工業管道(dao)伴熱方式主要有以下幾種:

1. 內(nei)伴熱(re)管(guan)伴熱(re)

伴熱(re)管安裝(zhuang)在工(gong)藝管道內部,伴熱(re)介(jie)(jie)質釋(shi)放出來的熱(re)量,全部用于補充主管內介(jie)(jie)質的熱(re)損失。這種方式的特點如(ru)下。

①. 熱效率高,用(yong)蒸汽作為(wei)熱源時,與外伴熱管比較,可以(yi)節省15%~25%的蒸汽耗(hao)量。

②. 內伴熱(re)管的外(wai)側傳熱(re)系數與(yu)主管內介質的流(liu)速、黏度有(you)關。

③. 由于它安裝在(zai)工(gong)藝管(guan)(guan)(guan)道(dao)內(nei)(nei)部,所以伴熱管(guan)(guan)(guan)的(de)管(guan)(guan)(guan)壁加厚。無(wu)縫鋼管(guan)(guan)(guan)的(de)自(zi)然長度(du)一(yi)般為(wei)8~13m,伴熱管(guan)(guan)(guan)的(de)焊縫又不允許留在(zai)工(gong)藝管(guan)(guan)(guan)道(dao)內(nei)(nei)部,因此彎(wan)管(guan)(guan)(guan)的(de)數量大(da)大(da)增多,施工(gong)工(gong)程量隨之加大(da)。

④. 伴熱(re)管(guan)的熱(re)變形問題(ti)應予考慮,否則將引(yin)起伴熱(re)管(guan)脹裂事故,既影響產品質量,又(you)要(yao)停產檢修。

⑤. 這(zhe)種結構(gou)形(xing)式不能用于輸送有腐蝕性及(ji)熱敏性介質的管道(dao)。

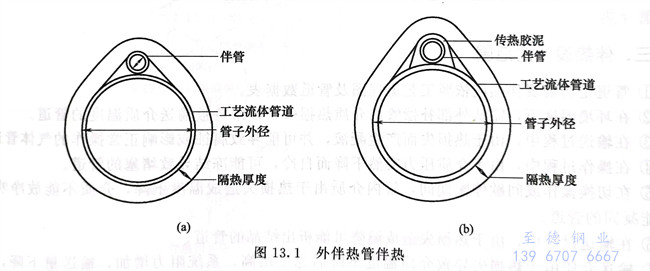

2. 外伴熱管伴熱(圖13.1)

伴熱(re)(re)介質一(yi)般有(you)蒸汽和(he)熱(re)(re)水(shui)兩種(zhong)。伴熱(re)(re)管(guan)放(fang)出的(de)(de)(de)(de)(de)熱(re)(re)量,一(yi)部(bu)分補充主(zhu)(zhu)管(guan)(或稱被伴管(guan))內介質的(de)(de)(de)(de)(de)熱(re)(re)損失,另一(yi)部(bu)分通過保(bao)溫(wen)層散(san)失到四周(zhou)大(da)(da)氣中。在(zai)硬質圓形保(bao)溫(wen)預制(zhi)管(guan)殼中,主(zhu)(zhu)管(guan)與(yu)伴熱(re)(re)管(guan)之間(jian)有(you)一(yi)最大(da)(da)的(de)(de)(de)(de)(de)保(bao)溫(wen)空間(jian),也(ye)就是伴熱(re)(re)管(guan)放(fang)出的(de)(de)(de)(de)(de)熱(re)(re)量,幾(ji)乎全部(bu)代替主(zhu)(zhu)管(guan)的(de)(de)(de)(de)(de)熱(re)(re)損失,因(yin)而這種(zhong)形式的(de)(de)(de)(de)(de)伴熱(re)(re)保(bao)溫(wen)結構,熱(re)(re)源的(de)(de)(de)(de)(de)耗量是最省的(de)(de)(de)(de)(de)。有(you)的(de)(de)(de)(de)(de)伴熱(re)(re)管(guan)采用傳熱(re)(re)系數大(da)(da)的(de)(de)(de)(de)(de)伴熱(re)(re)膠泥,填充在(zai)常規(gui)的(de)(de)(de)(de)(de)外伴熱(re)(re)管(guan)與(yu)主(zhu)(zhu)管(guan)之間(jian),使它們形成一(yi)個連續式的(de)(de)(de)(de)(de)熱(re)(re)結合(he)體(ti),可以提高伴熱(re)(re)的(de)(de)(de)(de)(de)效(xiao)率。

外伴熱管伴熱的特點如下(xia):

①. 適(shi)應范圍廣,一般操(cao)作(zuo)溫(wen)度在150℃以(yi)下的(de)(de)工藝管道(dao)(dao)都可以(yi)采用(yong)(yong)。輸送有腐蝕(shi)性或熱(re)敏(min)性介質的(de)(de)管道(dao)(dao),不能用(yong)(yong)內(nei)伴熱(re)及夾套伴熱(re),但對于常規的(de)(de)外伴熱(re)管,只要在主管與(yu)伴熱(re)管之間用(yong)(yong)石棉板(ban)隔(ge)熱(re)后,仍可采用(yong)(yong)。

②. 施工、生產(chan)管(guan)理及(ji)檢修(xiu)都比較方便。伴(ban)熱管(guan)損壞后(hou),可以及(ji)時修(xiu)理,既不影(ying)響生產(chan),又不會(hui)出現質量事故。

3. 夾套伴熱

夾套伴熱(re)(re)(re)管(guan)(guan)即在工藝管(guan)(guan)線(xian)的(de)(de)外面安裝一(yi)套管(guan)(guan),類似套管(guan)(guan)式(shi)換熱(re)(re)(re)器進行換熱(re)(re)(re)。只(zhi)要伴熱(re)(re)(re)介(jie)(jie)質(zhi)(zhi)溫度與內(nei)管(guan)(guan)介(jie)(jie)質(zhi)(zhi)的(de)(de)溫度相同或略高(gao)一(yi)些(xie),就能(neng)維持內(nei)管(guan)(guan)介(jie)(jie)質(zhi)(zhi)的(de)(de)溫度,這時蒸汽(qi)消(xiao)耗(hao)量只(zhi)要滿足(zu)(zu)本身的(de)(de)熱(re)(re)(re)損失,因而(er)伴熱(re)(re)(re)效率是(shi)比較高(gao)的(de)(de)。夾套管(guan)(guan)伴熱(re)(re)(re)耗(hao)鋼量大,施工工程亦大。但它能(neng)應(ying)用于外伴熱(re)(re)(re)管(guan)(guan)不能(neng)滿足(zu)(zu)工藝要求的(de)(de)介(jie)(jie)質(zhi)(zhi)管(guan)(guan)道。如石化企業中輸(shu)送高(gao)凝固(gu)點,高(gao)熔點介(jie)(jie)質(zhi)(zhi)的(de)(de)管(guan)(guan)道,需采(cai)用這種伴熱(re)(re)(re)方式(shi)。

4. 電伴(ban)熱

電(dian)(dian)(dian)伴(ban)(ban)熱(re)帶安裝在工(gong)藝(yi)管道(dao)外部,利(li)用(yong)電(dian)(dian)(dian)阻體發熱(re)來補充工(gong)藝(yi)管道(dao)的散熱(re)損失(shi)。采(cai)用(yong)電(dian)(dian)(dian)伴(ban)(ban)熱(re)可以有效利(li)用(yong)能(neng)量(liang),有效控(kong)制(zhi)溫度。電(dian)(dian)(dian)伴(ban)(ban)熱(re)方式有感應加(jia)熱(re)法(fa)、直接通電(dian)(dian)(dian)法(fa)、電(dian)(dian)(dian)阻加(jia)熱(re)法(fa)等。