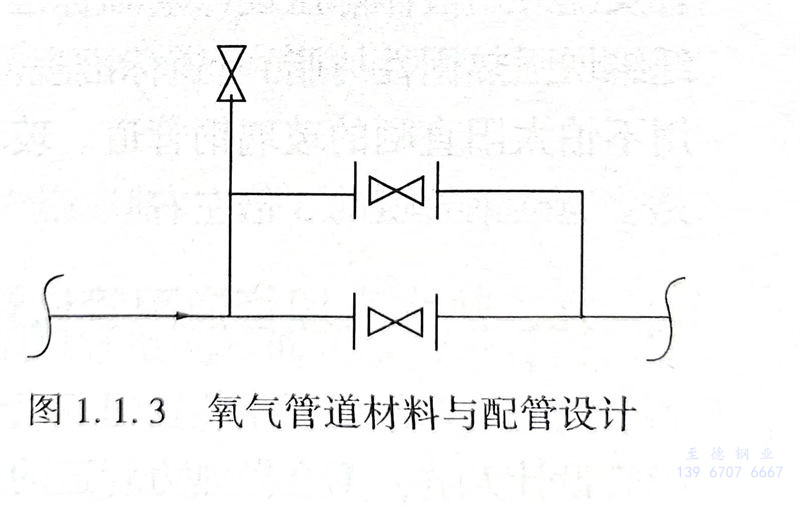

在某石化裝置,浙江至德鋼業有限公司工人人員發現某氧(yang)氣管(guan)道閥門側面還設計了防爆操作防護墻,有些防護過度。歸根結底是配管設計人員沒有真正理解標準規范的設計要求,由心中過度害怕引起。如圖1.1.3所示,某氧氣管道主管是18”的A312 TP304/TP304L(SMLS),后增加了旁路,配管設計人員仍選用A312 TP304/TP304L(SMLS)不銹鋼管道是錯誤的,因按照此工藝圖,旁路1.5"的流速加大了,需要選用鎳基(ji)合金材料(UNS N06600)才可以滿足工程設計質量。氧氣管道材料應根據管道壓力、溫度和流速不同選用碳鋼、不銹(xiu)鋼(gang)和鎳基合金;宜采用無縫鋼管、無縫管件、全通徑閥,其操作狀態全開或全關,不得使其處于半開半關狀態;切斷閥操作過程兩端壓差不能過大,閥門宜用法蘭連接;墊片宜選用帶內環聚四氟乙烯纏繞墊片;填料不應采用易脫落碎屑、纖維的材料或可燃的材料制成,宜選用聚四氟乙烯材料;三通宜選用等徑三通,氧氣管子、管件、閥門等應進行脫脂處理。見歐洲工業氣體協會標準(EIGA)《Oxygen Piping Systems》(氧氣管道系統)IGC DOC 13/12/E等規范。

如圖1.1.3所示,緊急(ji)切(qie)斷(duan)閥(fa)(fa)(fa)(fa)(fa)通(tong)(tong)(tong)(tong)常(chang)(chang)(chang)是自動(dong)的(de)(de),在(zai)全開位(wei)置運行,通(tong)(tong)(tong)(tong)常(chang)(chang)(chang)僅在(zai)緊急(ji)情況下(xia)關(guan)閉。緊急(ji)切(qie)斷(duan)閥(fa)(fa)(fa)(fa)(fa)是高流量(liang)(liang)(liang)閥(fa)(fa)(fa)(fa)(fa),通(tong)(tong)(tong)(tong)常(chang)(chang)(chang)為閘閥(fa)(fa)(fa)(fa)(fa)、刀形閘閥(fa)(fa)(fa)(fa)(fa)、蝶閥(fa)(fa)(fa)(fa)(fa)或(huo)球閥(fa)(fa)(fa)(fa)(fa)。旁(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)(fa)通(tong)(tong)(tong)(tong)常(chang)(chang)(chang)是從手(shou)動(dong)閥(fa)(fa)(fa)(fa)(fa)的(de)(de)上(shang)游到下(xia)游的(de)(de)隔離(li)閥(fa)(fa)(fa)(fa)(fa),安裝(zhuang)目的(de)(de)是通(tong)(tong)(tong)(tong)過隔離(li)閥(fa)(fa)(fa)(fa)(fa)對(dui)壓(ya)(ya)力(li)進行均衡,一旦(dan)建立了壓(ya)(ya)力(li)均衡,隔離(li)閥(fa)(fa)(fa)(fa)(fa)可以安全打開。旁(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)(fa)也用于(yu)對(dui)下(xia)游系(xi)統緩(huan)慢(man)加壓(ya)(ya),以緩(huan)解超速(su)和快(kuai)速(su)增壓(ya)(ya)風險(xian)。受控、緩(huan)慢(man)加壓(ya)(ya)需要使(shi)用節流流量(liang)(liang)(liang)控制(zhi)型閥(fa)(fa)(fa)(fa)(fa)門,由于(yu)其具(ju)有流量(liang)(liang)(liang)控制(zhi)功能(neng),旁(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)(fa)分為節流閥(fa)(fa)(fa)(fa)(fa)、過程控制(zhi)閥(fa)(fa)(fa)(fa)(fa)。雖然被歸(gui)類(lei)為過程控制(zhi)閥(fa)(fa)(fa)(fa)(fa),旁(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)(fa)通(tong)(tong)(tong)(tong)常(chang)(chang)(chang)為手(shou)動(dong)操(cao)作(zuo)閥(fa)(fa)(fa)(fa)(fa),通(tong)(tong)(tong)(tong)常(chang)(chang)(chang)是截(jie)止閥(fa)(fa)(fa)(fa)(fa)或(huo)球閥(fa)(fa)(fa)(fa)(fa)等。為盡量(liang)(liang)(liang)減少(shao)旁(pang)通(tong)(tong)(tong)(tong)管線(xian)中(zhong)可能(neng)聚(ju)集的(de)(de)顆(ke)粒數量(liang)(liang)(liang),旁(pang)通(tong)(tong)(tong)(tong)管連接應安裝(zhuang)到主管中(zhong)心(xin)線(xian)或(huo)中(zhong)心(xin)線(xian)以上(shang)。

按GB 50030《氧氣(qi)站設計(ji)規范》,設計(ji)壓(ya)力(li)大于0.1MPa的(de)氧氣(qi)管道(dao)上(shang),不得用(yong)閘(zha)閥(fa)。設計(ji)壓(ya)力(li)大于或等于1.0MPa且公(gong)稱直徑大于或等于150mm的(de)氧氣(qi)管道(dao)上(shang)的(de)手(shou)動(dong)(dong)閥(fa)門(men),宜設旁通閥(fa)。設計(ji)壓(ya)力(li)大于1.0MPa,公(gong)稱直徑大于或等于150mm的(de)氧氣(qi)管道(dao)上(shang)經(jing)常操作的(de)閥(fa)門(men),宜用(yong)氣(qi)動(dong)(dong)閥(fa)門(men)。