熱(re)水(shui)(shui)供應系統的安裝(zhuang)技術要求與(yu)熱(re)水(shui)(shui)采暖(nuan)系統安裝(zhuang)技術要求相(xiang)同。用水(shui)(shui)點(又稱配水(shui)(shui)點)多為衛生(sheng)設(she)備,安裝(zhuang)要求見給、排水(shui)(shui)、衛生(sheng)設(she)備安裝(zhuang)相(xiang)關部分。

熱(re)(re)水(shui)供(gong)應系統所(suo)需(xu)設(she)備如(ru)圖2-52所(suo)示(shi),主要有循(xun)環(huan)水(shui)泵、補(bu)充(chong)水(shui)泵、冷水(shui)箱(xiang)、閉式膨脹水(shui)箱(xiang)、自動排氣(qi)閥、安全閥、水(shui)的(de)加(jia)熱(re)(re)裝(zhuang)置(zhi)等。

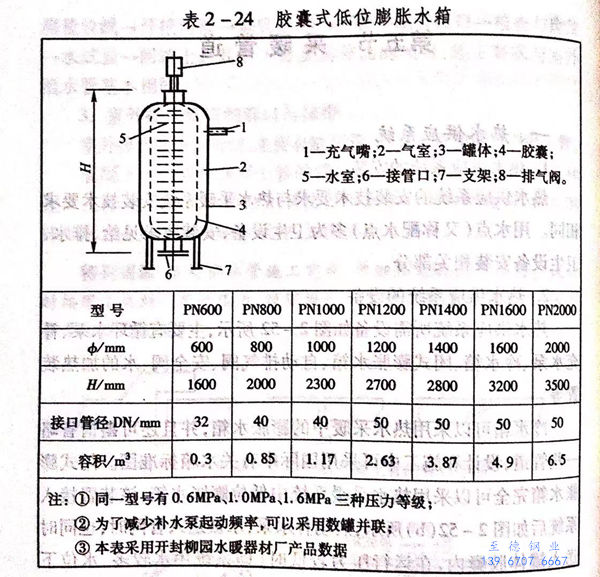

冷水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)可(ke)以采用(yong)(yong)熱水(shui)(shui)(shui)(shui)(shui)(shui)采暖(nuan)中(zhong)的(de)(de)膨(peng)脹(zhang)(zhang)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang),并(bing)(bing)且還可(ke)斟(zhen)情省略一些(xie)管道,設(she)(she)計(ji)和施工中(zhong)可(ke)采用(yong)(yong)國際中(zhong)有關水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)標準(zhun)圖。閉式膨(peng)脹(zhang)(zhang)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)完全可(ke)以采用(yong)(yong)熱水(shui)(shui)(shui)(shui)(shui)(shui)采暖(nuan)系(xi)統(tong)中(zhong)低位膨(peng)脹(zhang)(zhang)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang),該裝置接人(ren)系(xi)統(tong)后如圖2-52(b)所示(shi),啟(qi)動(dong)補(bu)水(shui)(shui)(shui)(shui)(shui)(shui)泵(beng)(beng),水(shui)(shui)(shui)(shui)(shui)(shui)被(bei)送入(ru)管網時(shi),也同(tong)時(shi)送入(ru)罐體膠囊(nang)內(nei)(nei)(nei),在(zai)運(yun)(yun)行壓(ya)力較低時(shi)(即系(xi)統(tong)用(yong)(yong)水(shui)(shui)(shui)(shui)(shui)(shui)較多、水(shui)(shui)(shui)(shui)(shui)(shui)位下(xia)降),補(bu)水(shui)(shui)(shui)(shui)(shui)(shui)泵(beng)(beng)把水(shui)(shui)(shui)(shui)(shui)(shui)不(bu)(bu)(bu)斷送入(ru)系(xi)統(tong)并(bing)(bing)送入(ru)膠囊(nang)內(nei)(nei)(nei),膠囊(nang)不(bu)(bu)(bu)斷向外擴大而擠壓(ya)氣室(shi),氣室(shi)的(de)(de)縮(suo)小使(shi)壓(ya)力升高(gao),當(dang)壓(ya)力達(da)(da)到設(she)(she)計(ji)最高(gao)壓(ya)力時(shi),膠囊(nang)內(nei)(nei)(nei)的(de)(de)容(rong)水(shui)(shui)(shui)(shui)(shui)(shui)量達(da)(da)到設(she)(she)計(ji)值(zhi),此時(shi)膠囊(nang)內(nei)(nei)(nei)外壓(ya)力相等,膠囊(nang)不(bu)(bu)(bu)脹(zhang)(zhang)不(bu)(bu)(bu)縮(suo),處于暫時(shi)平衡狀態。補(bu)水(shui)(shui)(shui)(shui)(shui)(shui)泵(beng)(beng)通過(guo)壓(ya)力控(kong)制器而停(ting)(ting)運(yun)(yun)。水(shui)(shui)(shui)(shui)(shui)(shui)泵(beng)(beng)停(ting)(ting)運(yun)(yun)后,氣室(shi)中(zhong)氣體壓(ya)力擠壓(ya)膠囊(nang),使(shi)膠囊(nang)內(nei)(nei)(nei)的(de)(de)水(shui)(shui)(shui)(shui)(shui)(shui)流人(ren)系(xi)統(tong),氣室(shi)壓(ya)力也隨之減(jian)小,當(dang)氣壓(ya)降到設(she)(she)計(ji)最低壓(ya)力時(shi),通過(guo)壓(ya)力控(kong)制器啟(qi)動(dong)水(shui)(shui)(shui)(shui)(shui)(shui)泵(beng)(beng),又(you)使(shi)水(shui)(shui)(shui)(shui)(shui)(shui)送進系(xi)統(tong)和膠囊(nang),這就既保證了用(yong)(yong)戶供(gong)熱水(shui)(shui)(shui)(shui)(shui)(shui)(或供(gong)冷水(shui)(shui)(shui)(shui)(shui)(shui))的(de)(de)需要,又(you)使(shi)水(shui)(shui)(shui)(shui)(shui)(shui)泵(beng)(beng)有條件地間斷工作,節約了電能。目前已成(cheng)為熱水(shui)(shui)(shui)(shui)(shui)(shui)供(gong)應系(xi)統(tong)或無(wu)塔供(gong)水(shui)(shui)(shui)(shui)(shui)(shui)的(de)(de)常(chang)用(yong)(yong)設(she)(she)備。其規格見表2-24。

水(shui)(shui)(shui)的(de)(de)加(jia)(jia)(jia)熱(re)(re)(re)(re)設備(bei)是熱(re)(re)(re)(re)水(shui)(shui)(shui)供(gong)應的(de)(de)熱(re)(re)(re)(re)源部分,又稱(cheng)加(jia)(jia)(jia)熱(re)(re)(re)(re)器(qi)。根據系統范圍(wei)大(da)小可采(cai)用(yong)水(shui)(shui)(shui)-水(shui)(shui)(shui)熱(re)(re)(re)(re)交換器(qi)、汽(qi)一水(shui)(shui)(shui)熱(re)(re)(re)(re)交換器(qi)、電熱(re)(re)(re)(re)水(shui)(shui)(shui)器(qi)、燃氣熱(re)(re)(re)(re)水(shui)(shui)(shui)器(qi)、太陽能熱(re)(re)(re)(re)水(shui)(shui)(shui)器(qi)等多種(zhong)。如要求這些熱(re)(re)(re)(re)水(shui)(shui)(shui)器(qi)不僅(jin)起加(jia)(jia)(jia)熱(re)(re)(re)(re)作(zuo)用(yong),還要有(you)貯(zhu)存和調(diao)節水(shui)(shui)(shui)量的(de)(de)功(gong)能,就必(bi)須(xu)有(you)一定(ding)的(de)(de)盛水(shui)(shui)(shui)體(ti)積,這種(zhong)加(jia)(jia)(jia)熱(re)(re)(re)(re)器(qi)稱(cheng)為容積式,對于只起加(jia)(jia)(jia)熱(re)(re)(re)(re)稱(cheng)為快速式。

容積式加(jia)熱(re)(re)器的結(jie)構(gou)如圖(tu)2-52所示,由罐(guan)體(ti)、盤管(guan)等(deng)組(zu)成。盤管(guan)內送(song)人(ren)高溫熱(re)(re)水(shui)(shui)或(huo)蒸汽(qi),將熱(re)(re)量(liang)通(tong)過盤管(guan)表(biao)面積傳(chuan)給冷水(shui)(shui)。罐(guan)體(ti)由支座直(zhi)接用地腳螺栓(shuan)固定在地基上(shang),高溫熱(re)(re)水(shui)(shui)或(huo)蒸汽(qi)通(tong)過管(guan)道與加(jia)熱(re)(re)器相(xiang)連(lian)接。采(cai)用蒸汽(qi)加(jia)熱(re)(re)時其蒸汽(qi)凝結(jie)水(shui)(shui)出口還要(yao)連(lian)接疏水(shui)(shui)閥(fa)等(deng)附件。

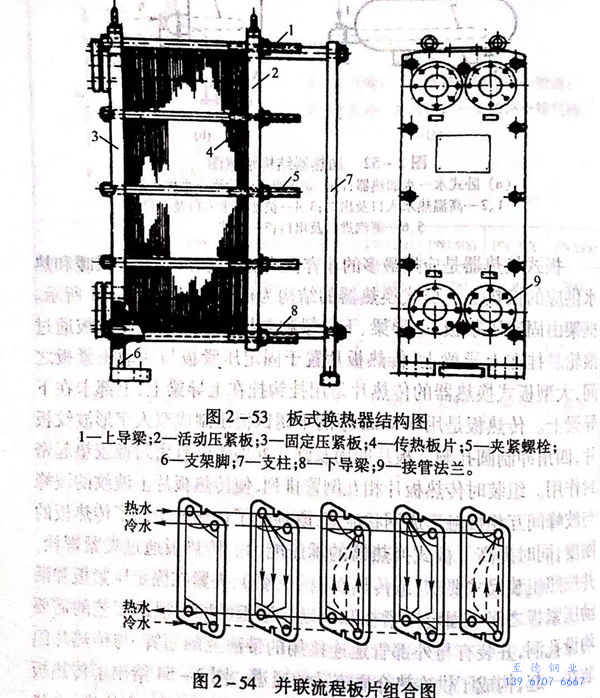

板式換熱器是應用最多的非容積式加熱器,廣泛用于采暖和熱水供應的換熱上。板式換熱器的結構為框架式,如圖2-53所示。框架由固定壓緊板、上導梁、下導梁和支柱組成。活動壓緊板通過滾輪懸掛在上導梁上,傳熱板片置于固定壓緊板與活動壓緊板之間,大型板式換熱器的傳熱片是用掛鉤掛在上導梁上,上部卡在下導梁上。傳熱板是用0.8mm厚的不銹鋼板壓制成雙人字形波紋板片,四角沖制圓孔洞。板片四周及圓孔處均鑲嵌有密封橡膠墊起密封作用。組裝時傳熱板片相互倒置排列,使傳熱板片上波紋的波峰與波峰間互相接觸形成網狀流道,既強化了傳熱又增加了傳熱板的剛度,同時提高了板式換熱器的承壓能力。傳熱板通過夾緊螺栓,并按照組裝尺寸要求(或傳熱面積一片數),夾緊固定壓緊板和活動壓緊板之間。固定壓緊板和活動壓緊板的四角根據工藝的需要均設孔洞,并裝有與外部管道連接用的帶法蘭的短管,與傳熱片組裝在一起,構成了供冷熱介質流動的通道。圖2-54給出了傳熱板片并聯流程組合流程圖,每兩張傳熱板片間就構成一個流道,冷熱介質交替地流過傳熱板片,同時熱量通過傳熱板片由熱介質傳給了冷介質。由于雙人字形傳熱板片的結構特性所決定,介質在傳熱板片流動時,在低流速下即可激發湍流,使冷熱介質進行強烈地熱交換,因此板式換熱器與其他換熱器相比,具有較高的傳熱系數。根據冷介質的出口溫度要求,流程可以組成串聯、并聯、混合等多種形式,在設計時提出要求,生產企業按要求進行組裝供貨。

板式換(huan)熱器豎直地用地腳(jiao)螺栓固定在(zai)混凝土地坪上,四周留有(you)一(yi)定距離,以便于(yu)管道、附(fu)件的安裝及設備的檢修。換(huan)熱器使用前應對熱側、冷側分(fen)別進行水壓(ya)(ya)試驗(yan),其試驗(yan)壓(ya)(ya)力(li)為(wei)設計壓(ya)(ya)力(li)的1.25倍(bei),并(bing)保壓(ya)(ya)20min,確認(ren)各(ge)密(mi)封部位(wei)無滲(shen)漏后方可投入使用。

在作(zuo)采暖時,循環(huan)水進出口均裝(zhuang)壓(ya)(ya)力表,在使(shi)用中若壓(ya)(ya)降增大說(shuo)明(ming)內(nei)部產生結垢淤塞,此時應松開夾(jia)緊(jin)螺栓,移動(dong)活動(dong)壓(ya)(ya)緊(jin)板(ban),然(ran)后(hou)進行清洗。清洗板(ban)片(pian)時要用棕(zong)刷,切勿用鋼絲刷,以免劃傷板(ban)片(pian)和橡膠(jiao)墊。損(sun)壞的板(ban)片(pian)要更換(huan),若沒有備(bei)用板(ban)片(pian),可拆下(xia)兩個相鄰的板(ban)片(pian),然(ran)后(hou)夾(jia)緊(jin)使(shi)用。

特別提醒:老(lao)化(hua)的密封(feng)(feng)(feng)橡膠墊(dian)要及(ji)時更新,要把(ba)板片的密封(feng)(feng)(feng)槽清洗干(gan)凈后涂粘結劑,再把(ba)密封(feng)(feng)(feng)膠墊(dian)鑲嵌在密封(feng)(feng)(feng)槽內。

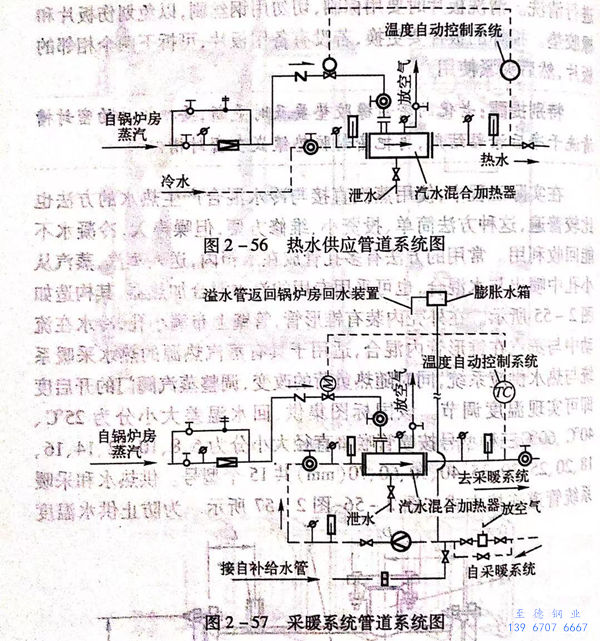

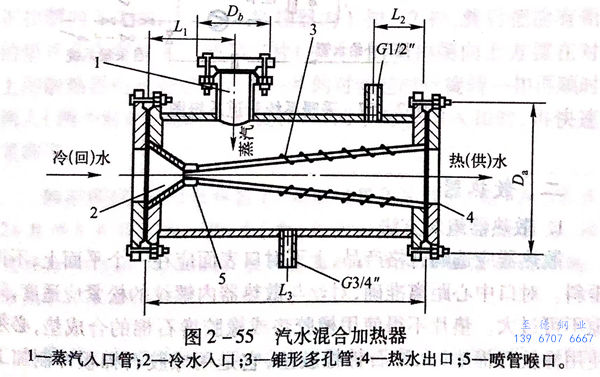

在實際工程中,使用蒸汽直接與冷水混合產生熱水的方法也比較普遍,這種方法簡單、投資小、維修方便,但噪聲大,冷凝水不能回收利用。常用的方法有多孔管放在水箱內,送入蒸汽,蒸汽從小孔中噴出與水混合,也可采用專用的汽水混合加熱器,其構造如圖2-55所示。在外殼內裝有錐形管,管壁上布滿小孔,冷水在流動中與蒸汽在錐形管內混合,適用于具有蒸汽熱源的熱水采暖系統與熱水供應系統,同時隨熱負荷的改變,調整蒸汽閥門的開啟度即可實現溫度調節。該國標圖集供、回水溫差大小分為25℃、40℃、60℃三種型號按噴管喉口直徑大小分為6、8、10、12、14、16、18、20、25、30、35、40、50、60、70(mm)共15個型號。供熱水和采暖系統管道連接方式如圖2-56、圖2-57所示。為防止供水溫度過熱,在蒸汽管道入口設置溫度自動控制系統,如安裝自力式溫度調(diao)節(jie)閥。為防止系統水倒灌入蒸汽系統中,在蒸汽管路上安裝逆止閥。