在一些檢修部門,習慣用手工來研磨在線亞洲日產一區二區:閥門密封面。手工研磨只使用簡單的研磨工具而不需復雜的研磨設備,但這是一種費力的工作,生產效率很低,研磨質量主要依靠工人的技術水平來保證,因此研磨質量往往不夠穩定。

手(shou)工(gong)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)分為(wei)粗(cu)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)、精研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)和拋(pao)光(guang)(guang)等(deng)。粗(cu)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)是為(wei)了(le)消除密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)上(shang)的(de)(de)(de)(de)(de)(de)(de)擦傷、壓痕(hen)、蝕點(dian)等(deng)缺(que)陷,提高(gao)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)平(ping)(ping)(ping)整(zheng)(zheng)度(du)和降(jiang)(jiang)低(di)粗(cu)糙(cao)(cao)(cao)(cao)度(du),為(wei)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)精研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)打下(xia)基礎。精研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)是為(wei)了(le)消除密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)上(shang)的(de)(de)(de)(de)(de)(de)(de)粗(cu)紋路,進一步提高(gao)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)的(de)(de)(de)(de)(de)(de)(de)平(ping)(ping)(ping)整(zheng)(zheng)度(du)和降(jiang)(jiang)低(di)粗(cu)糙(cao)(cao)(cao)(cao)度(du)。拋(pao)光(guang)(guang)的(de)(de)(de)(de)(de)(de)(de)目(mu)的(de)(de)(de)(de)(de)(de)(de)主要(yao)是降(jiang)(jiang)低(di)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)的(de)(de)(de)(de)(de)(de)(de)粗(cu)糙(cao)(cao)(cao)(cao)度(du),一般(ban)用(yong)(yong)(yong)于粗(cu)糙(cao)(cao)(cao)(cao)度(du)Ra在(zai)(zai)0.2μm以(yi)下(xia)的(de)(de)(de)(de)(de)(de)(de)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)。手(shou)工(gong)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)不(bu)管粗(cu)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)還(huan)是精研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo),整(zheng)(zheng)個過(guo)程(cheng)始終貫(guan)穿(chuan)提起、放下(xia)、旋轉(zhuan)、往復、輕敲、換向(xiang)等(deng)操作相(xiang)(xiang)結合的(de)(de)(de)(de)(de)(de)(de)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)過(guo)程(cheng)。其(qi)目(mu)的(de)(de)(de)(de)(de)(de)(de)是避免磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)粒軌跡重(zhong)復,使(shi)(shi)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)得到均勻的(de)(de)(de)(de)(de)(de)(de)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)削(xue),提高(gao)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)的(de)(de)(de)(de)(de)(de)(de)平(ping)(ping)(ping)整(zheng)(zheng)度(du),降(jiang)(jiang)低(di)粗(cu)糙(cao)(cao)(cao)(cao)度(du)。在(zai)(zai)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)過(guo)程(cheng)中(zhong)(zhong)(zhong),要(yao)始終貫(guan)穿(chuan)著檢驗過(guo)程(cheng),其(qi)目(mu)的(de)(de)(de)(de)(de)(de)(de)是隨(sui)(sui)時(shi)掌(zhang)握研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)情況,做到心中(zhong)(zhong)(zhong)有數,使(shi)(shi)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)質(zhi)量(liang)達到技術要(yao)求(qiu)(qiu)。在(zai)(zai)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)過(guo)程(cheng)中(zhong)(zhong)(zhong),清潔工(gong)作是很重(zhong)要(yao)的(de)(de)(de)(de)(de)(de)(de)環節(jie),應(ying)(ying)做到“三(san)不(bu)落地(di)”,即被(bei)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)件不(bu)落地(di)、工(gong)具(ju)不(bu)落地(di)、物料不(bu)落地(di);“三(san)不(bu)見天”,即顯示(shi)劑用(yong)(yong)(yong)后上(shang)蓋、研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)劑用(yong)(yong)(yong)后上(shang)蓋、稀釋(shi)劑(液)用(yong)(yong)(yong)后上(shang)蓋;“三(san)干(gan)凈(jing)”,即研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)具(ju)用(yong)(yong)(yong)前要(yao)抹洗(xi)(xi)干(gan)凈(jing)、密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)要(yao)清洗(xi)(xi)干(gan)凈(jing)、更換研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)劑時(shi)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)具(ju)和密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)要(yao)抹洗(xi)(xi)干(gan)凈(jing)。研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)中(zhong)(zhong)(zhong)應(ying)(ying)注意檢查(cha)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)具(ju)不(bu)與密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)外任何疤(ba)點(dian)臺肩相(xiang)(xiang)摩擦,使(shi)(shi)研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)具(ju)運動平(ping)(ping)(ping)穩,保證研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)質(zhi)量(liang)。經(jing)過(guo)滲(shen)氨、滲(shen)硼等(deng)表(biao)面(mian)(mian)(mian)(mian)處(chu)理(li)(li)的(de)(de)(de)(de)(de)(de)(de)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian),研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)時(shi)要(yao)小心謹慎(shen),因為(wei)滲(shen)透層的(de)(de)(de)(de)(de)(de)(de)硬度(du)隨(sui)(sui)著研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)量(liang)增大而明顯下(xia)降(jiang)(jiang),研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)時(shi)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)削(xue)量(liang)應(ying)(ying)盡量(liang)小,最好(hao)進行拋(pao)光(guang)(guang)使(shi)(shi)用(yong)(yong)(yong),至(zhi)少要(yao)精研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)后使(shi)(shi)用(yong)(yong)(yong),如達不(bu)到要(yao)求(qiu)(qiu),就(jiu)將殘存的(de)(de)(de)(de)(de)(de)(de)滲(shen)透層磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)掉,重(zhong)新滲(shen)透處(chu)理(li)(li),恢復原有密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)的(de)(de)(de)(de)(de)(de)(de)性(xing)能。用(yong)(yong)(yong)于深(shen)冷(leng)的(de)(de)(de)(de)(de)(de)(de)閥門(men)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)要(yao)經(jing)過(guo)深(shen)冷(leng)定型處(chu)理(li)(li)后再研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo),否(fou)則,研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)好(hao)的(de)(de)(de)(de)(de)(de)(de)密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)一經(jing)深(shen)冷(leng)就(jiu)會變(bian)形。深(shen)冷(leng)處(chu)理(li)(li)可在(zai)(zai)液氨中(zhong)(zhong)(zhong)進行。刀型密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)一般(ban)寬(kuan)度(du)為(wei)0.5~0.8mm,接近(jin)線密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)。研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)后,密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)會變(bian)寬(kuan),應(ying)(ying)注意恢復刀型密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)原有的(de)(de)(de)(de)(de)(de)(de)尺(chi)寸,可用(yong)(yong)(yong)車削(xue)或研(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)(yan)磨(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)(mo)刀型密(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)(mi)封(feng)(feng)(feng)(feng)面(mian)(mian)(mian)(mian)兩(liang)斜面(mian)(mian)(mian)(mian)的(de)(de)(de)(de)(de)(de)(de)方法(fa)恢復寬(kuan)度(du)尺(chi)寸。

研(yan)具(ju)使用后(hou)應進行一次檢查,對平整度(du)不高的平面要(yao)修理(li)好,并應清洗(xi)干(gan)凈,保持完整。要(yao)分門別類地把研(yan)磨工(gong)具(ju)擺放在工(gong)具(ju)箱內(nei),以便以后(hou)使用。

研(yan)(yan)磨(mo)(mo)分平面(mian)(mian)密(mi)(mi)封面(mian)(mian)研(yan)(yan)磨(mo)(mo)、錐(zhui)形密(mi)(mi)封面(mian)(mian)研(yan)(yan)磨(mo)(mo)、圓弧(hu)密(mi)(mi)封面(mian)(mian)研(yan)(yan)磨(mo)(mo)、圓柱體密(mi)(mi)封面(mian)(mian)研(yan)(yan)磨(mo)(mo)等幾種(zhong)。

①. 閥體平面(mian)密封面(mian)的(de)研磨

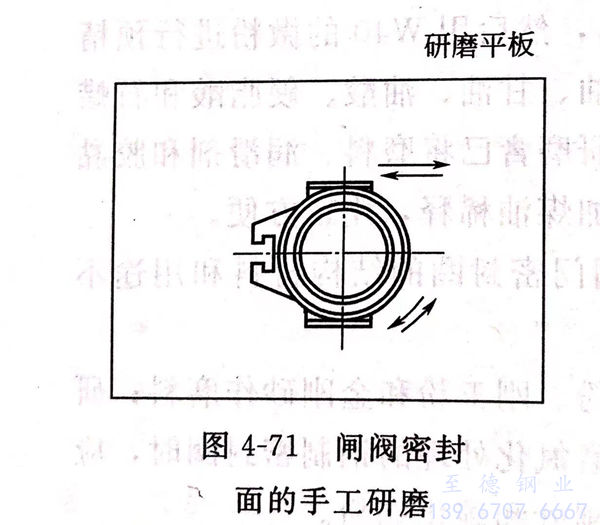

閥(fa)(fa)體密(mi)封平面位(wei)于閥(fa)(fa)體內腔(qiang),研(yan)磨(mo)比(bi)較困(kun)難。通常使用帶(dai)(dai)方孔的(de)圓盤(pan)狀(zhuang)研(yan)磨(mo)工具,放在(zai)內腔(qiang)的(de)密(mi)封面上(shang),再用帶(dai)(dai)方頭的(de)長柄手把來帶(dai)(dai)動(dong)研(yan)盤(pan)運(yun)動(dong)。研(yan)盤(pan)上(shang)有圓柱(zhu)凸臺或引導墊片,以(yi)防止在(zai)研(yan)磨(mo)過程中研(yan)具局部離開環狀(zhuang)密(mi)封面而造成研(yan)磨(mo)不勻的(de)現象(xiang)。圖4-71為閘閥(fa)(fa)密(mi)封面的(de)手工研(yan)磨(mo)。

研磨前應將研具(ju)(ju)(ju)(ju)工作面(mian)(mian)(mian)用丙(bing)酮(tong)或(huo)汽油(you)擦凈(jing)(jing),并(bing)去除閥體密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)上(shang)的(de)飛邊、毛刺,再(zai)在(zai)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)上(shang)涂敷一層研磨劑。研具(ju)(ju)(ju)(ju)放入閥體內腔時(shi)(shi),要仔(zi)細地貼合在(zai)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)上(shang),然后(hou)(hou)采(cai)用長柄手把使研盤做(zuo)正、反方向的(de)回轉運動(dong)。先順時(shi)(shi)針(zhen)回轉180°,再(zai)逆時(shi)(shi)針(zhen)回轉90°,如(ru)此反復地進行。一般回轉10余次(ci)后(hou)(hou)研磨劑中的(de)磨粒(li)便已磨鈍,故應該經常(chang)抬起研盤來添新的(de)研磨劑。研磨的(de)壓(ya)力(li)(li)要均勻(yun)(yun),且不(bu)宜(yi)過大(da)。粗研時(shi)(shi)壓(ya)力(li)(li)可(ke)(ke)大(da)些(xie),精(jing)研時(shi)(shi)應較小。應注意不(bu)要因施加壓(ya)力(li)(li)使研具(ju)(ju)(ju)(ju)局部脫(tuo)開密(mi)(mi)封(feng)(feng)平(ping)(ping)面(mian)(mian)(mian)。研磨一段時(shi)(shi)間后(hou)(hou),要檢(jian)查工件的(de)平(ping)(ping)面(mian)(mian)(mian)度(du)(du)。此時(shi)(shi)可(ke)(ke)取(qu)出(chu)研具(ju)(ju)(ju)(ju),用丙(bing)酮(tong)或(huo)汽油(you)將密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)擦凈(jing)(jing),再(zai)將圓盤形的(de)檢(jian)驗平(ping)(ping)板(ban)(ban)輕(qing)(qing)輕(qing)(qing)放在(zai)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)上(shang)并(bing)用手輕(qing)(qing)輕(qing)(qing)旋(xuan)動(dong),取(qu)出(chu)平(ping)(ping)板(ban)(ban)后(hou)(hou)就可(ke)(ke)觀察到密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)上(shang)出(chu)現的(de)接(jie)觸痕(hen)跡(ji)。當環狀(zhuang)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)上(shang)均勻(yun)(yun)地顯(xian)示接(jie)觸痕(hen)跡(ji),而徑向最小接(jie)觸寬度(du)(du)與密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)寬度(du)(du)之比(即(ji)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)與檢(jian)驗平(ping)(ping)板(ban)(ban)的(de)吻(wen)合度(du)(du))達到工藝上(shang)規定的(de)數值時(shi)(shi),平(ping)(ping)面(mian)(mian)(mian)度(du)(du)就可(ke)(ke)認為合格。為了保證檢(jian)驗的(de)準(zhun)確性,檢(jian)驗平(ping)(ping)板(ban)(ban)應經常(chang)檢(jian)查、修整。

②. 閘板、閥瓣平面(mian)密封面(mian)的研磨

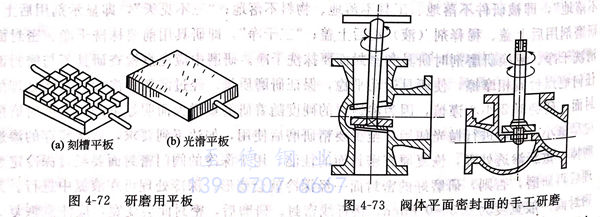

閘板(ban)、閥瓣和(he)閥座的(de)(de)密封平(ping)(ping)(ping)面(mian)可使用(yong)研(yan)(yan)磨(mo)(mo)(mo)平(ping)(ping)(ping)板(ban)來手(shou)工研(yan)(yan)磨(mo)(mo)(mo)。研(yan)(yan)磨(mo)(mo)(mo)平(ping)(ping)(ping)板(ban)平(ping)(ping)(ping)面(mian)應平(ping)(ping)(ping)整。研(yan)(yan)磨(mo)(mo)(mo)用(yong)平(ping)(ping)(ping)板(ban)分刻槽(cao)平(ping)(ping)(ping)板(ban)和(he)光滑(hua)平(ping)(ping)(ping)板(ban)兩種,如圖4-72所(suo)示。研(yan)(yan)磨(mo)(mo)(mo)工作前,先用(yong)丙酮或(huo)汽油將(jiang)研(yan)(yan)磨(mo)(mo)(mo)平(ping)(ping)(ping)板(ban)的(de)(de)表面(mian)擦干(gan)凈,然后(hou)在平(ping)(ping)(ping)板(ban)上(shang)均勻、適量(liang)地(di)涂一(yi)層研(yan)(yan)磨(mo)(mo)(mo)劑(ji),把需研(yan)(yan)磨(mo)(mo)(mo)的(de)(de)工件表面(mian)貼合在平(ping)(ping)(ping)板(ban)上(shang)即開始研(yan)(yan)磨(mo)(mo)(mo)。用(yong)手(shou)一(yi)邊(bian)旋轉一(yi)邊(bian)做直線(xian)運動(dong),或(huo)做“8”字形運動(dong)。由于研(yan)(yan)磨(mo)(mo)(mo)運動(dong)方向(xiang)的(de)(de)不斷變更,使磨(mo)(mo)(mo)粒不斷地(di)在新的(de)(de)方向(xiang)起磨(mo)(mo)(mo)削作用(yong),故可提(ti)高研(yan)(yan)磨(mo)(mo)(mo)效率。圖4-73所(suo)示為閥體平(ping)(ping)(ping)面(mian)密封面(mian)的(de)(de)手(shou)工研(yan)(yan)磨(mo)(mo)(mo)。

為了避(bi)免研磨(mo)平板(ban)(ban)的(de)磨(mo)耗不均,不要總是(shi)在平板(ban)(ban)的(de)中部(bu)(bu)研磨(mo),應(ying)沿平板(ban)(ban)的(de)全部(bu)(bu)表面上(shang)不斷變換(huan)部(bu)(bu)位,否則(ze)研磨(mo)平板(ban)(ban)將很(hen)快(kuai)失(shi)去平面精(jing)度(du)。

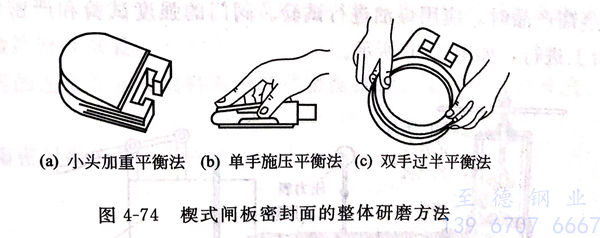

閘(zha)板(ban)及(ji)有些閥座呈楔(xie)(xie)(xie)(xie)狀,密封(feng)平面圓周上的質量(liang)不(bu)均,厚(hou)薄(bo)不(bu)一致,容易產生偏磨(mo)(mo)現(xian)象,厚(hou)的一頭容易多磨(mo)(mo),薄(bo)的一頭會少磨(mo)(mo)。所(suo)以,在研磨(mo)(mo)楔(xie)(xie)(xie)(xie)式(shi)閘(zha)板(ban)密封(feng)面時,應附(fu)加一個平衡力,使(shi)楔(xie)(xie)(xie)(xie)式(shi)閘(zha)板(ban)密封(feng)面均勻磨(mo)(mo)削。圖4-74所(suo)示為楔(xie)(xie)(xie)(xie)式(shi)閘(zha)板(ban)密封(feng)面的整體研磨(mo)(mo)方法(fa)。