在國家政策支持下,太鋼歷時七年,建設了世界上產量最大、自動化水平最高的熱軋帶鋼(80萬噸/年)和冷軋帶鋼(50萬噸/年)連續退火酸洗機組。對不銹鋼冷軋帶鋼流程進行大膽革新,建設了世界一流的不(bu)銹鋼連軋機組,創造性地把各個獨立的生產單元“五機架連軋機、退火、酸洗、平整、拉矯、縱切”等有機地集成在一條線上,建成了不銹鋼冷軋帶鋼“六位一體”的全連續生產線。該生產線經過一次上卷和一次卸卷即可產出成品,減少了生產過程環節,簡化了流程,提高生產效率,降低工藝介質消耗。該產線解決了多工序工藝匹配優化設計、鐵素體等特殊品種高質量生產、全線高效精準運行及智能控制等一系列難題,實現了不銹鋼冷軋帶鋼全連續生產線技術集成與創新。

太鋼(gang)不(bu)銹(xiu)鋼(gang)冷(leng)(leng)軋帶鋼(gang)全(quan)連續生產(chan)(chan)線有效(xiao)地(di)提高了(le)(le)冷(leng)(leng)軋過程(cheng)的(de)生產(chan)(chan)效(xiao)率,縮短(duan)了(le)(le)生產(chan)(chan)周期,降低了(le)(le)資金(jin)占(zhan)(zhan)用時間,加快訂(ding)單交(jiao)付周期;減少(shao)了(le)(le)各工(gong)(gong)(gong)序切損造(zao)成(cheng)的(de)帶鋼(gang)損失,提高成(cheng)材率4%以上(shang);節(jie)省了(le)(le)以前(qian)各工(gong)(gong)(gong)序的(de)上(shang)卷與下卷裝(zhuang)備,節(jie)約設備投資;節(jie)省了(le)(le)占(zhan)(zhan)地(di)面積(ji),提高土地(di)利(li)用率;減少(shao)操作(zuo)人員數量,降低綜合能源消(xiao)耗(hao)。該(gai)工(gong)(gong)(gong)程(cheng)設計工(gong)(gong)(gong)藝先進,布置緊湊,物流高效(xiao),裝(zhuang)備國產(chan)(chan)化率高,成(cheng)本低,質(zhi)量優,代表了(le)(le)當(dang)今世(shi)界不(bu)銹(xiu)鋼(gang)生產(chan)(chan)的(de)最高技術(shu)(shu)水平(ping)。項(xiang)目榮獲(huo)2016年度全(quan)國冶金(jin)行(xing)業(ye)優秀(xiu)工(gong)(gong)(gong)程(cheng)設計一(yi)等(deng)獎(jiang),2016-2017年度國家(jia)優質(zhi)工(gong)(gong)(gong)程(cheng)獎(jiang),2017年入選工(gong)(gong)(gong)業(ye)和(he)信息化部“智能制造(zao)試點示范項(xiang)目”。該(gai)生產(chan)(chan)線擁有多項(xiang)自(zi)主知識產(chan)(chan)權,授(shou)權專(zhuan)利(li)48件,其(qi)中(zhong)發明專(zhuan)利(li)26件,企業(ye)專(zhuan)有技術(shu)(shu)49件。經(jing)專(zhuan)家(jia)評價,其(qi)總體(ti)技術(shu)(shu)達國際(ji)領先水平(ping),為高質(zhi)量、高效(xiao)率、低成(cheng)本的(de)不(bu)銹(xiu)鋼(gang)冷(leng)(leng)板制造(zao)提供了(le)(le)新模式,成(cheng)為世(shi)界不(bu)銹(xiu)鋼(gang)冷(leng)(leng)軋生產(chan)(chan)技術(shu)(shu)的(de)標(biao)桿(gan),對不(bu)銹(xiu)鋼(gang)冷(leng)(leng)軋規模化發展有引領和(he)示范作(zuo)用。

太鋼不(bu)銹(xiu)鋼冷(leng)連軋工(gong)程(cheng)在(zai)(zai)(zai)工(gong)藝技術和裝(zhuang)備上(shang)實現了(le)(le)一系列(lie)重大(da)突破(po)和創新。在(zai)(zai)(zai)工(gong)藝技術上(shang),該生(sheng)產(chan)線(xian)集(ji)成(cheng)了(le)(le)當今世(shi)(shi)界上(shang)最(zui)先進的(de)不(bu)銹(xiu)鋼冷(leng)連軋軋制、超長連續退(tui)火(huo)等諸多新技術;配套實施了(le)(le)酸(suan)再(zai)生(sheng)、酸(suan)凈化、污水處(chu)理(li)、氮氧化物(wu)減排等一系列(lie)環(huan)保(bao)技術。在(zai)(zai)(zai)裝(zhuang)備配置(zhi)上(shang),建成(cheng)了(le)(le)目(mu)前世(shi)(shi)界上(shang)最(zui)先進的(de)激光(guang)焊(han)機(ji)(ji)、世(shi)(shi)界上(shang)第(di)一套5機(ji)(ji)架(jia)不(bu)銹(xiu)鋼冷(leng)連軋機(ji)(ji)、最(zui)大(da)的(de)冷(leng)軋不(bu)銹(xiu)鋼帶(dai)鋼連續退(tui)火(huo)爐及其酸(suan)洗系統,平(ping)整機(ji)(ji)、拉(la)轎機(ji)(ji)、在(zai)(zai)(zai)線(xian)切邊剪(jian)機(ji)(ji)實現了(le)(le)在(zai)(zai)(zai)線(xian)集(ji)成(cheng),可以直接(jie)生(sheng)產(chan)出成(cheng)品卷,成(cheng)為世(shi)(shi)界第(di)一條工(gong)序集(ji)成(cheng)度(du)最(zui)全(quan)最(zui)高、節(jie)能環(huan)保(bao)效果最(zui)優(you)的(de)不(bu)銹(xiu)鋼冷(leng)連軋生(sheng)產(chan)線(xian),將大(da)幅(fu)提(ti)升太鋼不(bu)銹(xiu)鋼產(chan)品的(de)生(sheng)產(chan)效率和產(chan)品質量水平(ping),提(ti)高產(chan)品的(de)市場(chang)競爭力。

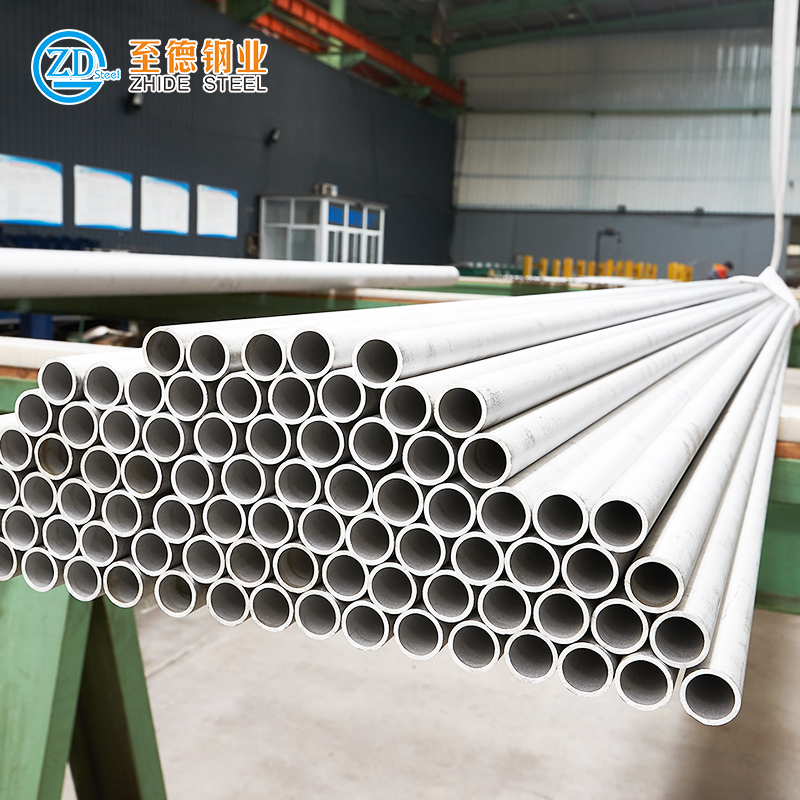

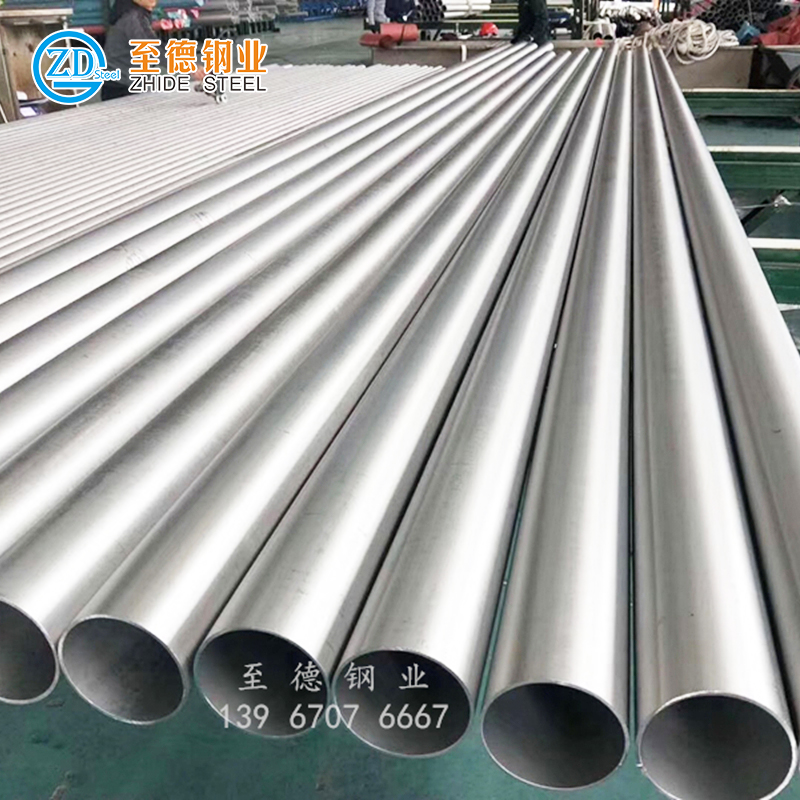

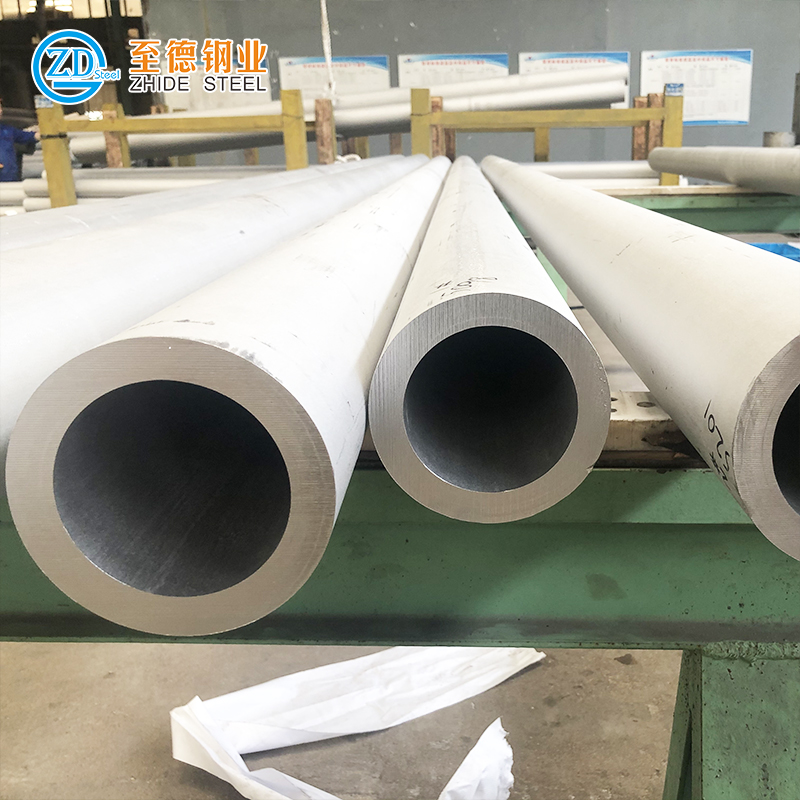

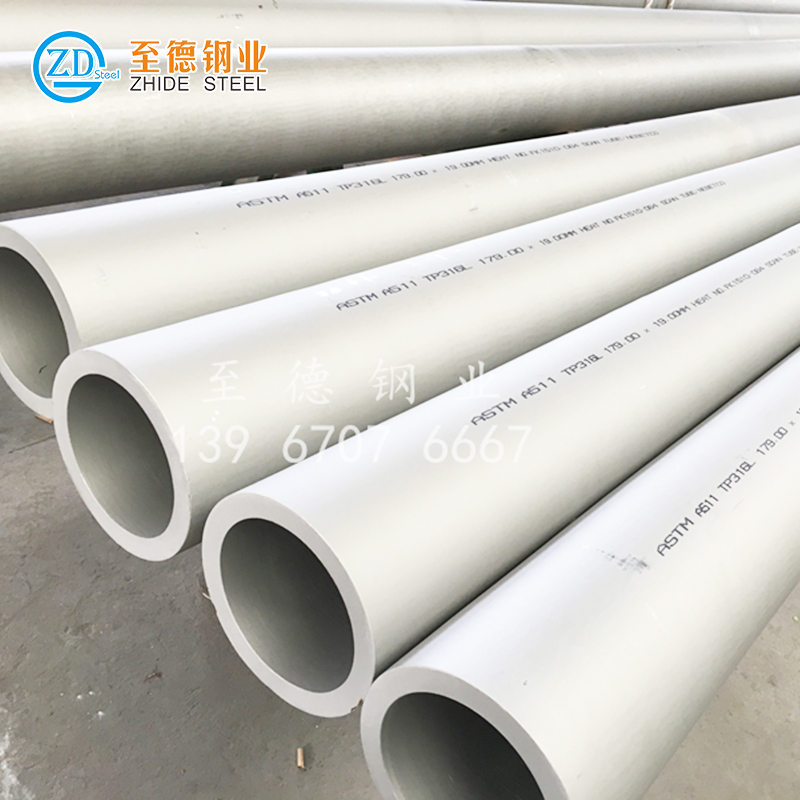

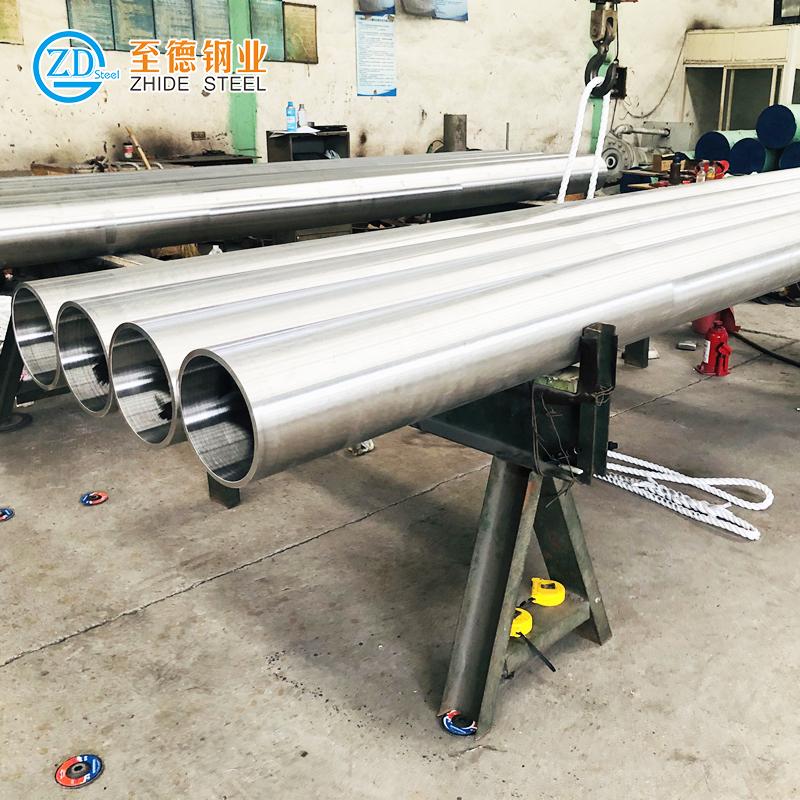

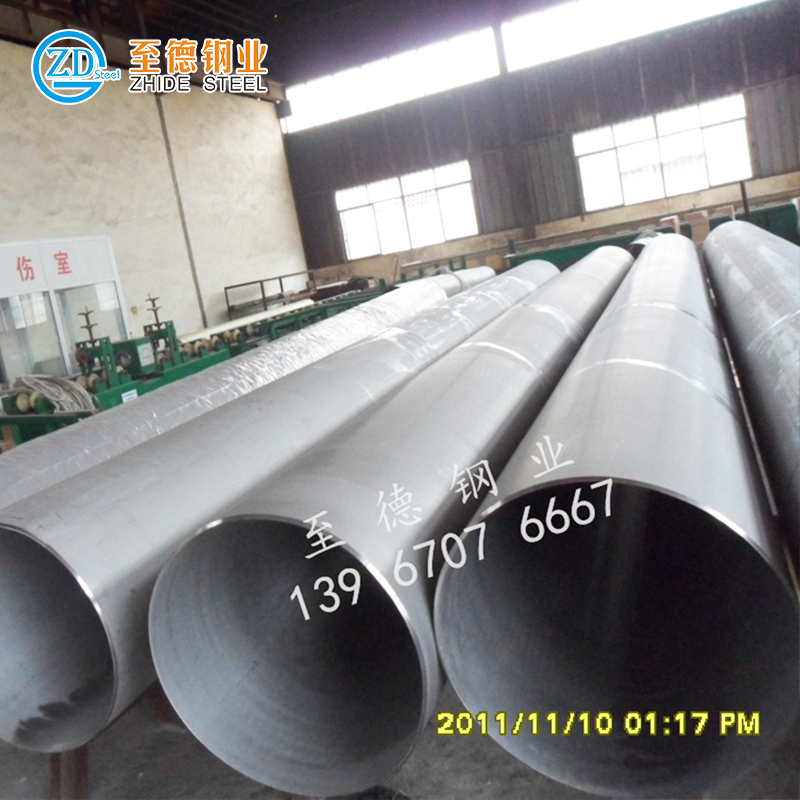

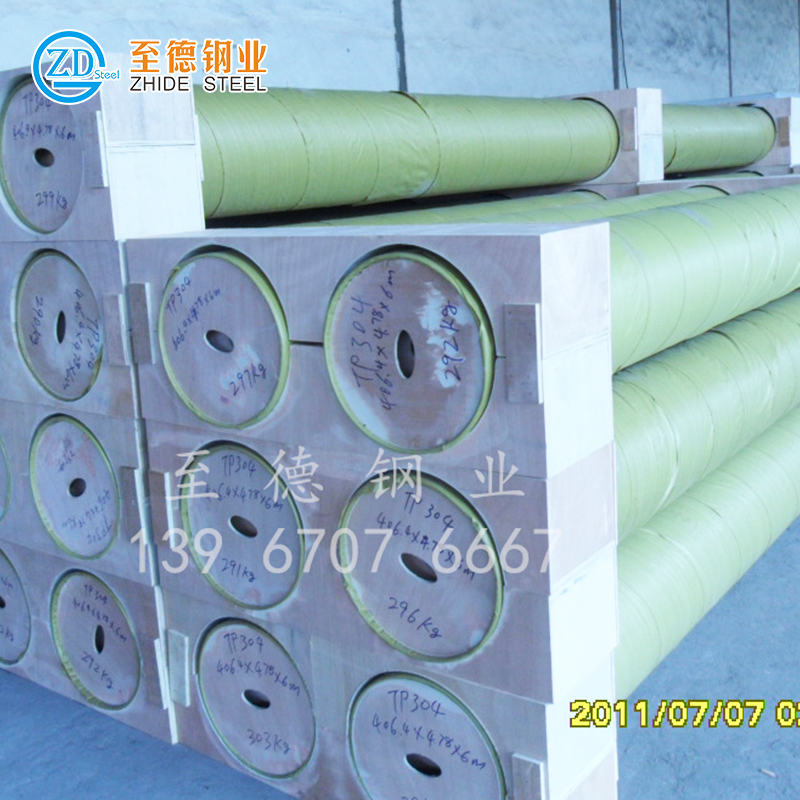

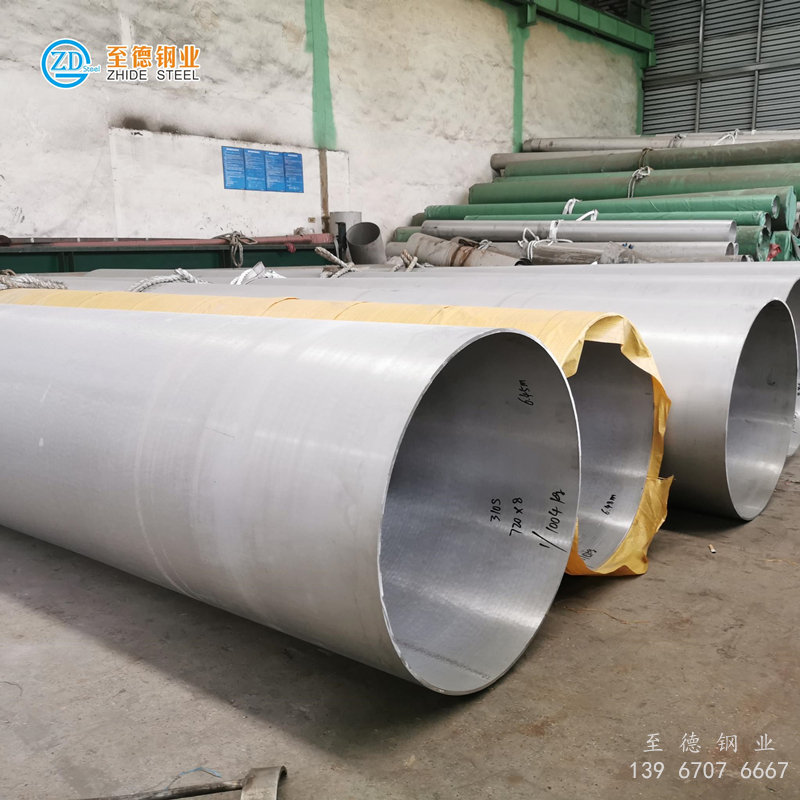

至德鋼業,我(wo)們根據(ju)您(nin)的(de)實際(ji)需(xu)求(qiu),給(gei)出參考(kao)建(jian)議,為您(nin)提供高性(xing)價比的(de)不銹鋼管(guan)道及配件。