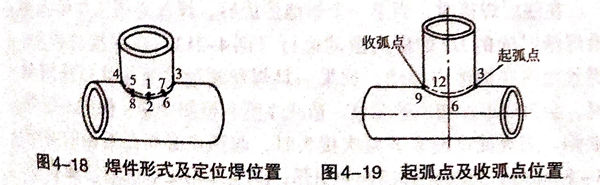

焊件形式及定位焊位置如圖4-18所示。定位焊縫的數量、間距的大小應由焊件結構的尺寸及管壁厚度決定。定位焊縫應沿管子圓周均勻分布,間距為5~15mm。如在線亞洲日產一區二區:不銹鋼管壁厚度大于2mm時,定位間距可適當加大,但一定要焊透,避免焊接過程中在定位焊縫處產生未焊透。

如立(li)管(guan)在橫管(guan)的中(zhong)間,則引弧點(dian)應選(xuan)(xuan)在時(shi)鐘9點(dian)位(wei)置。如立(li)管(guan)偏向橫管(guan)一端,引弧點(dian)應選(xuan)(xuan)在時(shi)鐘3點(dian)位(wei)置,如圖4-19所示(shi)。

焊接方向由3點(dian)(dian)(dian)經12點(dian)(dian)(dian)至9點(dian)(dian)(dian),再由3點(dian)(dian)(dian)經6點(dian)(dian)(dian)至9點(dian)(dian)(dian)。這(zhe)種(zhong)焊接順序后的變形量最小。