一、限(xian)流(liu)孔板的作(zuo)用(yong)與形(xing)式

限流(liu)(liu)孔(kong)板設置(zhi)在管(guan)道中用(yong)于(yu)限制流(liu)(liu)體(ti)的(de)流(liu)(liu)量或(huo)降低(di)流(liu)(liu)體(ti)的(de)壓力。有的(de)設計單位(wei)由管(guan)道專業負(fu)責選用(yong),有的(de)設計單位(wei)由儀表專業負(fu)責選用(yong)。限流(liu)(liu)孔(kong)板根據 GB/T 2624、HG/T20570、GD 2000、GD 87等標準設計制造。

限流孔板用(yong)于以下幾個方面:

①. 工藝物料(liao)需要降壓且精度要求不高。

②. 在管道中閥門上、下游需要有較大壓降時,為減少流體對閥門的沖蝕,當經孔板節流不會產生氣相時,可在閥門上游串聯孔板。

③. 流(liu)體(ti)需要小流(liu)量(liang)(liang)且連(lian)續流(liu)通(tong)的(de)地方,如泵的(de)沖(chong)洗管道(dao)(dao)、熱(re)備用泵的(de)旁路(lu)管道(dao)(dao)(低(di)流(liu)量(liang)(liang)保護管道(dao)(dao))、分析(xi)取樣管等場所(suo)。

④. 需要降壓以減(jian)少(shao)噪聲(sheng)或磨(mo)損(sun)的地方,如放空系統。

限(xian)流(liu)孔(kong)板為一同(tong)心(xin)銳孔(kong)板,用于限(xian)制(zhi)流(liu)體的(de)流(liu)量(liang)(liang)或降(jiang)(jiang)低(di)流(liu)體的(de)壓(ya)力(li)。流(liu)體通(tong)過(guo)孔(kong)板就會產生壓(ya)力(li)降(jiang)(jiang),通(tong)過(guo)孔(kong)板的(de)流(liu)量(liang)(liang)則(ze)隨壓(ya)力(li)降(jiang)(jiang)的(de)增大(da)而增大(da)。但當壓(ya)力(li)降(jiang)(jiang)超過(guo)一定數值,即超過(guo)臨界壓(ya)力(li)降(jiang)(jiang)時,不論出口(kou)壓(ya)力(li)如何(he)降(jiang)(jiang)低(di),流(liu)量(liang)(liang)將(jiang)維持一定的(de)數值而不再增加。限(xian)流(liu)孔(kong)板就是根據(ju)這個原(yuan)理用來限(xian)制(zhi)流(liu)體的(de)流(liu)量(liang)(liang)或降(jiang)(jiang)低(di)流(liu)體的(de)壓(ya)力(li)。

限(xian)流孔(kong)板(ban)作為節(jie)流元件,由于具有結構簡單、易加工、制造(zao)成本低(di)、安裝方(fang)便等(deng)優點,在(zai)滿足(zu)工藝要求的(de)(de)前提(ti)下,使用限(xian)流孔(kong)板(ban)代替調節(jie)閥來限(xian)定流量或降(jiang)低(di)壓力(li),將(jiang)會大大地(di)降(jiang)低(di)投資(zi)和操作維(wei)修費用,因(yin)此在(zai)國外已被廣泛地(di)應用于工藝裝置(zhi),對裝置(zhi)的(de)(de)安全運行起著重要的(de)(de)作用。

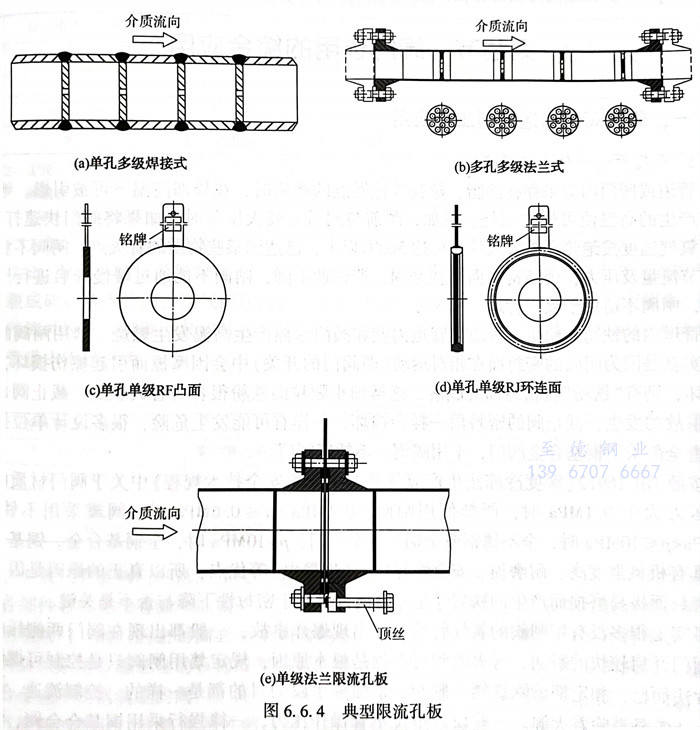

限(xian)流(liu)(liu)孔板按(an)孔板上開(kai)孔數分為(wei)單孔板和(he)多孔板,按(an)板數可分為(wei)單板和(he)多板。公稱(cheng)直(zhi)徑:10mm≤DN≤1000mm,公稱(cheng)壓力:PN≤42MPa。工作溫度(du):50℃≤t≤550℃ ,連(lian)接(jie)(jie)方式:焊(han)接(jie)(jie)、法蘭連(lian)接(jie)(jie)。典型限(xian)流(liu)(liu)孔板見圖6.6.4。

二、限(xian)流(liu)孔板選型的一般(ban)要(yao)求(qiu)

1. 氣體、蒸汽

為了避免使用(yong)限(xian)流(liu)孔板(ban)(ban)的管路出現噎塞流(liu),限(xian)流(liu)孔板(ban)(ban)后(hou)壓(ya)力(li)(P2)不能(neng)小于板(ban)(ban)前(qian)壓(ya)力(li)(p1)的55%,即P2≥0.55p1,因此當P2<0.55p1 時,不能(neng)用(yong)單板(ban)(ban),要(yao)(yao)選擇多板(ban)(ban)。板(ban)(ban)數要(yao)(yao)保證每板(ban)(ban)的板(ban)(ban)后(hou)壓(ya)力(li)大于板(ban)(ban)前(qian)壓(ya)力(li)的55%。

2. 液(ye)體

當液(ye)體(ti)壓(ya)降小于(yu)(yu)(yu)或(huo)等于(yu)(yu)(yu)2.5MPa時,選擇單(dan)板孔(kong)(kong)板。當液(ye)體(ti)壓(ya)降大于(yu)(yu)(yu)2.5MPa時,選擇多板孔(kong)(kong)板,且(qie)使每(mei)塊孔(kong)(kong)板的壓(ya)降小于(yu)(yu)(yu)2.5MPa。

三、孔數的(de)確定

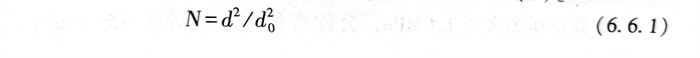

管道公稱直(zhi)徑(jing)(jing)≤150mm的管路,通常(chang)采用(yong)單孔(kong)(kong)(kong)(kong)(kong)(kong)孔(kong)(kong)(kong)(kong)(kong)(kong)板(ban);150mm時(shi),采用(yong)多(duo)孔(kong)(kong)(kong)(kong)(kong)(kong)孔(kong)(kong)(kong)(kong)(kong)(kong)板(ban)。多(duo)孔(kong)(kong)(kong)(kong)(kong)(kong)孔(kong)(kong)(kong)(kong)(kong)(kong)板(ban)的孔(kong)(kong)(kong)(kong)(kong)(kong)徑(jing)(jing)(do),一般可選用(yong)12.5mm,20mm,25mm,40mm。在計算(suan)多(duo)孔(kong)(kong)(kong)(kong)(kong)(kong)孔(kong)(kong)(kong)(kong)(kong)(kong)板(ban)時(shi),首先(xian)按(an)(an)單孔(kong)(kong)(kong)(kong)(kong)(kong)孔(kong)(kong)(kong)(kong)(kong)(kong)板(ban)求出孔(kong)(kong)(kong)(kong)(kong)(kong)徑(jing)(jing)(d),然后按(an)(an)式(6.6.1)求取選用(yong)的多(duo)孔(kong)(kong)(kong)(kong)(kong)(kong)孔(kong)(kong)(kong)(kong)(kong)(kong)板(ban)的孔(kong)(kong)(kong)(kong)(kong)(kong)數(N)。