影響埋弧焊接不(bu)銹鋼管操作因素主要有以下兩點:

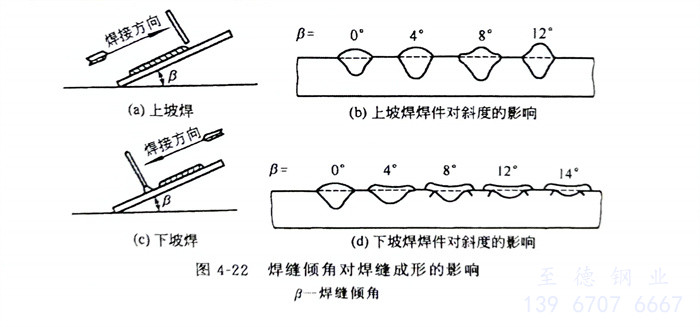

一、焊絲傾斜方向的(de)影響

焊絲傾斜方向分為前傾和后傾兩種,如圖4-21所示。焊絲傾角的大小不同,電弧對熔池的力和熱作用也就不同,從而影響到焊縫成形。當焊絲以一定傾角向后傾時,電弧力對熔池金屬的后緣作用減弱,熔池底部的金屬受熱減少,故熔深變淺,如圖4-21(c)所示。后傾角愈大,熔深愈淺,而熔寬增寬。相反,當焊絲做適當前傾時,可少許增加熔深。焊絲前傾斜通常較少采用,只有在特定情況下使用,如焊接小直徑圓筒形焊件的環焊縫時采用這種方法。

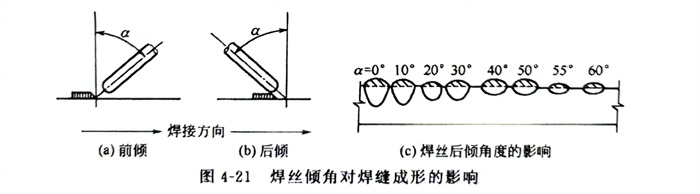

二、焊縫(feng)傾角(jiao)(inclination of weld axis,焊縫(feng)軸線(xian)與水平面之(zhi)間(jian)的夾角(jiao))對焊縫(feng)成(cheng)形(xing)的影響

焊(han)(han)(han)(han)(han)(han)件(jian)在傾斜位置焊(han)(han)(han)(han)(han)(han)接時,有(you)(you)上坡(po)(po)焊(han)(han)(han)(han)(han)(han)和(he)(he)下(xia)(xia)(xia)坡(po)(po)焊(han)(han)(han)(han)(han)(han)之分,如圖(tu)4-22所示。上坡(po)(po)焊(han)(han)(han)(han)(han)(han)、下(xia)(xia)(xia)坡(po)(po)焊(han)(han)(han)(han)(han)(han)對焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)成形(xing)(xing)的(de)影響明顯(xian)地不(bu)同。上坡(po)(po)焊(han)(han)(han)(han)(han)(han)時,焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)余高(gao)過(guo)(guo)高(gao),兩側易(yi)出現咬邊(bian),焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)表(biao)面成形(xing)(xing)明顯(xian)惡(e)化,實際工作中應避免采用(yong)上坡(po)(po)焊(han)(han)(han)(han)(han)(han)。下(xia)(xia)(xia)坡(po)(po)焊(han)(han)(han)(han)(han)(han)與上坡(po)(po)焊(han)(han)(han)(han)(han)(han)相反,焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)的(de)熔深和(he)(he)余高(gao)均有(you)(you)所減(jian)小,而焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)寬度(du)略有(you)(you)增加(jia),焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)成形(xing)(xing)得到改(gai)善。在焊(han)(han)(han)(han)(han)(han)接圓(yuan)筒焊(han)(han)(han)(han)(han)(han)件(jian)的(de)內、外環焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)時,一(yi)般均采用(yong)下(xia)(xia)(xia)坡(po)(po)焊(han)(han)(han)(han)(han)(han),以減(jian)少(shao)發生(sheng)燒穿的(de)現象(xiang),并(bing)改(gai)善焊(han)(han)(han)(han)(han)(han)縫(feng)(feng)(feng)成形(xing)(xing)。但焊(han)(han)(han)(han)(han)(han)件(jian)下(xia)(xia)(xia)坡(po)(po)焊(han)(han)(han)(han)(han)(han)的(de)角度(du)過(guo)(guo)大時,熔深減(jian)小可能產生(sheng)未(wei)焊(han)(han)(han)(han)(han)(han)透焊(han)(han)(han)(han)(han)(han)接缺陷。