鎢極氬(ya)弧(hu)焊接不銹(xiu)鋼(gang)管設備(bei)主要(yao)有(you)以下幾種

①. 鎢極(ji)氬(ya)弧(hu)焊(han)機(ji)

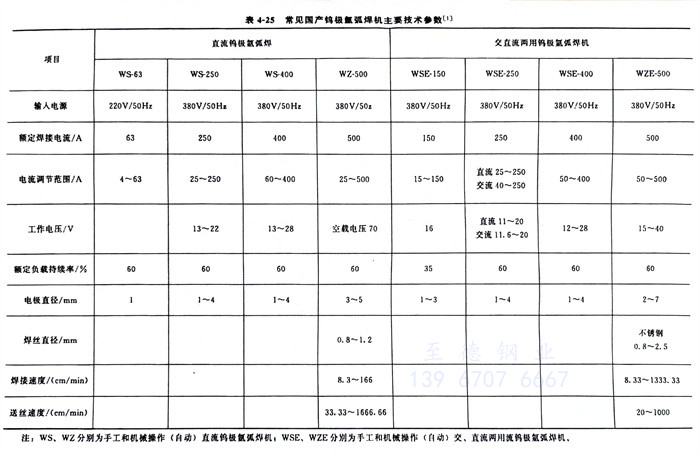

鎢(wu)極(ji)(ji)氬弧(hu)(hu)焊的(de)電(dian)源必須具(ju)有陡(dou)(dou)降或垂直陡(dou)(dou)降外(wai)特性,國內幾種專(zhuan)(zhuan)用的(de)鎢(wu)極(ji)(ji)氬弧(hu)(hu)焊機的(de)型(xing)號(hao)見(jian)表4-25。此(ci)外(wai),焊接非(fei)重要件,可用焊條(tiao)電(dian)弧(hu)(hu)焊的(de)弧(hu)(hu)焊發電(dian)機或弧(hu)(hu)焊整流器作(zuo)弧(hu)(hu)焊電(dian)源,配以專(zhuan)(zhuan)用焊槍,也可實(shi)現(xian)手工(gong)鎢(wu)極(ji)(ji)氬弧(hu)(hu)焊。

專用焊(han)(han)機應具有下(xia)列(lie)功能:焊(han)(han)前(qian)提前(qian)1.5~4.0s輸送保(bao)(bao)護(hu)氣(qi)(qi)(qi)體,以驅趕輸氣(qi)(qi)(qi)管內和(he)焊(han)(han)接(jie)(jie)區(qu)間(jian)的空氣(qi)(qi)(qi),防(fang)止(zhi)產生氣(qi)(qi)(qi)孔;焊(han)(han)后延遲(chi)5~15s停(ting)止(zhi)輸送保(bao)(bao)護(hu)氣(qi)(qi)(qi)體,以保(bao)(bao)證尚未冷卻(que)的鎢(wu)(wu)極和(he)熔池(chi)能在保(bao)(bao)護(hu)氣(qi)(qi)(qi)氛下(xia)冷卻(que),防(fang)止(zhi)氧化和(he)產生氣(qi)(qi)(qi)孔;自動(dong)接(jie)(jie)通和(he)切斷(duan)保(bao)(bao)護(hu)氣(qi)(qi)(qi)源及引(yin)弧(hu)(hu)、穩弧(hu)(hu)的電(dian)路,防(fang)止(zhi)接(jie)(jie)觸引(yin)弧(hu)(hu)燒損(sun)鎢(wu)(wu)極和(he)接(jie)(jie)頭產生夾鎢(wu)(wu)缺陷;控制電(dian)源的通斷(duan);焊(han)(han)接(jie)(jie)結束(shu)前(qian)電(dian)流能自動(dong)衰減,以消除弧(hu)(hu)坑和(he)防(fang)止(zhi)弧(hu)(hu)坑開裂(lie)。

②. 鎢極氬弧焊焊槍(arc welding gun)

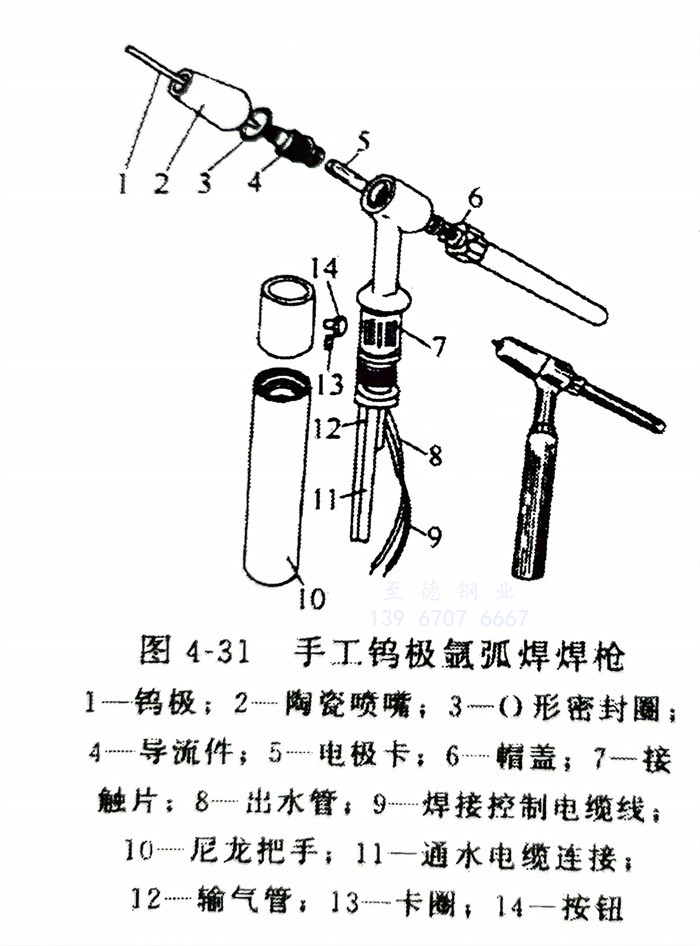

鎢(wu)極氬弧(hu)焊焊槍(qiang)由噴嘴(zui)、鎢(wu)極夾(jia)持裝置、導線(xian)、氣(qi)(qi)水輸送膠管、啟動開關等(deng)零部件組成(cheng)(結(jie)構詳見圖4-31)。根據適用的焊接電流大小,焊槍(qiang)分水冷(leng)式(shi)(shi)和氣(qi)(qi)冷(leng)式(shi)(shi)兩類。常用水冷(leng)卻(que)式(shi)(shi)焊槍(qiang)型號(hao)有QS-75°/400A、QS-75/500A等(deng),可(ke)匹配在大功率氬弧(hu)焊機(ji)上;氣(qi)(qi)冷(leng)卻(que)式(shi)(shi)的焊槍(qiang)型號(hao)有QQ-85/100A、QQ-85/200A等(deng)·可(ke)匹配在小功率氬弧(hu)焊機(ji)上。

③. 氣體保(bao)護裝置(zhi)

氣(qi)(qi)體保護裝置(zhi)有氬(ya)(ya)氣(qi)(qi)瓶、減(jian)(jian)壓器(qi)(qi)(qi)(qi)(qi)(qi)和(he)(he)流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)。氬(ya)(ya)氣(qi)(qi)瓶是(shi)儲存氬(ya)(ya)氣(qi)(qi)的(de)(de)(de)(de)(de)壓力容器(qi)(qi)(qi)(qi)(qi)(qi),使(shi)用(yong)時(shi)應(ying)注意(yi)安全規則(ze)。按 GB 7144-1999《氣(qi)(qi)瓶顏(yan)色標(biao)(biao)志》的(de)(de)(de)(de)(de)規定,氬(ya)(ya)氣(qi)(qi)瓶應(ying)為(wei)(wei)銀灰色,并標(biao)(biao)有“氬(ya)(ya)”(字(zi)的(de)(de)(de)(de)(de)顏(yan)色為(wei)(wei)深綠(lv)色)字(zi)樣。使(shi)用(yong)中應(ying)注意(yi)瓶內氬(ya)(ya)氣(qi)(qi)不得(de)用(yong)盡,應(ying)保留(liu)0.5MPa的(de)(de)(de)(de)(de)余氣(qi)(qi),以(yi)(yi)防止空氣(qi)(qi)混(hun)入而造(zao)成氬(ya)(ya)氣(qi)(qi)不純。減(jian)(jian)壓器(qi)(qi)(qi)(qi)(qi)(qi)可用(yong)普通(tong)氧(yang)氣(qi)(qi)減(jian)(jian)壓器(qi)(qi)(qi)(qi)(qi)(qi)QD-3A 和(he)(he)QD-2A代用(yong)。流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)是(shi)標(biao)(biao)定通(tong)入氣(qi)(qi)體流(liu)量(liang)(liang)(liang)的(de)(de)(de)(de)(de)裝置(zhi),保證氬(ya)(ya)氣(qi)(qi)在焊(han)接過程中按給定的(de)(de)(de)(de)(de)數量(liang)(liang)(liang)輸送。常(chang)用(yong)的(de)(de)(de)(de)(de)有LZB型玻璃(li)轉子流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)或醫(yi)用(yong)流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)均可。但應(ying)注意(yi)流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)的(de)(de)(de)(de)(de)示值受氣(qi)(qi)體密度的(de)(de)(de)(de)(de)影響。使(shi)用(yong)非氬(ya)(ya)氣(qi)(qi)專用(yong)流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)時(shi),表中的(de)(de)(de)(de)(de)示值并非氬(ya)(ya)氣(qi)(qi)的(de)(de)(de)(de)(de)真實流(liu)量(liang)(liang)(liang)。現(xian)在已有氬(ya)(ya)氣(qi)(qi)減(jian)(jian)壓器(qi)(qi)(qi)(qi)(qi)(qi)和(he)(he)流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)結合一(yi)體的(de)(de)(de)(de)(de)儀器(qi)(qi)(qi)(qi)(qi)(qi),如YQAR-195,以(yi)(yi)及(ji)CO2減(jian)(jian)壓器(qi)(qi)(qi)(qi)(qi)(qi)和(he)(he)流(liu)量(liang)(liang)(liang)計(ji)(ji)(ji)(ji)一(yi)體的(de)(de)(de)(de)(de)YQT-195。