半(ban)(ban)浮動(dong)(或半(ban)(ban)限動(dong))芯棒(bang)連續(xu)軋管(guan)機,德國人稱之為(wei)(wei)MRK-S(Mannesmann bohr-KontimillStripper),法國人則稱其(qi)為(wei)(wei)Neuval.半(ban)(ban)浮動(dong)芯棒(bang)連續(xu)軋管(guan)機一般(ban)7~8個機架。

德國人設計的MRK-S工藝在軋制過程中,前半程芯棒不是自由地隨軋件前進,而是受限動機構的控制,以一恒定速度前進,芯棒與軋件的速度差分布是不一致的,第1架的軋件出口速度小于芯棒速度;自第2架開始,軋件的速度快于芯棒的速度,形成穩定的差速軋制狀態;當完成主要變形、管子脫離倒數第3架時,限動機構加速釋放芯棒,像浮動芯棒一樣由不銹鋼(gang)管將芯棒帶出軋機。德國式的半浮動芯棒連續軋管機代表機組有20世紀80年代初投產的日本八幡廠的ф194mm機組和我國衡陽的ф89mm機組。

法(fa)(fa)國(guo)研制(zhi)的(de)Neuval工(gong)藝是在不銹鋼管(guan)由(you)最后(hou)一個機(ji)(ji)(ji)(ji)架軋(ya)出時才松開芯棒(bang),即在軋(ya)制(zhi)過程中(zhong)具有(you)限動芯棒(bang)軋(ya)機(ji)(ji)(ji)(ji)的(de)工(gong)藝特點(dian),而在終(zhong)軋(ya)后(hou)松開芯棒(bang),芯棒(bang)隨(sui)荒管(guan)至(zhi)連軋(ya)機(ji)(ji)(ji)(ji)后(hou)的(de)輸(shu)出輥道。法(fa)(fa)國(guo)式(shi)的(de)半浮動芯棒(bang)連續軋(ya)管(guan)機(ji)(ji)(ji)(ji)于20世紀70年代后(hou)期在法(fa)(fa)國(guo)的(de)圣索(suo)夫鋼管(guan)廠ф127mm機(ji)(ji)(ji)(ji)組投入生(sheng)產。法(fa)(fa)國(guo)模式(shi)的(de)機(ji)(ji)(ji)(ji)組至(zhi)今(jin)僅(jin)有(you)一套(tao)。

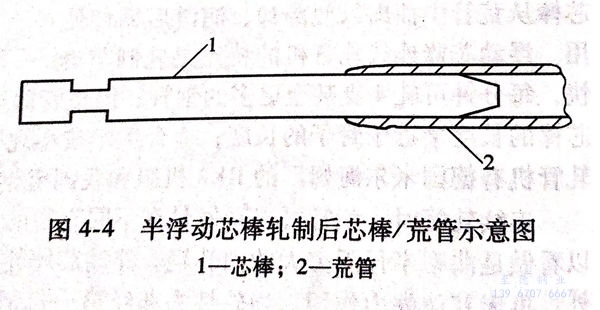

不論德國工藝還(huan)是(shi)法國工藝,半(ban)浮動(dong)芯(xin)棒(bang)(bang)軋(ya)管(guan)(guan)機軋(ya)制結(jie)束后(hou),約有1/3長(chang)的荒(huang)管(guan)(guan)(尾部)包住芯(xin)棒(bang)(bang)前端,如圖4-4所示。帶有芯(xin)棒(bang)(bang)的荒(huang)管(guan)(guan)橫移(yi)至脫棒(bang)(bang)線(xian),由脫棒(bang)(bang)機將芯(xin)棒(bang)(bang)從(cong)荒(huang)管(guan)(guan)中抽出(chu)以(yi)便冷卻、潤滑后(hou)循環使用。其(qi)特點是(shi)荒(huang)管(guan)(guan)壁厚(hou)的精度較高、節奏較快,每分鐘可軋(ya)3支甚(shen)至更(geng)多(duo)的不銹鋼管(guan)(guan),芯(xin)棒(bang)(bang)長(chang)度雖然比(bi)浮動(dong)式的短得(de)多(duo),但(dan)比(bi)限動(dong)芯(xin)棒(bang)(bang)還(huan)是(shi)略長(chang)一些,設有脫棒(bang)(bang)機工藝其(qi)流程較長(chang),適(shi)合生(sheng)產較小(xiao)(xiao)規(gui)格(外(wai)徑(jing)小(xiao)(xiao)于219mm)的無縫不銹鋼管(guan)(guan)生(sheng)產。

半浮(fu)動(dong)(dong)芯(xin)棒(bang)(bang)(bang)連續軋(ya)(ya)(ya)管機(ji)在軋(ya)(ya)(ya)制(zhi)過(guo)程中對(dui)芯(xin)棒(bang)(bang)(bang)速(su)度也進(jin)行控制(zhi),但在軋(ya)(ya)(ya)制(zhi)結(jie)束之前即將(jiang)(jiang)芯(xin)棒(bang)(bang)(bang)放開(kai),像浮(fu)動(dong)(dong)芯(xin)棒(bang)(bang)(bang)連續軋(ya)(ya)(ya)管機(ji)一(yi)(yi)樣由(you)不(bu)銹鋼管將(jiang)(jiang)芯(xin)棒(bang)(bang)(bang)帶出(chu)軋(ya)(ya)(ya)機(ji),然后由(you)脫棒(bang)(bang)(bang)機(ji)將(jiang)(jiang)芯(xin)棒(bang)(bang)(bang)從荒管中抽出(chu)。在對(dui)芯(xin)棒(bang)(bang)(bang)速(su)度進(jin)行限(xian)動(dong)(dong)時,就(jiu)在一(yi)(yi)定程度上解決了金(jin)屬(shu)流動(dong)(dong)規律性的問題,將(jiang)(jiang)芯(xin)棒(bang)(bang)(bang)放開(kai)以后,又如(ru)同(tong)浮(fu)動(dong)(dong)芯(xin)棒(bang)(bang)(bang)連續軋(ya)(ya)(ya)管機(ji)一(yi)(yi)樣要考(kao)慮脫棒(bang)(bang)(bang)條件(jian)的限(xian)制(zhi),因(yin)此半浮(fu)動(dong)(dong)芯(xin)棒(bang)(bang)(bang)連續軋(ya)(ya)(ya)管機(ji)所軋(ya)(ya)(ya)制(zhi)的鋼管直徑不(bu)宜(yi)太大(da)。

半浮動芯(xin)棒連續軋(ya)(ya)管(guan)機(ji)兼顧了(le)限動芯(xin)棒與浮動芯(xin)棒軋(ya)(ya)管(guan)機(ji)的優點,既保持了(le)較高的軋(ya)(ya)制節奏(zou),又確保了(le)不銹鋼管(guan)的壁(bi)厚精度及內外(wai)表面質量,只(zhi)是由于需要(yao)設置脫棒機(ji),使其軋(ya)(ya)制規(gui)格(ge)的上(shang)限受到限制。