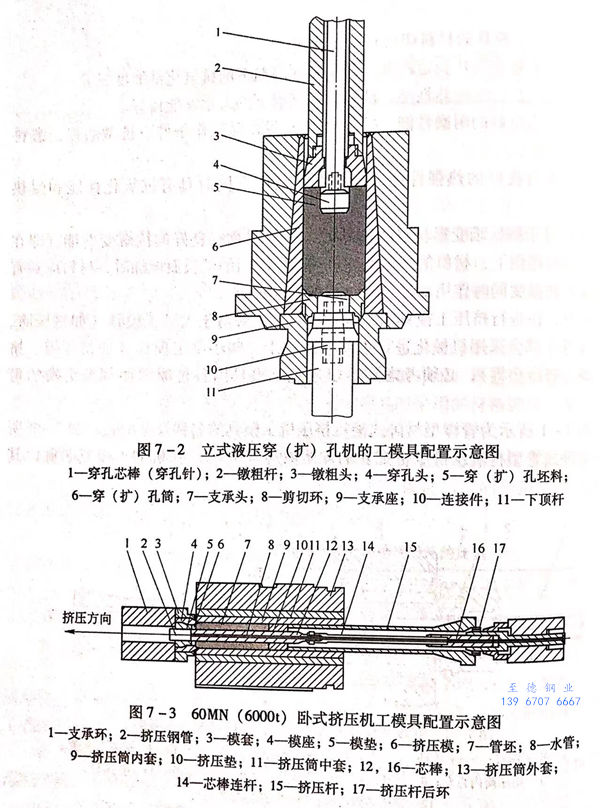

不銹鋼管擠壓過(guo)程的工(gong)模具配(pei)置如圖(tu)7-3所(suo)示(shi),可用以研究(jiu)不同的擠壓方法,以及各(ge)種結構配(pei)置的擠壓工(gong)模具的實(shi)際工(gong)況條(tiao)件。在(zai)每一(yi)個在線亞洲日產一區二區:不銹鋼管擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)周期(qi)的循(xun)環中(zhong),與加熱到高(gao)溫的坯料直接接觸的工具稱(cheng)為(wei)變(bian)(bian)形模(mo)具,包(bao)括(kuo)擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)內襯、擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)模(mo)、擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)墊、芯(xin)棒(bang)、擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)桿(gan)(gan)(擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)桿(gan)(gan)屬于大型(xing)(xing)變(bian)(bian)形模(mo)具,雖然沒和(he)高(gao)溫坯料直接接觸,但(dan)其由擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)墊保護傳送高(gao)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya),有些(xie)小型(xing)(xing)擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)機擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)時擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)桿(gan)(gan)直接接觸坯料);而(er)不直接與變(bian)(bian)形金屬接觸的工具稱(cheng)為(wei)輔助(zhu)工具,包(bao)括(kuo)擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)、中(zhong)套、外套、模(mo)座、模(mo)套、模(mo)支(zhi)承(cheng)、芯(xin)棒(bang)連桿(gan)(gan)、芯(xin)棒(bang)支(zhi)承(cheng)、擠(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)(ya)桿(gan)(gan)后(hou)支(zhi)承(cheng)等。將變(bian)(bian)形模(mo)具和(he)輔助(zhu)工具統稱(cheng)為(wei)工模(mo)具。

不(bu)銹鋼管擠(ji)壓(ya)工(gong)(gong)模(mo)具還(huan)有(you)其他(ta)的分(fen)類(lei)方(fang)法,如將工(gong)(gong)模(mo)具分(fen)別(bie)稱為(wei)運(yun)(yun)動部(bu)(bu)件工(gong)(gong)具和不(bu)運(yun)(yun)動部(bu)(bu)件工(gong)(gong)具。這是根據在擠(ji)壓(ya)過程中,工(gong)(gong)模(mo)具部(bu)(bu)件所(suo)處的運(yun)(yun)動和不(bu)運(yun)(yun)動狀態來進(jin)行分(fen)類(lei)的。

尼科(ke)波(bo)爾(er)南(nan)方(fang)不(bu)銹鋼(gang)管廠則(ze)將擠壓(ya)(ya)工(gong)(gong)模(mo)(mo)具分(fen)為(wei)操(cao)作工(gong)(gong)具和輔(fu)助工(gong)(gong)具。直(zhi)接(jie)接(jie)觸高溫(wen)變形金(jin)屬的部件稱(cheng)為(wei)操(cao)作工(gong)(gong)具,如擠壓(ya)(ya)筒內襯、擠壓(ya)(ya)模(mo)(mo)、芯棒、擠壓(ya)(ya)墊、擠壓(ya)(ya)桿(gan);而不(bu)直(zhi)接(jie)接(jie)觸高溫(wen)變形金(jin)屬的部件稱(cheng)為(wei)輔(fu)助工(gong)(gong)具,如座、套、環、支承、連桿(gan)等。

在(zai)不(bu)(bu)同結構的(de)擠(ji)(ji)壓機上(shang),上(shang)述擠(ji)(ji)壓工(gong)模具由于其在(zai)擠(ji)(ji)壓機上(shang)固定方法的(de)不(bu)(bu)同,做(zuo)成不(bu)(bu)同的(de)形式。

在(zai)老式結構的(de)擠(ji)壓(ya)(ya)(ya)機(ji)(ji)上,所有(you)的(de)工模(mo)(mo)具(ju)由專門的(de)液壓(ya)(ya)(ya)缸或(huo)機(ji)(ji)械裝(zhuang)置將其從擠(ji)壓(ya)(ya)(ya)機(ji)(ji)的(de)前梁(liang)中(zhong)拉出或(huo)推進,并用以使擠(ji)壓(ya)(ya)(ya)墊、擠(ji)壓(ya)(ya)(ya)制(zhi)品和壓(ya)(ya)(ya)余(yu)進行分離,檢查(cha)擠(ji)壓(ya)(ya)(ya)模(mo)(mo)及其固定(ding)裝(zhuang)置的(de)狀況,并且在(zai)必要時更換擠(ji)壓(ya)(ya)(ya)工模(mo)(mo)具(ju)。上海異形(xing)鋼管廠(chang)的(de)15MN(1500t)擠(ji)壓(ya)(ya)(ya)機(ji)(ji)就(jiu)是這種(zhong)結構形(xing)式。

在(zai)現代結構(gou)的(de)(de)擠壓機上,將工(gong)(gong)模(mo)具部件制(zhi)造(zao)成旋轉結構(gou)的(de)(de)形(xing)式(shi),或者橫(heng)向移動的(de)(de)壓模(mo)部件結構(gou)形(xing)式(shi),也稱抽(chou)屜式(shi)結構(gou)模(mo)架。在(zai)這種擠壓機上,更(geng)換和固定(ding)模(mo)子(zi)時(shi)(shi),擠壓機不(bu)必停止(zhi)工(gong)(gong)作(zuo)。旋轉式(shi)模(mo)架或抽(chou)屜式(shi)模(mo)架,在(zai)更(geng)換擠壓模(mo)時(shi)(shi),不(bu)需要附加(jia)的(de)(de)消耗工(gong)(gong)作(zuo)時(shi)(shi)間,并且可以輪流地使用2個(ge)擠壓模(mo)。在(zai)更(geng)換擠壓模(mo)的(de)(de)同(tong)時(shi)(shi),完(wan)成某些(xie)輔助工(gong)(gong)序。

旋轉式(shi)雙擠(ji)壓(ya)(ya)筒(tong)和(he)旋轉式(shi)雙穿孔(kong)(kong)(kong)(kong)筒(tong)結構(gou)(gou)形(xing)式(shi)的(de)工(gong)(gong)作原理(li)也是如此,一(yi)個(ge)擠(ji)壓(ya)(ya)(穿孔(kong)(kong)(kong)(kong))筒(tong)在擠(ji)壓(ya)(ya)(穿孔(kong)(kong)(kong)(kong))中心線上(shang)進(jin)行(xing)擠(ji)壓(ya)(ya)(穿孔(kong)(kong)(kong)(kong));另一(yi)個(ge)擠(ji)壓(ya)(ya)(穿孔(kong)(kong)(kong)(kong))筒(tong)則旋轉到中心線外,完成清掃、冷卻(que)和(he)裝(zhuang)料等輔助工(gong)(gong)序,不(bu)(bu)需(xu)要附(fu)加(jia)的(de)消(xiao)耗工(gong)(gong)作時間(jian)。俄羅斯伏爾加(jia)不(bu)(bu)銹鋼管廠(chang)(chang)的(de)55MN(5500t)擠(ji)壓(ya)(ya)機(ji)和(he)美國的(de)Lone Star 鋼管廠(chang)(chang)的(de)55MN(5500t)擠(ji)壓(ya)(ya)機(ji)都是這種結構(gou)(gou)形(xing)式(shi)。原上(shang)海(hai)第(di)五鋼鐵廠(chang)(chang)的(de)4000t擠(ji)壓(ya)(ya)機(ji)也是采用(yong)這種結構(gou)(gou)。