電(dian)火(huo)花表面(mian)強化(hua)是(shi)利用工具電(dian)極(ji)與(yu)工件間在氣體中產生的火(huo)花放電(dian)作用,把作為電(dian)極(ji)的導電(dian)材料熔滲進(jin)工件表層,形成合金(jin)化(hua)的表面(mian)強化(hua)層,改善工件表面(mian)的物理(li)及化(hua)學性能(neng)。

電火花表面強化層的性能主要決定于模具本身和電極材料,通常所用的電極材料有TiC、WC、ZrC、NbC、Cr3C2、硬質合金等。電火花強化表面因電極材料的沉積發生有規律的、較小的長大,除此之外,模具沒有其他變形。其心部的組織與性能也不發生變化,因此十分適用于工件表面強化處理。

金(jin)屬電(dian)(dian)火(huo)花表(biao)面(mian)強化(hua)(hua)的原理是在(zai)工(gong)(gong)(gong)具電(dian)(dian)極(ji)與工(gong)(gong)(gong)件(jian)之間接上(shang)直(zhi)流電(dian)(dian)源(yuan)或(huo)交流電(dian)(dian)源(yuan),由于振動(dong)器的作(zuo)用(yong)使電(dian)(dian)極(ji)與工(gong)(gong)(gong)件(jian)間的放電(dian)(dian)間隙頻繁變化(hua)(hua),工(gong)(gong)(gong)具電(dian)(dian)極(ji)與工(gong)(gong)(gong)件(jian)間不斷產生火(huo)花放電(dian)(dian),從而(er)實現對金(jin)屬表(biao)面(mian)的強化(hua)(hua)。

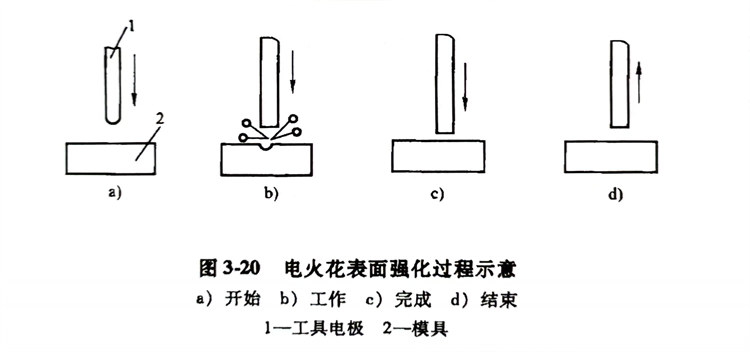

電(dian)(dian)(dian)火花強化(hua)(hua)過程如圖(tu)3-20所示。當(dang)電(dian)(dian)(dian)極(ji)(ji)(ji)與(yu)工(gong)件(jian)(jian)之(zhi)間(jian)的(de)距離較大時(shi),電(dian)(dian)(dian)源經(jing)電(dian)(dian)(dian)阻R對(dui)電(dian)(dian)(dian)容充(chong)電(dian)(dian)(dian),電(dian)(dian)(dian)極(ji)(ji)(ji)在(zai)振(zhen)動(dong)(dong)(dong)器的(de)帶動(dong)(dong)(dong)下(xia)向模具靠近(見(jian)(jian)圖(tu)3-20a)。當(dang)電(dian)(dian)(dian)極(ji)(ji)(ji)與(yu)模具之(zhi)間(jian)的(de)間(jian)隙接(jie)(jie)近到(dao)某個距離時(shi),間(jian)隙中(zhong)的(de)空氣在(zai)強電(dian)(dian)(dian)場(chang)的(de)作用(yong)(yong)下(xia)電(dian)(dian)(dian)離,產生火花放電(dian)(dian)(dian)(見(jian)(jian)圖(tu)3-20b),使電(dian)(dian)(dian)極(ji)(ji)(ji)和工(gong)件(jian)(jian)在(zai)發生放電(dian)(dian)(dian)部(bu)分的(de)金屬(shu)局部(bu)熔化(hua)(hua),甚至汽化(hua)(hua)。電(dian)(dian)(dian)極(ji)(ji)(ji)繼(ji)續(xu)接(jie)(jie)近工(gong)件(jian)(jian)并與(yu)工(gong)件(jian)(jian)接(jie)(jie)觸時(shi),火花放電(dian)(dian)(dian)停止,在(zai)接(jie)(jie)觸點流過短路電(dian)(dian)(dian)流,使該處繼(ji)續(xu)加熱,由于電(dian)(dian)(dian)極(ji)(ji)(ji)以適當(dang)壓力壓向工(gong)件(jian)(jian),使熔化(hua)(hua)的(de)材料互相粘接(jie)(jie)、擴散而形成合金或新(xin)的(de)化(hua)(hua)合物(見(jian)(jian)圖(tu)3-20c)。電(dian)(dian)(dian)極(ji)(ji)(ji)在(zai)振(zhen)動(dong)(dong)(dong)器的(de)作用(yong)(yong)下(xia),離開了工(gong)件(jian)(jian),放電(dian)(dian)(dian)部(bu)分急劇冷(leng)卻(見(jian)(jian)圖(tu)3-20d)。經(jing)多次放電(dian)(dian)(dian),并相應地移動(dong)(dong)(dong)電(dian)(dian)(dian)極(ji)(ji)(ji)的(de)位置,則在(zai)零件(jian)(jian)表面(mian)形成強化(hua)(hua)層。

電火花表面強化(hua)過(guo)程中(zhong)發生(sheng)了(le)物理化(hua)學變化(hua),主要包括超高速淬火、滲(shen)碳、滲(shen)氮(dan)、電極材料的轉(zhuan)移等。

a. 超高速淬火

電火(huo)花放電在模具(ju)表面(mian)(mian)的極(ji)小面(mian)(mian)積上產生高溫(wen),使該處的金屬(shu)熔化和部分(fen)汽化,當火(huo)花放電在極(ji)短的時間內停止(zhi)后,被加熱(re)了的金屬(shu)會(hui)以很快的速度冷卻下(xia)來。這相當于對模具(ju)表面(mian)(mian)層進行了超(chao)速淬火(huo)。

b. 滲氮(dan)

在電火花放電通道區(qu)域內(nei),溫度(du)很高,空氣中(zhong)的氮(dan)分子(zi)呈原子(zi)狀態,它和受高溫而熔化(hua)(hua)的金屬有關的元素(su)合(he)成高硬(ying)度(du)的金屬氮(dan)化(hua)(hua)物,如氮(dan)化(hua)(hua)鐵、氮(dan)化(hua)(hua)鉻(ge)等。

c. 滲(shen)碳

來自石墨電(dian)極(ji)或周圍介質的碳(tan)(tan)元素,熔(rong)(rong)解在(zai)受熱(re)而(er)熔(rong)(rong)化(hua)的鐵中,形成金屬(shu)的碳(tan)(tan)化(hua)物,如碳(tan)(tan)化(hua)鐵、碳(tan)(tan)化(hua)鉻等。

d. 電極材料(liao)的轉(zhuan)移(yi)

在(zai)操作壓(ya)力(li)和火花放電的(de)條件下(xia),電極材(cai)料轉移到模(mo)具金(jin)(jin)屬熔(rong)融表面,有(you)關金(jin)(jin)屬合(he)金(jin)(jin)元(yuan)素(W、Ti、Cr等)迅速擴散在(zai)金(jin)(jin)屬的(de)表面層。

電火花表面(mian)強化層具有如下特征(zheng):

a. 當采用硬(ying)質合金作電(dian)極(ji)材料時,硬(ying)度可達(da)1100~1400HV(約70HRC以上)或(huo)更高,耐熱性、耐蝕性和疲勞強度都大(da)大(da)提高。

b. 當使(shi)用鉻錳(meng)、鎢鉻鈷合(he)金、硬質合(he)金作工具電極強化45鋼時,其耐磨性比原表層提(ti)高2~2.5倍。

c. 用石墨作(zuo)電極(ji)材料強化45鋼(gang),用食鹽水(shui)作(zuo)腐蝕性(xing)試驗,其耐蝕性(xing)提高(gao)90%;用WC、CrMn作(zuo)電極(ji)強化不銹(xiu)鋼(gang)時(shi),其耐蝕性(xing)提高(gao)3~5倍。

d. 硬化層(ceng)厚度為0.01~0.08mm。

鋼制模具(ju)工(gong)作(zuo)表(biao)面(mian)的電火花強化通常(chang)采用(yong)硬質(zhi)合金(jin)電極。為了使被強化的表(biao)面(mian)光(guang)潔,事先必(bi)須將模具(ju)和電極表(biao)面(mian)清(qing)洗干凈,然(ran)后(hou)手持振動器,將電極沿(yan)模具(ju)工(gong)作(zuo)表(biao)面(mian)移(yi)動,并(bing)保持適當壓力(li),使火花放電均勻連續。

電(dian)火花熔(rong)滲合金(jin)化(hua)層(ceng)(ceng)的形成是(shi)一個漸(jian)近(jin)過程,在每一電(dian)規范(fan)下,合金(jin)化(hua)層(ceng)(ceng)厚(hou)度出(chu)(chu)現最大值(zhi),在通(tong)常使用(yong)的電(dian)容(rong)范(fan)圍內(nei),最佳單位面(mian)積(ji)涂(tu)覆時間為6~12min/c㎡。過分延長涂(tu)覆時間將出(chu)(chu)現層(ceng)(ceng)厚(hou)減薄的趨勢(shi),并使性能惡化(hua)。可用(yong)直線(xian)方程式(shi)表(biao)示:

如電(dian)極YG8、電(dian)壓60V,頻(pin)率250Hz,電(dian)容60μF,最佳涂(tu)覆時間為6.75min/c㎡,合金(jin)化層(ceng)厚度(du)為13μm;電(dian)容322μF,涂(tu)覆時間為11.99min/c㎡,合金(jin)化層(ceng)厚度(du)為27μm。

為了降(jiang)低合(he)金(jin)(jin)(jin)化(hua)(hua)層(ceng)的(de)(de)熱疲勞應力(li)和電火花合(he)金(jin)(jin)(jin)化(hua)(hua)處理的(de)(de)應力(li),可穿插1~2次500℃×4h去應力(li)退火,這(zhe)樣可獲(huo)得性能優良、層(ceng)深較厚(hou)(hou)的(de)(de)表面合(he)金(jin)(jin)(jin)化(hua)(hua)層(ceng)。改(gai)換(huan)電極材料,可使合(he)金(jin)(jin)(jin)化(hua)(hua)層(ceng)繼續增(zeng)厚(hou)(hou),電極斷(duan)面尺寸不影(ying)響合(he)金(jin)(jin)(jin)化(hua)(hua)層(ceng)的(de)(de)厚(hou)(hou)度(du)。鋼中w(C)小于0.8%時,隨(sui)鋼中碳含量的(de)(de)增(zeng)加合(he)金(jin)(jin)(jin)層(ceng)增(zeng)厚(hou)(hou);w(C)大于0.8%時,隨(sui)鋼中碳含量的(de)(de)增(zeng)加合(he)金(jin)(jin)(jin)層(ceng)變薄(bo)。

用YG8、Nb、Ti、Ta合金化,工件表面將獲(huo)得極高的顯微硬度值。

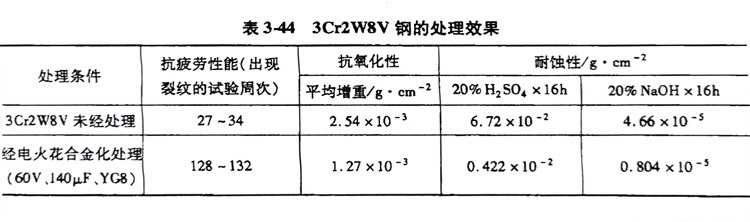

電火花(hua)合(he)金層比(bi)未(wei)經(jing)電火花(hua)合(he)金化處(chu)理的(de)模具的(de)熱疲勞(lao)性能(neng)提高(gao)(gao)3倍,抗氧化性能(neng)提高(gao)(gao)兩倍,在各種試(shi)驗介質中的(de)耐蝕性提高(gao)(gao)3~15倍;表(biao)3-44所示為(wei)3Cr2W8V鋼(gang)的(de)處(chu)理效果。

電火(huo)花(hua)(hua)表面強化應用(yong)效果顯著(zhu)。例(li)如用(yong)YG8作電極(ji),對3Cr2W8V鋼(gang)模(mo)(mo)具進行電火(huo)花(hua)(hua)強化處理以后,模(mo)(mo)具在各類酸(suan)堿中的(de)耐蝕性提(ti)高4~15倍(bei);而Cr12鋼(gang)模(mo)(mo)具刃口部位經電火(huo)花(hua)(hua)表面強化后,模(mo)(mo)具的(de)平均使用(yong)壽(shou)命由5萬次(ci)提(ti)高到20萬次(ci)。