美國Phoenix 鋼鐵公司無縫鋼管廠采用Calmes軋管工藝,其軋管機組的平面布置圖是由意大利 Albert Calmes博士設計的,Phoenix 鋼鐵公司設計科在其他工程公司的配合下完成詳細設計,為了生產各種鋼號的優質無縫鋼管,使其內外徑和壁厚均具有良好的公差,軋管機組的設計以下列三方面內容為核心:Calmes在水壓沖孔機方面的專利、Calmes關于改進曼內斯曼延伸機方面的專利以及他所提出的周期軋管機的軋輥孔型。

這(zhe)一軋管(guan)機組采用(yong)Phoenix 鋼(gang)鐵公司(si)平爐頂鑄生(sheng)產的(de)最大重量達8000磅的(de)波浪形鋼(gang)錠為原(yuan)料(liao),成品管(guan)直徑(jing)為51/2~16英寸壁(bi)厚(hou)為1/4~3英寸。

這種軋(ya)管(guan)機組的(de)一大特點(dian)是直接采用平(ping)爐(lu)鋼(gang)錠在(zai)一個連續的(de)工(gong)藝過(guo)(guo)程(cheng)中(zhong)軋(ya)制成(cheng)管(guan),并且僅一次加熱(re)(re)就能完成(cheng)沖孔(kong)(kong)、延(yan)伸,周(zhou)(zhou)期(qi)軋(ya)管(guan)各工(gong)藝過(guo)(guo)程(cheng),其主要(yao)工(gong)藝過(guo)(guo)程(cheng)是:鋼(gang)錠清理、加熱(re)(re)、沖孔(kong)(kong)、延(yan)伸、周(zhou)(zhou)期(qi)軋(ya)管(guan),再加熱(re)(re)、定(ding)徑、修磨,精整(zheng)和水壓試驗,以下(xia)主要(yao)論述沖孔(kong)(kong)、延(yan)伸和周(zhou)(zhou)期(qi)軋(ya)管(guan)等三(san)個工(gong)藝過(guo)(guo)程(cheng)。

1. 水(shui)壓沖孔

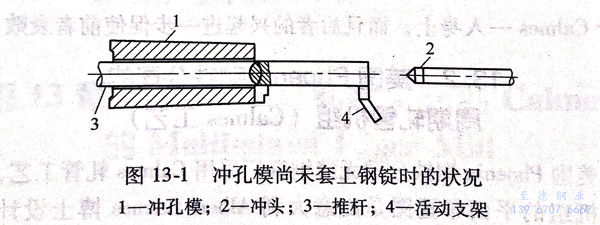

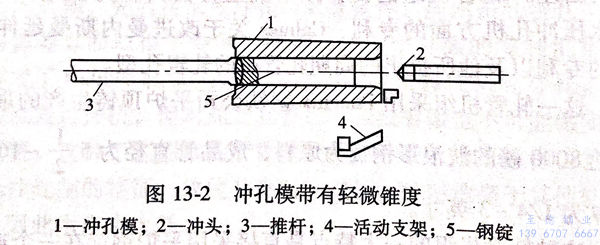

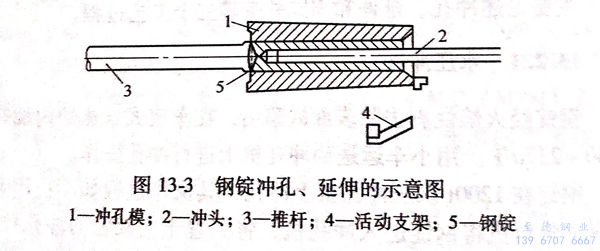

鋼(gang)(gang)錠經火焰燒剝去除(chu)表面缺陷后(hou)(hou),在車底式加(jia)(jia)熱(re)爐內加(jia)(jia)熱(re)到(dao)2340~2370℉。用小車運送到(dao)沖(chong)(chong)(chong)(chong)孔(kong)機(ji)(ji)(ji)(ji)上進行(xing)沖(chong)(chong)(chong)(chong)孔(kong)操(cao)作(zuo)。鋼(gang)(gang)錠在1200t水壓沖(chong)(chong)(chong)(chong)孔(kong)機(ji)(ji)(ji)(ji)上沖(chong)(chong)(chong)(chong)孔(kong),其(qi)操(cao)作(zuo)過程如下:用水壓操(cao)縱(zong)的(de)(de)裝料機(ji)(ji)(ji)(ji)將(jiang)鋼(gang)(gang)錠送人沖(chong)(chong)(chong)(chong)孔(kong)機(ji)(ji)(ji)(ji),將(jiang)其(qi)置于支(zhi)架(jia)(jia)上的(de)(de)沖(chong)(chong)(chong)(chong)孔(kong)位置,兩個支(zhi)架(jia)(jia)中(zhong)有一個是固定在沖(chong)(chong)(chong)(chong)孔(kong)模(mo)上的(de)(de),而另一個則(ze)可(ke)以伸縮(suo)(suo),沖(chong)(chong)(chong)(chong)孔(kong)模(mo)前(qian)移時(shi)即將(jiang)鋼(gang)(gang)錠套(tao)住,開始沖(chong)(chong)(chong)(chong)孔(kong)操(cao)作(zuo)。鋼(gang)(gang)錠沖(chong)(chong)(chong)(chong)孔(kong)后(hou)(hou),其(qi)形狀(zhuang)(zhuang)像杯(bei)子,被(bei)稱為杯(bei)狀(zhuang)(zhuang)體(ti),沖(chong)(chong)(chong)(chong)孔(kong)模(mo)的(de)(de)內徑決定杯(bei)狀(zhuang)(zhuang)體(ti)的(de)(de)外徑。沖(chong)(chong)(chong)(chong)頭直徑則(ze)確定杯(bei)狀(zhuang)(zhuang)體(ti)內孔(kong)的(de)(de)直徑,圖13-1所示是沖(chong)(chong)(chong)(chong)孔(kong)模(mo)前(qian)移但尚未套(tao)上鋼(gang)(gang)錠前(qian)端(duan)時(shi)的(de)(de)狀(zhuang)(zhuang)況,沖(chong)(chong)(chong)(chong)孔(kong)模(mo)前(qian)移達到(dao)其(qi)沖(chong)(chong)(chong)(chong)程的(de)(de)75%,可(ke)伸縮(suo)(suo)支(zhi)架(jia)(jia)從下部移出(chu),圖13-2示出(chu)鋼(gang)(gang)錠已被(bei)套(tao)入沖(chong)(chong)(chong)(chong)孔(kong)模(mo)內。

圖(tu)13-3示出(chu)整個杯(bei)狀(zhuang)體(ti)還套在沖孔(kong)模內(nei)的(de)情況,從圖(tu)13-3可(ke)以看出(chu)被沖孔(kong)的(de)鋼錠前(qian)端只剩下(xia)很薄的(de)杯(bei)底。鋼錠呈(cheng)方形(xing)或圓形(xing),即直徑為13英(ying)寸(cun),16英(ying)寸(cun),19英(ying)寸(cun)和21英(ying)寸(cun)的(de)波浪形(xing)圓錠。

2. 杯狀體(ti)延伸

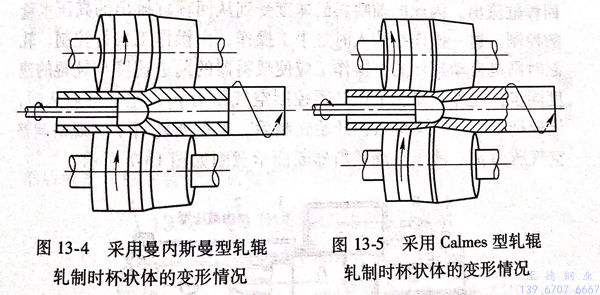

在(zai)延(yan)(yan)伸(shen)機(ji)上(shang),杯狀體在(zai)兩(liang)個在(zai)水(shui)平面上(shang)成(cheng)反向傾斜(xie)的斜(xie)置軋(ya)輥間,通過(guo)具有一定形(xing)(xing)狀的頂(ding)頭進行軋(ya)制。在(zai)垂直平面上(shang)有兩(liang)個固定導(dao)板(ban),其作(zuo)用是限制變形(xing)(xing)區(qu)的杯狀體的斷(duan)面形(xing)(xing)狀使之不至于過(guo)分橢圓。這種延(yan)(yan)伸(shen)機(ji)與曼(man)內斯曼(man)斜(xie)軋(ya)穿(chuan)(chuan)孔(kong)機(ji)很(hen)相似,它可以延(yan)(yan)伸(shen)杯狀體,并穿(chuan)(chuan)透杯底使之成(cheng)為空(kong)心坯。

圖13-4示出采用曼內斯曼輥型的延(yan)(yan)伸(shen)機對杯(bei)狀體(ti)進行延(yan)(yan)伸(shen)的過程。圖13-5所示是采用了Calmes軋輥的情況,空心坯延(yan)(yan)伸(shen)時,最好選用延(yan)(yan)伸(shen)率(lv) λ=1.75,最大不(bu)超過2。

延伸機采用(yong)3相、60Hz、功率為2208kW(3000馬(ma)力(li))的同步電機傳動,額定電壓、轉速(su)分別為6900V,1500r/min,減(jian)速(su)機的速(su)比為3。

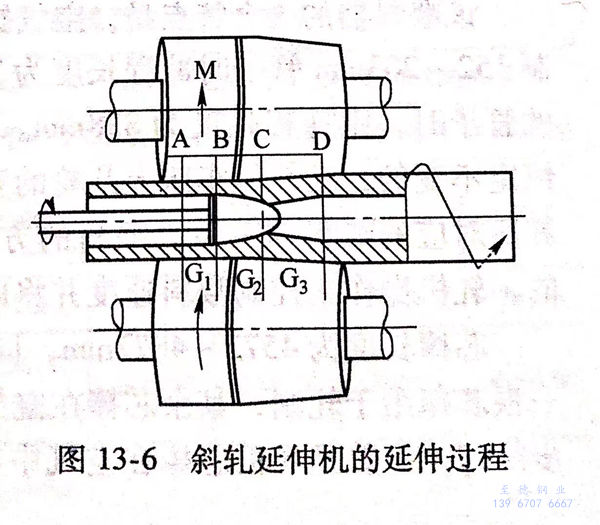

延伸機的主(zhu)要特點之一是它(ta)所生(sheng)產的空心坯(pi)壁厚比(bi)較均(jun)勻。斜軋(ya)延伸機的延伸過程可參看(kan)圖13-6。

杯狀(zhuang)體離開(kai)軋(ya)輥成為空心(xin)坯(pi)后,用以夾持頂桿的鎖門就打開(kai),空心(xin)坯(pi)從(cong)延伸機輸出,用橫移小(xiao)車(che)將其運送到周期軋(ya)管機。

3. 周期(qi)軋(ya)管機軋(ya)管

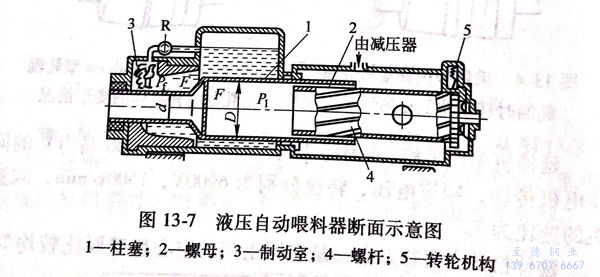

周(zhou)期軋(ya)(ya)管(guan)(guan)機由一臺額定功率為(wei)1472kW(2000馬力(li))的(de)(de)(de)電(dian)動(dong)機傳動(dong),該(gai)電(dian)動(dong)機的(de)(de)(de)功率能達2208kW(3000馬力(li))而不至于過分(fen)發熱。電(dian)動(dong)機軸上配有飛(fei)輪,在每一轉中它(ta)既提供能量又獲得能量,軋(ya)(ya)機速(su)(su)(su)(su)度(du)(du)是(shi)30~105r/min,較低的(de)(de)(de)速(su)(su)(su)(su)度(du)(du)用于軋(ya)(ya)制(zhi)(zhi)大管(guan)(guan),而較高的(de)(de)(de)速(su)(su)(su)(su)度(du)(du)用來軋(ya)(ya)小管(guan)(guan)。操(cao)作(zuo)(zuo)喂(wei)料器(qi)的(de)(de)(de)高壓水(shui)(shui)(shui)壓力(li)為(wei)2800 Ibl/in或1500 Ibf/in,以向一個前進缸(gang)和兩個回(hui)程缸(gang)供水(shui)(shui)(shui),正常運轉時(shi),向前進缸(gang)連續(xu)地供高壓水(shui)(shui)(shui),向前喂(wei)料時(shi),高壓水(shui)(shui)(shui)由回(hui)程缸(gang)流出,因此向前喂(wei)料的(de)(de)(de)速(su)(su)(su)(su)度(du)(du)受到(dao)從回(hui)程缸(gang)排出的(de)(de)(de)高壓水(shui)(shui)(shui)量的(de)(de)(de)控(kong)(kong)制(zhi)(zhi)。這一操(cao)作(zuo)(zuo)在咬(yao)人時(shi)是(shi)手工(gong)操(cao)作(zuo)(zuo),由操(cao)作(zuo)(zuo)工(gong)自行控(kong)(kong)制(zhi)(zhi),軋(ya)(ya)制(zhi)(zhi)時(shi)則是(shi)自動(dong)操(cao)作(zuo)(zuo)的(de)(de)(de),操(cao)作(zuo)(zuo)工(gong)應使喂(wei)料器(qi)的(de)(de)(de)前進速(su)(su)(su)(su)度(du)(du)與軋(ya)(ya)輥(gun)的(de)(de)(de)速(su)(su)(su)(su)度(du)(du)同(tong)步;此外(wai),操(cao)作(zuo)(zuo)工(gong)還必須控(kong)(kong)制(zhi)(zhi)空(kong)氣(qi)壓力(li)p1,空(kong)心坯(pi)咬(yao)人時(shi),迅速(su)(su)(su)(su)把空(kong)氣(qi)從缸(gang)里排出,開(kai)始軋(ya)(ya)制(zhi)(zhi)后,根據所(suo)軋(ya)(ya)管(guan)(guan)子的(de)(de)(de)規格調整空(kong)氣(qi)壓力(li)P1.液壓自動(dong)喂(wei)料器(qi)斷面示(shi)意圖(tu)如圖(tu)13-7所(suo)示(shi)。

該喂料(liao)(liao)器(qi)的(de)一(yi)(yi)個(ge)特點是,空氣缸的(de)沖程長度(du)都(dou)保持不變。軋(ya)制(zhi)(zhi)152~203mm管(guan)子時沖程長度(du)為(wei)762mm,而軋(ya)制(zhi)(zhi)228~406mm的(de)管(guan)子時,則沖程長度(du)為(wei)838mm.這意味著軋(ya)輥工(gong)作(zuo)段長度(du)是恒定不變的(de),在(zai)軋(ya)輥車床上(shang)凸輪的(de)安裝位(wei)置恰可使(shi)(shi)軋(ya)輥的(de)工(gong)作(zuo)段和所對(dui)應的(de)喂料(liao)(liao)器(qi)一(yi)(yi)致(zhi)。喂料(liao)(liao)的(de)方(fang)向與軋(ya)輥旋轉(zhuan)的(de)方(fang)向是相反的(de),軋(ya)機操(cao)作(zuo)工(gong)控(kong)制(zhi)(zhi)喂料(liao)(liao)速(su)度(du)并將此速(su)度(du)和軋(ya)輥轉(zhuan)速(su)保持同步。芯(xin)棒(bang)(bang)(bang)長度(du)為(wei)4572~4877mm,同時使(shi)(shi)用(yong)的(de)芯(xin)棒(bang)(bang)(bang)為(wei)5根(gen),其中一(yi)(yi)根(gen)芯(xin)棒(bang)(bang)(bang)用(yong)于軋(ya)制(zhi)(zhi),其余芯(xin)棒(bang)(bang)(bang)在(zai)空氣中冷(leng)卻(que),然后浸人水(shui)中進一(yi)(yi)步冷(leng)卻(que),一(yi)(yi)般是3根(gen)芯(xin)棒(bang)(bang)(bang)在(zai)空氣中冷(leng)卻(que),一(yi)(yi)根(gen)芯(xin)棒(bang)(bang)(bang)在(zai)水(shui)里冷(leng)卻(que),軋(ya)機運行中5根(gen)芯(xin)棒(bang)(bang)(bang)就(jiu)這樣(yang)反復循(xun)環著。

根據所軋管子規(gui)格調(diao)(diao)下(xia)(xia)輥高(gao)度,調(diao)(diao)整(zheng)后(hou)其高(gao)度是(shi)(shi)不變的。當(dang)空心(xin)坯被軋成帶(dai)有(you)皮爾(er)格頭的管子后(hou),應將(jiang)(jiang)上(shang)輥抬起。上(shang)輥是(shi)(shi)由高(gao)壓水缸來平衡的,其升降由電(dian)動(dong)機操(cao)作(zuo),由于芯(xin)棒全長有(you)1.6mm左右(you)的“退拔”,為使(shi)壁(bi)厚保(bao)持不變,軋制時(shi)通過(guo)一個微調(diao)(diao)裝置而(er)將(jiang)(jiang)軋輥升高(gao),微調(diao)(diao)裝置由專用電(dian)動(dong)機和減(jian)速(su)箱組成,減(jian)速(su)箱的出軸(zhou)通過(guo)空氣離合器與壓下(xia)(xia)螺絲(si)電(dian)動(dong)機的軸(zhou)相連,軋制時(shi)操(cao)作(zuo)工(gong)將(jiang)(jiang)上(shang)軋輥逐漸抬高(gao)以補償芯(xin)棒的錐度和熱膨脹。

軋制過程(cheng)中金屬流(liu)動的(de)(de)(de)方向(xiang)與喂料(liao)的(de)(de)(de)方向(xiang)相同(tong),軋輥每轉一周后(hou),芯(xin)棒(bang)回轉90°左右。當(dang)空(kong)心坯被軋制并(bing)由芯(xin)棒(bang)前端(duan)向(xiang)前移(yi)動時(shi),毛管繼續(xu)在導槽(cao)上滑(hua)移(yi),空(kong)心坯完全軋成管子后(hou),上軋輥抬(tai)起(qi),升降輥升起(qi),將(jiang)毛管輸(shu)送到熱鋸,切去(qu)端(duan)頭和(he)皮爾格頭,然后(hou)測量(liang)和(he)稱(cheng)量(liang)管子,在管壁上標出測得(de)的(de)(de)(de)重量(liang)。