1. 散熱器組對方法

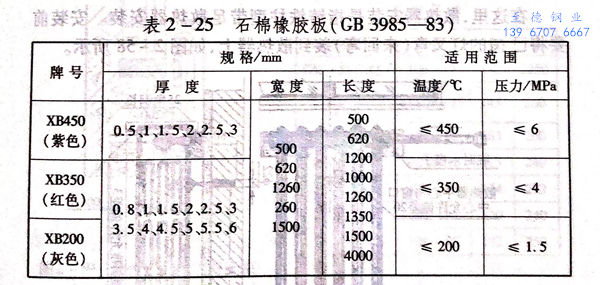

散熱器應(ying)(ying)選購合格產(chan)品,上下(xia)對(dui)口表(biao)(biao)面應(ying)(ying)在一個(ge)平面上,不(bu)(bu)得歪斜。對(dui)口中(zhong)心(xin)距離準確,對(dui)絲與散熱器內(nei)螺紋的(de)(de)松(song)緊應(ying)(ying)適度(du)(du),間隙不(bu)(bu)可過(guo)大(da)。墊(dian)(dian)(dian)(dian)片(pian)(pian)不(bu)(bu)得使(shi)用(yong)(yong)(yong)橡(xiang)膠(jiao)墊(dian)(dian)(dian)(dian)或橡(xiang)膠(jiao)攙石(shi)棉的(de)(de)合成墊(dian)(dian)(dian)(dian),必須使(shi)用(yong)(yong)(yong)橡(xiang)膠(jiao)石(shi)棉墊(dian)(dian)(dian)(dian)(又(you)稱(cheng)石(shi)棉橡(xiang)膠(jiao)墊(dian)(dian)(dian)(dian),它是用(yong)(yong)(yong)橡(xiang)膠(jiao)石(shi)棉板沖制加工的(de)(de)墊(dian)(dian)(dian)(dian)片(pian)(pian)),其厚度(du)(du)為1.0mm~1.5mm,不(bu)(bu)能用(yong)(yong)(yong)雙(shuang)墊(dian)(dian)(dian)(dian)。橡(xiang)膠(jiao)石(shi)棉板的(de)(de)牌號和規格見表(biao)(biao)2-25。表(biao)(biao)中(zhong)分高(gao)壓(ya)(ya)、中(zhong)壓(ya)(ya)、低(di)壓(ya)(ya)三種(zhong)牌號,常用(yong)(yong)(yong)的(de)(de)中(zhong)壓(ya)(ya)板和低(di)壓(ya)(ya)板沖制的(de)(de)墊(dian)(dian)(dian)(dian)片(pian)(pian)。中(zhong)壓(ya)(ya)墊(dian)(dian)(dian)(dian)片(pian)(pian)在使(shi)用(yong)(yong)(yong)前應(ying)(ying)在機油(you)(you)里浸泡(pao)幾分鐘;低(di)壓(ya)(ya)板墊(dian)(dian)(dian)(dian)片(pian)(pian)應(ying)(ying)在機油(you)(you)里蘸(zhan)一下(xia)撈出(chu)來(lai)控(kong)干。使(shi)用(yong)(yong)(yong)時將墊(dian)(dian)(dian)(dian)片(pian)(pian)放(fang)入已調和(用(yong)(yong)(yong)清(qing)油(you)(you)調和)稀(xi)稠適度(du)(du)的(de)(de)鉛(qian)油(you)(you)桶(tong)里攪動,撈出(chu)來(lai)且不(bu)(bu)流淌,或輕(qing)度(du)(du)流淌即可使(shi)用(yong)(yong)(yong)。

組對(dui)時(shi),應將散(san)熱(re)器(qi)對(dui)口表面的(de)(de)(de)銹污清除干凈,將正(zheng)扣(kou)(kou)(kou)朝向(xiang)(xiang)上(shang)(shang)方(fang),對(dui)絲(si)的(de)(de)(de)正(zheng)扣(kou)(kou)(kou)朝向(xiang)(xiang)下方(fang)碼放好備用(yong)。把組對(dui)散(san)熱(re)器(qi)的(de)(de)(de)架(jia)子(zi)與地(di)面固定牢固。把正(zheng)扣(kou)(kou)(kou)朝向(xiang)(xiang)上(shang)(shang)方(fang)的(de)(de)(de)散(san)熱(re)器(qi)邊片(pian)固定在架(jia)子(zi)上(shang)(shang),再(zai)(zai)把正(zheng)扣(kou)(kou)(kou)朝向(xiang)(xiang)下方(fang)的(de)(de)(de)對(dui)絲(si)擰入散(san)熱(re)器(qi)內1扣(kou)(kou)(kou)~2扣(kou)(kou)(kou),然(ran)后把涂有鉛油的(de)(de)(de)墊片(pian)套在對(dui)絲(si)上(shang)(shang)。把第二片(pian)(中片(pian))的(de)(de)(de)正(zheng)扣(kou)(kou)(kou)朝向(xiang)(xiang)上(shang)(shang)方(fang)摞在對(dui)絲(si)上(shang)(shang)用(yong)散(san)熱(re)器(qi)鑰匙把已擰入第一片(pian)的(de)(de)(de)對(dui)絲(si)逆時(shi)針旋(xuan)(xuan)轉一扣(kou)(kou)(kou)再(zai)(zai)順時(shi)針兩(liang)(liang)人(ren)(兩(liang)(liang)個對(dui)絲(si))同(tong)時(shi)輕(qing)輕(qing)旋(xuan)(xuan)轉,待兩(liang)(liang)個對(dui)絲(si)均人(ren)扣(kou)(kou)(kou)時(shi),再(zai)(zai)快速擰緊即可(ke)。

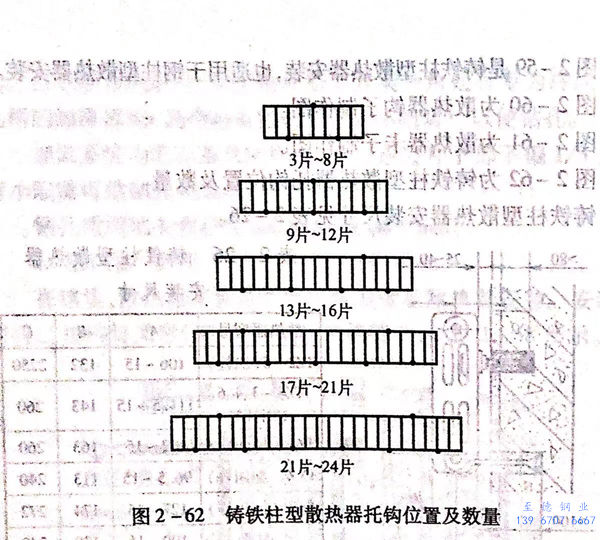

特別提醒(xing):柱(zhu)形散熱器14片(pian)(pian)(pian)以(yi)內用2片(pian)(pian)(pian)帶足(zu)(邊)片(pian)(pian)(pian),15片(pian)(pian)(pian)~24片(pian)(pian)(pian)用3片(pian)(pian)(pian)帶足(zu)片(pian)(pian)(pian)。20片(pian)(pian)(pian)(含(han))以(yi)上(shang)應加裝4根附(fu)加拉(la)條,拉(la)條直徑為(wei)ф10mm或(huo)ф8mm,散熱器與螺母之間(jian)應加裝鑄鐵騎碼(由散熱器廠家提供)。

需要安裝(zhuang)冷風(feng)門時(shi),應把(ba)與支管連(lian)接的異側邊(bian)片在(zai)(zai)組對(dui)前鉆(zhan)孔。當系統為(wei)熱水時(shi),應在(zai)(zai)邊(bian)片最上方(fang)某(mou)一角處有專為(wei)冷風(feng)門鉆(zhan)孔用的加厚(hou)部位(其中(zhong)心有凹進表面的小陷窩(wo)),以便鉆(zhan)孔。如該系統為(wei)低壓蒸(zheng)汽采用時(shi),則應在(zai)(zai)邊(bian)片下部下偏1/3處亦有小陷窩(wo)可供鉆(zhan)孔和攻絲。

鉆孔(kong)所用鉆頭直徑為ф8.6mm或ф8.7mm.

2. 散熱器安裝

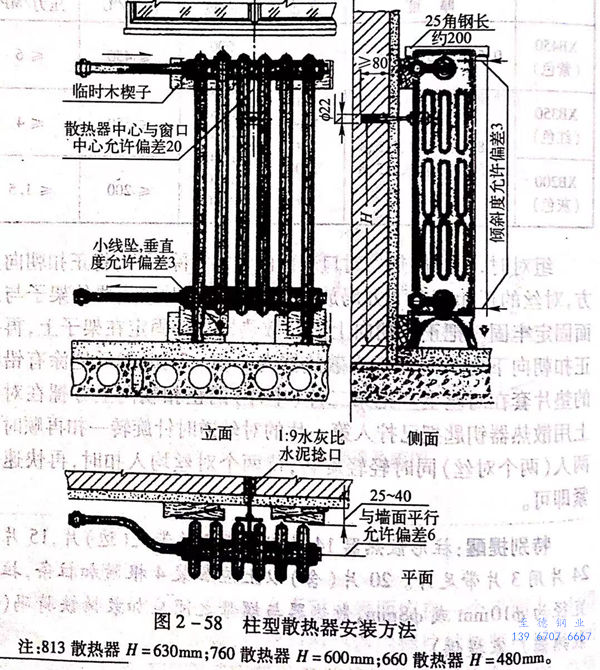

在(zai)這里,散(san)熱(re)器(qi)(qi)安裝是指(zhi)鑄鐵柱型帶足散(san)熱(re)器(qi)(qi)安裝。安裝前要將已(yi)撼的燈叉彎(來回彎)裝到散(san)熱(re)器(qi)(qi)上(shang),如圖2-58所(suo)示。

圖(tu)2-59是鑄(zhu)鐵(tie)柱型散熱器(qi)安裝(zhuang),也(ye)適用于鋼(gang)柱型散熱器(qi)安裝(zhuang)。

圖2-60為散(san)熱器鉤子制作圖。

圖2-61 為散(san)熱器卡子(zi)制作圖。

圖(tu)2-62為鑄(zhu)鐵柱型散熱器托鉤位置(zhi)及(ji)數量。

鑄(zhu)鐵柱型散執器安裝尺寸見(jian)表2-26。

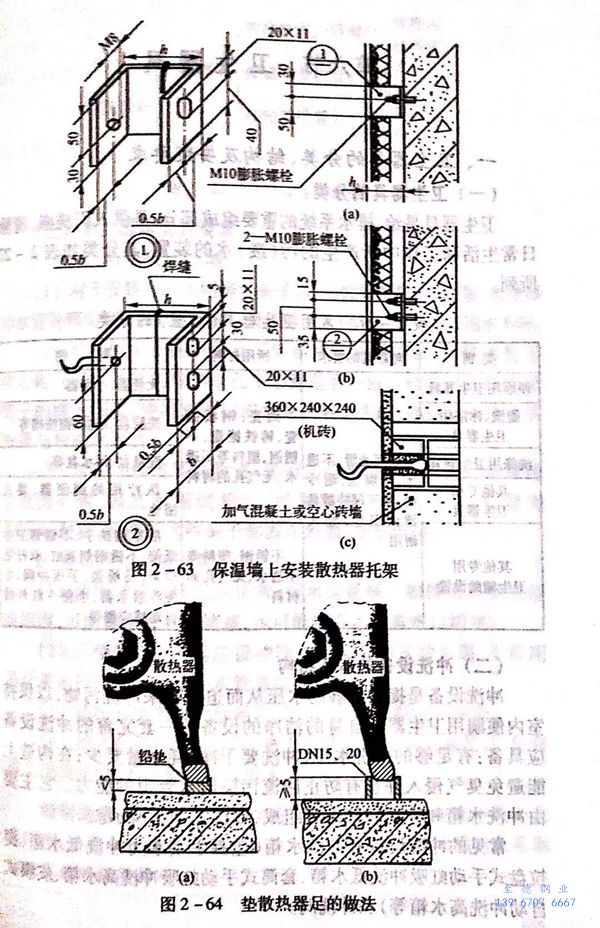

圖(tu)2-63是在有保(bao)溫層(ceng)、空(kong)(kong)氣隔(ge)層(ceng)的墻上安裝散(san)熱器托(tuo)(tuo)架(鉤(gou)(gou))的做法。圖(tu)2-63(a)和圖(tu)2-63(b)的保(bao)溫層(ceng)、空(kong)(kong)氣隔(ge)層(ceng)的總厚度用(yong)h表示。散(san)熱器的托(tuo)(tuo)鉤(gou)(gou)(架)固定(ding)在用(yong)14號(hao)槽鋼改制的“過渡件”上。如(ru)(ru)用(yong)于柱形散(san)熱器的固定(ding)卡等,在槽鋼的腿上所需位(wei)置鉆ф6.7的孔(kong)(kong),進行M8普(pu)通螺紋(wen)攻絲;如(ru)(ru)果是柱形散(san)熱器托(tuo)(tuo)鉤(gou)(gou),可鉆?16孔(kong)(kong)將?16托(tuo)(tuo)鉤(gou)(gou)插入孔(kong)(kong)內(nei)焊牢(見圖(tu)2-63)。

圖2-63(c)是(shi)在加氣混凝土(tu)或空心磚墻上安裝散熱器托鉤做法。在所需標高(gao)、位置用機磚砌:長度(du)=360mm、高(gao)度(du)=240mm、厚度(du)同墻厚度(du)。托鉤上下(xia)均應有不少于(yu)一層整(zheng)磚;托鉤左右方(fang)向(xiang)凈距(ju)均不小于(yu)120mm。

由于(yu)樓層高度(du)(du)和(he)地面抹(mo)灰(hui)厚度(du)(du)的(de)(de)偏差(cha)而影響立管甩口高度(du)(du)時,只能采取(qu)鋸或墊(dian)散熱(re)(re)器的(de)(de)足來解(jie)決(jue)。圖2-64是(shi)墊(dian)的(de)(de)方法,圖2-64(a)的(de)(de)做(zuo)法是(shi)因為散熱(re)(re)器與地面的(de)(de)間(jian)隙小,而采用青鉛(qian);圖2-64(b)的(de)(de)做(zuo)法是(shi)因為間(jian)隙較大時的(de)(de)做(zuo)法。如果(guo)墊(dian)的(de)(de)再高些(xie)時,則應點焊在散熱(re)(re)器足上。