ya)力(li)(li)主要(yao)(yao)通(tong)(tong)過改變由(you)凝固(gu)(gu)(gu)收縮導(dao)(dao)(dao)(dao)致界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)隙(xi)的(de)(de)尺(chi)寸(cun)(cun),從(cong)而(er)(er)影響(xiang)(xiang)界(jie)(jie)(jie)面(mian)(mian)(mian)換(huan)(huan)(huan)熱(re)(re)(re)。為了評(ping)估壓(ya)(ya)力(li)(li)對(dui)凝固(gu)(gu)(gu)收縮導(dao)(dao)(dao)(dao)致界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)隙(xi)形(xing)成的(de)(de)影響(xiang)(xiang),利(li)用界(jie)(jie)(jie)面(mian)(mian)(mian)換(huan)(huan)(huan)熱(re)(re)(re)系(xi)(xi)(xi)(xi)(xi)數(shu)對(dui)界(jie)(jie)(jie)面(mian)(mian)(mian)氣(qi)(qi)(qi)隙(xi)宏觀平(ping)均(jun)尺(chi)寸(cun)(cun)(wm)進行(xing)計(ji)算(suan),計(ji)算(suan)公式如下:

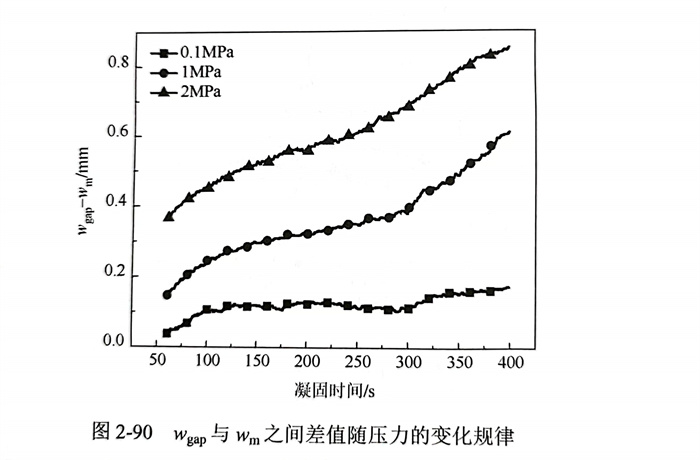

式中,hz3為宏觀(guan)界面換熱(re)(re)系(xi)數,通過將(jiang)測溫數據作為輸入(ru)量,利用Beck 非(fei)線性求解法(fa)獲得,計算流程(cheng)如圖2-78所示。在(zai)整個凝(ning)(ning)固(gu)過程(cheng)中,界面氣(qi)(qi)隙宏觀(guan)平均尺(chi)寸(cun)(wm)明顯小于(yu)因固(gu)態(tai)收縮(suo)導(dao)致(zhi)的(de)界面氣(qi)(qi)隙尺(chi)寸(cun)(wgap),同時,兩者差值(zhi)(wgap-wm)隨著(zhu)壓力(li)的(de)增(zeng)加(jia)(jia)而增(zeng)大(da)(圖2-90).這(zhe)表明在(zai)鑄錠(ding)和鑄型(xing)間存在(zai)一定的(de)固(gu)-固(gu)接觸區或微間隙區。這(zhe)些區域的(de)面積(ji)隨著(zhu)壓力(li)的(de)增(zeng)大(da)而增(zeng)大(da),從而導(dao)致(zhi)傳(chuan)導(dao)換熱(re)(re)的(de)增(zeng)加(jia)(jia),這(zhe)與鑄錠(ding)表面粗糙(cao)度的(de)實驗結果符合(he),也進(jin)一步說明了加(jia)(jia)壓對界面氣(qi)(qi)隙尺(chi)寸(cun)的(de)影(ying)響主要集(ji)中在(zai)凝(ning)(ning)固(gu)收縮(suo)階段。

因此(ci),加壓主(zhu)要(yao)通過抑制(zhi)由凝(ning)固收縮導致的(de)氣(qi)隙形成,增大固固接觸(chu)或微(wei)氣(qi)隙的(de)界(jie)(jie)面(mian)(mian)面(mian)(mian)積,強化鑄錠和鑄型界(jie)(jie)面(mian)(mian)完全接觸(chu)狀態,從而增加界(jie)(jie)面(mian)(mian)氣(qi)體導熱換熱系數(shu);此(ci)外,加壓下,界(jie)(jie)面(mian)(mian)換熱系數(shu)的(de)增加,加快了鑄錠固態收縮,導致凝(ning)固初期由固態收縮引(yin)起的(de)氣(qi)隙的(de)尺寸快速增大。