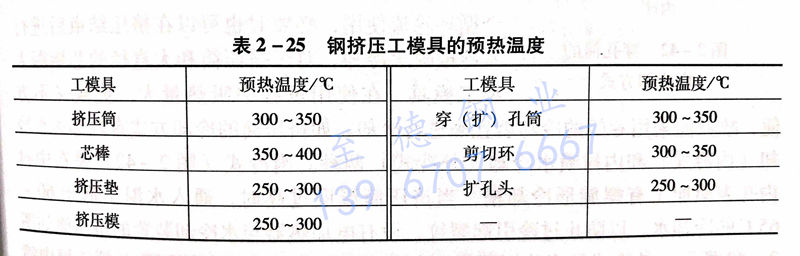

浙江至德鋼業有限公司為了減少不銹鋼(gang)管坯料與工模具接觸表面的溫降,有利于玻璃潤滑劑的軟化,提高潤滑效果,降低工模具表面熱沖擊引起的溫度應力,提高工模具的使用壽命,擠壓工模具使用前應進行預熱,其預熱溫度與擠壓材料和工模具的材質有關。擠壓不(bu)銹(xiu)鋼管和型材時,工模具的預熱溫度見表2-25。

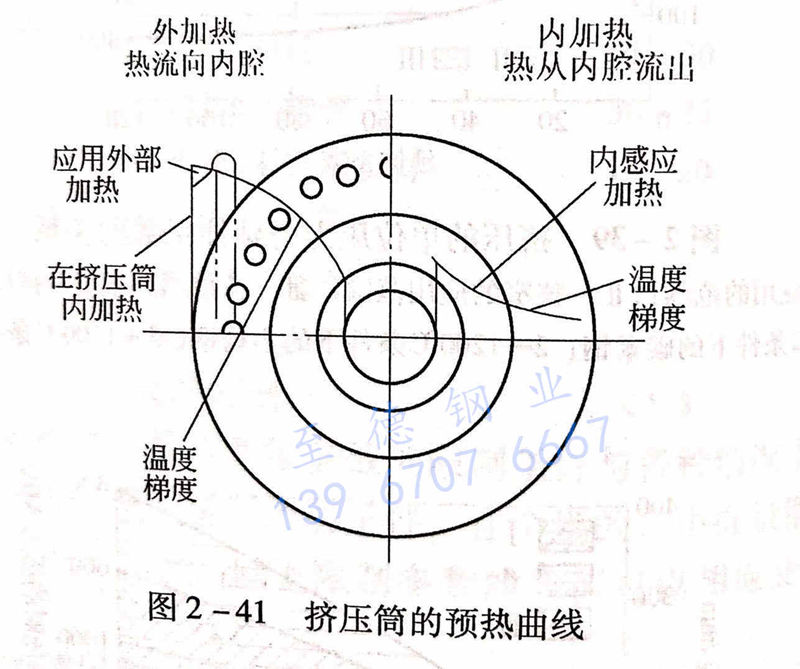

美國PMAC公司的2500噸(dun)擠(ji)(ji)壓(ya)(ya)機推薦(jian)的預熱溫度(du)如下:工(gong)具鋼制作的擠(ji)(ji)壓(ya)(ya)模和(he)穿孔(kong)頭為(wei)200℃,擠(ji)(ji)壓(ya)(ya)芯棒為(wei)250~320℃,擠(ji)(ji)壓(ya)(ya)筒為(wei)260~320℃,穿孔(kong)筒為(wei)360~370℃。擠(ji)(ji)壓(ya)(ya)模、擠(ji)(ji)壓(ya)(ya)墊、芯棒等(deng)小型工(gong)模具的預熱一般采用(yong)箱式電爐。擠(ji)(ji)壓(ya)(ya)筒的預熱主(zhu)要有電阻加(jia)(jia)(jia)熱和(he)感(gan)(gan)應(ying)加(jia)(jia)(jia)熱兩種。感(gan)(gan)應(ying)加(jia)(jia)(jia)熱是將感(gan)(gan)應(ying)線(xian)圈放(fang)入擠(ji)(ji)壓(ya)(ya)筒內(nei)進行(xing)加(jia)(jia)(jia)熱,加(jia)(jia)(jia)熱時熱流由內(nei)襯(chen)(chen)向外(wai)傳導,擠(ji)(ji)壓(ya)(ya)簡內(nei)的溫度(du)分布較電阻加(jia)(jia)(jia)熱合理(圖2-41),因為(wei)內(nei)襯(chen)(chen)、中和(he)外(wai)套之間的過盈配合應(ying)力不會降低,但感(gan)(gan)應(ying)加(jia)(jia)(jia)熱時操作不便,感(gan)(gan)應(ying)圈易損(sun)壞,所以目(mu)前主(zhu)要還是采用(yong)電阻加(jia)(jia)(jia)熱。

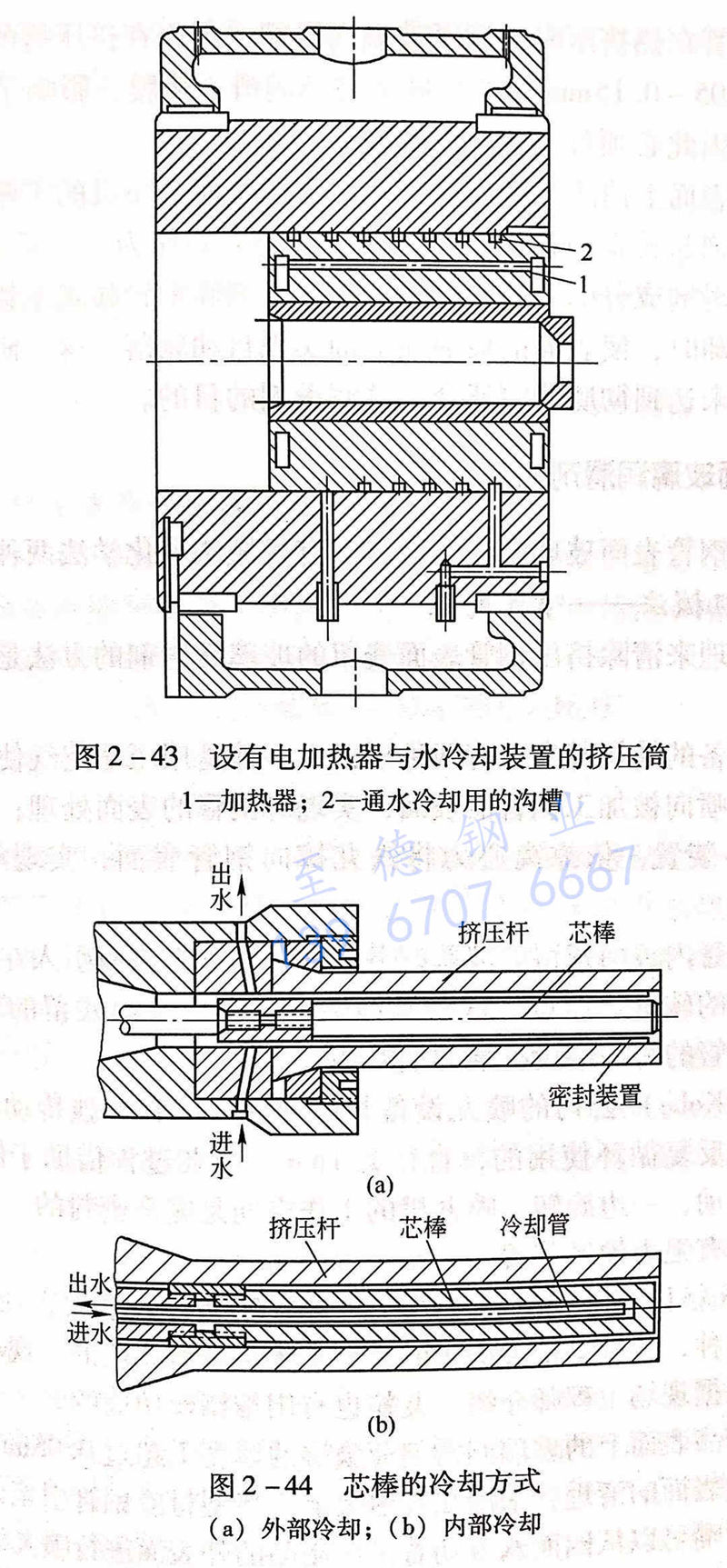

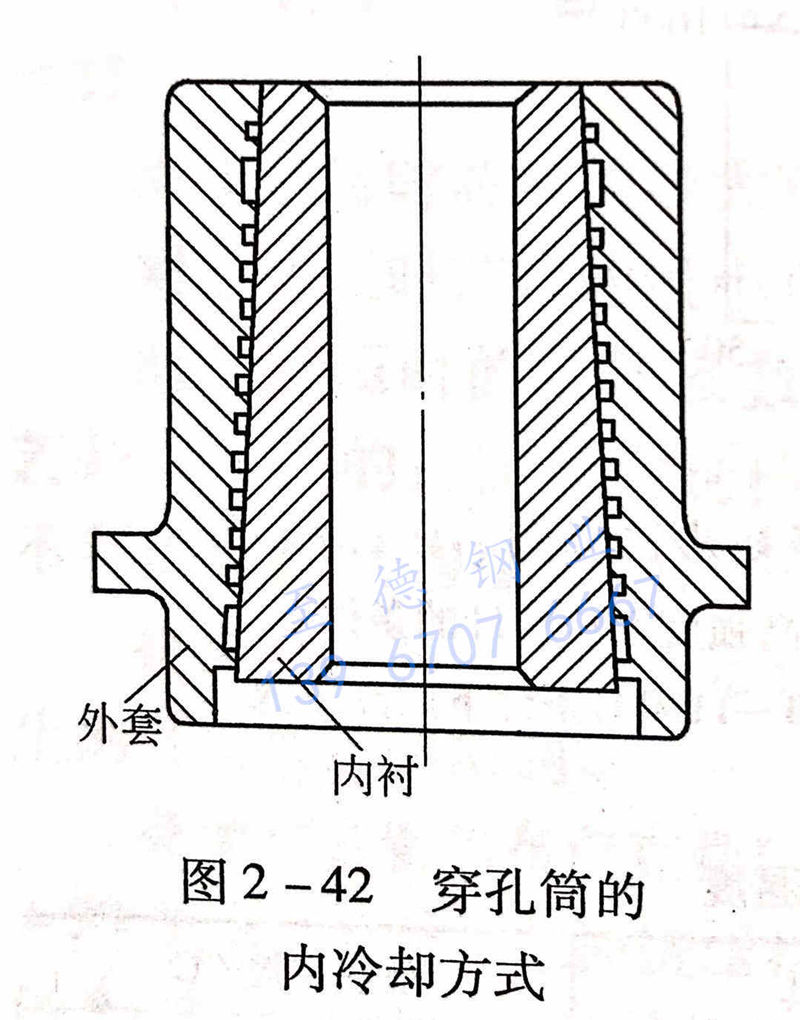

在正(zheng)常擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)生(sheng)(sheng)(sheng)產(chan)不(bu)(bu)銹鋼管過程中(zhong),擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)工(gong)(gong)(gong)模(mo)(mo)具連續使(shi)用(yong)時(shi),溫(wen)度(du)將會逐漸升高,而引(yin)起(qi)工(gong)(gong)(gong)模(mo)(mo)具材質高溫(wen)回火,降(jiang)低了紅(hong)硬性(xing),導(dao)致工(gong)(gong)(gong)模(mo)(mo)具產(chan)生(sheng)(sheng)(sheng)變形(xing)而影響(xiang)擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)過程的順利進(jin)行。如擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)墊的使(shi)用(yong)溫(wen)度(du)過高,因熱膨脹過大產(chan)生(sheng)(sheng)(sheng)變形(xing)而引(yin)起(qi)擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)墊卡在擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)筒(tong)(tong)內(nei)。為此,擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)工(gong)(gong)(gong)模(mo)(mo)具在使(shi)用(yong)過程中(zhong)又(you)需要(yao)進(jin)行必(bi)要(yao)的冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que),使(shi)其(qi)保(bao)持在所要(yao)求的溫(wen)度(du)范圍內(nei)工(gong)(gong)(gong)作。對(dui)于(yu)(yu)(yu)外套內(nei)襯(chen)(chen)擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)墊,擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)模(mo)(mo)和(he)小直徑(jing)(jing)的芯棒一(yi)般可以(yi)采用(yong)3~4個循環輪流使(shi)用(yong),必(bi)要(yao)時(shi)也(ye)(ye)可以(yi)在擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)結束后進(jin)行水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)或噴水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)。對(dui)于(yu)(yu)(yu)擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)筒(tong)(tong)和(he)大直徑(jing)(jing)的芯棒等大型工(gong)(gong)(gong)模(mo)(mo)具,在使(shi)用(yong)過程中(zhong)吸熱量大,更換(huan)又(you)不(bu)(bu)方便,故只能(neng)采用(yong)專(zhuan)門的冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)裝置來進(jin)行冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)。如擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)筒(tong)(tong)的冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)方式(shi)有(you)(you)(you)內(nei)部通(tong)(tong)水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)(內(nei)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)式(shi))和(he)內(nei)襯(chen)(chen)噴水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)(外冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)式(shi))兩(liang)種(zhong)。內(nei)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)式(shi)(圖2-42)是在中(zhong)襯(chen)(chen)內(nei)孔表(biao)面加工(gong)(gong)(gong)有(you)(you)(you)螺(luo)旋形(xing)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)槽,當(dang)擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)筒(tong)(tong)溫(wen)度(du)過高時(shi),通(tong)(tong)入水(shui)(shui)(shui)溫(wen)不(bu)(bu)低于(yu)(yu)(yu)60~65℃的冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)水(shui)(shui)(shui),以(yi)防止過冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)引(yin)起(qi)裂紋,設有(you)(you)(you)電(dian)加熱器與(yu)水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)裝置的擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)筒(tong)(tong),如圖2-43所示;外冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)式(shi)是當(dang)擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)循環結束時(shi),采用(yong)環狀噴嘴在擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)筒(tong)(tong)一(yi)端向筒(tong)(tong)內(nei)噴入壓(ya)(ya)(ya)力(li)水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que),這種(zhong)方法比較簡單,但內(nei)襯(chen)(chen)的材質要(yao)具有(you)(you)(you)良好(hao)的耐急冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)急熱性(xing)能(neng)。擠(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)芯棒的冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(que)(que)也(ye)(ye)有(you)(you)(you)內(nei)冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)式(shi)和(he)外冷(leng)(leng)(leng)(leng)(leng)(leng)(leng)(leng)式(shi)兩(liang)種(zhong)(圖2-44)。