一(yi)、焊接性

不銹(xiu)鋼與銅及銅合金焊接時,主要的問題是在焊縫及熔合區易產生裂紋。這種裂紋有焊縫裂紋和熱影響區滲透裂紋兩種形態。

1. 焊縫(feng)裂紋

不銹(xiu)鋼(gang)(gang)與(yu)銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金(jin)(jin)焊(han)(han)接(jie)時(shi),焊(han)(han)縫(feng)中產(chan)(chan)生(sheng)的(de)(de)裂(lie)(lie)(lie)紋屬(shu)于熱(re)裂(lie)(lie)(lie)紋。產(chan)(chan)生(sheng)焊(han)(han)縫(feng)熱(re)裂(lie)(lie)(lie)紋的(de)(de)原(yuan)(yuan)因(yin)(yin)在于,不銹(xiu)鋼(gang)(gang)與(yu)銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金(jin)(jin)熔(rong)合(he)的(de)(de)合(he)金(jin)(jin)體(ti)系成分(fen)復雜,還含有硫、磷、氧等多種(zhong)雜質(zhi),因(yin)(yin)而(er)在熔(rong)池結晶(jing)(jing)過(guo)程易出現低熔(rong)共晶(jing)(jing)體(ti),包(bao)括Ni+NiS之類(lei)(其熔(rong)點溫(wen)度(du)為625℃),削弱(ruo)了高(gao)溫(wen)時(shi)的(de)(de)晶(jing)(jing)間結合(he)能(neng)力。眾所周知,不銹(xiu)鋼(gang)(gang)與(yu)銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金(jin)(jin)的(de)(de)熱(re)物理性(xing)能(neng)差(cha)(cha)異(yi)很大(da)(da)(da),見表5-82。從表中可(ke)以看出,不銹(xiu)鋼(gang)(gang)和(he)銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金(jin)(jin)的(de)(de)線脹系數(shu)(shu)大(da)(da)(da),因(yin)(yin)而(er)焊(han)(han)后的(de)(de)收縮應(ying)(ying)變力大(da)(da)(da),這(zhe)是形(xing)成裂(lie)(lie)(lie)紋傾向在的(de)(de)又一(yi)個原(yuan)(yuan)因(yin)(yin)。此(ci)外(wai),無論(lun)碳鋼(gang)(gang)、還是不銹(xiu)鋼(gang)(gang),都與(yu)銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金(jin)(jin)的(de)(de)熱(re)導(dao)率相差(cha)(cha)較大(da)(da)(da),因(yin)(yin)此(ci)在焊(han)(han)接(jie)過(guo)程中的(de)(de)溫(wen)度(du)場不對(dui)稱,因(yin)(yin)而(er)應(ying)(ying)變、應(ying)(ying)力場也(ye)不對(dui)稱,也(ye)可(ke)能(neng)對(dui)焊(han)(han)接(jie)接(jie)頭產(chan)(chan)生(sheng)裂(lie)(lie)(lie)紋有影響。當以不銹(xiu)鋼(gang)(gang)或銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金(jin)(jin)為填(tian)充材(cai)料直(zhi)接(jie)熔(rong)焊(han)(han),焊(han)(han)縫(feng)金(jin)(jin)屬(shu)中鐵的(de)(de)質(zhi)量(liang)分(fen)數(shu)(shu)又較低時(shi)(如(ru)0.2%~1.1%),生(sheng)產(chan)(chan)實踐證明焊(han)(han)縫(feng)的(de)(de)抗裂(lie)(lie)(lie)性(xing)能(neng)較差(cha)(cha);焊(han)(han)縫(feng)金(jin)(jin)屬(shu)中鐵的(de)(de)質(zhi)量(liang)分(fen)數(shu)(shu)增加到10%~43%時(shi),焊(han)(han)縫(feng)具有最高(gao)的(de)(de)抗熱(re)裂(lie)(lie)(lie)性(xing)能(neng);但是進一(yi)步提高(gao)焊(han)(han)縫(feng)金(jin)(jin)屬(shu)中鐵的(de)(de)含量(liang),其抗裂(lie)(lie)(lie)性(xing)能(neng)卻(que)迅速下(xia)降(jiang)。

2. 熱影響滲透(tou)裂紋(wen)

不銹鋼(gang)(gang)(gang)與銅(tong)(tong)(tong)及(ji)銅(tong)(tong)(tong)合(he)(he)金(jin)(jin)焊(han)接時(shi),在(zai)與液(ye)態銅(tong)(tong)(tong)及(ji)銅(tong)(tong)(tong)合(he)(he)金(jin)(jin)相接觸的(de)(de)(de)鋼(gang)(gang)(gang)中(zhong),易產生(sheng)滲(shen)透(tou)(tou)(tou)裂(lie)(lie)(lie)紋(wen)(wen)。滲(shen)透(tou)(tou)(tou)裂(lie)(lie)(lie)紋(wen)(wen)是指(zhi)低熔(rong)合(he)(he)金(jin)(jin)融體向(xiang)固態合(he)(he)金(jin)(jin)的(de)(de)(de)縫(feng)隙甚至晶(jing)界滲(shen)透(tou)(tou)(tou),使之喪失應變能力而導致的(de)(de)(de)裂(lie)(lie)(lie)紋(wen)(wen)。在(zai)高溫時(shi)形成(cheng)的(de)(de)(de)裂(lie)(lie)(lie)紋(wen)(wen)可能以單條出現,也(ye)可能是沿(yan)晶(jing)界呈(cheng)網狀(zhuang)(zhuang)分(fen)布,其長(chang)度在(zai)幾微(wei)米到幾十(shi)微(wei)米之間。不銹鋼(gang)(gang)(gang)與銅(tong)(tong)(tong)及(ji)銅(tong)(tong)(tong)合(he)(he)金(jin)(jin)焊(han)接時(shi),不銹鋼(gang)(gang)(gang)熱影響區之所以產生(sheng)滲(shen)透(tou)(tou)(tou)裂(lie)(lie)(lie)紋(wen)(wen)是液(ye)態銅(tong)(tong)(tong)及(ji)銅(tong)(tong)(tong)合(he)(he)金(jin)(jin)對(dui)鋼(gang)(gang)(gang)的(de)(de)(de)滲(shen)透(tou)(tou)(tou)作用和焊(han)接應力共(gong)同(tong)作用的(de)(de)(de)結(jie)果(guo)。在(zai)實際的(de)(de)(de)工程金(jin)(jin)屬中(zhong)常存在(zai)一些(xie)微(wei)小的(de)(de)(de)缺陷,以條狀(zhuang)(zhuang)(實為(wei)片狀(zhuang)(zhuang))夾(jia)雜、分(fen)層之類居多,接近于(yu)微(wei)觀裂(lie)(lie)(lie)口(kou)(kou)(kou)。處于(yu)液(ye)體狀(zhuang)(zhuang)態的(de)(de)(de)銅(tong)(tong)(tong)及(ji)銅(tong)(tong)(tong)合(he)(he)金(jin)(jin),如果(guo)固相鋼(gang)(gang)(gang)的(de)(de)(de)微(wei)裂(lie)(lie)(lie)口(kou)(kou)(kou)(或晶(jing)界)表(biao)面(mian)是活性的(de)(de)(de),則會浸潤到微(wei)觀裂(lie)(lie)(lie)口(kou)(kou)(kou)的(de)(de)(de)表(biao)面(mian),并通過(guo)毛細(xi)管效應,慢慢向(xiang)微(wei)觀裂(lie)(lie)(lie)口(kou)(kou)(kou)中(zhong)滲(shen)透(tou)(tou)(tou)。在(zai)整個(ge)滲(shen)透(tou)(tou)(tou)過(guo)程中(zhong),也(ye)伴隨著(zhu)鋼(gang)(gang)(gang)在(zai)銅(tong)(tong)(tong)及(ji)銅(tong)(tong)(tong)合(he)(he)金(jin)(jin)液(ye)體中(zhong)溶解(jie)度的(de)(de)(de)增加(jia)和銅(tong)(tong)(tong)沿(yan)鋼(gang)(gang)(gang)晶(jing)界的(de)(de)(de)擴散(san)過(guo)程。進(jin)入微(wei)裂(lie)(lie)(lie)口(kou)(kou)(kou)中(zhong)的(de)(de)(de)銅(tong)(tong)(tong)及(ji)銅(tong)(tong)(tong)合(he)(he)金(jin)(jin)沿(yan)晶(jing)界的(de)(de)(de)滲(shen)透(tou)(tou)(tou),在(zai)微(wei)裂(lie)(lie)(lie)口(kou)(kou)(kou)中(zhong)產生(sheng)一個(ge)附(fu)加(jia)應力,另一方面(mian)焊(han)縫(feng)從(cong)冷卻瞬間開始,在(zai)焊(han)接接頭中(zhong)就(jiu)出現拉伸應力,并且這(zhe)種(zhong)(zhong)應力隨著(zhu)不斷冷卻而增加(jia)。微(wei)裂(lie)(lie)(lie)口(kou)(kou)(kou)在(zai)這(zhe)兩種(zhong)(zhong)應力作用下,最后發展成(cheng)為(wei)熱影響區滲(shen)透(tou)(tou)(tou)裂(lie)(lie)(lie)紋(wen)(wen)。

不銹鋼的組織狀態對滲透裂紋有很大的影響。液態銅及銅合金浸潤奧氏體,但不浸潤鐵素體,所以鐵素體的存在將使銅及銅合金的滲透能力降低。因此,不銹鋼與銅及銅合金焊接時,含有奧氏體+鐵素體組織的18-8型不銹鋼與單一奧氏體組織的06Cr25Ni20不銹鋼鋼相比較,18-8型不銹鋼具有較高的抗熱影響區滲透裂紋的能力。

銅焊絲(si)中含錫,其滲(shen)透力更(geng)強;而鎳則有減弱銅對鋼滲(shen)透力的作用。

二、焊接方法

不銹鋼與銅及銅合金熔焊(han)的方法有焊(han)條電弧焊(han)、埋弧焊(han)和氣體(ti)保護焊(han)等。

1. 焊條電弧焊

a. 焊條的選擇

焊(han)(han)(han)(han)(han)(han)(han)條(tiao)(tiao)的(de)(de)(de)(de)選(xuan)用(yong)(yong)對(dui)防(fang)止(zhi)焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)接(jie)(jie)(jie)頭(tou)產(chan)生熱裂(lie)(lie)(lie)紋(wen),確保(bao)焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)構件的(de)(de)(de)(de)質(zhi)量關(guan)系很大。不(bu)(bu)銹鋼與銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)時,銅(tong)(tong)是(shi)(shi)(shi)奧氏(shi)體(ti)形成元素,若選(xuan)用(yong)(yong)奧氏(shi)體(ti)不(bu)(bu)銹鋼焊(han)(han)(han)(han)(han)(han)(han)條(tiao)(tiao),其焊(han)(han)(han)(han)(han)(han)(han)縫(feng)仍為奧氏(shi)體(ti)組織,結(jie)晶(jing)時晶(jing)粒之間(jian)存有(you)(you)一薄層的(de)(de)(de)(de)低(di)(di)(di)熔(rong)點(dian)液態(tai)銅(tong)(tong)及(ji)低(di)(di)(di)熔(rong)共晶(jing)體(ti)(Ni+NiS),易(yi)引起(qi)裂(lie)(lie)(lie)紋(wen),不(bu)(bu)宜(yi)采用(yong)(yong)。選(xuan)用(yong)(yong)蒙乃爾(er)型(xing)焊(han)(han)(han)(han)(han)(han)(han)條(tiao)(tiao)[w(Ni)為70%,w(Cr)為(Ni+NiS)30%]時,由(you)于(yu)焊(han)(han)(han)(han)(han)(han)(han)縫(feng)中(zhong)(zhong)(zhong)(zhong)含鎳量較高(gao)(gao),能(neng)(neng)(neng)(neng)增加銅(tong)(tong)在(zai)奧氏(shi)體(ti)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)溶解度(du)(du),從而可降低(di)(di)(di)銅(tong)(tong)的(de)(de)(de)(de)有(you)(you)害(hai)作(zuo)用(yong)(yong),熱裂(lie)(lie)(lie)紋(wen)傾(qing)向可以減小(xiao)。但是(shi)(shi)(shi)晶(jing)粒間(jian)仍有(you)(you)少(shao)量的(de)(de)(de)(de)低(di)(di)(di)熔(rong)點(dian)銅(tong)(tong),因(yin)此(ci)焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)接(jie)(jie)(jie)頭(tou)還有(you)(you)可能(neng)(neng)(neng)(neng)產(chan)生熱裂(lie)(lie)(lie)紋(wen);選(xuan)用(yong)(yong)T107(ECu型(xing))和(he)T237(ECuAl-C型(xing))焊(han)(han)(han)(han)(han)(han)(han)條(tiao)(tiao)進行施焊(han)(han)(han)(han)(han)(han)(han),熔(rong)池(chi)中(zhong)(zhong)(zhong)(zhong)銅(tong)(tong)含量較高(gao)(gao),結(jie)晶(jing)時奧氏(shi)體(ti)晶(jing)粒間(jian)低(di)(di)(di)熔(rong)點(dian)銅(tong)(tong)液較多,有(you)(you)一定愈(yu)合(he)作(zuo)用(yong)(yong)。因(yin)此(ci)焊(han)(han)(han)(han)(han)(han)(han)縫(feng)熱裂(lie)(lie)(lie)紋(wen)傾(qing)向也較小(xiao),但熔(rong)入焊(han)(han)(han)(han)(han)(han)(han)縫(feng)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)鐵和(he)鉻等(deng)合(he)金元素使焊(han)(han)(han)(han)(han)(han)(han)縫(feng)金屬(shu)硬度(du)(du)提(ti)高(gao)(gao),韌性下降,在(zai)不(bu)(bu)銹鋼母材側的(de)(de)(de)(de)近縫(feng)區中(zhong)(zhong)(zhong)(zhong)仍有(you)(you)可能(neng)(neng)(neng)(neng)產(chan)生滲透(tou)裂(lie)(lie)(lie)紋(wen)。因(yin)此(ci),該焊(han)(han)(han)(han)(han)(han)(han)條(tiao)(tiao)只適用(yong)(yong)于(yu)對(dui)力(li)學(xue)性能(neng)(neng)(neng)(neng)要求(qiu)不(bu)(bu)高(gao)(gao)的(de)(de)(de)(de)焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)構件,通常可作(zuo)為角(jiao)接(jie)(jie)(jie)和(he)塔接(jie)(jie)(jie)焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)接(jie)(jie)(jie)頭(tou)使用(yong)(yong),也可以在(zai)中(zhong)(zhong)(zhong)(zhong)等(deng)厚度(du)(du)的(de)(de)(de)(de)奧氏(shi)體(ti)不(bu)(bu)銹鋼與銅(tong)(tong)及(ji)銅(tong)(tong)合(he)金的(de)(de)(de)(de)對(dui)接(jie)(jie)(jie)接(jie)(jie)(jie)頭(tou)中(zhong)(zhong)(zhong)(zhong)使用(yong)(yong)。選(xuan)用(yong)(yong)純鎳焊(han)(han)(han)(han)(han)(han)(han)條(tiao)(tiao)是(shi)(shi)(shi)比較理(li)想的(de)(de)(de)(de),因(yin)為鎳在(zai)液態(tai)或固態(tai)均(jun)可與銅(tong)(tong)無限互溶,所以能(neng)(neng)(neng)(neng)消除銅(tong)(tong)的(de)(de)(de)(de)有(you)(you)害(hai)作(zuo)用(yong)(yong),可有(you)(you)效地防(fang)止(zhi)裂(lie)(lie)(lie)紋(wen)的(de)(de)(de)(de)產(chan)生,提(ti)高(gao)(gao)焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)接(jie)(jie)(jie)頭(tou)的(de)(de)(de)(de)力(li)學(xue)性能(neng)(neng)(neng)(neng),適用(yong)(yong)于(yu)不(bu)(bu)同位置的(de)(de)(de)(de)焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie),可焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)各種(zhong)不(bu)(bu)同焊(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)接(jie)(jie)(jie)頭(tou),材料(liao)厚度(du)(du)不(bu)(bu)小(xiao)于(yu)1.5mm的(de)(de)(de)(de)材料(liao)均(jun)能(neng)(neng)(neng)(neng)施焊(han)(han)(han)(han)(han)(han)(han),但該種(zhong)焊(han)(han)(han)(han)(han)(han)(han)條(tiao)(tiao)價格昂貴。

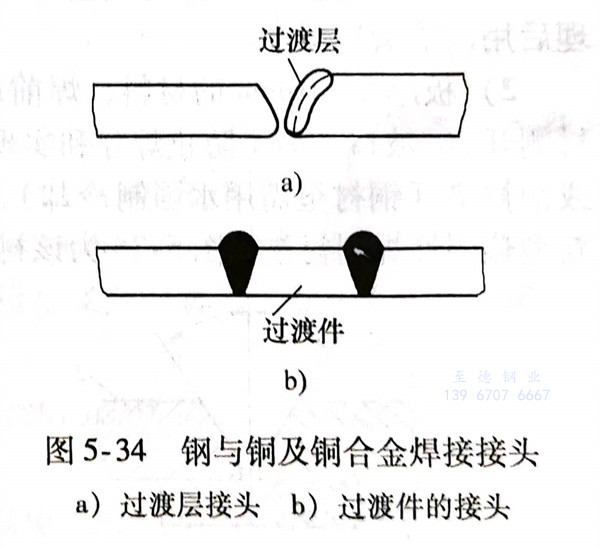

上面介紹的(de)(de)只是用一種(zhong)(zhong)焊(han)條焊(han)接(jie)(jie)(jie)兩種(zhong)(zhong)金屬的(de)(de)情(qing)況。但實際(ji)情(qing)況要(yao)復(fu)雜一些。由(you)于銅(tong)及銅(tong)合金的(de)(de)種(zhong)(zhong)類繁多,母(mu)材中某些合金元(yuan)素過(guo)(guo)(guo)渡(du)到焊(han)縫后(hou)效果往往難以預測,常常使焊(han)接(jie)(jie)(jie)性變差(cha)。在(zai)(zai)這種(zhong)(zhong)情(qing)況下可(ke)采(cai)用下列(lie)兩種(zhong)(zhong)方(fang)法(fa):在(zai)(zai)銅(tong)及銅(tong)合金上,或在(zai)(zai)不銹鋼上,或同時在(zai)(zai)兩種(zhong)(zhong)母(mu)材上堆焊(han)過(guo)(guo)(guo)渡(du)層(見圖5-34a過(guo)(guo)(guo)渡(du)層接(jie)(jie)(jie)頭),然(ran)后(hou)進行焊(han)接(jie)(jie)(jie);另(ling)一種(zhong)(zhong)方(fang)法(fa)是選擇一種(zhong)(zhong)與這兩種(zhong)(zhong)都有良好焊(han)接(jie)(jie)(jie)性的(de)(de)過(guo)(guo)(guo)渡(du)件(見圖5-34b),然(ran)后(hou)通過(guo)(guo)(guo)過(guo)(guo)(guo)渡(du)件分別選用不同的(de)(de)焊(han)條將這兩種(zhong)(zhong)金屬焊(han)接(jie)(jie)(jie)起來。

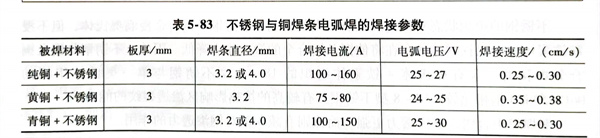

介紹一(yi)組不銹鋼與銅(tong)及銅(tong)合金的焊(han)條(tiao)電弧焊(han)的焊(han)接(jie)參數見表5-83。可選蒙乃爾型(xing)焊(han)條(tiao)[w(Ni)為(wei)70%,w(Cr)為(wei)30%]或銅(tong)焊(han)條(tiao)(T237)。

b. 焊接工(gong)藝

焊前應認真清理被焊處,徹底(di)清除油污、雜質及(ji)氧化物,使不(bu)銹鋼(gang)和銅及(ji)銅合(he)金的(de)待焊表面露出金屬光澤。

由于(yu)銅的導(dao)熱(re)(re)性比不銹(xiu)鋼(gang)好,若(ruo)對(dui)這兩種材料進行焊(han)(han)(han)前預(yu)熱(re)(re),其預(yu)熱(re)(re)溫(wen)度(du)(du)將有(you)所不同。例(li)如(ru),不銹(xiu)鋼(gang)焊(han)(han)(han)前預(yu)熱(re)(re)溫(wen)度(du)(du)若(ruo)為300~350℃,銅及(ji)銅合(he)金的預(yu)熱(re)(re)溫(wen)度(du)(du)要(yao)提高到400~450℃,才有(you)可(ke)能(neng)保證兩種金屬在焊(han)(han)(han)接熔(rong)池中溫(wen)度(du)(du)差不大。預(yu)熱(re)(re)方(fang)式(shi)可(ke)采用爐加(jia)熱(re)(re)或氣體火焰加(jia)熱(re)(re)。

焊接不銹(xiu)鋼與銅及銅合金(jin)時,為(wei)了使電弧穩定燃燒,通常采用直流反極性(xing)短弧焊方式進行施焊。

不(bu)銹(xiu)鋼鋼管(guan)(guan)與純(chun)銅(tong)銅(tong)管(guan)(guan)焊(han)接(jie)(jie)時,若(ruo)被(bei)焊(han)工件不(bu)轉(zhuan)動(dong),可(ke)采(cai)用爬坡滅弧(hu)焊(han);若(ruo)被(bei)焊(han)焊(han)件可(ke)以轉(zhuan)動(dong),則采(cai)用下坡焊(han)。最后焊(han)到(dao)焊(han)道起點(dian)接(jie)(jie)頭處(chu),先(xian)將電(dian)弧(hu)稍稍抬(tai)起,吹掉起弧(hu)端覆(fu)蓋(gai)的(de)(de)(de)熔(rong)(rong)(rong)渣,隨后壓低電(dian)弧(hu)超過引弧(hu)端的(de)(de)(de)一個(ge)熔(rong)(rong)(rong)池(chi)的(de)(de)(de)長度(du),再將電(dian)弧(hu)向(xiang)回拉(la),以填滿(man)弧(hu)坑。當不(bu)銹(xiu)鋼管(guan)(guan)與純(chun)銅(tong)管(guan)(guan)焊(han)接(jie)(jie)時,將2/3的(de)(de)(de)熔(rong)(rong)(rong)池(chi)面(mian)積(ji)控制在不(bu)銹(xiu)鋼管(guan)(guan)一側,即(ji)可(ke)保證良好的(de)(de)(de)焊(han)縫成形;這兩種金屬(shu)的(de)(de)(de)管(guan)(guan)子與管(guan)(guan)子或者板(ban)與板(ban)的(de)(de)(de)對接(jie)(jie)焊(han)時,熔(rong)(rong)(rong)池(chi)控制在接(jie)(jie)頭中間(jian)即(ji)可(ke)。

為(wei)了防止焊(han)(han)(han)(han)接接頭(tou)產生(sheng)裂(lie)紋和變形,焊(han)(han)(han)(han)后(hou)需(xu)要(yao)進行緩冷處理,以減緩焊(han)(han)(han)(han)后(hou)應(ying)變應(ying)力的(de)(de)增長(chang)速率(lv)。每焊(han)(han)(han)(han)完一(yi)道焊(han)(han)(han)(han)縫,要(yao)立即錘擊焊(han)(han)(han)(han)縫周圍,以消除焊(han)(han)(han)(han)接殘余(yu)應(ying)力,以防止下一(yi)道焊(han)(han)(han)(han)縫的(de)(de)開裂(lie)傾向;同時還能(neng)提高焊(han)(han)(han)(han)接接頭(tou)的(de)(de)致密性。

2. 埋弧焊

為了防止(zhi)焊(han)接接頭產(chan)生裂紋和(he)氣孔,應采取下述工藝(yi)措施:

a. 焊(han)接之前要徹底清除(chu)待焊(han)處的接頭、坡(po)口兩側及(ji)焊(han)絲表(biao)面的氧化物及(ji)雜質,清理后用丙酮清洗干凈。

b. 板厚8~16mm的材(cai)(cai)料,焊(han)(han)前(qian)應開(kai)70°坡口(kou)(kou),銅母(mu)(mu)材(cai)(cai)側開(kai)40°坡口(kou)(kou);在不銹鋼母(mu)(mu)材(cai)(cai)側開(kai)30°坡口(kou)(kou)。為了防止焊(han)(han)穿和實現單面(mian)焊(han)(han)雙面(mian)成形,待焊(han)(han)接頭的背面(mian)應加焊(han)(han)劑襯(chen)(chen)墊(dian)或(huo)銅襯(chen)(chen)墊(dian)(銅襯(chen)(chen)墊(dian)需用(yong)水強制冷卻),如(ru)圖(tu)5-35所(suo)示。另外,也(ye)可以采用(yong)最近出現的新型熱固性焊(han)(han)劑襯(chen)(chen)墊(dian),圖(tu)5-36為該襯(chen)(chen)墊(dian)結構示意(yi)圖(tu)。

c. 選用合理的焊劑和(he)焊絲。通常采用HJ431焊劑或(huo)HJ430焊劑,焊前必須烘干(gan),烘干(gan)溫度為200℃,烘干(gan)時間為2h。

采(cai)用奧氏體不銹鋼焊(han)(han)(han)絲,施焊(han)(han)(han)后焊(han)(han)(han)縫金屬(shu)為(wei)(wei)奧氏體組(zu)織,從銅母材側熔入焊(han)(han)(han)縫中(zhong)(zhong)的低熔點銅液聚集(ji)在(zai)奧氏體晶(jing)粒(li)之間,易(yi)使焊(han)(han)(han)縫形(xing)成裂紋。采(cai)用銅絲或(huo)鎳絲作為(wei)(wei)填充材料(liao),熔池中(zhong)(zhong)含有大量銅和鎳,結晶(jing)時(shi)奧氏體晶(jing)粒(li)間銅或(huo)鎳較(jiao)多,有一(yi)定愈合作用,所以熱裂紋傾向很小。在(zai)焊(han)(han)(han)接(jie)生(sheng)產現場,采(cai)用純銅焊(han)(han)(han)絲,在(zai)坡口中(zhong)(zhong)填放純鎳焊(han)(han)(han)絲或(huo)鎳銅焊(han)(han)(han)絲,可(ke)獲得優質的焊(han)(han)(han)接(jie)接(jie)頭。

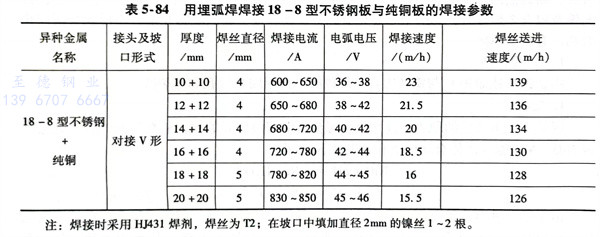

d. 選擇合(he)(he)適的(de)焊(han)(han)(han)接(jie)(jie)熱(re)輸入進(jin)行施焊(han)(han)(han)。由于銅的(de)導熱(re)性能好(hao),采用較小(xiao)的(de)焊(han)(han)(han)接(jie)(jie)熱(re)輸入施焊(han)(han)(han),在銅母材側容易產(chan)生大量氣(qi)孔和未(wei)(wei)焊(han)(han)(han)透(tou)、未(wei)(wei)熔合(he)(he)等缺陷,所(suo)以需要(yao)采用較大的(de)熱(re)輸入進(jin)行焊(han)(han)(han)接(jie)(jie)。用埋弧焊(han)(han)(han)焊(han)(han)(han)接(jie)(jie)18-8型不銹鋼板(ban)(ban)與純銅板(ban)(ban)對接(jie)(jie)焊(han)(han)(han)的(de)焊(han)(han)(han)接(jie)(jie)參數見表(biao)5-84。在焊(han)(han)(han)接(jie)(jie)過程中(zhong),焊(han)(han)(han)絲(si)偏向銅母材一(yi)側,偏離(li)焊(han)(han)(han)縫(feng)中(zhong)心線的(de)距(ju)離(li)為5~6mm。

注(zhu):焊(han)接時(shi)采用HJ431焊(han)劑,焊(han)絲為T2;在坡口中填加直徑2mm的鎳(nie)絲1~2根。

3. 氣體保護焊

由于(yu)氬氣保護可靠,熔池金屬不易發(fa)生氧化,用氬弧焊(han)焊(han)接(jie)不銹鋼與銅及(ji)銅合金時,其焊(han)接(jie)接(jie)頭質量很(hen)高。重要的焊(han)接(jie)結構均選(xuan)用此焊(han)接(jie)方法。

氬(ya)弧(hu)焊時,為(wei)了(le)提高生產效率和防止焊縫出現缺陷,應注(zhu)意(yi)下述事項:

a. 焊接時應在引弧板上引燃電弧,電弧引燃后(hou)應迅速移到(dao)銅母材側進(jin)行局(ju)部預(yu)熱(re),預(yu)熱(re)溫度為300~400℃,預(yu)熱(re)時要通入氬(ya)氣(qi)保護,以防氧化。

b. 采用(yong)短弧焊(han),電(dian)弧中心要偏向銅母材約(yue)2~4mm,使不銹(xiu)(xiu)鋼與銅受(shou)熱(re)均勻,以防止不銹(xiu)(xiu)鋼一側受(shou)熱(re)過多而(er)產生燒(shao)穿、咬邊(bian)或銅母材受(shou)熱(re)溫度不足而(er)發(fa)生未焊(han)透和未熔合等(deng)缺陷。

c. 焊(han)接(jie)結束時(shi),由于電弧熱作(zuo)用已(yi)有較長時(shi)間的積累效應,熔池(chi)溫度高,應提高焊(han)接(jie)速度,并要注意填滿弧坑。

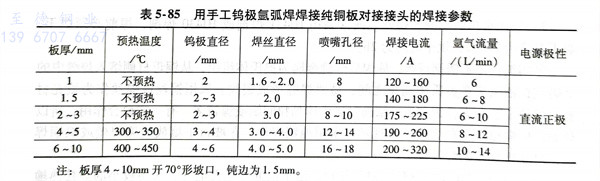

d. 焊(han)(han)(han)(han)后緩冷(leng)時(shi),也應(ying)通入氬(ya)氣進行(xing)保護,以(yi)免焊(han)(han)(han)(han)縫氧化。不銹鋼(gang)與銅(tong)及(ji)銅(tong)合金(jin)的氬(ya)弧(hu)焊(han)(han)(han)(han)焊(han)(han)(han)(han)接(jie)參數(shu),可參照氬(ya)弧(hu)焊(han)(han)(han)(han)單(dan)獨焊(han)(han)(han)(han)接(jie)銅(tong)及(ji)銅(tong)合金(jin)的焊(han)(han)(han)(han)接(jie)參數(shu)。表5-85為用手工鎢(wu)極(ji)氬(ya)弧(hu)焊(han)(han)(han)(han)焊(han)(han)(han)(han)接(jie)純(chun)銅(tong)板對接(jie)接(jie)頭的焊(han)(han)(han)(han)接(jie)參數(shu)。焊(han)(han)(han)(han)絲(si)可選用ERNi-1、ERNiCrFe-5、ERNi-CrFe-7和(he)ERNiCr-3等(deng)型號。

注:板厚4~10mm開(kai)70°形坡口,鈍邊為(wei)1.5mm。