1. 銅合(he)金法蘭的尺寸公差應符合(he)GB/T 15530.8-1995《銅合(he)金及(ji)復(fu)合(he)法蘭技術條件》的規定。

2. 銅(tong)合金(jin)(jin)整體鑄造法蘭、銅(tong)合金(jin)(jin)帶頸(jing)平焊法蘭、銅(tong)合金(jin)(jin)平焊環松套鋼法蘭、銅(tong)管折(zhe)邊(bian)和銅(tong)合金(jin)(jin)對(dui)焊環松套鋼法蘭等四種法蘭的未(wei)(wei)注形狀和位(wei)(wei)置公(gong)差(cha)應符合GB/T 1184-1996《形狀和位(wei)(wei)置公(gong)差(cha) 未(wei)(wei)注公(gong)差(cha)值》中的K級(ji);未(wei)(wei)注尺寸的線性(xing)和角(jiao)度尺寸公(gong)差(cha)應符合GB/T1804-2000《一般(ban)公(gong)差(cha) 未(wei)(wei)注公(gong)差(cha)的線性(xing)和角(jiao)度尺寸的公(gong)差(cha)》中的m級(ji)。另外,后兩種法蘭的端(duan)面應與其軸線垂直,偏差(cha)不大(da)于30'。

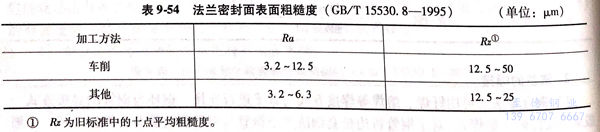

3. 船(chuan)用銅合(he)金整體(ti)鑄造(zao)法(fa)(fa)蘭、船(chuan)用銅合(he)金帶頸平(ping)焊(han)法(fa)(fa)蘭、船(chuan)用銅合(he)金平(ping)焊(han)環松(song)套鋼法(fa)(fa)蘭、船(chuan)用銅管折邊和銅合(he)金對焊(han)環松(song)套鋼法(fa)(fa)蘭的(de)厚(hou)度極限(xian)偏差見(jian)表9-52和表9-53。

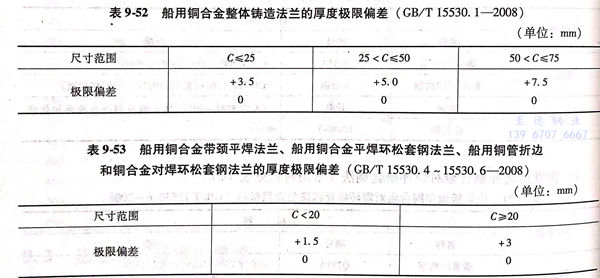

4. 所(suo)有型式的銅合金法(fa)蘭連接密封(feng)面均(jun)應進行機加工,機加工表(biao)面粗糙度見表(biao)9-54。