在線亞洲日產一區二區:不銹鋼管道系統的吹掃適用于氣體管道。蒸汽管道應用蒸汽吹掃;非蒸汽管道一般用空氣進行吹掃,如不能滿足要求時,也可用蒸汽吹掃,但要考慮管道承受高溫和熱膨脹因素的影響;氧氣管道應用不帶油的壓縮空氣或氨氣吹掃;儀表管道應用無油干燥壓縮空氣吹掃。

①. 蒸汽吹掃(sao)

a. 蒸汽吹(chui)掃前(qian),應先緩慢升(sheng)溫(wen)(wen)(wen)(wen)暖管(guan),當吹(chui)洗管(guan)段末端(duan)與進氣端(duan)溫(wen)(wen)(wen)(wen)度基本相等時(shi),恒溫(wen)(wen)(wen)(wen)1小時(shi)后(hou)進行(xing)吹(chui)掃;然后(hou)自然降溫(wen)(wen)(wen)(wen)至環境溫(wen)(wen)(wen)(wen)度,再升(sheng)溫(wen)(wen)(wen)(wen)、暖管(guan)、恒溫(wen)(wen)(wen)(wen),進行(xing)第二次吹(chui)掃;如此反復進行(xing),一般不少于(yu)3次。

b. 吹(chui)(chui)(chui)掃(sao)(sao)(sao)蒸(zheng)(zheng)汽(qi)總(zong)管(guan)時,用(yong)總(zong)汽(qi)閥(fa)控制蒸(zheng)(zheng)汽(qi)流(liu)量(liang),吹(chui)(chui)(chui)掃(sao)(sao)(sao)支(zhi)管(guan)用(yong)管(guan)路分支(zhi)處(chu)的(de)(de)(de)(de)(de)閥(fa)門控制流(liu)量(liang)。在開啟閥(fa)門前,應先將管(guan)道(dao)中的(de)(de)(de)(de)(de)冷凝水經疏水閥(fa)排放干凈(jing)。吹(chui)(chui)(chui)掃(sao)(sao)(sao)壓(ya)力(li)應盡量(liang)維持在管(guan)道(dao)設計(ji)壓(ya)力(li)的(de)(de)(de)(de)(de)75%左右,最低不(bu)應低于設計(ji)壓(ya)力(li)的(de)(de)(de)(de)(de)25%.吹(chui)(chui)(chui)掃(sao)(sao)(sao)流(liu)量(liang)為設計(ji)流(liu)量(liang)的(de)(de)(de)(de)(de)40%~60%,流(liu)速一(yi)般(ban)不(bu)低于30m/s.吹(chui)(chui)(chui)掃(sao)(sao)(sao)時間每次20~30min,當排氣口吹(chui)(chui)(chui)出的(de)(de)(de)(de)(de)蒸(zheng)(zheng)汽(qi)完(wan)全清潔(jie)時,才(cai)能停止吹(chui)(chui)(chui)掃(sao)(sao)(sao)。蒸(zheng)(zheng)汽(qi)閥(fa)的(de)(de)(de)(de)(de)開啟和關(guan)閉都(dou)應緩慢,不(bu)能過(guo)急,以免形成(cheng)水錘現象而引起閥(fa)件破裂。

c. 蒸汽(qi)吹掃(sao)的(de)排(pai)(pai)氣(qi)(qi)管應(ying)(ying)引至室外,并加明顯標志(zhi)。管口應(ying)(ying)離(li)開地面一定高度并向上傾斜,以保證排(pai)(pai)放安全。排(pai)(pai)氣(qi)(qi)管應(ying)(ying)具有(you)牢固的(de)支撐,以承(cheng)受排(pai)(pai)放的(de)反作用力(li)。排(pai)(pai)氣(qi)(qi)管的(de)直(zhi)徑不宜小于被(bei)吹掃(sao)管直(zhi)徑,長(chang)度應(ying)(ying)盡量短。

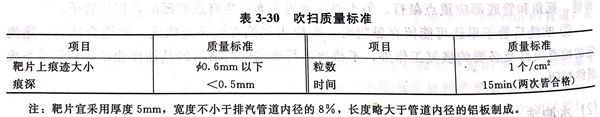

d. 蒸(zheng)汽(qi)(qi)吹(chui)掃的(de)檢(jian)(jian)查(cha)方法及合格(ge)標準為(wei):對于一般蒸(zheng)汽(qi)(qi)管道(dao),可用刨光木(mu)板置于排汽(qi)(qi)口(kou)處(chu)檢(jian)(jian)查(cha),木(mu)板上無鐵銹、臟物為(wei)合格(ge);對于通(tong)往汽(qi)(qi)輪機或設計文件有規定(ding)的(de)管道(dao),經蒸(zheng)汽(qi)(qi)吹(chui)掃后應檢(jian)(jian)驗(yan)靶(ba)片。當設計無規定(ding)時,其質量應符合表(biao)3-30的(de)規定(ding)。

e. 管道系統吹(chui)(chui)(chui)掃(sao)(sao)后,對可(ke)能(neng)留(liu)存雜物的(de)部(bu)位,應(ying)當用人工加以清除。在吹(chui)(chui)(chui)掃(sao)(sao)過程(cheng)中(zhong),不(bu)應(ying)使用疏水(shui)(shui)器來排除系統中(zhong)的(de)凝結(jie)水(shui)(shui),最好將(jiang)疏水(shui)(shui)器暫時拆除,待吹(chui)(chui)(chui)掃(sao)(sao)工作(zuo)結(jie)束后再裝上,并(bing)進行調整和投入使用。絕熱管道的(de)蒸汽吹(chui)(chui)(chui)掃(sao)(sao)工作(zuo),一般宜(yi)在絕熱施(shi)工前進行,必(bi)要時可(ke)采取(qu)局部(bu)的(de)人體防燙措施(shi),確保安(an)全。

②. 氣體(ti)吹(chui)掃

a. 空氣(qi)吹掃的方法和步驟,可(ke)參(can)照蒸汽管(guan)道的方法進(jin)行(xing)。吹掃效果的檢查(cha),可(ke)在排氣(qi)口用(yong)白(bai)布或涂有白(bai)漆的靶板(ban)檢查(cha),當管(guan)道系統(tong)吹掃一定時間(jian)后,把用(yong)于檢查(cha)的靶板(ban)在排出處停放5min,若其上無鐵銹、塵(chen)土、水(shui)分(fen)及其他(ta)臟物即為合格。

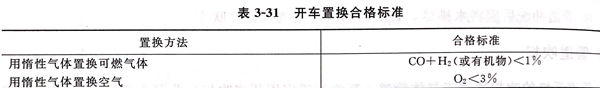

b. 對于(yu)輸送可燃及助燃氣(qi)體的管(guan)道,用(yong)壓(ya)縮空氣(qi)吹掃合(he)格后,使(shi)用(yong)前(qian)還必(bi)須用(yong)安全氣(qi)體進行置換,置換方(fang)法和合(he)格標準(zhun)見表(biao)3-31。

c. 常(chang)用工作介質(zhi)的置換氣體。

· 氧氣管道

用不含油的壓縮空氣(qi)或氮氣(qi)吹掃(sao)合格后,在投入使用前須用氧氣(qi)吹掃(sao)置換,氧氣(qi)用量不小于被置換管(guan)道總容積的3倍,吹掃(sao)置換用排氣(qi)管(guan),應(ying)接至(zhi)室外安全地。

· 乙(yi)炔管道

用空氣(qi)(qi)或氮氣(qi)(qi)吹(chui)掃(sao)合(he)格后(hou),在投入使用前必(bi)須用3倍于(yu)管道總容積的氮氣(qi)(qi)(含氧量(liang)不大于(yu)1%)進(jin)行吹(chui)掃(sao)置(zhi)換,直至排(pai)出(chu)管排(pai)出(chu)氮氣(qi)(qi)中(zhong)含氧量(liang)少于(yu)3%時,才允許輸人(ren)乙炔氣(qi)(qi)。

· 煤(mei)氣或天然氣管道(dao)

采用(yong)壓力(li)不小于(yu)(yu)管道設計(ji)壓力(li)的(de)壓縮空(kong)(kong)氣(qi)(qi)吹(chui)(chui)(chui)掃合格(ge)后,在(zai)投(tou)人使用(yong)前,天然氣(qi)(qi)管道必(bi)須用(yong)天然氣(qi)(qi)進行吹(chui)(chui)(chui)掃置(zhi)換(huan),直至(zhi)氣(qi)(qi)體經取(qu)樣化驗合格(ge)為止(zhi);煤氣(qi)(qi)管道可先(xian)用(yong)氮(dan)氣(qi)(qi)吹(chui)(chui)(chui)掃置(zhi)換(huan),再輸入煤氣(qi)(qi)進行置(zhi)換(huan),但此(ci)法費用(yong)較高,應用(yong)較少,通常是用(yong)煤氣(qi)(qi)直接(jie)置(zhi)換(huan)空(kong)(kong)氣(qi)(qi),直至(zhi)取(qu)樣化驗合格(ge)后,才允許(xu)投(tou)入運(yun)行,應用(yong)此(ci)法,其壓力(li)不得超過(guo)0.049MPa,并(bing)要(yao)求管道沿程無明火或熾(chi)熱物。由于(yu)(yu)用(yong)煤氣(qi)(qi)直接(jie)置(zhi)換(huan)空(kong)(kong)氣(qi)(qi)過(guo)程中,有一段時(shi)間煤氣(qi)(qi)的(de)濃(nong)度在(zai)爆炸區(qu)間范圍內(nei),在(zai)常溫、常壓下遇(yu)火就會(hui)爆炸。因此(ci)在(zai)使用(yong)此(ci)方法時(shi),必(bi)須采取(qu)相應的(de)安全(quan)措施。