在半(ban)球形或圓(yuan)頂形工件(jian)沖(chong)(chong)(chong)(chong)壓(ya)(ya)成型時,由(you)于坯料(liao)在沖(chong)(chong)(chong)(chong)壓(ya)(ya)過程(cheng)中,金(jin)屬(shu)的大部分表面(mian)是不與(yu)沖(chong)(chong)(chong)(chong)模表面(mian)相(xiang)接觸(chu)的,為(wei)此(ci)應特(te)別注意坯料(liao)夾緊力的大小是否(fou)合適,以避(bi)免在沖(chong)(chong)(chong)(chong)壓(ya)(ya)過程(cheng)中產生皺折。很(hen)明顯,在沖(chong)(chong)(chong)(chong)壓(ya)(ya)開始時只有沖(chong)(chong)(chong)(chong)頭端部與(yu)工件(jian)表面(mian)接觸(chu),而只有在沖(chong)(chong)(chong)(chong)頭下降至足夠深時,沖(chong)(chong)(chong)(chong)頭的整個表面(mian)才能夠與(yu)工件(jian)全部接觸(chu)。

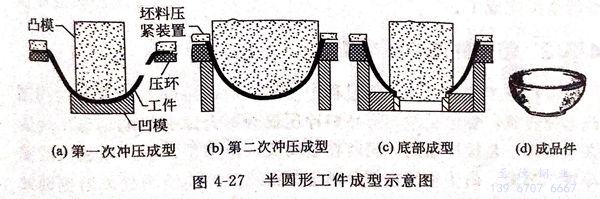

在成(cheng)型(xing)時,有時可以采(cai)用(yong)小規格的(de)沖頭先進行(xing)預成(cheng)型(xing)沖壓,然后再換用(yong)應采(cai)用(yong)的(de)圓頂(ding)沖頭進行(xing)最終(zhong)沖壓成(cheng)型(xing),如圖(tu)4-27所(suo)示。

在圖4-27所示的真(zhen)(zhen)空瓶頂蓋(gai)(gai)成(cheng)型加工中,關鍵一步是(shi)半(ban)球形(xing)頂蓋(gai)(gai)大端的臺肩成(cheng)型。這個臺肩的階梯形(xing)內徑必須(xu)與(yu)(yu)真(zhen)(zhen)空瓶殼體精確吻合。頂蓋(gai)(gai)小端的沖孔也必須(xu)精確成(cheng)型,以便與(yu)(yu)內容器(qi)的嘴部相配合。

加工瓶蓋所用的原料是寬為288.925mm、厚為1.067mm的退火06Cr19Ni10(304)型不(bu)銹鋼(gang)帶(dai)。

沖(chong)切設備是一臺帶有彈簧壓力墊的(de)單行(xing)程(cheng)機械式沖(chong)壓機。從帶鋼上(shang)沖(chong)剪下直徑為282.575mm的(de)坯(pi)料(liao)后(hou),所剩余的(de)邊角料(liao)每邊寬度(du)僅為3.175mm.

第一次沖壓(ya)是在一臺250噸往復(fu)式機械沖壓(ya)機上完成(cheng)(cheng)(cheng)的(de),所用(yong)的(de)沖頭(tou)直(zhi)徑(jing)為82.55mm.所以(yi),此(ci)(ci)時大部分半(ban)球形蓋(gai)的(de)表(biao)面(mian)是處于自(zi)由延伸狀態(tai),見圖4-27(a)。因此(ci)(ci),這就需(xu)要精(jing)心控制坯料(liao)的(de)壓(ya)緊(jin)力,以(yi)防止(zhi)折疊和皺折的(de)產生。每(mei)批鋼材的(de)坯料(liao)夾(jia)具壓(ya)力,必(bi)須每(mei)次對其進行精(jing)心調整,其變化(hua)范(fan)圍(wei)為0.562~0.70kg/m㎡.沖模的(de)圓角半(ban)徑(jing)也必(bi)須嚴格(ge)加以(yi)控制,應(ying)為坯料(liao)厚度的(de)5.2倍。第一次沖壓(ya)成(cheng)(cheng)(cheng)型出的(de)半(ban)成(cheng)(cheng)(cheng)品(pin)杯形工件的(de)直(zhi)徑(jing)為174.625mm,并帶有一個直(zhi)徑(jing)為234.95mm的(de)凸緣。

第二次(ci)沖(chong)(chong)(chong)壓(ya)也是在250t的(de)往復式沖(chong)(chong)(chong)壓(ya)機上完成(cheng)的(de)。它所使用(yong)的(de)沖(chong)(chong)(chong)頭形狀(zhuang)與所要求的(de)工件內輪廓相同。當沖(chong)(chong)(chong)頭壓(ya)制行(xing)進到頂點時(半(ban)球形頂蓋(gai)底(di)部開口(kou)處的(de)臺(tai)肩也可同時成(cheng)型),見(jian)圖(tu)4-27(b).本工序采用(yong)的(de)是直段(duan)拉伸(shen)成(cheng)型,使底(di)部呈(cheng)半(ban)圓形。臺(tai)階上方的(de)金屬有部分(fen)是用(yong)第一次(ci)沖(chong)(chong)(chong)壓(ya)所留的(de)凸(tu)緣經(jing)再次(ci)沖(chong)(chong)(chong)壓(ya)成(cheng)型的(de)。

在第(di)三道工(gong)(gong)(gong)序中(zhong),進行(xing)半球形(xing)頂部(bu)沖孔(kong)工(gong)(gong)(gong)序,并在孔(kong)的(de)(de)周圍形(xing)成(cheng)(cheng)內(nei)部(bu)拉伸凸緣(yuan)。這些工(gong)(gong)(gong)作是在彈簧支撐(cheng)的(de)(de)沖孔(kong)模(mo)上完(wan)成(cheng)(cheng)的(de)(de)。在沖切坯(pi)料時,該沖模(mo)具有足夠(gou)的(de)(de)拉力,然(ran)后用(yong)沖頭的(de)(de)邊緣(yuan)部(bu)位(wei)進行(xing)再次(ci)成(cheng)(cheng)型(xing),見圖4-27(c).最后,沖壓成(cheng)(cheng)型(xing)完(wan)成(cheng)(cheng)[見圖4-27(d)]。工(gong)(gong)(gong)件的(de)(de)兩端還需在車床上進行(xing)精加工(gong)(gong)(gong)。至(zhi)此,真空瓶頂蓋的(de)(de)半球形(xing)成(cheng)(cheng)型(xing)就全部(bu)完(wan)成(cheng)(cheng)了。