浙江金洲管道工業有(you)限公(gong)司φ508~1626mm預(yu)精焊(han)(han)螺旋縫埋弧焊(han)(han)鋼管生(sheng)產(chan)(chan)(chan)線引進德(de)國SMS MEER集(ji)團旗下PWS公(gong)司國際先進的預(yu)精焊(han)(han)(二步法)螺旋焊(han)(han)管生(sheng)產(chan)(chan)(chan)技術(shu)和(he)設備,于2015年1月正式投產(chan)(chan)(chan),年生(sheng)產(chan)(chan)(chan)能(neng)力20萬噸,生(sheng)產(chan)(chan)(chan)壁厚6.4mm~25.4mm,最高生(sheng)產(chan)(chan)(chan)鋼級 L690/X100。

金州管道不銹(xiu)鋼(gang)焊管生產線控制系統基于工業以太網技術,實現分布式自動化控制,是目前世界上裝備最先進、工藝最成熟、自動化程度最高的螺旋焊管生產線之一,在檢測設備方面生產線配備了112通道100%母材超聲波探傷、32通道焊縫超聲波探傷、數字平板X射線實時成像檢測系統、4000t水壓試驗機等。

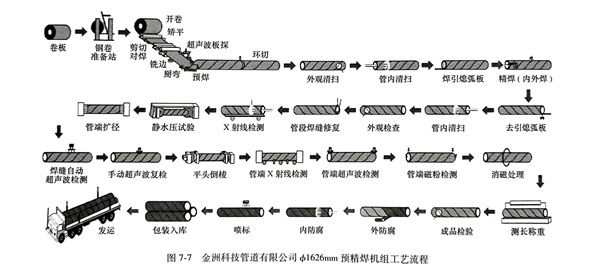

一、生產(chan)工藝流程(cheng)

金洲(zhou)科(ke)技(ji)管(guan)道有限公(gong)司ф1626mm預精(jing)焊(han)不銹鋼焊(han)管(guan)機(ji)組工藝(yi)流(liu)程(cheng)生產工藝(yi)流(liu)程(cheng)如圖7-7所示。

二(er)、主(zhu)要技術特點

1. 高速(su)成型預焊機組技術

穩(wen)定的(de)(de)(de)鋼帶工作寬度(du)和穩(wen)定的(de)(de)(de)遞送狀態(tai)是實(shi)現(xian)穩(wen)定高(gao)速成(cheng)型的(de)(de)(de)前提,通過以(yi)下(xia)各(ge)系統的(de)(de)(de)協同工作,使鋼帶以(yi)最穩(wen)的(de)(de)(de)狀態(tai)進入成(cheng)型器,在高(gao)精度(du)模型化的(de)(de)(de)成(cheng)型系統中(zhong)實(shi)現(xian)低應(ying)力穩(wen)定成(cheng)型,對外(wai)徑、圓度(du)、直度(du)實(shi)現(xian)高(gao)精度(du)控(kong)制(zhi),為預(yu)焊(han)提供穩(wen)定的(de)(de)(de)焊(han)接(jie)環境。

a. 鋼(gang)帶(dai)矯(jiao)(jiao)平(ping)裝置(zhi)配備七輥矯(jiao)(jiao)平(ping)機,矯(jiao)(jiao)平(ping)高(gao)度由電(dian)機調節,矯(jiao)(jiao)平(ping)力大(da)(da)小由液壓缸提供,可(ke)對每個矯(jiao)(jiao)平(ping)輥進行獨立控制,精(jing)確(que)調整每個矯(jiao)(jiao)平(ping)輥位置(zhi)的(de)壓力,使(shi)出口側(ce)鋼(gang)帶(dai)快速(su)達到(dao)理想(xiang)的(de)矯(jiao)(jiao)平(ping)狀(zhuang)態(tai),其最大(da)(da)矯(jiao)(jiao)平(ping)力600噸,滿足大(da)(da)壁(bi)厚高(gao)鋼(gang)級的(de)高(gao)速(su)矯(jiao)(jiao)平(ping)。

b. 剪切(qie)對(dui)焊(han)(han)機配(pei)備伊(yi)薩等離子切(qie)割(ge)系(xi)(xi)統、板頭尾(wei)銑(xian)邊機、預焊(han)(han)系(xi)(xi)統、雙(shuang)絲(si)(si)自動埋弧焊(han)(han)系(xi)(xi)統,通(tong)過(guo)先(xian)銑(xian)邊后焊(han)(han)接(jie)(jie)(jie)的工(gong)藝,有效避(bi)免因板頭尾(wei)對(dui)接(jie)(jie)(jie)人(ren)為地產生鐮刀彎。采用Y型焊(han)(han)接(jie)(jie)(jie)坡口,配(pei)合(he)預焊(han)(han)+雙(shuang)絲(si)(si)自動埋弧焊(han)(han)工(gong)藝,使(shi)得對(dui)接(jie)(jie)(jie)接(jie)(jie)(jie)頭達到足夠的熔深和強(qiang)度,確(que)保對(dui)頭焊(han)(han)縫質量,實現鋼帶對(dui)接(jie)(jie)(jie)接(jie)(jie)(jie)頭在成型器(qi)快(kuai)速(su)穩定通(tong)過(guo)。

c. 自適應銑(xian)邊(bian)(bian)(bian)機(ji)配備三(san)組(zu)(zu)鋼帶(dai)寬(kuan)(kuan)度自適應銑(xian)邊(bian)(bian)(bian)機(ji)。第(di)一、二組(zu)(zu)銑(xian)邊(bian)(bian)(bian)機(ji)為(wei)粗(cu)銑(xian),寬(kuan)(kuan)度自適應系統通過實時檢測鋼帶(dai)銑(xian)邊(bian)(bian)(bian)前后寬(kuan)(kuan)度,合理地(di)分配每組(zu)(zu)銑(xian)邊(bian)(bian)(bian)機(ji)切削深度,提高刀片的(de)使用壽命,保證(zheng)銑(xian)邊(bian)(bian)(bian)質(zhi)量;第(di)三(san)組(zu)(zu)銑(xian)邊(bian)(bian)(bian)機(ji)為(wei)精銑(xian),根據(ju)壁厚(hou)和焊(han)接工藝(yi)設定(ding)銑(xian)邊(bian)(bian)(bian)后工作寬(kuan)(kuan)度、坡口(kou)(kou)角度,鈍邊(bian)(bian)(bian)厚(hou)度、鈍邊(bian)(bian)(bian)位置,穩(wen)(wen)定(ding)的(de)銑(xian)邊(bian)(bian)(bian)控制為(wei)后續的(de)焊(han)接提供有利(li)條件。三(san)組(zu)(zu)銑(xian)邊(bian)(bian)(bian)機(ji)刀盤在豎直方向具有仿形(xing)隨動(dong)功(gong)能,有效地(di)防止由于帶(dai)鋼波(bo)動(dong)引起的(de)坡口(kou)(kou)不均勻,保證(zheng)邊(bian)(bian)(bian)部形(xing)狀良好穩(wen)(wen)定(ding),從(cong)而確(que)保成(cheng)型過程(cheng)穩(wen)(wen)定(ding)。同時銑(xian)邊(bian)(bian)(bian)機(ji)銑(xian)削速度在3~10m/min的(de)遞送速度下自動(dong)進(jin)行(xing)自適應動(dong)態調節(jie),滿足高速預(yu)焊(han)的(de)需求。

d. 鋼帶(dai)(dai)(dai)自(zi)動(dong)(dong)對(dui)中(zhong)系統配備(bei)多組鋼帶(dai)(dai)(dai)自(zi)動(dong)(dong)對(dui)中(zhong)裝置(zhi),每組對(dui)中(zhong)裝置(zhi)均配備(bei)獨立位置(zhi)傳(chuan)感(gan)器(qi),實(shi)時監測(ce)鋼帶(dai)(dai)(dai)的位置(zhi)信息(xi),系統自(zi)動(dong)(dong)判斷鋼帶(dai)(dai)(dai)位置(zhi)狀態和變化(hua)趨勢(shi),通過先進的PI閉環控制算法,實(shi)時動(dong)(dong)態分(fen)配各組對(dui)中(zhong)輥推力,實(shi)現(xian)鋼帶(dai)(dai)(dai)自(zi)動(dong)(dong)對(dui)中(zhong),通過數(shu)據對(dui)比自(zi)動(dong)(dong)分(fen)析鋼帶(dai)(dai)(dai)鐮(lian)刀彎程度,實(shi)時糾偏,保(bao)證成型(xing)過程穩(wen)定(ding)。

e. 主驅動(dong)是整個成型預(yu)焊(han)機(ji)組的唯一動(dong)力(li),由(you)兩(liang)臺210kW交流電機(ji)提(ti)(ti)供(gong)(gong),動(dong)力(li)通過(guo)行星齒(chi)輪傳輸到驅動(dong)輥,最大(da)驅動(dong)扭矩480kN·m,兩(liang)輥夾送(song)壓力(li)由(you)液壓缸提(ti)(ti)供(gong)(gong),液壓回路中的蓄能裝置可(ke)有(you)效吸收焊(han)縫通過(guo)輥子時的壓力(li)變化,提(ti)(ti)供(gong)(gong)穩定的遞送(song)速度。

f. 高(gao)精度成型(xing)機主要由三輥(gun)彎曲系(xi)統(tong)和(he)外控輥(gun)系(xi)統(tong)組(zu)成,最大(da)成型(xing)力300t,各成型(xing)輥(gun)梁均配置伺(si)服電(dian)機和(he)絕對值編碼器(qi),采用PWS先進的(de)成型(xing)模(mo)型(xing)算(suan)法(fa),通(tong)過(guo)(guo)精確定(ding)位(wei)各成型(xing)輥(gun)位(wei)置,實(shi)現(xian)高(gao)速(su)穩定(ding)成型(xing),同時各位(wei)置信息通(tong)過(guo)(guo)PLC儲(chu)存,可重復調用,提(ti)高(gao)成型(xing)效(xiao)率。

g. 數字(zi)式預(yu)(yu)焊(han)系(xi)統(tong)采用(yong)CO2氣體(ti)保護(hu)焊(han),由兩(liang)臺1500A數字(zi)式焊(han)接(jie)(jie)(jie)(jie)(jie)電源(yuan)串聯(lian)而成,內置專家級焊(han)接(jie)(jie)(jie)(jie)(jie)數據庫,根據壁厚和(he)焊(han)絲直徑(jing)不同,選(xuan)擇合適的焊(han)接(jie)(jie)(jie)(jie)(jie)程(cheng)序,程(cheng)序自(zi)動調用(yong)數據庫參數,并(bing)在焊(han)接(jie)(jie)(jie)(jie)(jie)過(guo)程(cheng)中對(dui)參數進行PI閉環(huan)控(kong)制,其控(kong)制了(le)頻(pin)率達(da)到5kHz,確保參數輸(shu)出穩(wen)(wen)定(ding)。焊(han)接(jie)(jie)(jie)(jie)(jie)過(guo)程(cheng)采用(yong)潛弧式的過(guo)渡形(xing)式,配合活性(xing)保護(hu)氣體(ti),可在較高的焊(han)接(jie)(jie)(jie)(jie)(jie)速(su)(su)度下(xia)保持穩(wen)(wen)定(ding)的熔深(shen),確保于(yu)焊(han)縫的強(qiang)度,最高焊(han)接(jie)(jie)(jie)(jie)(jie)速(su)(su)度達(da)10m/min。預(yu)(yu)焊(han)系(xi)統(tong)配備激(ji)光自(zi)動跟蹤系(xi)統(tong)和(he)視頻(pin)監控(kong)系(xi)統(tong),可對(dui)焊(han)點位置和(he)預(yu)(yu)焊(han)縫狀態實時監控(kong),實現自(zi)動化(hua)焊(han)接(jie)(jie)(jie)(jie)(jie)。

2. 雙(shuang)環(huan)噴水式等(deng)離(li)子環(huan)切機

配備(bei)(bei)雙(shuang)環(huan)(huan)(huan)噴水式等(deng)離(li)(li)子切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)機。其雙(shuang)環(huan)(huan)(huan)即夾持(chi)環(huan)(huan)(huan)和切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)環(huan)(huan)(huan),夾持(chi)環(huan)(huan)(huan)包含(han)3組抱夾裝置(zhi),同時(shi)環(huan)(huan)(huan)切(qie)(qie)(qie)(qie)機具備(bei)(bei)長度(du)(du)測量系(xi)(xi)統(tong)(tong),控(kong)制精度(du)(du)達(da)(da)到1mm,當鋼(gang)(gang)管(guan)(guan)長度(du)(du)達(da)(da)到切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)所設定(ding)的長度(du)(du)時(shi),夾持(chi)環(huan)(huan)(huan)夾緊鋼(gang)(gang)管(guan)(guan),使切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)系(xi)(xi)統(tong)(tong)與不銹鋼(gang)(gang)焊(han)管(guan)(guan)以同樣的速度(du)(du)前進,隨后切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)環(huan)(huan)(huan)實施環(huan)(huan)(huan)切(qie)(qie)(qie)(qie)作業。雙(shuang)環(huan)(huan)(huan)等(deng)離(li)(li)子切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)系(xi)(xi)統(tong)(tong)使切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)系(xi)(xi)統(tong)(tong)與鋼(gang)(gang)管(guan)(guan)形成(cheng)一(yi)個相對速度(du)(du)為(wei)0的狀態,提供穩定(ding)的切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)環(huan)(huan)(huan)境,使得切(qie)(qie)(qie)(qie)口更加整齊;其噴水系(xi)(xi)統(tong)(tong)一(yi)方(fang)面(mian)對等(deng)離(li)(li)子弧進行收弧聚能,使切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)能量更加集中,提高切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)效率,另一(yi)方(fang)面(mian)對切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)周圍(wei)進行冷卻(que),減少(shao)切(qie)(qie)(qie)(qie)割(ge)(ge)(ge)熱影響區(qu),保證(zheng)管(guan)(guan)端母(mu)材性能。

3. 精焊機(FWM)

配(pei)(pei)備(bei)3條(tiao)精焊(han)(han)線(xian),每(mei)條(tiao)精焊(han)(han)線(xian)配(pei)(pei)置內焊(han)(han)三(san)絲和(he)外(wai)焊(han)(han)雙(shuang)絲的(de)(de)焊(han)(han)接系(xi)統(tong)(tong),內焊(han)(han)和(he)外(wai)焊(han)(han)均配(pei)(pei)置獨(du)(du)立(li)的(de)(de)焊(han)(han)縫激光自(zi)動(dong)跟蹤系(xi)統(tong)(tong)、視頻(pin)監視系(xi)統(tong)(tong)、焊(han)(han)槍高度(du)跟蹤系(xi)統(tong)(tong)、焊(han)(han)接參(can)數控(kong)制系(xi)統(tong)(tong)等(deng),通(tong)過(guo)各結構聯動(dong),實(shi)現(xian)(xian)自(zi)動(dong)的(de)(de)、實(shi)時(shi)的(de)(de)焊(han)(han)頭位置調節和(he)校正,確保每(mei)一條(tiao)焊(han)(han)縫的(de)(de)焊(han)(han)接質量,同時(shi)每(mei)支不銹鋼焊(han)(han)管的(de)(de)焊(han)(han)接參(can)數實(shi)時(shi)曲(qu)線(xian)可獨(du)(du)立(li)存(cun)檔、回(hui)放,通(tong)過(guo)參(can)數曲(qu)線(xian)可提前(qian)發現(xian)(xian)焊(han)(han)縫存(cun)在(zai)的(de)(de)隱(yin)患點,以進行針對(dui)性檢測。

4. PWS數字(zi)焊接系統

預焊(han)(han)(han)(han)和精焊(han)(han)(han)(han)工(gong)藝(yi)均配備(bei)了PWS數字焊(han)(han)(han)(han)接(jie)(jie)(jie)系(xi)統,即焊(han)(han)(han)(han)接(jie)(jie)(jie)電源和焊(han)(han)(han)(han)接(jie)(jie)(jie)工(gong)藝(yi)均通過(guo)(guo)微處理器控制,從起弧到(dao)整個焊(han)(han)(han)(han)接(jie)(jie)(jie)過(guo)(guo)程,微處理器均以(yi)5kHz的(de)頻(pin)率(lv)對焊(han)(han)(han)(han)接(jie)(jie)(jie)工(gong)藝(yi)進行(xing)分(fen)析(xi)和優化。焊(han)(han)(han)(han)接(jie)(jie)(jie)工(gong)藝(yi)過(guo)(guo)程采(cai)取極(ji)高的(de)頻(pin)率(lv)不(bu)斷進行(xing)分(fen)析(xi)和優化,實現了對整個焊(han)(han)(han)(han)接(jie)(jie)(jie)過(guo)(guo)程實時精確的(de)PI閉環控制,其(qi)直接(jie)(jie)(jie)效果使得(de)焊(han)(han)(han)(han)接(jie)(jie)(jie)過(guo)(guo)程十分(fen)穩定(ding),減少了焊(han)(han)(han)(han)縫缺陷和管端焊(han)(han)(han)(han)接(jie)(jie)(jie)缺陷。

5. 112通道在線鋼管超聲(sheng)波(bo)檢測(ce)系(xi)統

生產(chan)線配(pei)備(bei)112通(tong)(tong)道在線鋼管超聲(sheng)波(bo)檢(jian)測系統(tong),采用8×30mm雙晶組合探(tan)頭(tou),共(gong)25組,100通(tong)(tong)道,探(tan)頭(tou)固定梳狀掃查方(fang)式對鋼板(ban)100%探(tan)傷(shang),用于(yu)(yu)檢(jian)測平行于(yu)(yu)軋制方(fang)向(xiang)線性缺(que)(que)陷(xian)(xian)。同(tong)時(shi)鋼板(ban)兩邊(bian)200mm范(fan)圍內各(ge)有5個橫(heng)波(bo)探(tan)頭(tou),用于(yu)(yu)檢(jian)測鋼板(ban)邊(bian)緣與軋制方(fang)向(xiang)平行的缺(que)(que)陷(xian)(xian)。鋼板(ban)兩側(ce)各(ge)15mm范(fan)圍內各(ge)有1個橫(heng)波(bo)探(tan)頭(tou),用于(yu)(yu)檢(jian)測鋼板(ban)邊(bian)緣與軋制方(fang)向(xiang)垂直(zhi)的缺(que)(que)陷(xian)(xian)。設(she)備(bei)具(ju)有聲(sheng)、光(guang)報警系統(tong),缺(que)(que)陷(xian)(xian)自動(dong)噴(pen)標系統(tong),以及各(ge)通(tong)(tong)道的耦合監(jian)視系統(tong),缺(que)(que)陷(xian)(xian)檢(jian)出率(lv)100%。

6. 32通道(dao)焊(han)縫超聲波檢(jian)測系統

生產線配(pei)備(bei)32通道(dao)焊縫(feng)超(chao)聲波檢(jian)(jian)(jian)測系(xi)統,具有(you)24個探傷通道(dao)和8個耦合監視通道(dao),采用(yong)雙探架設計,配(pei)備(bei)激光圖像自動跟(gen)蹤系(xi)統,確保檢(jian)(jian)(jian)測過程(cheng)穩(wen)定性。布局探頭有(you)X型(xing)和串列型(xing),可檢(jian)(jian)(jian)測焊縫(feng)內縱向、橫(heng)向、斜向、焊縫(feng)中(zhong)間缺陷以(yi)及(ji)焊縫(feng)兩側50mm范圍內的熱影響區分層缺陷。

7. X射線實時成(cheng)像檢測(ce)系統(tong)

生(sheng)產線配備數(shu)字平板X射線實時成像檢測系統,采用(yong)美國(guo)珀金埃爾默公司的8in非晶數(shu)字平板系統XRD 0822 AP,空間分辨率優于(yu)3.0p/mm,具有全焊縫實時存(cun)圖(tu)及回放功能,檢測靜態(tai)靈(ling)敏度1.0%~1.5%,動(dong)態(tai)靈(ling)敏度2.2%~2.5%。

8. 自動化鋼管(guan)輸送控制系(xi)統

輸(shu)送(song)系統(tong)由輸(shu)送(song)輥(gun)道、橫(heng)移小(xiao)(xiao)車(che)、存管(guan)臺(tai)架(jia)構成(cheng),輸(shu)送(song)輥(gun)道每(mei)4個(ge)為(wei)一組,存管(guan)臺(tai)架(jia)采用(yong)V形(xing)臺(tai)架(jia),每(mei)組輥(gun)道、橫(heng)移小(xiao)(xiao)車(che)和每(mei)個(ge)V形(xing)臺(tai)架(jia)均配置傳感器(qi),用(yong)于檢測鋼(gang)管(guan)位置,鋼(gang)管(guan)自(zi)(zi)動(dong)化輸(shu)送(song)控制(zhi)(zhi)系統(tong)由中央控制(zhi)(zhi)室進行(xing)監控,并自(zi)(zi)動(dong)選擇最(zui)優程(cheng)序實(shi)現整(zheng)個(ge)車(che)間鋼(gang)管(guan)的運輸(shu)和存放,提高車(che)間作業效率。

9. ERP信息化管理系統

ERP系統包括制造數(shu)據管理(li)、計劃(hua)排產(chan)管理(li)、生(sheng)(sheng)產(chan)調度(du)管理(li)、庫存(cun)管理(li)、質(zhi)量(liang)(liang)管理(li)、工(gong)藝過程(cheng)管理(li)、采購(gou)管理(li)、成本(ben)管理(li)、生(sheng)(sheng)產(chan)過程(cheng)控制、質(zhi)量(liang)(liang)數(shu)據集成分析(xi)。實現從訂(ding)單下達到產(chan)品(pin)(pin)完成的(de)整(zheng)個(ge)生(sheng)(sheng)產(chan)過程(cheng)的(de)優化管理(li),改善各個(ge)環節的(de)銜接效率(lv),對生(sheng)(sheng)產(chan)進(jin)度(du)、產(chan)品(pin)(pin)質(zhi)量(liang)(liang)數(shu)據實時反(fan)饋,從而(er)保障(zhang)產(chan)品(pin)(pin)質(zhi)量(liang)(liang)和工(gong)廠及時交貨能力(li)。

10. 機器人自動噴標系統

生產線配備機器人自動噴(pen)標系統(tong),實現生產過程鋼(gang)管(guan)信息的(de)自動讀(du)取和收集,中控匯(hui)總鋼(gang)管(guan)的(de)過程狀態(tai)信息,同時產品標識更加(jia)美觀、規范、準確(que)。通過機器換人,降低工人勞動強度。

三、技術水平(ping)與業績

自2015年投產以來,金洲管道以預精焊生產線為依托(tuo),成(cheng)立(li)了能源(yuan)管道研(yan)究(jiu)所,焊接實驗室等研(yan)發部門,整合公司優(you)質(zhi)資源(yuan),通過自主創新和產學研(yan)等方式,加(jia)快預精焊工藝技術消化吸(xi)收(shou)再創新,先后試制進(jin)行了(le)φ1219mmx16.3mm、X90M,φ1219mmx22mm、X80M,ф1219m219mmx25.425.4mm、Q345B,φ508mmx6.4mm,X65M等規格,參與了(le)新粵浙管(guan)(guan)(guan)線(xian)(xian)φ1219x18.4,X80M管(guan)(guan)(guan)線(xian)(xian)的(de)單爐(lu)試制,在高鋼級大(da)壁厚的(de)螺(luo)旋不(bu)銹鋼焊管(guan)(guan)(guan)生(sheng)產工(gong)(gong)(gong)藝上積累一定的(de)經驗(yan)。針對預焊飛濺、精(jing)焊質量、生(sheng)產效率等重點(dian)難點(dian)問題,進(jin)行了(le)專(zhuan)項(xiang)(xiang)(xiang)技術攻關,通過(guo)多項(xiang)(xiang)(xiang)科研成果的(de)應用,金(jin)洲管(guan)(guan)(guan)道預精(jing)焊工(gong)(gong)(gong)藝技術水平達到國內領(ling)先(xian)水平。產品廣(guang)泛用于石(shi)油、天然(ran)氣輸送、海底(di)管(guan)(guan)(guan)線(xian)(xian)、城(cheng)市管(guan)(guan)(guan)網以及(ji)大(da)型鋼管(guan)(guan)(guan)樁管(guan)(guan)(guan)等領(ling)域。先(xian)后承接了(le)惠(hui)州海底(di)管(guan)(guan)(guan)道項(xiang)(xiang)(xiang)目(mu)(mu)、金(jin)麗溫(wen)省級天然(ran)氣管(guan)(guan)(guan)道工(gong)(gong)(gong)程(cheng)、海南環島(dao)管(guan)(guan)(guan)線(xian)(xian)工(gong)(gong)(gong)程(cheng)、江(jiang)陰燃氣管(guan)(guan)(guan)道工(gong)(gong)(gong)程(cheng)、馬(ma)來西亞管(guan)(guan)(guan)網項(xiang)(xiang)(xiang)目(mu)(mu)、文萊(lai)管(guan)(guan)(guan)線(xian)(xian)項(xiang)(xiang)(xiang)目(mu)(mu)、伊朗(lang)管(guan)(guan)(guan)線(xian)(xian)項(xiang)(xiang)(xiang)目(mu)(mu),以及(ji)港華燃氣、中燃燃氣、華潤(run)燃氣等各大(da)城(cheng)市管(guan)(guan)(guan)網工(gong)(gong)(gong)程(cheng)。