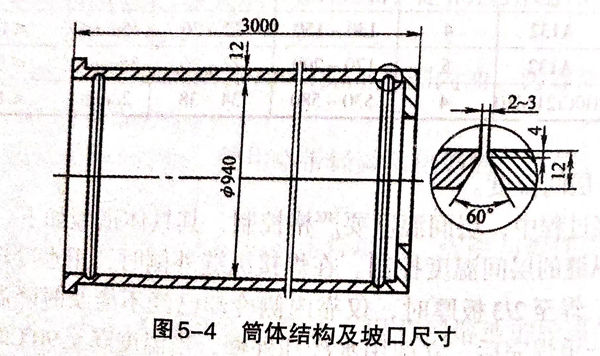

合成塔筒體采用材料為321不銹鋼制作,板厚12mm,筒體直徑940mm,長9m.工作壓力1.76MPa,溫度≤530℃.筒體焊后要求焊縫總長25%進行X射線探傷檢測。

筒(tong)體縱縫、環縫的坡(po)口(kou)形(xing)式均為V形(xing),如(ru)圖5-4所示(shi)。坡(po)口(kou)用機械加工方法(fa)或用碳弧氣刨加工,氣刨后的坡(po)口(kou)表面要清除熔渣(zha),并打磨光亮(liang)。筒(tong)體所有縱、環縫的坡(po)口(kou)開(kai)在(zai)筒(tong)內,鈍邊開(kai)在(zai)筒(tong)外(wai)(wai)。其優(you)點(dian)是焊根(gen)(gen)在(zai)筒(tong)外(wai)(wai),便于碳弧氣刨進行清根(gen)(gen)操(cao)作,另外(wai)(wai),氣刨產生的熔渣(zha)不粘在(zai)筒(tong)體內壁上(shang),保證筒(tong)體光潔(jie),提高耐腐蝕性。

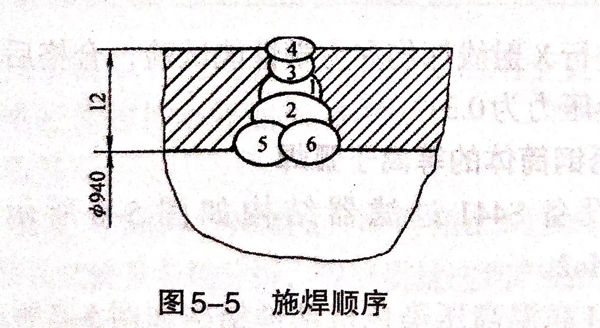

筒體成形后裝(zhuang)配定(ding)位(wei)(wei)焊,每隔200~250mm定(ding)位(wei)(wei)焊25mm,定(ding)位(wei)(wei)焊縫(feng)高度為4~5mm.施(shi)焊順序(xu)如圖5-5所(suo)示。先在筒體內焊第1和(he)第2道(dao)(第1層),這(zhe)兩道(dao)焊縫(feng)的起焊和(he)終止端應相反。

然后(hou)(hou)在(zai)筒(tong)外清根(gen),再焊(han)(han)(han)(han)第(di)3和第(di)4道(第(di)2層)。同樣注意各道之間的焊(han)(han)(han)(han)接方向(xiang)(xiang)要相反(fan)。這樣焊(han)(han)(han)(han)波(bo)錯(cuo)開避(bi)免夾渣。焊(han)(han)(han)(han)條(tiao)不(bu)要做橫(heng)向(xiang)(xiang)擺動,對準中心線焊(han)(han)(han)(han)接。清根(gen)時在(zai)筒(tong)外用碳(tan)弧氣刨進行,碳(tan)棒直徑8mm,電(dian)流250~300A,碳(tan)棒與焊(han)(han)(han)(han)縫夾角45°,刨槽深度4mm,將(jiang)第(di)1層焊(han)(han)(han)(han)道根(gen)部可能(neng)有缺陷的金屬全部創除(chu),刨后(hou)(hou)清理熔渣。第(di)3、4層焊(han)(han)(han)(han)道焊(han)(han)(han)(han)完后(hou)(hou),最后(hou)(hou)在(zai)筒(tong)體內焊(han)(han)(han)(han)接與腐蝕介質接觸(chu)的第(di)5、6層焊(han)(han)(han)(han)道。

環縫(feng)(feng)在(zai)筒(tong)體外(wai)部進行點(dian)固,點(dian)牢之后將筒(tong)體吊放在(zai)轉(zhuan)胎上,焊(han)(han)工在(zai)筒(tong)內(nei)焊(han)(han)接(jie)(jie),轉(zhuan)胎轉(zhuan)動(dong)開關在(zai)面罩(zhao)上,由焊(han)(han)工自己控制(zhi)轉(zhuan)動(dong)速度,邊焊(han)(han)邊轉(zhuan),保(bao)持平焊(han)(han)位置,施焊(han)(han)次序與縱(zong)縫(feng)(feng)要(yao)求(qiu)相同(tong)。第1道焊(han)(han)接(jie)(jie)時采(cai)用焊(han)(han)條直徑4mm,焊(han)(han)接(jie)(jie)電(dian)流120~140A.其他各(ge)道焊(han)(han)接(jie)(jie)電(dian)流為(wei)130~150A.