寶鋼德盛地處依山傍水的福州市羅源灣畔,坐落在羅源灣開發區金港工業區,坐北朝南,東距羅源灣華能碼頭6千米、西接羅源縣城13千米、南瀕羅源灣海域濱海新城,占地面積4170余畝,注冊資本42.53億元人民幣,主要從事鎳(nie)合金及不銹鋼材料生產,集燒結、煉鐵、煉鋼、熱軋、固溶、冷軋等完整的不銹鋼生產工藝,目前有員工2300余人,已具備年產200萬噸鋼的能力。

寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)不(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)有(you)限(xian)公(gong)司(si)(si)(簡稱(cheng)“寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)”)的前身為(wei)(wei)(wei)福(fu)(fu)建(jian)(jian)(jian)德(de)(de)(de)(de)盛(sheng)鎳(nie)業(ye)(ye)(ye)有(you)限(xian)公(gong)司(si)(si)。2005年(nian)(nian)(nian)(nian)(nian)(nian)(nian),德(de)(de)(de)(de)盛(sheng)鎳(nie)業(ye)(ye)(ye)有(you)限(xian)公(gong)司(si)(si)成(cheng)(cheng)立并開始(shi)建(jian)(jian)(jian)設,2009年(nian)(nian)(nian)(nian)(nian)(nian)(nian),高(gao)爐(lu)、煉鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)、熱(re)軋(ya)等主要(yao)工(gong)序(xu)(xu)建(jian)(jian)(jian)成(cheng)(cheng)并投(tou)入(ru)試(shi)(shi)生產。煉鐵工(gong)序(xu)(xu)主要(yao)裝備有(you)126平(ping)方米(mi)(mi)燒結(jie)機(ji)(ji)(ji)(ji)3臺,600立方米(mi)(mi)高(gao)爐(lu)3座(zuo)(zuo);煉鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)工(gong)序(xu)(xu)主要(yao)有(you)80噸(dun)轉爐(lu)4座(zuo)(zuo)、80噸(dun)LF爐(lu)2臺,連鑄機(ji)(ji)(ji)(ji)2臺;熱(re)軋(ya)工(gong)序(xu)(xu)主要(yao)有(you)1150毫米(mi)(mi)機(ji)(ji)(ji)(ji)架熱(re)連軋(ya)機(ji)(ji)(ji)(ji)組一條,步進式(shi)加熱(re)爐(lu)2臺。2011年(nian)(nian)(nian)(nian)(nian)(nian)(nian)3月(yue),福(fu)(fu)建(jian)(jian)(jian)省(sheng)人民政府與(yu)寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)集團簽(qian)訂戰略合作(zuo)協議,寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)不(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)有(you)限(xian)公(gong)司(si)(si)正式(shi)揭牌成(cheng)(cheng)立,寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)集團入(ru)資控股。2015年(nian)(nian)(nian)(nian)(nian)(nian)(nian),寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)冷(leng)軋(ya)DRAPL產線熱(re)負(fu)(fu)荷(he)試(shi)(shi)車(che)。2018年(nian)(nian)(nian)(nian)(nian)(nian)(nian),冷(leng)軋(ya)黑卷軋(ya)制退火酸洗(xi)工(gong)程(cheng)(HRAPL機(ji)(ji)(ji)(ji)組)成(cheng)(cheng)功(gong)軋(ya)制第一卷黑皮卷。2018年(nian)(nian)(nian)(nian)(nian)(nian)(nian),寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)以福(fu)(fu)建(jian)(jian)(jian)省(sheng)大力支(zhi)持(chi)羅源灣鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)鐵產業(ye)(ye)(ye)發展(zhan)(zhan)為(wei)(wei)(wei)契機(ji)(ji)(ji)(ji),積(ji)極踐行精(jing)(jing)品(pin)、綠色、智慧發展(zhan)(zhan)理(li)念,開工(gong)建(jian)(jian)(jian)設精(jing)(jing)品(pin)不(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)綠色產業(ye)(ye)(ye)基地(di),依(yi)托(tuo)現有(you)產線,新建(jian)(jian)(jian)360平(ping)方米(mi)(mi)燒結(jie)機(ji)(ji)(ji)(ji)、2500立方米(mi)(mi)高(gao)爐(lu)、1780毫米(mi)(mi)熱(re)軋(ya)、1600毫米(mi)(mi)酸洗(xi)及(ji)公(gong)輔配套設施(shi)項目(mu),總投(tou)資約(yue)136億元,2021年(nian)(nian)(nian)(nian)(nian)(nian)(nian)全(quan)面建(jian)(jian)(jian)成(cheng)(cheng)投(tou)產。2020年(nian)(nian)(nian)(nian)(nian)(nian)(nian)9月(yue)28日,寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)1780毫米(mi)(mi)熱(re)軋(ya)成(cheng)(cheng)功(gong)熱(re)負(fu)(fu)荷(he)試(shi)(shi)車(che),2020年(nian)(nian)(nian)(nian)(nian)(nian)(nian)12月(yue)22日,1600毫米(mi)(mi)HAPL機(ji)(ji)(ji)(ji)組熱(re)負(fu)(fu)荷(he)試(shi)(shi)車(che)成(cheng)(cheng)功(gong),標志著寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)精(jing)(jing)品(pin)不(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)綠色產業(ye)(ye)(ye)基地(di)建(jian)(jian)(jian)設取得關鍵性進展(zhan)(zhan)。項目(mu)全(quan)面建(jian)(jian)(jian)成(cheng)(cheng)投(tou)產后,寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)將形(xing)成(cheng)(cheng)年(nian)(nian)(nian)(nian)(nian)(nian)(nian)產470萬噸(dun)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)的能力,產品(pin)覆蓋200系(xi)列(lie)、300系(xi)列(lie)、400系(xi)列(lie)不(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)及(ji)優(you)特(te)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)等品(pin)種。寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)2012年(nian)(nian)(nian)(nian)(nian)(nian)(nian)、2013年(nian)(nian)(nian)(nian)(nian)(nian)(nian)度連續兩年(nian)(nian)(nian)(nian)(nian)(nian)(nian)躋身福(fu)(fu)建(jian)(jian)(jian)企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)50強,2013年(nian)(nian)(nian)(nian)(nian)(nian)(nian)被(bei)評(ping)(ping)為(wei)(wei)(wei)福(fu)(fu)州(zhou)市(shi)級企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)技(ji)(ji)術中心,2015年(nian)(nian)(nian)(nian)(nian)(nian)(nian)被(bei)評(ping)(ping)為(wei)(wei)(wei)福(fu)(fu)州(zhou)市(shi)直機(ji)(ji)(ji)(ji)關文明(ming)單位(wei),2016年(nian)(nian)(nian)(nian)(nian)(nian)(nian)榮(rong)獲(huo)福(fu)(fu)州(zhou)市(shi)知識產權示范企(qi)(qi)(qi)(qi)業(ye)(ye)(ye),2017年(nian)(nian)(nian)(nian)(nian)(nian)(nian)被(bei)評(ping)(ping)為(wei)(wei)(wei)福(fu)(fu)州(zhou)市(shi)誠(cheng)信用工(gong)企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)、福(fu)(fu)建(jian)(jian)(jian)省(sheng)科技(ji)(ji)型企(qi)(qi)(qi)(qi)業(ye)(ye)(ye),2018年(nian)(nian)(nian)(nian)(nian)(nian)(nian)榮(rong)獲(huo)福(fu)(fu)州(zhou)市(shi)2015-2017年(nian)(nian)(nian)(nian)(nian)(nian)(nian)度市(shi)級文明(ming)單位(wei)、福(fu)(fu)建(jian)(jian)(jian)企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)100強,2019年(nian)(nian)(nian)(nian)(nian)(nian)(nian)被(bei)評(ping)(ping)為(wei)(wei)(wei)福(fu)(fu)建(jian)(jian)(jian)省(sheng)級企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)技(ji)(ji)術中心、福(fu)(fu)建(jian)(jian)(jian)企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)100強、福(fu)(fu)州(zhou)市(shi)勞動關系(xi)和諧企(qi)(qi)(qi)(qi)業(ye)(ye)(ye),2020年(nian)(nian)(nian)(nian)(nian)(nian)(nian)被(bei)評(ping)(ping)為(wei)(wei)(wei)福(fu)(fu)州(zhou)市(shi)平(ping)安(an)企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)、福(fu)(fu)建(jian)(jian)(jian)企(qi)(qi)(qi)(qi)業(ye)(ye)(ye)100強,2021年(nian)(nian)(nian)(nian)(nian)(nian)(nian)榮(rong)獲(huo)福(fu)(fu)州(zhou)市(shi)2018-2020年(nian)(nian)(nian)(nian)(nian)(nian)(nian)度市(shi)級文明(ming)單位(wei)。2021年(nian)(nian)(nian)(nian)(nian)(nian)(nian)1月(yue)1日起,中國寶(bao)(bao)(bao)(bao)(bao)武將寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)委托(tuo)太鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)集團管理(li),由此,寶(bao)(bao)(bao)(bao)(bao)鋼(gang)(gang)(gang)(gang)(gang)(gang)(gang)德(de)(de)(de)(de)盛(sheng)開始(shi)了發展(zhan)(zhan)的新征(zheng)程(cheng)。

寶(bao)鋼(gang)(gang)德(de)(de)盛(sheng)緊跟(gen)國內外不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)技(ji)術發(fa)展(zhan)動向(xiang),加強對新(xin)產(chan)(chan)(chan)品(pin)(pin)、新(xin)工藝、新(xin)技(ji)術的(de)(de)(de)前瞻性研(yan)(yan)發(fa)和應用,不(bu)(bu)(bu)(bu)(bu)(bu)斷拓展(zhan)不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)產(chan)(chan)(chan)品(pin)(pin)的(de)(de)(de)市場空間(jian),提升產(chan)(chan)(chan)品(pin)(pin)附加值(zhi)和競爭(zheng)力。2014年10月(yue),寶(bao)鋼(gang)(gang)德(de)(de)盛(sheng)BN1TP(管(guan)料產(chan)(chan)(chan)品(pin)(pin))、BD11(中(zhong)鎳(nie)產(chan)(chan)(chan)品(pin)(pin))研(yan)(yan)發(fa)成功(gong);2016年,成功(gong)開(kai)發(fa)400系(xi)鐵素體(ti)(ti)產(chan)(chan)(chan)品(pin)(pin)、低(di)碳奧氏(shi)體(ti)(ti)產(chan)(chan)(chan)品(pin)(pin)。之后,寶(bao)鋼(gang)(gang)德(de)(de)盛(sheng)開(kai)發(fa)出具有低(di)碳、節(jie)能、環(huan)保、美(mei)觀(guan)等特點的(de)(de)(de)綠色不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)產(chan)(chan)(chan)品(pin)(pin),如高氮(dan)不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)BN2R、馬氏(shi)體(ti)(ti)不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)系(xi)列、雙相(xiang)不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)、抗菌(jun)不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)及新(xin)一代(dai)汽(qi)車(che)用高強鋼(gang)(gang)BFS系(xi)列產(chan)(chan)(chan)品(pin)(pin),“紅(hong)土(tu)鎳(nie)礦冶(ye)煉鎳(nie)鐵及冶(ye)煉渣增值(zhi)利用關鍵技(ji)術與應用”項目獲2019年國家科技(ji)進(jin)步(bu)獎(jiang)二等獎(jiang)。寶(bao)鋼(gang)(gang)德(de)(de)盛(sheng)依托沿海區位優勢、靈(ling)活(huo)多變的(de)(de)(de)銷(xiao)售手段和穩定的(de)(de)(de)產(chan)(chan)(chan)品(pin)(pin)質量(liang)贏得市場。隨著制造能力的(de)(de)(de)提升,產(chan)(chan)(chan)品(pin)(pin)不(bu)(bu)(bu)(bu)(bu)(bu)斷拓展(zhan),寶(bao)鋼(gang)(gang)德(de)(de)盛(sheng)不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)產(chan)(chan)(chan)品(pin)(pin)由最初單一的(de)(de)(de)鉻(ge)-錳系(xi)奧氏(shi)體(ti)(ti)不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang),逐漸(jian)實現不(bu)(bu)(bu)(bu)(bu)(bu)銹(xiu)鋼(gang)(gang)各系(xi)列產(chan)(chan)(chan)品(pin)(pin)全覆蓋;產(chan)(chan)(chan)品(pin)(pin)質量(liang)提升由最初的(de)(de)(de)表面質量(liang)提升發(fa)展(zhan)為產(chan)(chan)(chan)品(pin)(pin)表面質量(liang)、性能等全方位提升,更好滿足用戶(hu)對產(chan)(chan)(chan)品(pin)(pin)越來(lai)越高的(de)(de)(de)質量(liang)需(xu)求。

寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)堅持綠色發展(zhan),大力(li)推進環(huan)境保(bao)(bao)護(hu)和(he)節能減排(pai)(pai)(pai)。2011-2013年(nian)(nian),寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)先后投人2.974億元,對(dui)原(yuan)工藝(yi)落后、設(she)計能力(li)不足、處理效果差(cha)的(de)(de)(de)廢(fei)(fei)(fei)氣和(he)廢(fei)(fei)(fei)水(shui)治(zhi)理設(she)施(shi)進行(xing)了整改(gai)(gai),并新(xin)增原(yuan)料場(chang)雨污排(pai)(pai)(pai)水(shui)回用系統(tong)、燒(shao)結(jie)機煙(yan)氣濕法脫(tuo)硫設(she)施(shi)、10萬平(ping)方(fang)米燒(shao)結(jie)封閉原(yuan)料大棚(peng)、燒(shao)結(jie)配料室(shi)脈沖布袋除(chu)塵(chen)器、除(chu)塵(chen)灰氣力(li)輸送系統(tong)、500噸(dun)廢(fei)(fei)(fei)酸水(shui)處理系統(tong)、凈車(che)出廠裝(zhuang)置等多套(tao)環(huan)保(bao)(bao)治(zhi)理設(she)施(shi),環(huan)保(bao)(bao)水(shui)平(ping)有所提(ti)升(sheng)。從(cong)2014年(nian)(nian)起(qi),寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)制定和(he)實(shi)施(shi)《環(huan)境保(bao)(bao)護(hu)改(gai)(gai)造(zao)三年(nian)(nian)行(xing)動規(gui)劃》,分(fen)別從(cong)廢(fei)(fei)(fei)水(shui)、廢(fei)(fei)(fei)氣、固體(ti)廢(fei)(fei)(fei)棄物(wu)、環(huan)境監測(ce)設(she)施(shi)和(he)總(zong)圖(tu)道路等五個(ge)方(fang)面進行(xing)環(huan)保(bao)(bao)改(gai)(gai)造(zao)。2014-2018年(nian)(nian),寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)先后實(shi)施(shi)規(gui)劃內(nei)環(huan)保(bao)(bao)改(gai)(gai)造(zao)項目(mu)22項,規(gui)劃外環(huan)保(bao)(bao)項目(mu)11項,完(wan)成環(huan)保(bao)(bao)投資(zi)5.17億元。從(cong)2019年(nian)(nian)起(qi),遵循國家《關于(yu)推進實(shi)施(shi)鋼(gang)(gang)(gang)鐵行(xing)業(ye)(ye)超(chao)(chao)低(di)排(pai)(pai)(pai)放的(de)(de)(de)意見》,按照(zhao)中國寶(bao)(bao)武“三治(zhi)四(si)化”要(yao)(yao)求(qiu),寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)在新(xin)產(chan)線綠色制造(zao)的(de)(de)(de)基礎上(shang),聚焦老產(chan)線的(de)(de)(de)綠色轉型(xing)升(sheng)級(ji),制定了老產(chan)線轉型(xing)升(sheng)級(ji)超(chao)(chao)低(di)排(pai)(pai)(pai)放改(gai)(gai)造(zao)方(fang)案,總(zong)體(ti)規(gui)劃,分(fen)步實(shi)施(shi),有序推進超(chao)(chao)低(di)排(pai)(pai)(pai)放改(gai)(gai)造(zao)。通過十(shi)年(nian)(nian)不懈(xie)努力(li),寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)現有環(huan)保(bao)(bao)設(she)施(shi)配套(tao)完(wan)善(shan),污染物(wu)排(pai)(pai)(pai)放濃度(du)符合現行(xing)標準,排(pai)(pai)(pai)放總(zong)量(liang)受控,并實(shi)現廢(fei)(fei)(fei)水(shui)零(ling)排(pai)(pai)(pai)放及(ji)固廢(fei)(fei)(fei)不出廠的(de)(de)(de)規(gui)劃要(yao)(yao)求(qiu),環(huan)境績效大幅提(ti)升(sheng)。寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)正規(gui)劃建設(she)3A級(ji)智(zhi)慧(hui)工業(ye)(ye)體(ti)驗式生(sheng)態旅游(you)項目(mu),內(nei)容主要(yao)(yao)包括(kuo)鋼(gang)(gang)(gang)城門戶廣場(chang)、智(zhi)慧(hui)運營中心等特(te)色場(chang)景體(ti)驗,憑借區域內(nei)的(de)(de)(de)優質(zhi)資(zi)源,圍繞“鋼(gang)(gang)(gang)鐵是(shi)怎(zen)樣煉(lian)成的(de)(de)(de)”主題(ti),通過工藝(yi)流程、5G智(zhi)慧(hui)運營中心等展(zhan)示,建設(she)具(ju)有冶金行(xing)業(ye)(ye)特(te)色的(de)(de)(de)產(chan)學研一(yi)體(ti)化基地,打造(zao)集生(sheng)產(chan)辦(ban)公、科(ke)普教育(yu)、生(sheng)態旅游(you)為一(yi)體(ti)的(de)(de)(de)綜合性(xing)特(te)色產(chan)業(ye)(ye)園區,塑造(zao)區域新(xin)標桿、新(xin)名片,展(zhan)現寶(bao)(bao)鋼(gang)(gang)(gang)德盛(sheng)鳳凰(huang)涅槃、浴火重生(sheng)般的(de)(de)(de)新(xin)變化,打造(zao)羅源灣畔的(de)(de)(de)“生(sheng)態明珠(zhu)”。

寶(bao)鋼(gang)德(de)盛(sheng)以創(chuang)建(jian)一流不銹(xiu)(xiu)(xiu)鋼(gang)精品智造(zao)基地(di)(di)為發(fa)展(zhan)目標,堅持(chi)技(ji)術、規(gui)模、效益(yi)引領,抓住國家供(gong)給側結構性改革機遇,堅持(chi)價(jia)值創(chuang)造(zao)、堅持(chi)綠(lv)色發(fa)展(zhan)、堅持(chi)技(ji)術創(chuang)新和發(fa)展(zhan)模式創(chuang)新,為汽車、機械、家電、能源、船舶、海洋(yang)工程、核電建(jian)設、交通等(deng)下(xia)游行業提(ti)供(gong)精品不銹(xiu)(xiu)(xiu)鋼(gang)等(deng)鋼(gang)材,助(zhu)力中國不銹(xiu)(xiu)(xiu)鋼(gang)行業轉型升級(ji)。目前(qian),寶(bao)鋼(gang)德(de)盛(sheng)制定(ding)(ding)了“十(shi)四五”規(gui)劃(hua),確定(ding)(ding)了新的(de)發(fa)展(zhan)戰略(lve):第一步,2021年(nian)建(jian)成(cheng)年(nian)產(chan)(chan)470萬噸精品不銹(xiu)(xiu)(xiu)鋼(gang)綠(lv)色產(chan)(chan)業基地(di)(di),規(gui)模做大,實(shi)現200系(xi)(xi)、300系(xi)(xi)、400系(xi)(xi)不銹(xiu)(xiu)(xiu)鋼(gang)產(chan)(chan)品全覆(fu)蓋;第二(er)步,2022年(nian)完成(cheng)老產(chan)(chan)線超低排(pai)放及轉型升級(ji)技(ji)術改造(zao),實(shi)現生產(chan)(chan)超低排(pai)放,不銹(xiu)(xiu)(xiu)鋼(gang)綠(lv)色、精品、成(cheng)本、智造(zao)全方(fang)位領先;第三步,2025年(nian)不銹(xiu)(xiu)(xiu)鋼(gang)綜合競爭力穩居(ju)世界一流地(di)(di)位。

圍繞(rao)上(shang)述目標,寶鋼德盛將堅持(chi)通(tong)過對(dui)標找差、內部(bu)挖潛,持(chi)續(xu)降低產(chan)品制(zhi)造成(cheng)本(ben);優化(hua)品種結構,提(ti)高高技術及高附加值產(chan)品銷(xiao)量比(bi)例;依(yi)托(tuo)協同支撐,提(ti)高管理能(neng)力、經營能(neng)力和抵御風險(xian)能(neng)力;對(dui)接中國寶武(wu)鋼鐵生態圈戰(zhan)略,共(gong)享優質資源(yuan);拓(tuo)寬物資采購渠(qu)道,降低采購成(cheng)本(ben);借助銷(xiao)售(shou)平臺,提(ti)升產(chan)品附加值,提(ti)升市場占(zhan)有(you)率(lv),實現商業模式新突破;加強人才隊(dui)伍建設,著力推進員(yuan)工素質工程,優化(hua)員(yuan)工隊(dui)伍結構,大力培(pei)養優秀(xiu)青(qing)年人才,為后續(xu)規劃發(fa)展奠定基礎,做優做強做大不銹鋼產(chan)業。

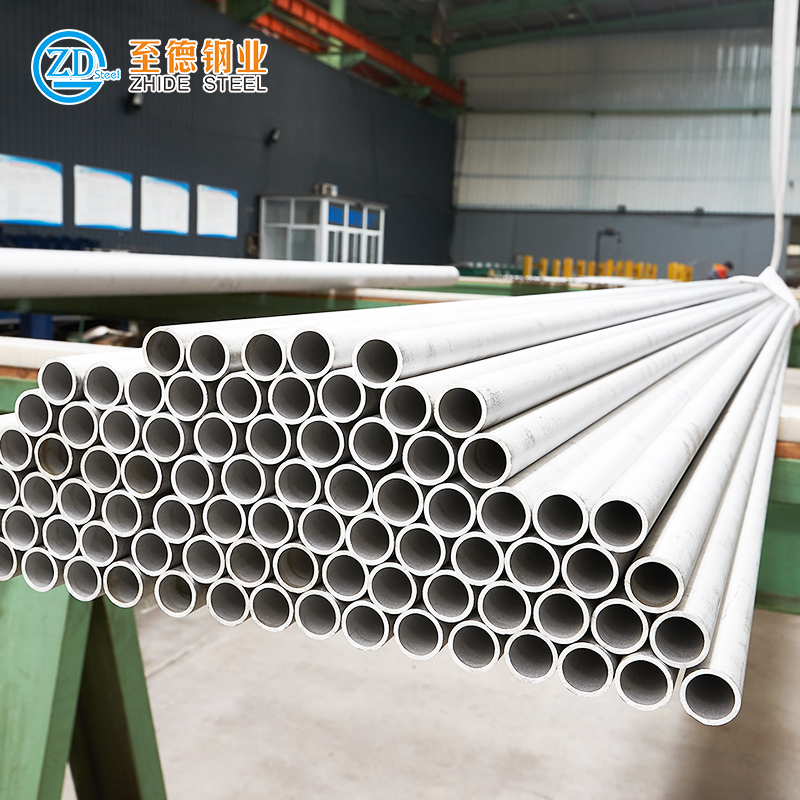

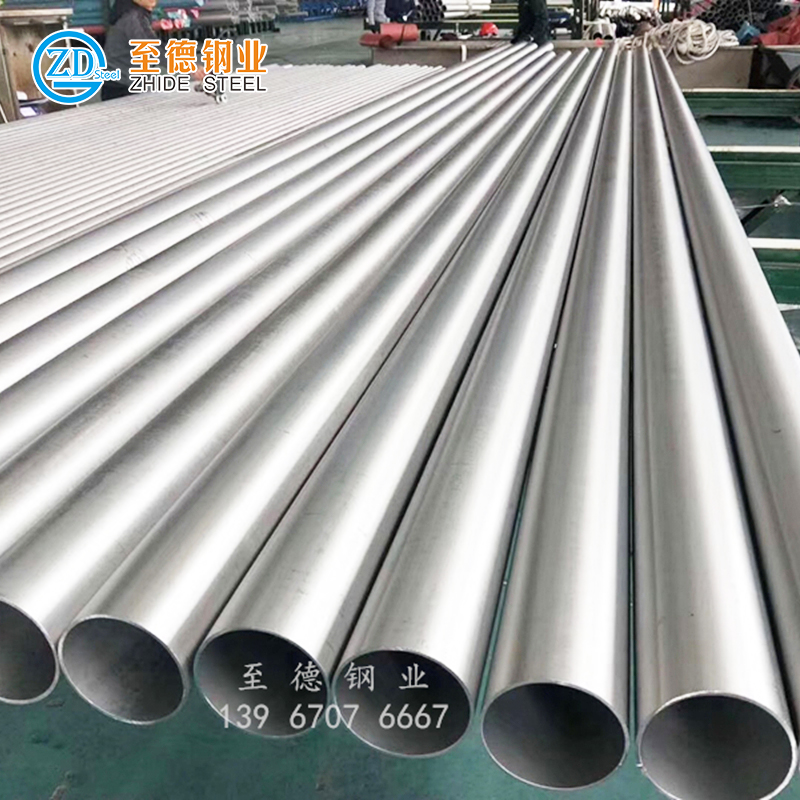

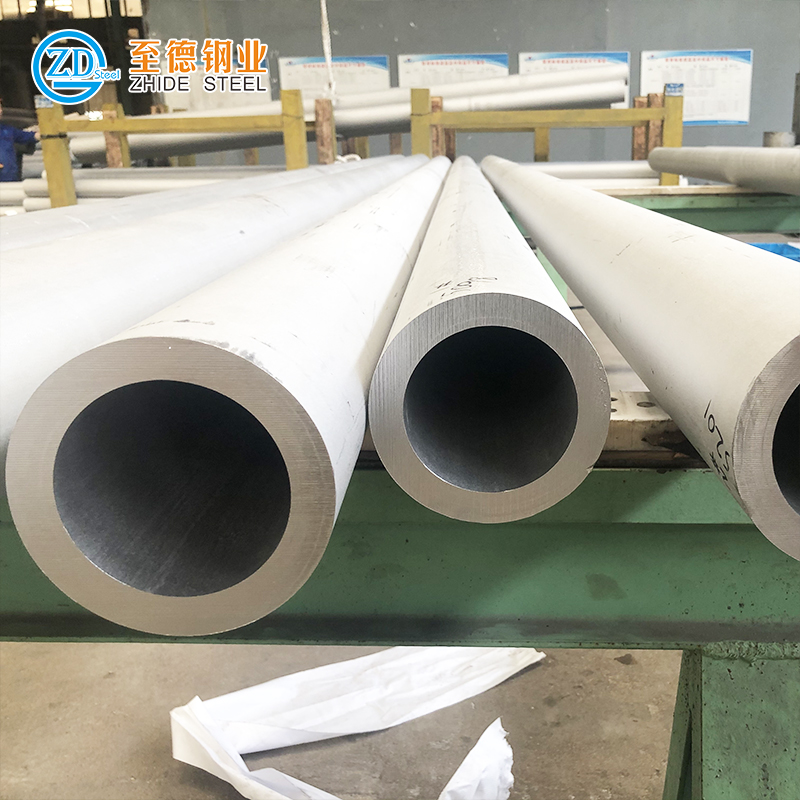

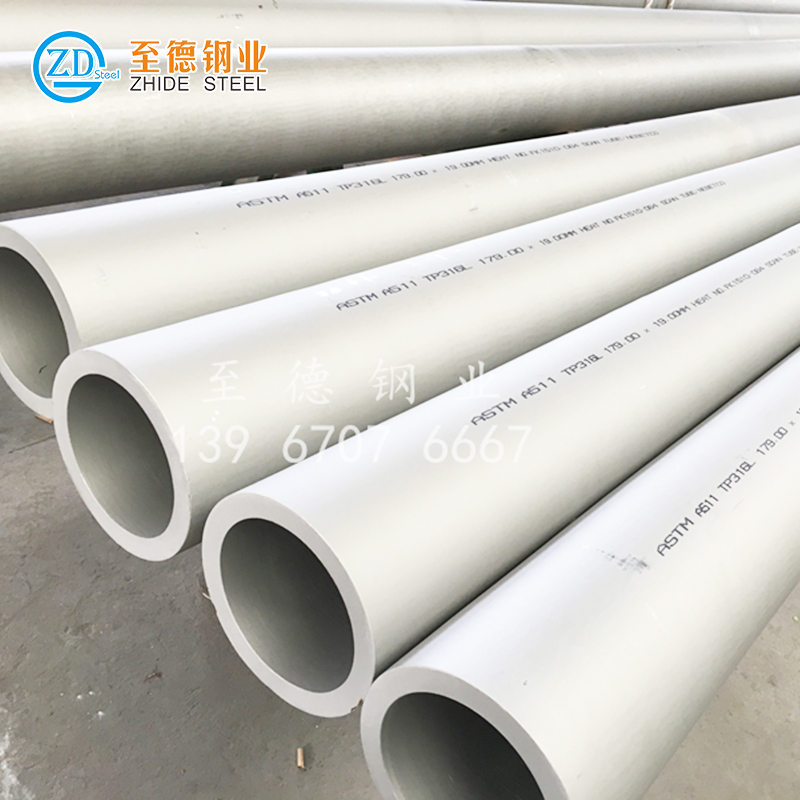

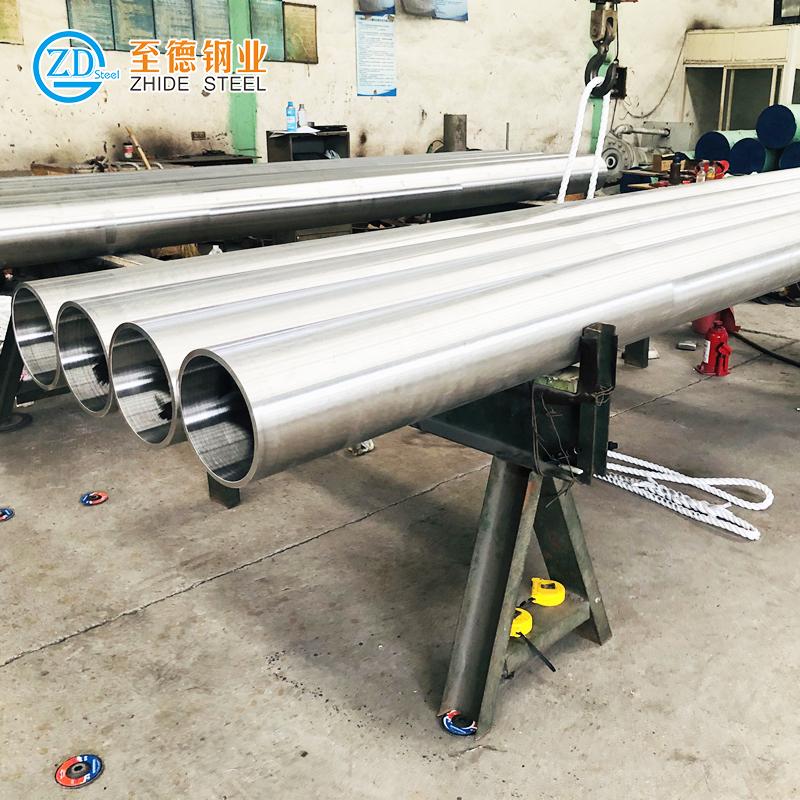

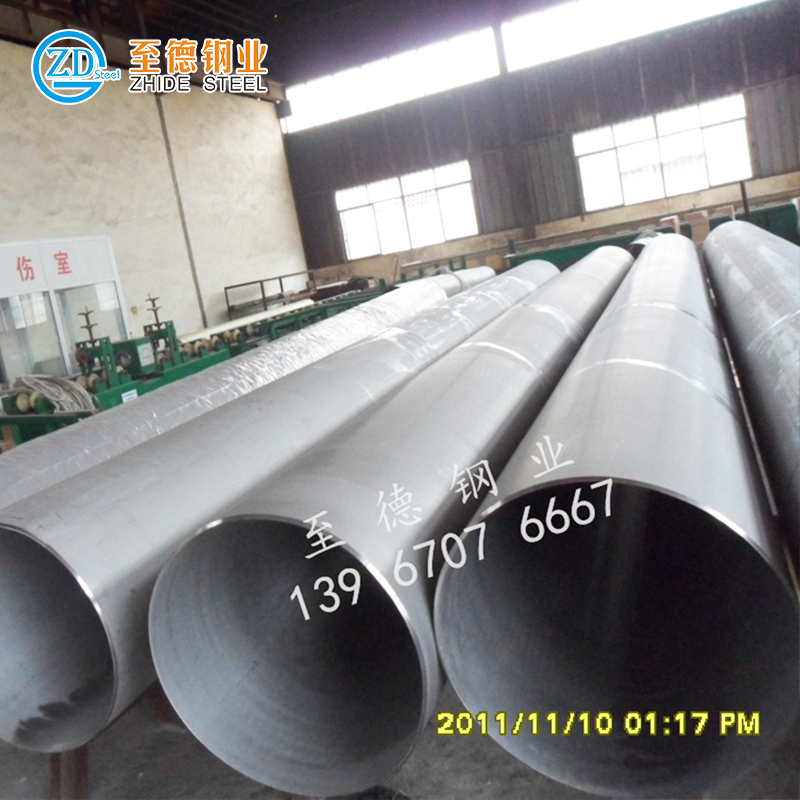

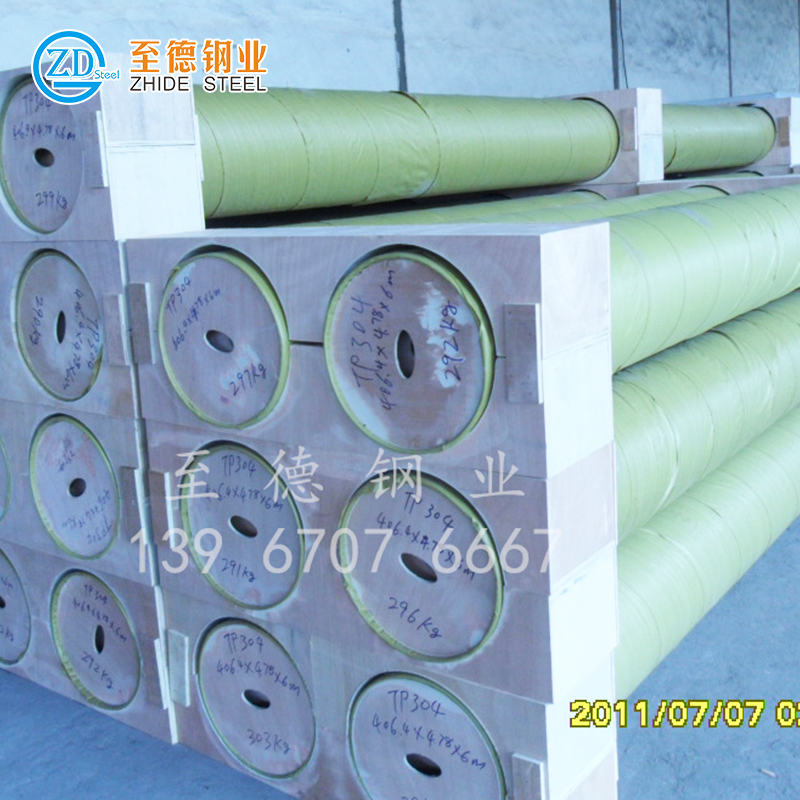

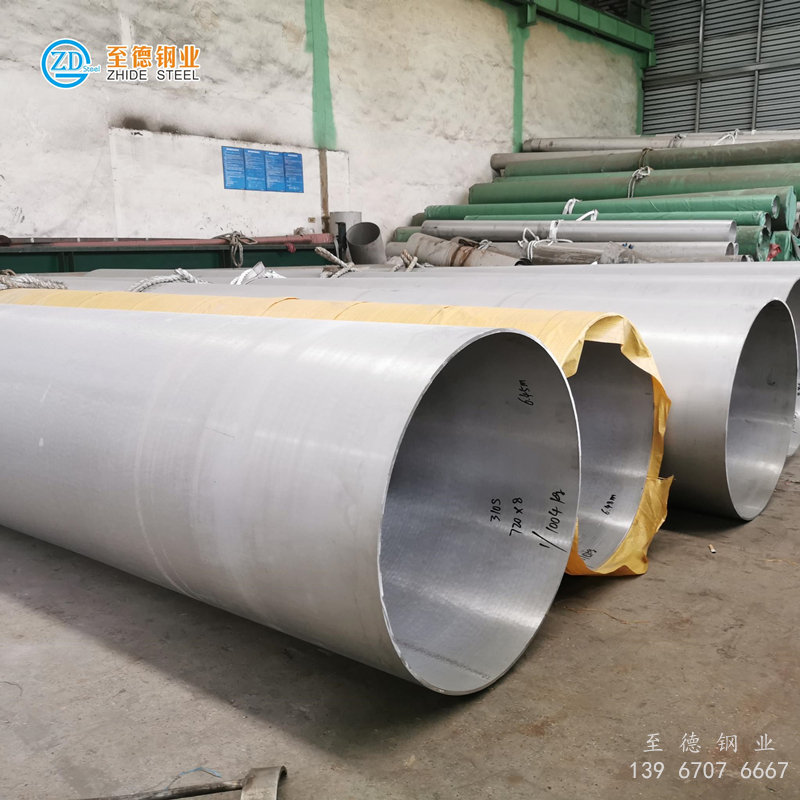

至德鋼業(ye),我們根(gen)據您的實際需求,給出(chu)參考建(jian)議,為您提(ti)供(gong)高性價比(bi)的不銹(xiu)鋼管道及(ji)配件。