不銹鋼(gang)熱(re)軋中(zhong)厚(hou)板工藝(yi)技術(shu)裝備(bei)主要體(ti)現在爐卷軋機。

爐卷(juan)軋(ya)機技術始于(yu)20世(shi)(shi)紀30年(nian)代(dai),主(zhu)要生(sheng)(sheng)產厚度3毫米以上的熱(re)軋(ya)帶(dai)鋼。帶(dai)鋼進卷(juan)取爐的厚度為(wei)15~17毫米,爐內溫(wen)度950~1050℃,生(sheng)(sheng)產能(neng)力20萬~30萬噸/年(nian)。20世(shi)(shi)紀50-60年(nian)代(dai)其(qi)發(fa)展較快,至(zhi)20世(shi)(shi)紀70年(nian)代(dai)全(quan)世(shi)(shi)界已建爐卷(juan)軋(ya)機約34套,形成(cheng)第一次發(fa)展高潮。但由(you)于(yu)爐卷(juan)軋(ya)機存在諸多不足,20世(shi)(shi)紀80年(nian)代(dai)初,仍在生(sheng)(sheng)產的爐卷(juan)軋(ya)機已不超過20套。

20世紀80年代中后期爐卷軋機復興,以生產不銹鋼為主的爐卷軋機因采用多項熱連軋機的控制技術得到長足發展,已成為不銹鋼領域的主力熱軋機。采用爐卷軋機軋制不銹鋼的主要原因為:(1)爐卷軋機前后設保溫卷取爐,適合不銹鋼等加工溫度范圍窄、難變形金屬的軋制;(2)專業化不銹帶鋼廠規模在25萬~50萬噸/年,用爐卷軋機生產能力適中,投資低,效益好;(3)現代化的爐卷軋機由于采用了厚度自動控制、板形控制、多次高壓水除鱗、快速換輥裝置等,從而保證了產品的尺寸精度、表面質量及板形等;(4)爐卷軋機在特種材料的軋制方面優勢明顯,可實現卷板品種優化。

爐(lu)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)可兼作(zuo)(zuo)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)厚(hou)(hou)板(ban)。20世(shi)紀80-90年(nian)代新建(jian)的(de)26套(tao)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)碳鋼(gang)(gang)(gang)(gang)不(bu)銹鋼(gang)(gang)(gang)(gang),其中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)約(yue)15套(tao)兼作(zuo)(zuo)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)厚(hou)(hou)板(ban),并配(pei)備(bei)了(le)(le)(le)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)厚(hou)(hou)板(ban)精軋(ya)(ya)(ya)(ya)(ya)(ya)線(xian)。在(zai)10套(tao)不(bu)銹鋼(gang)(gang)(gang)(gang)專用(yong)爐(lu)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong),有5套(tao)兼作(zuo)(zuo)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)厚(hou)(hou)板(ban),其中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)輥身長度最大的(de)是瑞典阿(a)維斯塔(Avesta)廠(chang)的(de)2800毫(hao)米粗軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)。2003年(nian)5月我(wo)國南(nan)京(jing)鋼(gang)(gang)(gang)(gang)鐵公(gong)司與奧鋼(gang)(gang)(gang)(gang)聯簽訂(ding)合(he)同(tong)(tong),引進了(le)(le)(le)用(yong)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)工藝(yi)生(sheng)產(chan)(chan)(chan)的(de)爐(lu)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji),并于(yu)2005年(nian)9月28日(ri)成(cheng)功軋(ya)(ya)(ya)(ya)(ya)(ya)出(chu)第一塊鋼(gang)(gang)(gang)(gang)板(ban)。同(tong)(tong)期,安陽(yang)、韶關(guan)鋼(gang)(gang)(gang)(gang)鐵公(gong)司從達涅利(li)公(gong)司引進用(yong)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)工藝(yi)生(sheng)產(chan)(chan)(chan)的(de)爐(lu)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji),其中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)安鋼(gang)(gang)(gang)(gang)建(jian)設(she)(she)了(le)(le)(le)卷(juan)(juan)(juan)(juan)取(qu)爐(lu),但預留了(le)(le)(le)卷(juan)(juan)(juan)(juan)取(qu)機(ji)(ji)(ji),韶鋼(gang)(gang)(gang)(gang)對卷(juan)(juan)(juan)(juan)取(qu)爐(lu)和卷(juan)(juan)(juan)(juan)取(qu)機(ji)(ji)(ji)均做(zuo)了(le)(le)(le)預留。在(zai)我(wo)國投(tou)(tou)產(chan)(chan)(chan)的(de)3套(tao)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)厚(hou)(hou)板(ban)爐(lu)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong),南(nan)鋼(gang)(gang)(gang)(gang)爐(lu)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)配(pei)備(bei)了(le)(le)(le)完整的(de)板(ban)、卷(juan)(juan)(juan)(juan)生(sheng)產(chan)(chan)(chan)設(she)(she)備(bei),軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)力(li)達80兆(zhao)牛,可較好地(di)實現(xian)控制(zhi)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)和控制(zhi)冷卻工藝(yi),在(zai)管線(xian)鋼(gang)(gang)(gang)(gang)生(sheng)產(chan)(chan)(chan)方面取(qu)得(de)了(le)(le)(le)較好的(de)業績。我(wo)國已建(jian)成(cheng)投(tou)(tou)產(chan)(chan)(chan)的(de)板(ban)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)主要是在(zai)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)等(deng)規模的(de)鋼(gang)(gang)(gang)(gang)廠(chang),其利(li)用(yong)爐(lu)卷(juan)(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)軋(ya)(ya)(ya)(ya)(ya)(ya)線(xian)設(she)(she)備(bei)少、投(tou)(tou)資省、產(chan)(chan)(chan)品(pin)市(shi)場適(shi)應面廣的(de)特點,生(sheng)產(chan)(chan)(chan)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)厚(hou)(hou)板(ban)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)不(bu)宜軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)的(de)薄、窄規格中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)板(ban),同(tong)(tong)時生(sheng)產(chan)(chan)(chan)熱連(lian)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)(ji)不(bu)能生(sheng)產(chan)(chan)(chan)的(de)寬規格熱軋(ya)(ya)(ya)(ya)(ya)(ya)卷(juan)(juan)(juan)(juan)。

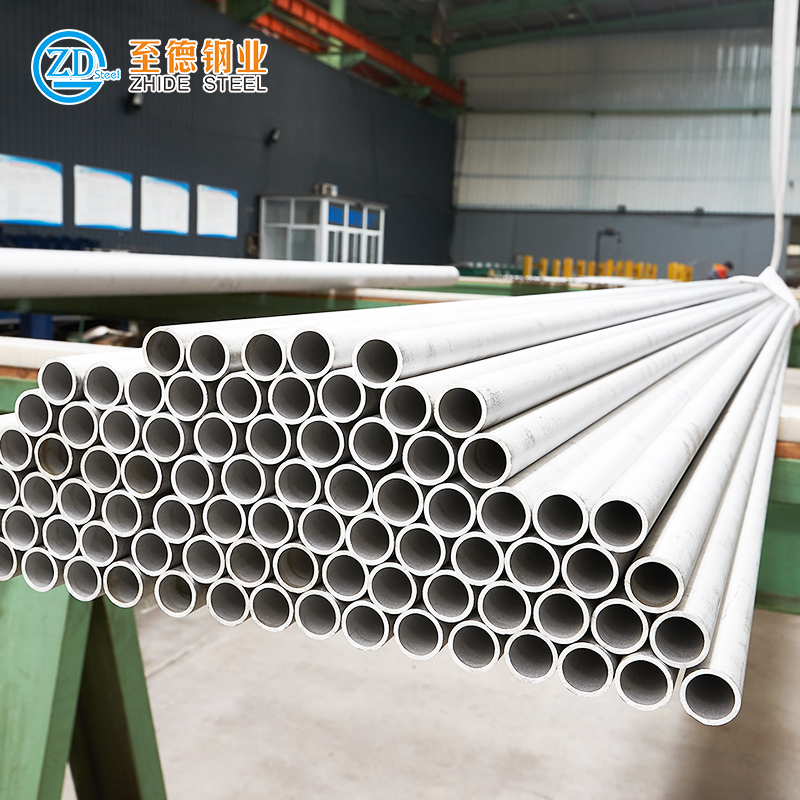

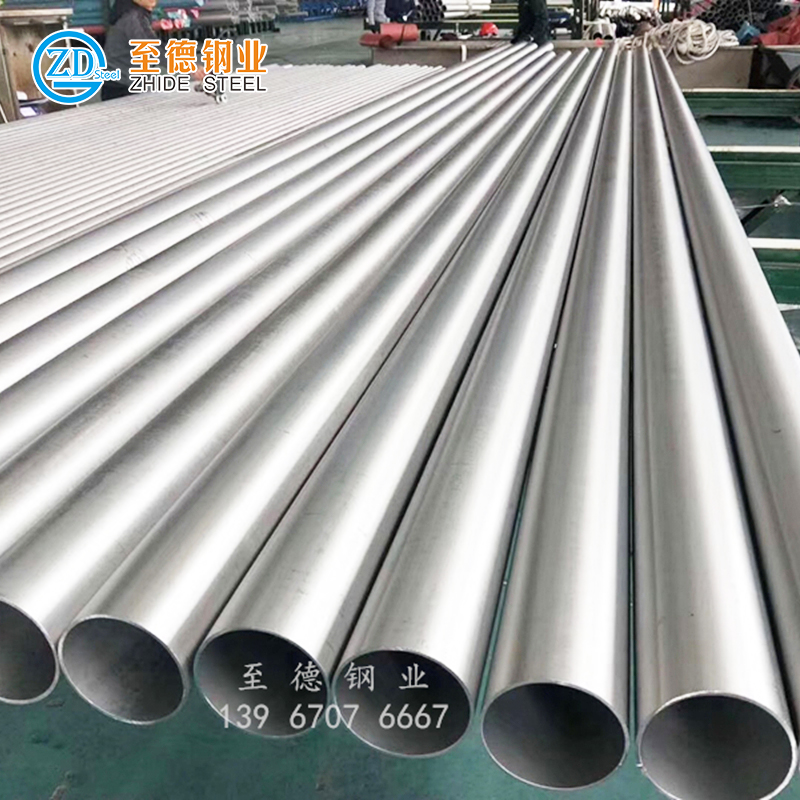

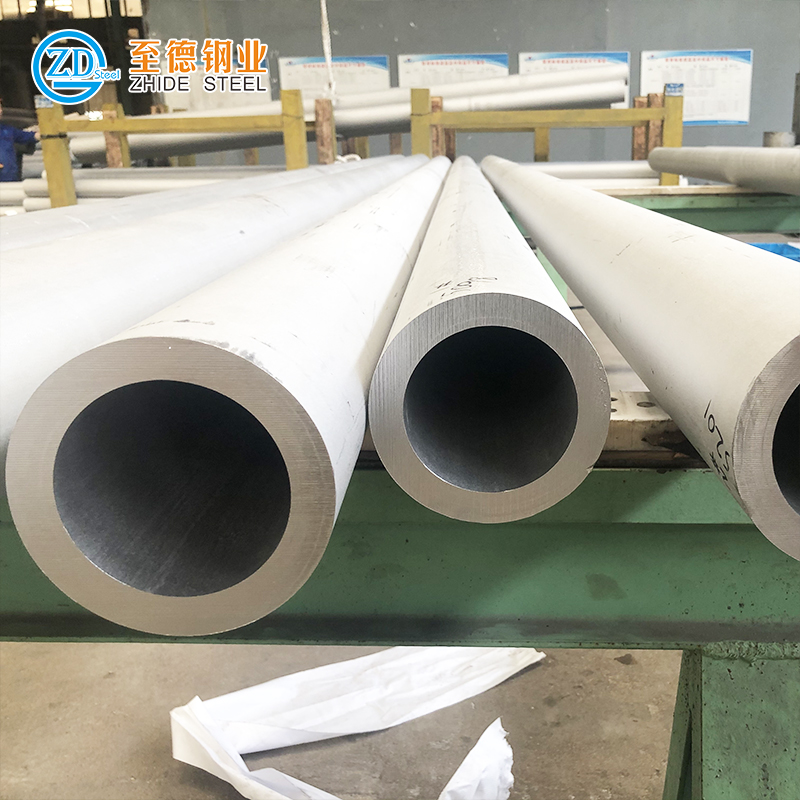

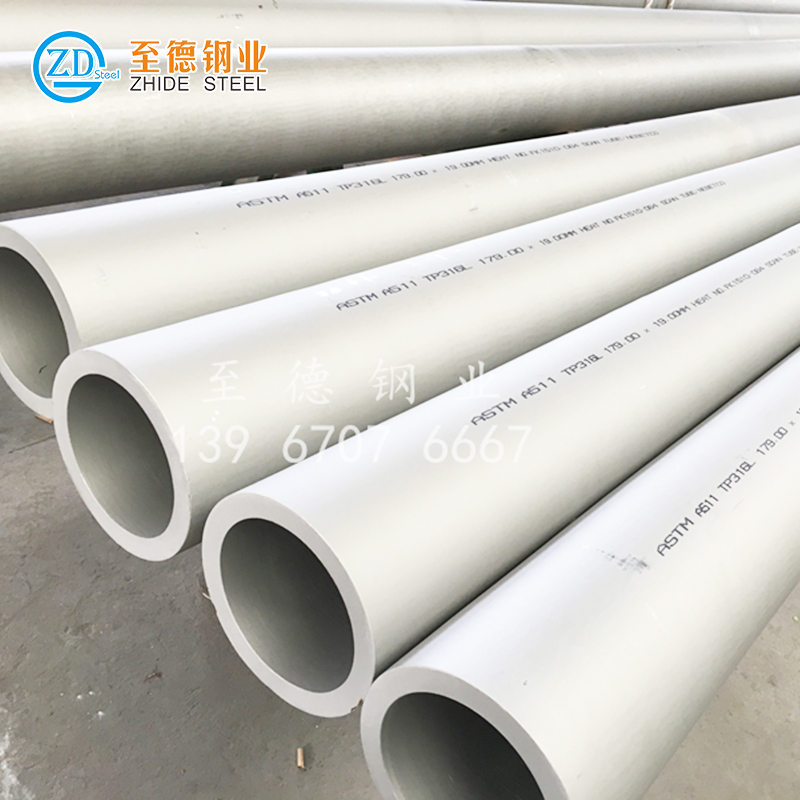

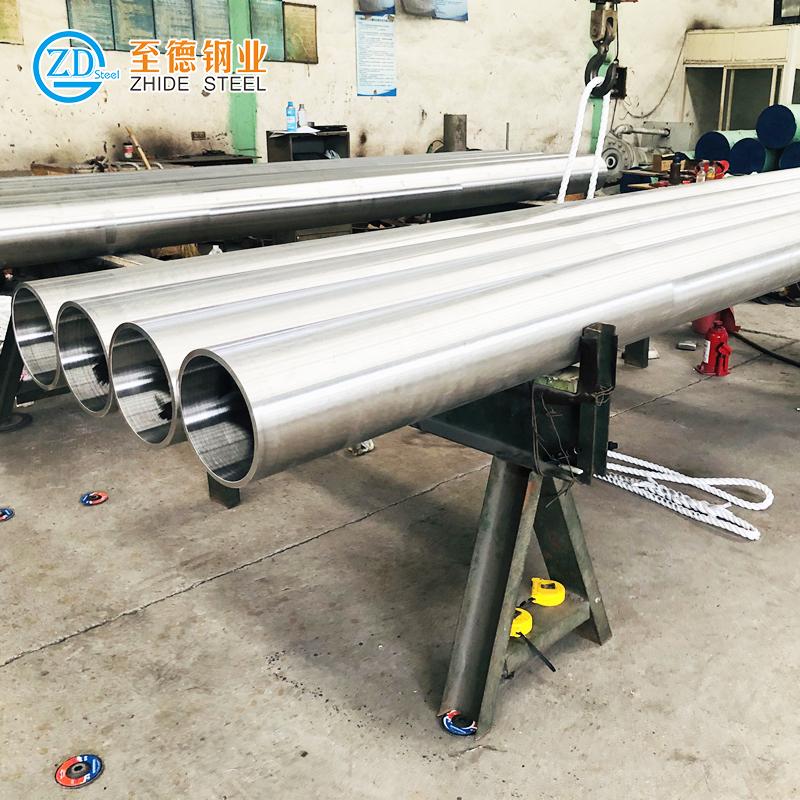

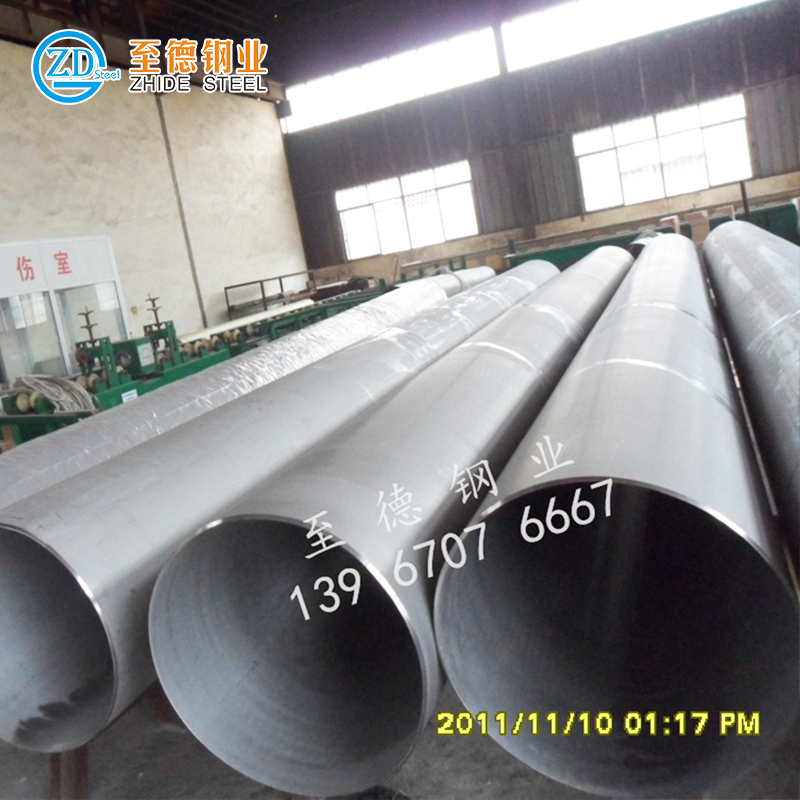

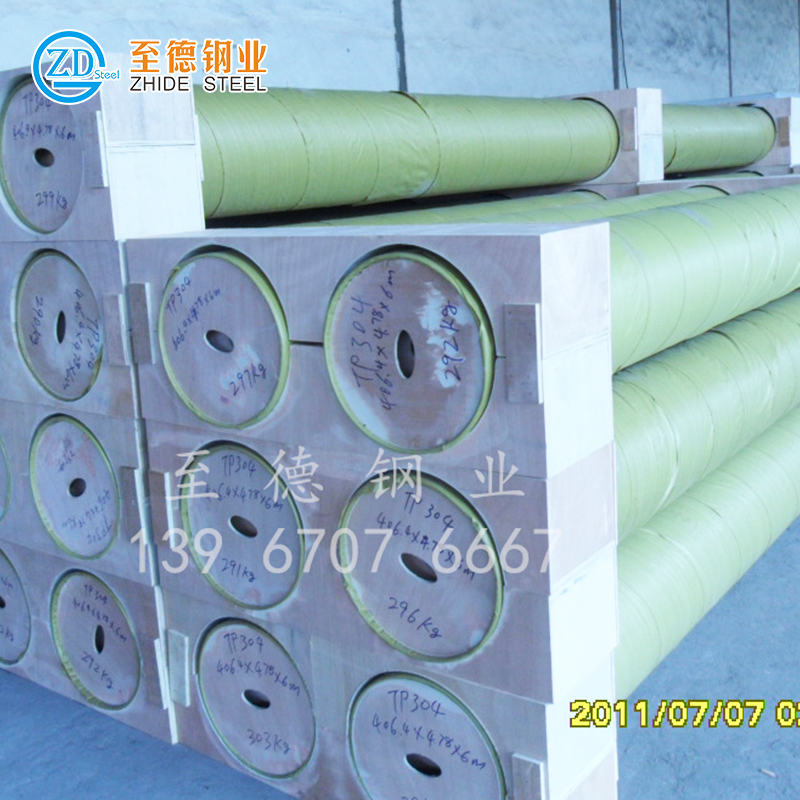

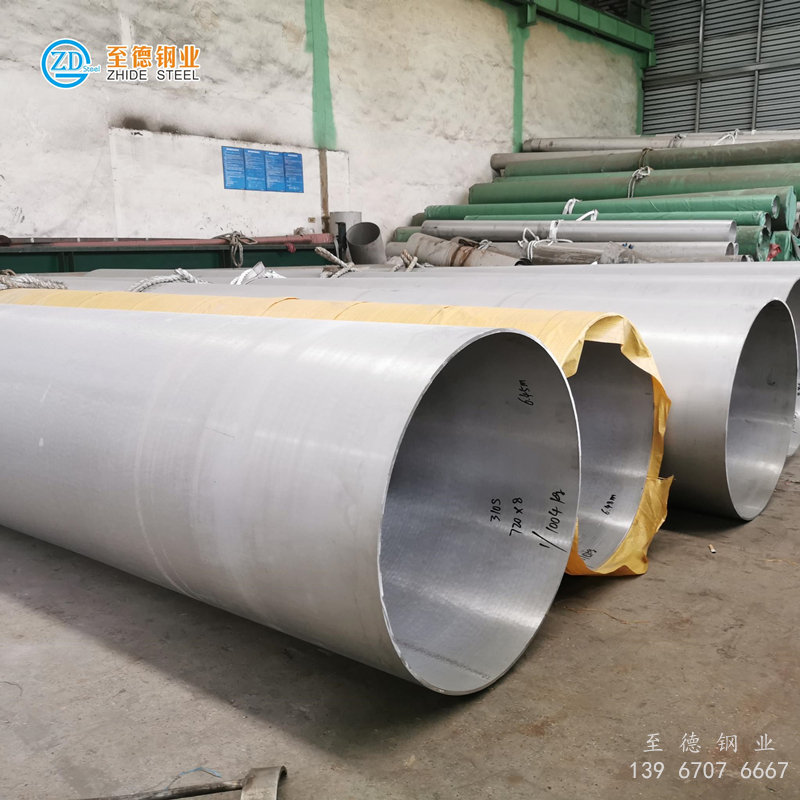

至德鋼業,我們根據(ju)您的(de)實際需求,給出參(can)考建(jian)議,為(wei)您提供高性價比的(de)不銹鋼管道(dao)及配件。