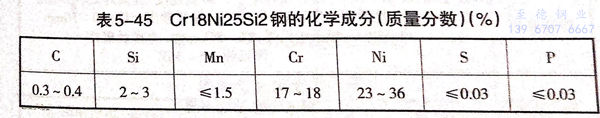

Cr18Ni25Si2鋼屬(shu)奧氏體(ti)鋼,它適(shi)合在900~1000℃高溫下工(gong)作,是各種爐用鋼中的一種,其化學成(cheng)分(fen)見表(biao)5-45.

坡(po)口采用60°V形坡(po)口。裝(zhuang)配時留間隙(xi)(用2mm厚(hou)的(de)(de)塞(sai)鐵),兩(liang)端用托架支承,以外圓(yuan)找(zhao)正中(zhong)心,在(zai)(zai)圓(yuan)周上定(ding)位焊(han)(han)4~6處(chu),定(ding)位焊(han)(han)縫長(chang)度25~35mm,焊(han)(han)條用A407,焊(han)(han)接電源(yuan)采用直(zhi)流(liu)反接。此種鋼的(de)(de)破損件或缺陷(xian)鑄(zhu)件焊(han)(han)補(bu)時,事先應在(zai)(zai)裂紋的(de)(de)兩(liang)端用直(zhi)徑6~8mm鉆頭鉆孔,然后(hou)沿(yan)裂紋用風鏟開坡(po)口(坡(po)口角度60°),并(bing)用有機(ji)溶劑清洗坡(po)口后(hou),進行(xing)補(bu)焊(han)(han)。