1. 電刷(shua)鍍修復(fu)目的物

航空上使(shi)用的(de)1Cr18Ni9Ti不銹鋼(gang)導(dao)管(guan),在使(shi)用過程中,表(biao)面產生劃傷、壓痕、腐(fu)蝕等(deng)損傷,當缺陷深度在0.05mm以內時(shi),經電刷鍍技術修復后,鍍層質量完全滿足使(shi)用要求。

2. 工(gong)藝流(liu)程

除油→膠(jiao)帶粘貼(tie)→電凈(jing)→沖(chong)(chong)(chong)洗→2號(hao)活化液活化→沖(chong)(chong)(chong)洗→3號(hao)活化液活化→鍍特殊鎳(nie)打底(di)層→沖(chong)(chong)(chong)洗→鍍高堆積堿銅作(zuo)尺寸層→沖(chong)(chong)(chong)洗→修光→鍍鎳(nie)-鎢-鈷合金(jin)工作(zuo)層→沖(chong)(chong)(chong)洗→吹干。

3. 工藝條(tiao)件

①. 鍍前(qian)預處理

用(yong)丙(bing)酮擦洗(xi)待鍍(du)(du)表面及(ji)鄰近部位,用(yong)膠帶將鄰近部位粘貼保護好,將工件(jian)(jian)夾持(chi)到車床上,在(zai)刷(shua)鍍(du)(du)過(guo)程(cheng)中(zhong),工件(jian)(jian)轉動(dong),鍍(du)(du)筆(bi)不(bu)動(dong),工件(jian)(jian)和鍍(du)(du)筆(bi)之(zhi)間保持(chi)一定的相對運動(dong)速(su)率。

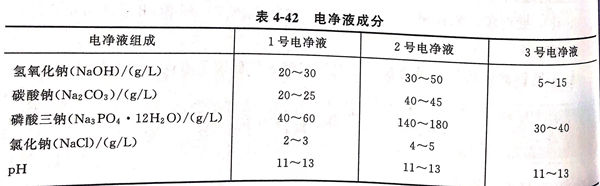

②. 電凈

電(dian)(dian)凈(jing)溶(rong)液參見表4-42 1號電(dian)(dian)凈(jing)液,工作電(dian)(dian)壓12V,電(dian)(dian)極(ji)連(lian)接是鍍(du)筆(bi)接正極(ji),工件接負極(ji),鍍(du)筆(bi)與工件的相(xiang)對(dui)運(yun)動(dong)速率9~12m/min.電(dian)(dian)凈(jing)時間30秒自來水(shui)沖洗干凈(jing)。

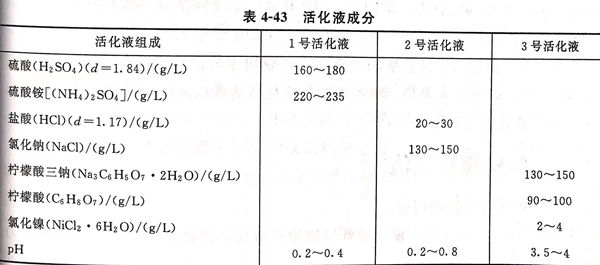

③. 活化

先用2號活化(hua)液活化(hua),2號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua)液(ye)成(cheng)(cheng)分參見(jian)表4-43,再用3號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua)液(ye)活(huo)(huo)(huo)化(hua)(hua)(hua)。3號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua)液(ye)成(cheng)(cheng)分參見(jian)表4-43.3號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua)液(ye)處理除(chu)去2號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua)液(ye)處理后(hou)在不(bu)(bu)銹鋼表面(mian)上表現的污物(殘留炭(tan)),污物的存在降低了打底層(ceng)(ceng)與(yu)基體(ti)的結合力,導致(zhi)鍍(du)層(ceng)(ceng)起皮,脫落(luo)或鍍(du)不(bu)(bu)上。經3號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua)液(ye)活(huo)(huo)(huo)化(hua)(hua)(hua)后(hou),表面(mian)呈銀(yin)灰(hui)色(se),無(wu)黑斑,無(wu)掛水(shui)珠現象。工(gong)作(zuo)電壓(ya)2號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua) 10V,3號(hao)活(huo)(huo)(huo)化(hua)(hua)(hua) 18V, 電極(ji)連(lian)接(jie)方式是鍍(du)筆負極(ji),工(gong)件接(jie)正極(ji)。鍍(du)筆與(yu)工(gong)件的相對(dui)運動速率9~18m/min,活(huo)(huo)(huo)化(hua)(hua)(hua)時間(jian)≤30秒,活(huo)(huo)(huo)化(hua)(hua)(hua)后(hou)不(bu)(bu)必水(shui)洗直接(jie)刷鍍(du)。

④. 刷(shua)鍍特(te)殊鎳打底層

采用特(te)殊(shu)(shu)鎳(nie)作打(da)底層,鎳(nie)層可(ke)提高鍍(du)(du)(du)(du)(du)層與(yu)不銹鋼基(ji)體的結合(he)力,有(you)利于承受較大的負荷。特(te)殊(shu)(shu)鎳(nie)刷(shua)鍍(du)(du)(du)(du)(du)液(ye)見表44.工作電壓10V,電按連(lian)接(jie)方式(shi)是鍍(du)(du)(du)(du)(du)筆(bi)(bi)接(jie)正極,工件接(jie)負極;鍍(du)(du)(du)(du)(du)筆(bi)(bi)與(yu)工件的相對運動(dong)速(su)率為(wei)(wei)9~12/min; 鍍(du)(du)(du)(du)(du)液(ye)補充方式(shi)是鍍(du)(du)(du)(du)(du)筆(bi)(bi)浸藍鍍(du)(du)(du)(du)(du)液(ye);刷(shua)鍍(du)(du)(du)(du)(du)時間為(wei)(wei)60~120s; 鍍(du)(du)(du)(du)(du)層厚度(du)為(wei)(wei)0.001~0.003m0m,自來(lai)水沖洗干凈。

⑤. 刷鍍厚沉(chen)積堿性(xing)銅作(zuo)為尺(chi)寸層(ceng)

厚(hou)沉(chen)積(ji)堿(jian)性(xing)銅(tong)具有較(jiao)高的沉(chen)積(ji)速率(lv),可(ke)獲得較(jiao)厚(hou)的鍍(du)(du)(du)(du)層,致密性(xing)好,可(ke)填補(bu)溝槽。鍍(du)(du)(du)(du)液(ye)厚(hou)沉(chen)積(ji)堿(jian)性(xing)銅(tong)成(cheng)分(fen)見。工(gong)作(zuo)電(dian)壓為(wei)12V;電(dian)極連接方(fang)式(shi)是鍍(du)(du)(du)(du)筆接正極,工(gong)件接負極;鍍(du)(du)(du)(du)筆與工(gong)件的相對運(yun)動(dong)速率(lv)為(wei)9~18m/min;鍍(du)(du)(du)(du)液(ye)補(bu)充方(fang)式(shi)是鍍(du)(du)(du)(du)筆浸蘸鍍(du)(du)(du)(du)液(ye)。一次(ci)鍍(du)(du)(du)(du)成(cheng)填平后,用自(zi)來水(shui)沖洗干凈。

⑥. 刷(shua)鍍鎳-鎢-鈷合金(jin)作(zuo)工作(zuo)層(ceng)

采用鎳(nie)-鎢(wu)(wu)-鈷(gu)合(he)金(jin)(jin)(又稱鎳(nie)-鎢(wu)(wu)D合(he)金(jin)(jin))作(zuo)工作(zuo)層可提(ti)高導管表面鍍層的耐(nai)磨性。鎳(nie)-鎢(wu)(wu)-鈷(gu)合(he)金(jin)(jin)電(dian)(dian)刷(shua)鍍液成(cheng)分。工作(zuo)電(dian)(dian)壓(ya)為(wei)(wei)12V;電(dian)(dian)極連接(jie)方式是鍍筆接(jie)正極,工件接(jie)負極;鍍筆與(yu)工件的相對運動(dong)速(su)率為(wei)(wei)9~18m/min;刷(shua)鍍時間為(wei)(wei)5~10min;鍍層厚度(du)約為(wei)(wei)0.01mm.最后用自來水(shui)沖洗(xi)干凈,冷風吹(chui)干。