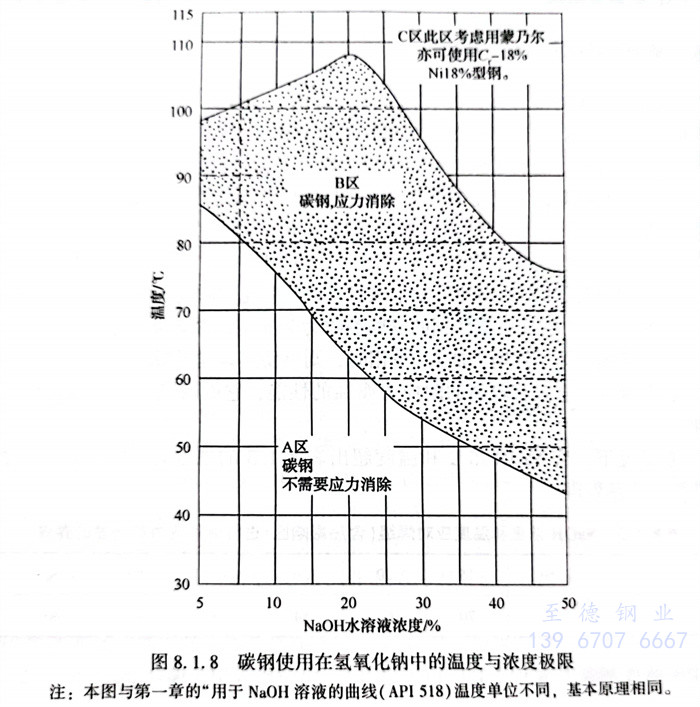

金屬在堿液中的應力腐蝕破裂稱堿脆。碳鋼、低合金鋼、不銹(xiu)鋼(gang)等多種金屬材料皆可發生堿脆。碳鋼(含低合金鋼)發生堿脆的趨向見圖8.1.6。輸送NaOH的碳鋼或低合金鋼管道在一定的條件下,能引起碳鋼材料的應力腐蝕開裂(堿脆)。

由(you)圖(tu)8.1.6可知(zhi),氫氧化(hua)鈉濃(nong)度(du)在5%以(yi)上的(de)(de)全(quan)部濃(nong)度(du)范圍內(nei)碳(tan)鋼幾乎都(dou)可能產生(sheng)(sheng)堿(jian)脆,堿(jian)脆的(de)(de)最(zui)低(di)溫度(du)為(wei)(wei)50℃,所(suo)需堿(jian)液的(de)(de)濃(nong)度(du)為(wei)(wei)40%~50%。以(yi)沸(fei)點附近(jin)的(de)(de)高(gao)溫區最(zui)易發生(sheng)(sheng)。裂紋(wen)呈晶(jing)間(jian)型。奧(ao)氏體(ti)不銹(xiu)鋼發生(sheng)(sheng)堿(jian)脆的(de)(de)趨向見圖(tu)8.1.7。氫氧化(hua)鈉濃(nong)度(du)在0.1%以(yi)上的(de)(de)濃(nong)度(du)時(shi)(shi)18-8型奧(ao)氏體(ti)不銹(xiu)鋼即可發生(sheng)(sheng)堿(jian)脆。以(yi)氫氧化(hua)鈉濃(nong)度(du)40%最(zui)危險,這(zhe)時(shi)(shi)發生(sheng)(sheng)堿(jian)脆的(de)(de)溫度(du)為(wei)(wei)115℃左右。超低(di)碳(tan)不銹(xiu)鋼的(de)(de)堿(jian)脆裂紋(wen)為(wei)(wei)穿晶(jing)型,含碳(tan)量高(gao)時(shi)(shi),堿(jian)脆裂紋(wen)則為(wei)(wei)晶(jing)間(jian)型或(huo)混合(he)型。當奧(ao)氏體(ti)不銹(xiu)鋼中加(jia)入2%鉬時(shi)(shi),則可使其堿(jian)脆界限(xian)縮小,并向堿(jian)的(de)(de)高(gao)濃(nong)度(du)區域(yu)移動(dong)。鎳和鎳基合(he)金具有較高(gao)的(de)(de)耐應力腐(fu)蝕的(de)(de)性能,它的(de)(de)堿(jian)脆范圍變得(de)狹窄,而且位于高(gao)溫濃(nong)堿(jian)區。

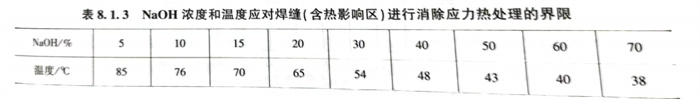

一般情況下(xia),當NaOH濃(nong)度和溫度超出表8.1.3的規定時(shi),應對(dui)焊(han)縫(feng)(含熱(re)影響區)進行消(xiao)除應力熱(re)處理。

表(biao)8.1.3 NaOH 濃度和(he)溫度應對焊縫(含熱(re)影響(xiang)區)進行(xing)消除應力熱(re)處理的界(jie)限

當NaOH濃度和(he)溫度超出表8.1.4的規定時,應考慮采用含鎳合金。

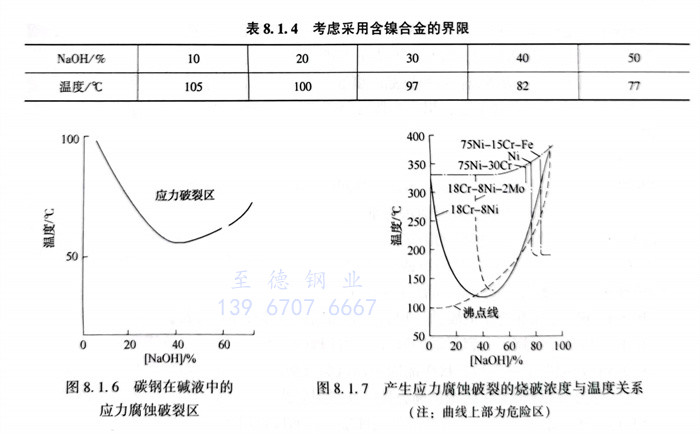

碳(tan)鋼和鎳合(he)金(jin)鋼在NaOH溶液中的應用范圍見圖(tu) 8.1.8 所示