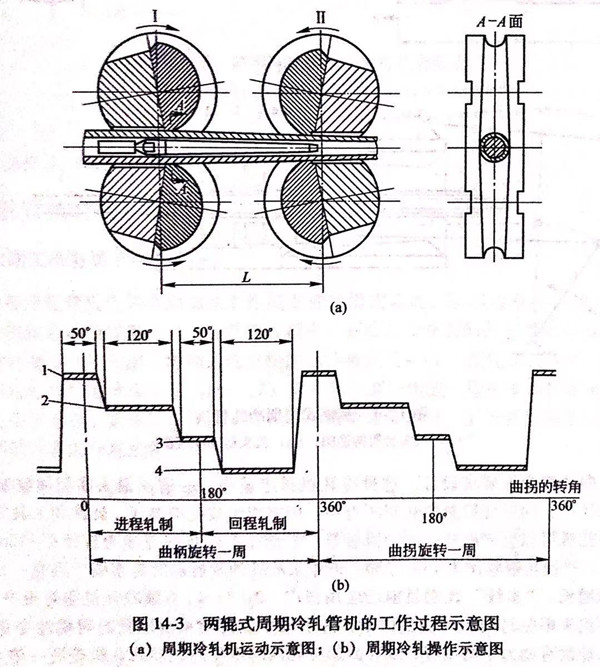

冷軋管機根據軋機結構的特點分為:1. 2輥式冷軋管機;2. LD型多輥式冷軋管機;3. 冷連續軋管機;4. 多排輥冷軋管機。目前生產中應用最廣的還是周期式冷軋管機,該機1928年研制,1932年在美國首先使用。它們是獲得高精度薄壁不銹鋼管(guan)的重要手段,也是外徑或內徑要求高精度的不銹鋼厚壁管和特厚壁管,以及異形管、變斷面管等的主要生產方法。兩輥式周期冷軋(ya)不銹(xiu)鋼管機的生產規格范圍為:外徑4~250mm,壁厚0.1~40mm,并可生產外徑與壁厚比等于60~100的薄壁管。圖14-3是兩輥式周期冷軋管機的工作過程示意圖。

兩(liang)輥(gun)(gun)(gun)式周期冷軋(ya)(ya)(ya)不銹鋼管機(ji)的(de)孔型沿工作(zuo)弧由大(da)向(xiang)(xiang)小(xiao)變化(hua),入口比來料外徑(jing)略大(da),出(chu)口與(yu)成品管直(zhi)徑(jing)相同,再后(hou)(hou)(hou)孔型略有放大(da),以便(bian)管體在孔內轉(zhuan)動。軋(ya)(ya)(ya)輥(gun)(gun)(gun)隨機(ji)架的(de)往(wang)復(fu)運動在軋(ya)(ya)(ya)件上(shang)左(zuo)右滾軋(ya)(ya)(ya)。如(ru)以曲拐轉(zhuan)角為橫坐標,操作(zuo)過程如(ru)圖14-3(b)所示(shi)。開始50°將坯料送(song)進,然后(hou)(hou)(hou)在120°范圍內軋(ya)(ya)(ya)制,軋(ya)(ya)(ya)輥(gun)(gun)(gun)輾(zhan)至右端(duan)后(hou)(hou)(hou),再用50°間隙軋(ya)(ya)(ya)件轉(zhuan)動60°,芯棒也作(zuo)相應旋轉(zhuan),只(zhi)是轉(zhuan)角略異,以求芯棒能(neng)均勻磨損。回(hui)軋(ya)(ya)(ya)軋(ya)(ya)(ya)輥(gun)(gun)(gun)向(xiang)(xiang)左(zuo)滾輾(zhan),消除壁厚不均提高精(jing)度(du),直(zhi)至左(zuo)端(duan)止。如(ru)此反(fan)復(fu)。

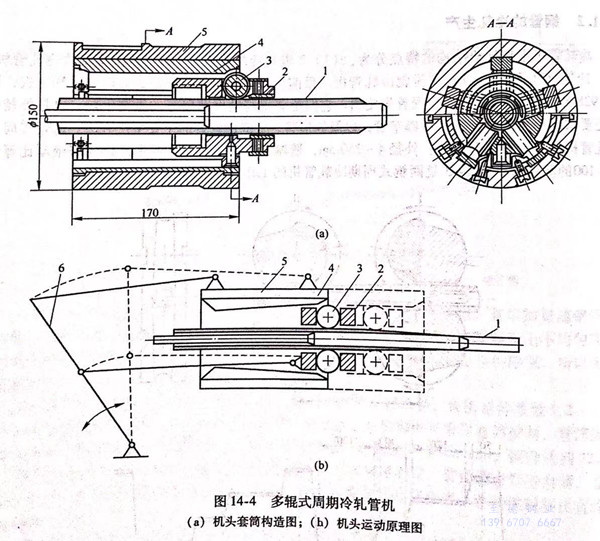

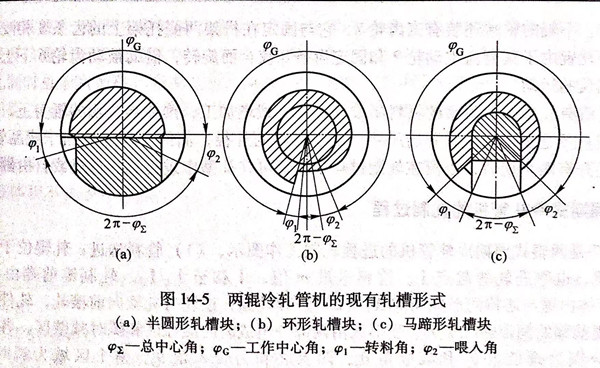

圖(tu)14-4為多(duo)輥(gun)(gun)(gun)式(shi)周(zhou)期冷(leng)軋(ya)(ya)(ya)(ya)不銹鋼管(guan)機(ji)(ji)(ji)的(de)(de)(de)(de)(de)(de)工(gong)作(zuo)(zuo)示意(yi)圖(tu)。這(zhe)種(zhong)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)的(de)(de)(de)(de)(de)(de)操作(zuo)(zuo)過(guo)程和(he)兩(liang)輥(gun)(gun)(gun)式(shi)相同(tong),不同(tong)的(de)(de)(de)(de)(de)(de)是(shi)(shi)(shi)對軋(ya)(ya)(ya)(ya)件(jian)1的(de)(de)(de)(de)(de)(de)加(jia)工(gong)是(shi)(shi)(shi)由安裝(zhuang)在隔離架(jia)2內的(de)(de)(de)(de)(de)(de)3~5個小(xiao)輥(gun)(gun)(gun)3進(jin)行(xing)(xing)(xing)的(de)(de)(de)(de)(de)(de),小(xiao)輥(gun)(gun)(gun)沿著固定在機(ji)(ji)(ji)頭套簡5上(shang)的(de)(de)(de)(de)(de)(de)楔(xie)形滑軌(gui)4往返運動(dong)(dong),依(yi)靠滑軌(gui)的(de)(de)(de)(de)(de)(de)摩擦力(li)傳動(dong)(dong)滾軋(ya)(ya)(ya)(ya)管(guan)材。機(ji)(ji)(ji)頭套筒和(he)小(xiao)輥(gun)(gun)(gun)隔架(jia)間(jian)的(de)(de)(de)(de)(de)(de)運動(dong)(dong)關系見圖(tu)14-4(b),搖桿在往復擺動(dong)(dong)的(de)(de)(de)(de)(de)(de)過(guo)程中,一(yi)般使(shi)套筒兩(liang)倍于(yu)隔離架(jia)的(de)(de)(de)(de)(de)(de)速(su)(su)(su)度(du)(du)運行(xing)(xing)(xing),楔(xie)形滑軌(gui)的(de)(de)(de)(de)(de)(de)表(biao)(biao)面(mian)曲線(xian)(xian)按變(bian)形要(yao)(yao)(yao)求設計。這(zhe)種(zhong)冷(leng)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)送(song)進(jin)量小(xiao),一(yi)道(dao)次最大橫截面(mian)收縮率約70左右(you)但它的(de)(de)(de)(de)(de)(de)輥(gun)(gun)(gun)徑(jing)小(xiao),同(tong)樣(yang)變(bian)形量的(de)(de)(de)(de)(de)(de)軋(ya)(ya)(ya)(ya)制(zhi)(zhi)壓力(li)小(xiao);用(yong)(yong)多(duo)輥(gun)(gun)(gun)組成(cheng)孔(kong)型(xing)槽(cao)淺,軋(ya)(ya)(ya)(ya)件(jian)和(he)工(gong)具之間(jian)的(de)(de)(de)(de)(de)(de)滑小(xiao),因(yin)而這(zhe)種(zhong)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)可以(yi)生產高精度(du)(du)的(de)(de)(de)(de)(de)(de)特薄壁管(guan)。目前生產的(de)(de)(de)(de)(de)(de)規格范(fan)圍(wei)為直徑(jing)4~120mm,壁0.03~3.0mm,外(wai)徑(jing)與(yu)壁厚(hou)比為150~250。近年來冷(leng)軋(ya)(ya)(ya)(ya)的(de)(de)(de)(de)(de)(de)發展(zhan)趨(qu)勢是(shi)(shi)(shi)多(duo)線(xian)(xian)、高速(su)(su)(su)、長(chang)(chang)行(xing)(xing)(xing)程,料長(chang)(chang)度(du)(du)也不斷增長(chang)(chang)。“多(duo)線(xian)(xian)”軋(ya)(ya)(ya)(ya)制(zhi)(zhi)目前已應(ying)用(yong)(yong)很廣,2、3、4、6線(xian)(xian)冷(leng)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)均有投產;“高速(su)(su)(su)是(shi)(shi)(shi)指(zhi)不斷提高機(ji)(ji)(ji)頭單位時間(jian)內的(de)(de)(de)(de)(de)(de)往復次數,為了(le)減(jian)小(xiao)主傳動(dong)(dong)系統承(cheng)受(shou)的(de)(de)(de)(de)(de)(de)周(zhou)期性變(bian)化(hua)的(de)(de)(de)(de)(de)(de)負載度(du)(du),這(zhe)類軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)皆設有動(dong)(dong)力(li)平衡(heng)裝(zhuang)置,現(xian)在高速(su)(su)(su)冷(leng)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)的(de)(de)(de)(de)(de)(de)速(su)(su)(su)度(du)(du)約比舊式(shi)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)提高一(yi)倍左右(you);“長(chang)(chang)行(xing)(xing)(xing)程”是(shi)(shi)(shi)指(zhi)加(jia)大送(song)進(jin)量,每(mei)次軋(ya)(ya)(ya)(ya)制(zhi)(zhi)的(de)(de)(de)(de)(de)(de)延伸長(chang)(chang)度(du)(du)也隨(sui)之增加(jia),因(yin)此要(yao)(yao)(yao)求軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)的(de)(de)(de)(de)(de)(de)行(xing)(xing)(xing)程長(chang)(chang)度(du)(du)與(yu)其相適應(ying),不然就不能(neng)獲得光(guang)潔的(de)(de)(de)(de)(de)(de)表(biao)(biao)面(mian)和(he)尺寸精度(du)(du)。這(zhe)樣(yang)就從工(gong)具設計到軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)結構(gou)引起了(le)一(yi)系列變(bian)化(hua),兩(liang)輥(gun)(gun)(gun)式(shi)冷(leng)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)出現(xian)了(le)馬蹄形軋(ya)(ya)(ya)(ya)槽(cao)和(he)環(huan)形軋(ya)(ya)(ya)(ya)槽(cao)(見圖(tu)14-5),以(yi)充分利用(yong)(yong)圓周(zhou)長(chang)(chang)度(du)(du)滿足行(xing)(xing)(xing)程需(xu)要(yao)(yao)(yao)。應(ying)當指(zhi)出,馬蹄形和(he)環(huan)形軋(ya)(ya)(ya)(ya)槽(cao)也是(shi)(shi)(shi)提高軋(ya)(ya)(ya)(ya)制(zhi)(zhi)速(su)(su)(su)度(du)(du)和(he)多(duo)線(xian)(xian)軋(ya)(ya)(ya)(ya)制(zhi)(zhi)的(de)(de)(de)(de)(de)(de)需(xu)要(yao)(yao)(yao),因(yin)為同(tong)一(yi)行(xing)(xing)(xing)程使(shi)用(yong)(yong)這(zhe)種(zhong)軋(ya)(ya)(ya)(ya)槽(cao)的(de)(de)(de)(de)(de)(de)輥(gun)(gun)(gun)徑(jing)小(xiao),降低軋(ya)(ya)(ya)(ya)制(zhi)(zhi)壓力(li),能(neng)減(jian)輕(qing)整(zheng)個機(ji)(ji)(ji)架(jia)結構(gou)。

為增加變(bian)(bian)形(xing)區的有效長度,還出現了:1. 附(fu)加輥(gun)架冷(leng)軋(ya)機(ji),即在(zai)主(zhu)軋(ya)機(ji)出口側裝(zhuang)置一(yi)小(xiao)輥(gun)機(ji)架起定徑作用,以(yi)增加變(bian)(bian)形(xing)區長度;2. 雙對(dui)輥(gun)冷(leng)軋(ya)機(ji),即將兩對(dui)軋(ya)輥(gun)安(an)裝(zhuang)在(zai)同一(yi)機(ji)架上;3. 多(duo)輥(gun)式冷(leng)軋(ya)機(ji)出現了雙排(pai)多(duo)輥(gun)式冷(leng)軋(ya)機(ji),即在(zai)同一(yi)隔(ge)離架上前后各安(an)裝(zhuang)一(yi)組(zu)小(xiao)輥(gun)。

加(jia)長(chang)不銹鋼管(guan)坯料(liao)(liao)是提高(gao)軋機(ji)利用率的(de)(de)重要措(cuo)施,近年來的(de)(de)冷軋機(ji)最大上(shang)料(liao)(liao)長(chang)度一(yi)般(ban)已(yi)達(da)12.5m左右(you),幾(ji)乎增加(jia)了一(yi)倍。同時(shi)也產生了一(yi)個問題,就(jiu)是如何改(gai)變上(shang)料(liao)(liao)和(he)上(shang)芯棒(bang)的(de)(de)方(fang)法,縮短已(yi)經(jing)很長(chang)了的(de)(de)機(ji)身長(chang)度。如采用雙絲杠側(ce)裝料(liao)(liao)結構等(deng)。