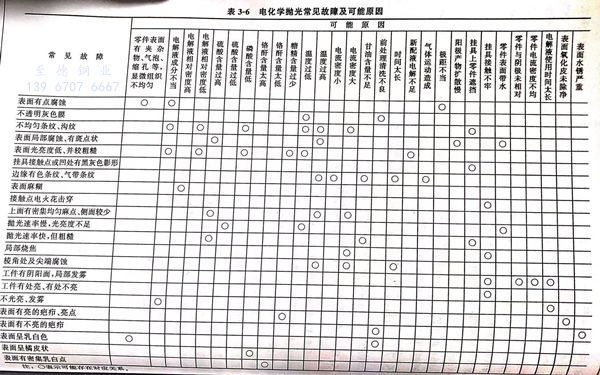

電(dian)化學拋光常見(jian)故障及可能原因見(jian)表3-6.

電化學拋光用電源、設備(bei)和夾具(ju)如下:

1. 電(dian)源

拋光對(dui)電源波形要求(qiu)不嚴,因此,一(yi)般使用的(de)直流發電機、硅整流器或可(ke)控硅整流器等(deng)均(jun)可(ke)。電源電壓(ya)空載要求(qiu)0~20V可(ke)調,帶負荷的(de)負載為8~10V工作電壓(ya)。工作電壓(ya)低(di)于6V,拋光速率慢,光亮度不足。

2. 電化學拋光槽

可(ke)用聚氯(lv)乙(yi)烯硬板材焊接而成(cheng)(cheng),其上(shang)裝有三根(gen)電極(ji)棒,中(zhong)間為(wei)可(ke)移動(dong)的(de)陽極(ji)棒,接電源(yuan)陽極(ji),兩(liang)側(ce)為(wei)陰(yin)極(ji)棒,并連接電源(yuan)陰(yin)極(ji)。槽(cao)(cao)上(shang)應有加溫和冷卻(que)裝置。加熱(re)可(ke)安裝鈦加熱(re)管,降溫可(ke)安裝通冷水的(de)鈦管。也可(ke)以(yi)采用厚度(du)5mm的(de)鋼板制(zhi)成(cheng)(cheng)內外(wai)夾套槽(cao)(cao),內槽(cao)(cao)上(shang)面(mian)襯鉛(qian)皮5mm厚,或襯軟(ruan)的(de)厚度(du)3mm的(de)聚氯(lv)乙(yi)烯塑料(liao)片(pian),夾套中(zhong)可(ke)通水和蒸氣,以(yi)便進行加熱(re)和冷卻(que),可(ke)以(yi)自如地控制(zhi)槽(cao)(cao)內拋(pao)光液的(de)溫度(du)。

3. 夾具材料

用(yong)鋁合金(jin)或純(chun)鈦材料制作的(de)夾具(ju)比較理想。它們導電(dian)好,有一(yi)定的(de)彈性(xing)和剛性(xing),耐腐蝕,壽命長(chang)。鋁或鈦離(li)子(zi)(zi)進(jin)入槽液(ye)無不良(liang)影(ying)響。不宜使(shi)用(yong)銅(tong)、黃銅(tong)或磷銅(tong)作夾具(ju),銅(tong)離(li)子(zi)(zi)進(jin)入電(dian)解液(ye)中,在(zai)陰極(ji)上(shang)析出(chu),在(zai)斷電(dian)取零件的(de)瞬(shun)時,在(zai)不銹鋼表面會(hui)立即置換上(shang)一(yi)層(ceng)結合力不良(liang)的(de)銅(tong)層(ceng)覆蓋在(zai)拋光表面,嚴重影(ying)響拋光質量。為了提高夾具(ju)的(de)使(shi)用(yong)壽命,夾具(ju)裸露部位必須(xu)包上(shang)聚氯乙烯膠(jiao)帶,或涂(tu)上(shang)聚氯乙烯糊狀樹脂或綠鉤膠(jiao),然后在(zai)200℃烘(hong)箱(xiang)上(shang)烤熔(rong)成膜,如此要進(jin)行多次(ci),使(shi)膜達(da)到一(yi)定的(de)厚度。然后在(zai)接(jie)(jie)觸點處用(yong)小刀刮去絕(jue)緣膜,露出(chu)金(jin)屬面以利于導電(dian)。每次(ci)使(shi)用(yong)時都要在(zai)堿液(ye)中活化接(jie)(jie)觸點。

4. 夾具的(de)導電(dian)能(neng)力

電化(hua)學拋光(guang)(guang)時(shi)(shi)所用(yong)(yong)的(de)(de)(de)電流(liu)密度比較(jiao)高(gao),一般情況下,一槽電流(liu)通過(guo)可達數以(yi)(yi)千(qian)安計,夾(jia)(jia)(jia)具設計制作時(shi)(shi)要(yao)(yao)考慮零(ling)件(jian)所用(yong)(yong)最大電流(liu)要(yao)(yao)能夠通過(guo)夾(jia)(jia)(jia)具的(de)(de)(de)導電板而不(bu)(bu)(bu)至于(yu)過(guo)度發燙,對(dui)鋁板以(yi)(yi)每平方毫米通過(guo)電流(liu)不(bu)(bu)(bu)超過(guo)4A為宜(yi)。夾(jia)(jia)(jia)具溫升太高(gao),不(bu)(bu)(bu)便于(yu)提放(fang),更易使(shi)夾(jia)(jia)(jia)具失去彈性及夾(jia)(jia)(jia)持零(ling)件(jian)的(de)(de)(de)能力(li)。夾(jia)(jia)(jia)具連接(jie)(jie)零(ling)件(jian)的(de)(de)(de)接(jie)(jie)觸(chu)面積要(yao)(yao)合(he)理。根(gen)據拋光(guang)(guang)表面形狀和電流(liu)在溶液中(zhong)的(de)(de)(de)分布,要(yao)(yao)適(shi)當增加導電接(jie)(jie)觸(chu)點(dian)(dian),最少不(bu)(bu)(bu)小(xiao)于(yu)3點(dian)(dian),導電板與零(ling)件(jian)的(de)(de)(de)接(jie)(jie)觸(chu)點(dian)(dian)必須緊密牢固,在拋光(guang)(guang)過(guo)程中(zhong)不(bu)(bu)(bu)得松(song)動(dong),對(dui)于(yu)重量較(jiao)大的(de)(de)(de)零(ling)件(jian)可用(yong)(yong)螺釘擰緊,又要(yao)(yao)有較(jiao)小(xiao)的(de)(de)(de)裝卡印痕。鋁夾(jia)(jia)(jia)具在使(shi)用(yong)(yong)前,要(yao)(yao)用(yong)(yong)熱(re)堿腐(fu)蝕一下才可使(shi)用(yong)(yong),以(yi)(yi)除(chu)去鋁在空氣中(zhong)長(chang)時(shi)(shi)間放(fang)置后生成(cheng)的(de)(de)(de)氧化(hua)膜,影(ying)響電流(liu)的(de)(de)(de)正常導入工作。

5. 拋(pao)光槽液位高度

在電化學拋(pao)光過程中(zhong),特別(bie)是含有(you)甘(gan)油(you)或添加劑的拋(pao)光液(ye)(ye)(ye)(ye),會產生大(da)量泡沫浮于液(ye)(ye)(ye)(ye)面(mian),為防止泡沫溢出槽(cao)(cao)外,方(fang)便(bian)調整槽(cao)(cao)液(ye)(ye)(ye)(ye)的相對密度(du)(du),液(ye)(ye)(ye)(ye)面(mian)應留有(you)空間,因此,拋(pao)光槽(cao)(cao)液(ye)(ye)(ye)(ye)位高應比槽(cao)(cao)總高度(du)(du)低(di)300mm.在設計槽(cao)(cao)的高度(du)(du)時,根據最大(da)拋(pao)光零件(jian)長度(du)(du)(a)、距(ju)槽(cao)(cao)底空250mm、距(ju)液(ye)(ye)(ye)(ye)面(mian)水平面(mian)50mm,液(ye)(ye)(ye)(ye)面(mian)水平面(mian)距(ju)槽(cao)(cao)口300mm,即(ji)可求得槽(cao)(cao)的高度(du)(du)h=250+50+a+300(mm)=a+600(mm).

6. 拋光槽陽極移動裝置

置放夾具和零件的(de)陽極桿(gan)為可移動的(de),移動速率以每分鐘往復10~20次(ci),左右(you)行程為100mm。