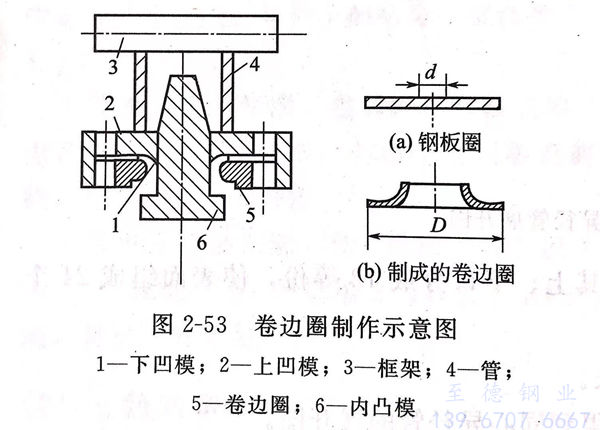

1. 卷邊圈制作方法

如圖2-53所示,將(jiang)鋼板圈置于上下(xia)凹模之間,內凸模在外力的(de)(de)作用下(xia)將(jiang)鋼板圈壓(ya)成(cheng)卷邊(bian)圈。施力的(de)(de)機具可(ke)采用液壓(ya)千斤(jin)頂(ding)(ding)。當鋼板厚為3mm時(shi)(材質為1Cr18Ni9Ti),100kN(10t)的(de)(de)液壓(ya)千斤(jin)頂(ding)(ding)可(ke)制作公稱尺(chi)寸(cun)DN25mm的(de)(de)卷邊(bian)圈;當板厚3.5mm時(shi),500kN(50t)液壓(ya)千斤(jin)頂(ding)(ding)可(ke)制作公稱尺(chi)寸(cun)DN50mm的(de)(de)卷邊(bian)圈;當板厚4mm時(shi),1000kN(100t)液壓(ya)千斤(jin)頂(ding)(ding)可(ke)制作公稱尺(chi)寸(cun)DN80mm的(de)(de)卷邊(bian)圈。

在加工鋼板圈時,應使其內徑與管子外徑的比為(1:2.1)~(1:2.2)。

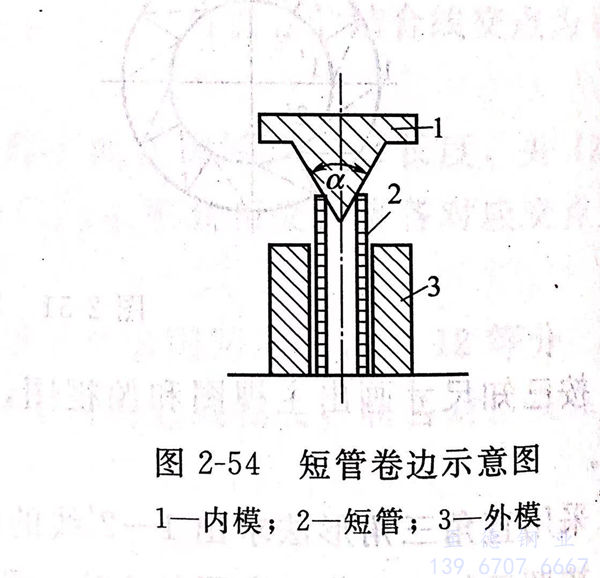

2. 卷(juan)邊短(duan)管(guan)的制作(zuo)

短管卷(juan)(juan)邊(bian)(bian)可(ke)采用電動卷(juan)(juan)邊(bian)(bian)機(ji),其制作方法如圖2-54所示。內(nei)模的角(jiao)度a有45°、90°、125°、180°四(si)種。在管子上(shang)卷(juan)(juan)邊(bian)(bian)時,內(nei)模(中碳鋼制成)更換4次(ci),沖(chong)壓即成。短管卷(juan)(juan)邊(bian)(bian)比鋼圈(quan)卷(juan)(juan)邊(bian)(bian)麻煩些,但安裝方便。卷(juan)(juan)邊(bian)(bian)圈(quan)與管道(dao)焊(han)接時,常因焊(han)縫高度較大,焊(han)后要進行加工(gong),否則(ze)會造成卷(juan)(juan)邊(bian)(bian)圈(quan)與鋼法蘭接觸不緊密的缺陷。