一、爆破片概述

爆(bao)(bao)破(po)片的(de)作用是在設備(bei)或管(guan)道壓(ya)力(li)突然升(sheng)高(gao)尚未引起爆(bao)(bao)炸前(qian),由于爆(bao)(bao)破(po)片兩(liang)側(ce)壓(ya)力(li)差達到預定溫(wen)度(du)下(xia)的(de)預定值時,即先行(xing)破(po)裂,排(pai)出設備(bei)或管(guan)道內的(de)高(gao)壓(ya)介質。因此(ci)爆(bao)(bao)破(po)片是防(fang)止設備(bei)或管(guan)道破(po)裂的(de)一(yi)種安全泄放(fang)(fang)裝置(zhi)。爆(bao)(bao)破(po)片安全裝置(zhi)具有結(jie)構簡(jian)單、靈敏(min)、準確、無泄漏、泄放(fang)(fang)能力(li)強等優(you)點。能夠在黏稠、高(gao)溫(wen)、低溫(wen)、腐蝕的(de)環境下(xia)可靠地工作,還是超(chao)高(gao)壓(ya)容(rong)器(qi)的(de)理想安全裝置(zhi)。

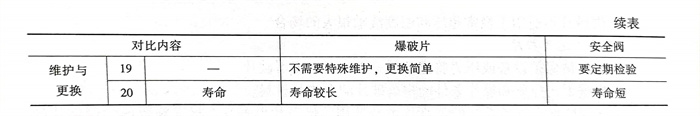

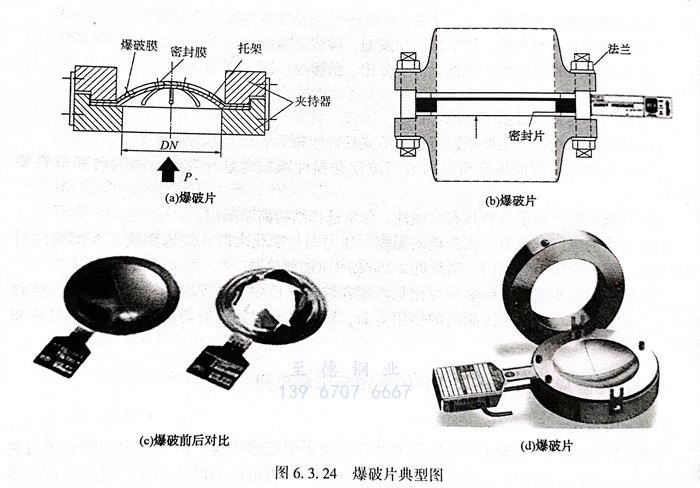

爆破片典型圖(tu)(tu)見圖(tu)(tu)6.3.24。

二、爆破片的分類(lei)

按(an)照結構(gou)型(xing)(xing)(xing)式來(lai)分類,爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)主要有(you)三種,即(ji)平板型(xing)(xing)(xing)、正(zheng)拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)和反拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)。平板型(xing)(xing)(xing)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)的(de)(de)綜合性(xing)能較差,主要用于(yu)低壓(ya)和超低壓(ya)工況(kuang),尤其(qi)是(shi)大型(xing)(xing)(xing)料倉。正(zheng)拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)和反拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)的(de)(de)應用場合較多。對于(yu)傳(chuan)統的(de)(de)正(zheng)拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian),其(qi)工作原理是(shi)利(li)用材料的(de)(de)拉伸強(qiang)度(du)(du)來(lai)控(kong)制(zhi)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)壓(ya)力(li)(li),爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)的(de)(de)拱(gong)(gong)(gong)(gong)出(chu)方(fang)向與壓(ya)力(li)(li)作用方(fang)向一(yi)致(zhi)。在使用中發現,所有(you)的(de)(de)正(zheng)拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)都存在相同的(de)(de)局(ju)限:爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)時,爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)碎(sui)片(pian)(pian)(pian)(pian)會(hui)進入泄放管(guan)道;由于(yu)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)的(de)(de)中心厚度(du)(du)被有(you)意減弱,易于(yu)因疲勞而提(ti)前(qian)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po);操作壓(ya)力(li)(li)不(bu)(bu)能超過(guo)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)最小(xiao)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)壓(ya)力(li)(li)的(de)(de)65%,由此(ci)導致(zhi)了(le)反拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)的(de)(de)出(chu)現。這種爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)利(li)用材料的(de)(de)抗壓(ya)強(qiang)度(du)(du)來(lai)控(kong)制(zhi)其(qi)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)壓(ya)力(li)(li),較之(zhi)傳(chuan)統的(de)(de)正(zheng)拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian),其(qi)具有(you)抗疲勞性(xing)能優(you)良、爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)時不(bu)(bu)產生(sheng)碎(sui)片(pian)(pian)(pian)(pian)且操作壓(ya)力(li)(li)可(ke)達其(qi)最小(xiao)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)壓(ya)力(li)(li)90%以上的(de)(de)優(you)點(dian)。細分之(zhi)下,反拱(gong)(gong)(gong)(gong)型(xing)(xing)(xing)爆(bao)(bao)(bao)(bao)破(po)(po)(po)(po)(po)(po)(po)片(pian)(pian)(pian)(pian)包括反拱(gong)(gong)(gong)(gong)刻槽型(xing)(xing)(xing)、反拱(gong)(gong)(gong)(gong)腭(e)齒型(xing)(xing)(xing)以及(ji)反拱(gong)(gong)(gong)(gong)刀(dao)架型(xing)(xing)(xing)等。

三、爆破(po)片(pian)的特點

爆破(po)片與安全閥(fa)比(bi)較(jiao),具有結(jie)構簡單、靈敏、可靠(kao)、經濟(ji)、無(wu)泄漏、適用(yong)性(xing)強等優越性(xing),但(dan)也有其局限性(xing),其特點(dian)如下:

(1)密封性能好(hao),在(zai)設備正常工作壓力(li)下(xia)能保(bao)持嚴(yan)密不(bu)漏(lou)。

(2)泄壓反應(ying)迅速,爆(bao)破片的動作一般在2~10ms內(nei)完成,而安全閥則(ze)因為機械滯后作用,全部動作時間要高(gao)1~2個(ge)數量級。

(3)對黏稠性或粉末(mo)狀污物不敏(min)感。即使氣體(ti)中含有一定(ding)量的污物也不致影響它的正常動作,不像安全閥(fa)那樣(yang),容易黏結或堵塞。

(4)爆破(po)元件(膜片)動作后不(bu)能復位,不(bu)但設備內介質全部流(liu)失,設備也得中止運行。

(5)動作壓(ya)力不太穩定,爆破片(pian)的爆破壓(ya)力允許(xu)偏差(cha)一般都(dou)比安全閥的穩定壓(ya)力允許(xu)偏差(cha)大一些(xie)。

(6)爆破(po)片的(de)使用壽命(ming)較短,常因疲勞而(er)早期失效。

四、爆破片的適用場所

(1)獨立的(de)(de)壓力(li)容器和/或(huo)壓力(li)管道系統設有安全閥、爆破片裝(zhuang)置(zhi)或(huo)這二者的(de)(de)組合裝(zhuang)置(zhi)。

(2)滿足下列情況之一(yi)應優先選(xuan)用爆破片:

①. 壓力有(you)可能(neng)迅速上升的;

②. 泄放介質(zhi)含(han)有顆粒、易沉淀、易結晶、易聚合和介質(zhi)黏度(du)較大;

③. 泄放介(jie)質有強腐蝕性,使用安全閥時其價值很高;

④. 工(gong)藝(yi)介質(zhi)十分昂貴(gui)或有劇毒,在工(gong)作過程中(zhong)不允(yun)許有任何泄(xie)漏,應與安(an)全閥串聯使用;

⑤. 工(gong)作壓(ya)力很(hen)低(di)或很(hen)高(gao)時,選用安全閥則其(qi)制(zhi)造比(bi)較困(kun)難;

⑥. 當(dang)使(shi)用溫度(du)較低(di)而(er)影響(xiang)安全閥工作特性時;

⑦. 需要較大泄放面積。

(3)對于一次性使用(yong)的(de)管(guan)路系(xi)統(tong)(如開車吹(chui)掃的(de)管(guan)路放空系(xi)統(tong)),爆破片的(de)破裂不影響操作和生產(chan)的(de)場(chang)合,設置爆破片。

(4)為(wei)減(jian)少爆破(po)片破(po)裂后的(de)工藝介質的(de)損失,可與(yu)安(an)全閥串(chuan)聯使用。

(5)作(zuo)為(wei)壓(ya)力容(rong)器的(de)附加安(an)全設(she)施(shi),可與(yu)安(an)全閥并(bing)聯使用(yong),例如爆破(po)片僅用(yong)于(yu)火災情(qing)況下的(de)超壓(ya)泄(xie)放(fang)。

(6)為增(zeng)加異(yi)常工況(如火(huo)災(zai)等)下的(de)泄(xie)放面積,爆(bao)破片可并聯使用。

(7)爆破片不(bu)適用于經常(chang)超(chao)壓和溫度波動很大的場合(he)。

五、爆破(po)片選用(yong)程序(xu)

(1)確定(ding)被保(bao)護設備或壓力管(guan)道系統(tong)是(shi)否需要設置爆破片。

(2)根據工(gong)藝介(jie)質和操作條件(jian)確(que)定爆破片的形式及材(cai)料。

(3)根據被保護(hu)管道系統(tong)的最高壓(ya)力(li)(li)及選用的爆破(po)片形(xing)式,按(an)標準(zhun)規范(fan)確定爆破(po)片的最小標定爆破(po)壓(ya)力(li)(li),設計爆破(po)壓(ya)力(li)(li)。

(4)根據工藝條件、物理參數計算(suan)爆破(po)片(pian)的安(an)全泄(xie)放(fang)量(liang),選定爆破(po)片(pian)的泄(xie)放(fang)面積和泄(xie)放(fang)口徑(jing)。

(5)填寫爆(bao)破片(pian)裝置(zhi)規格(ge)書,提供(gong)給(gei)材(cai)料采購專(zhuan)業(ye),作為訂(ding)貨的技術條件。

六、爆破(po)片有關(guan)標(biao)準規范(fan)

HG/T 20570.3《工(gong)藝系統(tong)工(gong)程設(she)計(ji)技(ji)術(shu)規定--爆(bao)破片的設(she)置和選(xuan)用》

GB 567《爆破片與爆破片裝置》

GB 12353《拱(gong)型金(jin)屬爆(bao)破片(pian)裝(zhuang)置(zhi)分類與安裝(zhuang)尺寸》

GB/T 14566《正拱形金屬爆破片型式與參數》

GB/T 14567《反拱形(xing)金屬(shu)爆破片型(xing)式與參數》

GB/T 14568《開縫形金屬爆破片型式(shi)與(yu)參(can)數》

GB/T 16181《爆破片裝置夾(jia)持器型式和外形尺(chi)寸》

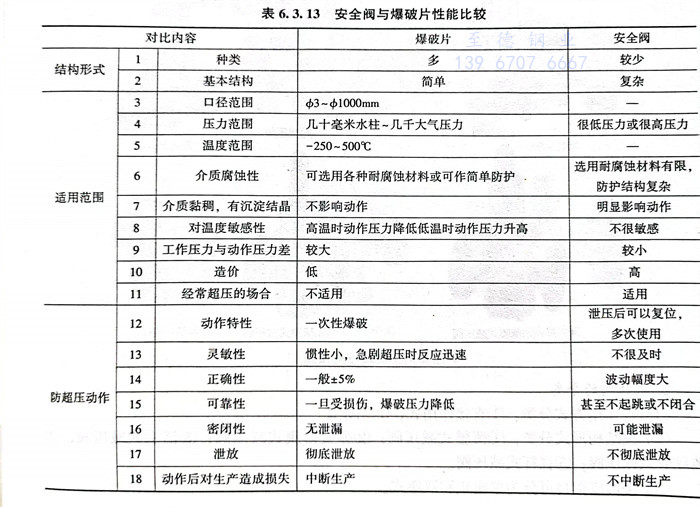

七、安全閥與爆破片性能比較(jiao)

安全閥與爆(bao)破片(pian)性能比(bi)較見(jian)表6.3.13。