1. 伴管管徑及(ji)根數的選用

①. 伴(ban)管(guan)管(guan)徑(jing)宜為10、12、DN15、DN20、DN25,伴(ban)管(guan)根(gen)數不宜超(chao)過4根(gen)。

②. 在不(bu)同(tong)環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)及(ji)工藝操作條件下,蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管管徑(jing)及(ji)根(gen)(gen)數從SH/T 3040提供的(de)四個表(biao)(biao)(biao)(表(biao)(biao)(biao)1蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du)143℃/183℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)5℃;表(biao)(biao)(biao)2蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du)143℃/183℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)-5℃;表(biao)(biao)(biao)3蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du)143℃/183℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)-15℃;表(biao)(biao)(biao)4蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du)143℃/183℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)-25℃)中(zhong)選(xuan)擇(ze);熱水伴(ban)(ban)(ban)(ban)管管徑(jing)及(ji)根(gen)(gen)數從SH/T 3040提供的(de)四個表(biao)(biao)(biao)(表(biao)(biao)(biao)5蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du)90℃/100℃/110℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)5℃;表(biao)(biao)(biao)6蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du) 90℃/100℃/110℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)-5℃;表(biao)(biao)(biao)7蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du)90℃/100℃/110℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)-15℃;表(biao)(biao)(biao)8蒸(zheng)汽(qi)伴(ban)(ban)(ban)(ban)管溫(wen)(wen)度(du)(du)90℃/100℃/110℃、環(huan)(huan)境(jing)(jing)(jing)溫(wen)(wen)度(du)(du)-25℃)中(zhong)選(xuan)擇(ze)。

③. 環境溫(wen)度、伴管(guan)(guan)介質(zhi)(zhi)的操作(zuo)條件、保溫(wen)材(cai)料制(zhi)品的熱導(dao)率及傳熱系(xi)數等數據與表1~表8不同時,伴管(guan)(guan)管(guan)(guan)徑(jing)及根數(采用硬質(zhi)(zhi)或半硬質(zhi)(zhi)圓形保溫(wen)材(cai)料制(zhi)品)按下面公(gong)式計算。

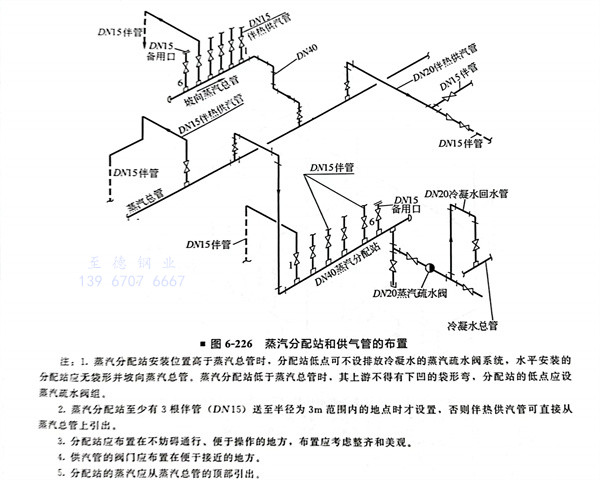

2. 蒸(zheng)汽(qi)分配站(zhan)和疏水站(zhan)

①. 對于(yu)蒸(zheng)汽(qi)分配(pei)站(zhan)和疏(shu)水站(zhan)的(de)管徑(jing)也給出(chu)了下面的(de)公式,計算出(chu)S值,再查(cha)詢SH3040相應的(de)表格來獲得(de)蒸(zheng)汽(qi)分配(pei)站(zhan)和疏(shu)水站(zhan)的(de)管徑(jing)。

S=A+2B+3C 式中A-DN15、612、10伴(ban)管(guan)(guan)根數;B-DN20伴(ban)管(guan)(guan)根數;C-DN25伴(ban)管(guan)(guan)根數。

②. 在3m半徑范圍內如有(you)3個或3個以上的伴熱(re)點(dian)及回收點(dian)時(shi),蒸(zheng)汽伴熱(re)系(xi)統(tong)應設置(zhi)(zhi)蒸(zheng)汽分配站和疏水站,熱(re)水伴熱(re)系(xi)統(tong)應設置(zhi)(zhi)熱(re)水分配站和熱(re)水回水站。站的設置(zhi)(zhi)應考(kao)(kao)慮(lv)統(tong)一考(kao)(kao)慮(lv),布局合理,方便操作和維(wei)修。

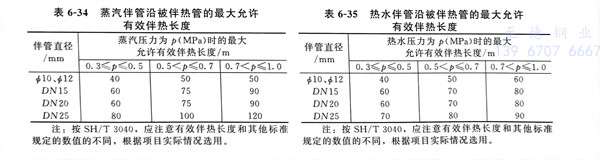

3. 蒸汽伴(ban)(ban)管(guan)沿被(bei)伴(ban)(ban)熱管(guan)的(de)最大允許有(you)效伴(ban)(ban)熱長(chang)度(包括(kuo)垂直管(guan)道)(表(biao)6-34)

凝結水不回收時,最(zui)(zui)(zui)大(da)允許(xu)有效(xiao)(xiao)伴(ban)熱(re)長度(du)可延長20%;采(cai)用導熱(re)膠泥時,最(zui)(zui)(zui)大(da)允許(xu)有效(xiao)(xiao)伴(ban)熱(re)長度(du)宜縮短(duan)20%;對于(yu)(yu)出現U形(xing)彎時,在超(chao)過(guo)規(gui)定(ding)數值(蒸(zheng)汽壓(ya)(ya)力0.3~0.5MPa,累(lei)計(ji)上(shang)升(sheng)4m;蒸(zheng)汽壓(ya)(ya)力大(da)于(yu)(yu)0.5~0.7MPa,累(lei)計(ji)上(shang)升(sheng)5m;蒸(zheng)汽壓(ya)(ya)力大(da)于(yu)(yu)0.7~1MPa,累(lei)計(ji)上(shang)升(sheng)6m)時宜適當(dang)減少(shao)最(zui)(zui)(zui)大(da)允許(xu)有效(xiao)(xiao)伴(ban)熱(re)長度(du),但伴(ban)管累(lei)計(ji)上(shang)升(sheng)高度(du)不宜超(chao)過(guo)10m。

注(zhu):1. 蒸(zheng)汽(qi)(qi)(qi)分(fen)(fen)配(pei)站安裝位(wei)置高于(yu)蒸(zheng)汽(qi)(qi)(qi)總管(guan)時(shi),分(fen)(fen)配(pei)站低點可不(bu)設排放(fang)冷凝(ning)水的(de)蒸(zheng)汽(qi)(qi)(qi)疏(shu)水閥系統,水平安裝的(de)分(fen)(fen)配(pei)站應無袋(dai)形并坡向(xiang)蒸(zheng)汽(qi)(qi)(qi)總管(guan)。蒸(zheng)汽(qi)(qi)(qi)分(fen)(fen)配(pei)站低于(yu)蒸(zheng)汽(qi)(qi)(qi)總管(guan)時(shi),其(qi)上游不(bu)得(de)有下凹的(de)袋(dai)形彎,分(fen)(fen)配(pei)站的(de)低點應設蒸(zheng)汽(qi)(qi)(qi)疏(shu)水閥組。

2. 蒸汽(qi)分配站至(zhi)少有3根伴(ban)管(DN15)送至(zhi)半徑為3m范圍內的地(di)點時才設(she)置,否則(ze)伴(ban)熱(re)供汽(qi)管可直接從蒸汽(qi)總管上引出。

3. 分配站應布置在不妨礙通行(xing)、便于操作(zuo)的地方,布置應考慮整齊和(he)美觀。

4. 供汽管的閥(fa)門(men)應(ying)布(bu)置(zhi)在便于接近的地方(fang)。

5. 分(fen)配站(zhan)的(de)蒸汽(qi)應從蒸汽(qi)總(zong)管的(de)頂部引出。

4. 熱水伴管沿(yan)被伴熱管的最大(da)允許有(you)效伴熱長度(包括垂直(zhi)管道)(表(biao)6-35)

注(zhu):按SH/T 3040,應注(zhu)意有效伴熱長(chang)度和(he)其他標準規(gui)定的(de)數值的(de)不同,根(gen)據項目(mu)實際情況選用。

注:按 SH/T 3040,應注意有效伴(ban)熱長度和其(qi)他(ta)標準規定的數值的不同(tong),根據(ju)項目實際(ji)情況(kuang)選用。