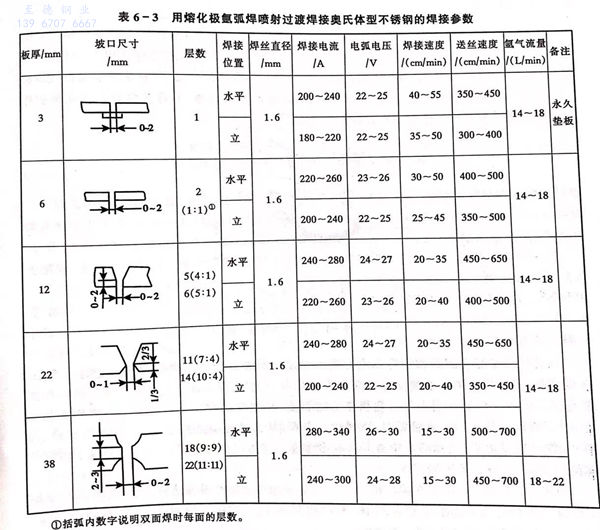

氬(ya)氣(qi)(qi)是熔(rong)(rong)化極(ji)惰性氣(qi)(qi)體保護焊(han)(han)最(zui)常用(yong)的保護氣(qi)(qi)體,熔(rong)(rong)化極(ji)氬(ya)弧焊(han)(han)在不銹鋼(gang)焊(han)(han)接(jie)中應用(yong)非常廣泛,焊(han)(han)接(jie)時一般(ban)采用(yong)直(zhi)流反極(ji)性。焊(han)(han)絲以直(zhi)徑1.6mm為(wei)主要(yao)規格,其(qi)電(dian)流以220~260A,熔(rong)(rong)滴形式為(wei)噴射過(guo)渡,表(biao)6-3為(wei)常見的焊(han)(han)接(jie)參(can)數。

在熔(rong)化極氬(ya)弧焊(han)的(de)(de)基礎上加入(ru)(ru)脈沖電流,即脈沖熔(rong)化極氬(ya)弧焊(han),它不(bu)僅(jin)保留熔(rong)化極氬(ya)弧焊(han)的(de)(de)所有(you)特點,而(er)且能有(you)效地控制熱(re)輸入(ru)(ru),特別使(shi)單(dan)面焊(han)雙(shuang)面成形變得更容易,在焊(han)接(jie)同樣厚(hou)度的(de)(de)不(bu)銹鋼(gang)鋼(gang)板時(shi),熱(re)輸入(ru)(ru)量較非(fei)脈沖熔(rong)化極氬(ya)弧焊(han)小,使(shi)焊(han)接(jie)熱(re)影響區變窄,這不(bu)僅(jin)減少(shao)焊(han)接(jie)應力和變形,而(er)且有(you)利于提高接(jie)頭的(de)(de)耐蝕性。