焊條電弧焊(shielded metal arc welding,SMAW)過去稱之為手弧焊,它是焊接奧氏體不銹鋼常用的一種焊接方法。

一、對(dui)弧焊電源的基本要(yao)求

①. 應具有陡降外特(te)性(xing)、良好的動特(te)性(xing)和良好的調(diao)節特(te)性(xing)。

②. 合適的(de)(de)空(kong)(kong)載電(dian)壓。為(wei)了保證焊工的(de)(de)安全和易引(yin)弧(hu),弧(hu)焊電(dian)源應有(you)合適的(de)(de)空(kong)(kong)載電(dian)壓。交(jiao)流焊機空(kong)(kong)載電(dian)壓為(wei)65~85V,直(zhi)流焊機空(kong)(kong)載電(dian)壓為(wei)50~90V。

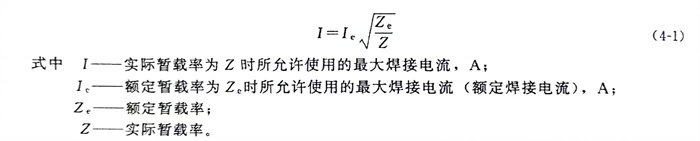

③. 合適的功率。為保證焊機在焊接過程中發熱量不超過焊機額定的發熱量,電焊機應有合適的功率。不銹鋼管(guan)焊接的最大焊接電流一般控制在200A左右,用老式大功率焊接電源在小電流段的性能往往不太好,難于保證電弧高度的穩定性,所以選用中、小功率新式焊機為好。為充分發揮設備的潛力并不超過焊機額定的發熱量,焊接的最大許可焊接電流可按下式確定:

二、常(chang)用弧焊電(dian)源

①. ZXG1-400系列弧焊(han)(han)(han)電(dian)源(yuan)(yuan)。ZXG1-400系列整流(liu)弧焊(han)(han)(han)電(dian)源(yuan)(yuan)是動圈式硅整流(liu)直流(liu)弧焊(han)(han)(han)電(dian)源(yuan)(yuan),此產品技術上比較成熟,較受焊(han)(han)(han)工歡迎。這類(lei)弧焊(han)(han)(han)整流(liu)器具備(bei)弧焊(han)(han)(han)所要求的各種功能,成本(ben)低(di)、空(kong)載(zai)耗電(dian)量小(xiao),但噪(zao)聲稍大,是焊(han)(han)(han)接不銹鋼(gang)常用的弧焊(han)(han)(han)電(dian)源(yuan)(yuan)之(zhi)一。

②. ZX5-400系列(lie)弧(hu)焊(han)(han)電(dian)(dian)源(yuan)。ZX5-400系列(lie)弧(hu)焊(han)(han)電(dian)(dian)源(yuan)是(shi)(shi)晶閘管(guan)整流(liu)式直流(liu)弧(hu)焊(han)(han)電(dian)(dian)源(yuan),此產品(pin)技(ji)術上比(bi)較(jiao)成熟(shu),所以較(jiao)受焊(han)(han)工(gong)歡迎(ying)。這類弧(hu)焊(han)(han)整流(liu)器具備弧(hu)焊(han)(han)所要求的各種功能,成本(ben)低、空載耗(hao)電(dian)(dian)量小,使用(yong)時噪聲小,是(shi)(shi)焊(han)(han)接(jie)不銹鋼常用(yong)的弧(hu)焊(han)(han)電(dian)(dian)源(yuan)之一(yi)。

③. ZX7-250系(xi)列(lie)逆變式弧(hu)焊(han)電源。1977年(nian)瑞典首(shou)次推出逆變式(變頻(pin)式)弧(hu)焊(han)電源,20世紀(ji)80年(nian)代,我國逆變式弧(hu)焊(han)整流(liu)(liu)器(qi)得(de)到(dao)迅速發展。它是以工業用50Hz/60Hz頻(pin)率的(de)交流(liu)(liu)電,經整流(liu)(liu)后逆變成幾千至幾萬赫茲(zi)的(de)中(zhong)頻(pin)交流(liu)(liu)電,再經中(zhong)頻(pin)變壓器(qi)降壓后通過(guo)整流(liu)(liu)器(qi)、電抗器(qi)、濾(lv)波后得(de)到(dao)焊(han)接所需的(de)電弧(hu)電壓和焊(han)接電流(liu)(liu)。這種設(she)備耗(hao)材(cai)更少,體積更小,重量(liang)輕,具有良好(hao)的(de)動特性,調(diao)節速度快,焊(han)接參數均(jun)可無級調(diao)節。由于省去了鐵芯變壓器(qi),空載損耗(hao)極(ji)少,只有數十到(dao)百余瓦,是一種高效節能的(de)弧(hu)焊(han)電源。

④. AXQ-320、AXC-400焊(han)(han)(han)(han)機(ji)(ji)(ji)。AXQ-320焊(han)(han)(han)(han)機(ji)(ji)(ji)是(shi)汽油機(ji)(ji)(ji)驅(qu)(qu)動的電(dian)(dian)(dian)焊(han)(han)(han)(han)機(ji)(ji)(ji),額(e)定焊(han)(han)(han)(han)接電(dian)(dian)(dian)流(liu)320A、AXC-400焊(han)(han)(han)(han)機(ji)(ji)(ji)是(shi)柴油機(ji)(ji)(ji)驅(qu)(qu)動的電(dian)(dian)(dian)焊(han)(han)(han)(han)機(ji)(ji)(ji),額(e)定焊(han)(han)(han)(han)接電(dian)(dian)(dian)流(liu)400A,兩者的缺點是(shi)噪聲(sheng)大(da)(da)、耗能大(da)(da),屬于淘汰(tai)產品(pin)。目前此類產品(pin)主要用(yong)于野外(wai)無(wu)電(dian)(dian)(dian)源的情況下使用(yong)。

⑤. BX3-300 系(xi)列焊(han)機(ji)。BX3-300 系(xi)列焊(han)機(ji)是動(dong)圈(quan)式交(jiao)流弧焊(han)電源(又稱弧焊(han)變壓器),其特(te)點(dian)是設(she)備結構簡單、成(cheng)本低,但電弧穩定性差(cha)(特(te)別是焊(han)接電流小(xiao)于(yu)90A時),焊(han)接過程(cheng)中(zhong)飛濺(jian)多,焊(han)機(ji)噪聲較(jiao)大(da),一般用于(yu)焊(han)接非重要焊(han)接件。