不銹鋼管軋制過程中,受制于特殊的環形斷面形狀,使得軋制的工藝、設備具有特殊性和復雜性。同時在成型過程中存在擠壓、扭轉、拉伸等多種形變方式,因此實現變形溫度與變形量匹配的控制靈活性非常小。在此條件的制約下,軋制成型的控制思想往往也只能是在高溫環境變形抗力較小的條件下盡快完成熱變形過程。顯然,這種“無奈之舉”與控制軋制的通過對加熱溫度、軋制溫度、變形制度等工藝參數的匹配控制,進而基于“低溫軋制”實現對奧氏體及相變產物組織狀態的調控機制相違背,最終在改善性能方面無能為力。因此,在不實際改變高溫熱軋成型條件的背景下,如何實現奧氏體的調控進而為后續相變提供理想奧氏體狀態成為不銹鋼管組織進一步細化的突破口。

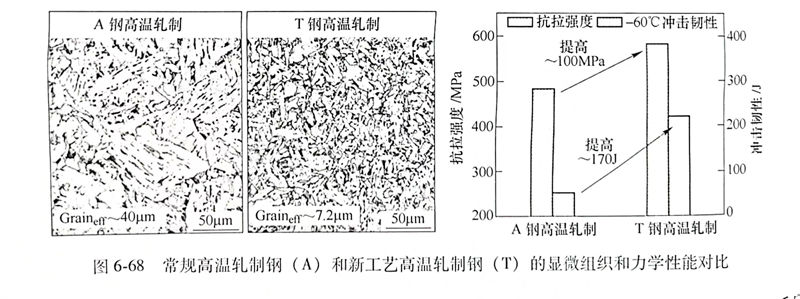

通過(guo)(guo)(guo)對(dui)第(di)二相(xiang)(xiang)粒子(zi)(zi)的(de)(de)(de)(de)適當控(kong)制(zhi)(zhi),可在(zai)實(shi)現(xian)(xian)釘扎奧氏(shi)體(ti)(ti)晶(jing)界的(de)(de)(de)(de)同(tong)時利用(yong)第(di)二相(xiang)(xiang)誘導(dao)晶(jing)內鐵(tie)(tie)素(su)體(ti)(ti)形(xing)(xing)核(he)機(ji)制(zhi)(zhi),獲(huo)(huo)得一定程度細化(hua)的(de)(de)(de)(de)奧氏(shi)體(ti)(ti)并(bing)為后續相(xiang)(xiang)變(bian)(bian)提(ti)供豐富的(de)(de)(de)(de)相(xiang)(xiang)變(bian)(bian)形(xing)(xing)核(he)點。該組(zu)(zu)織(zhi)調(diao)控(kong)思想目(mu)前(qian)廣泛(fan)應用(yong)于大(da)線(xian)能(neng)量焊(han)接用(yong)鋼材的(de)(de)(de)(de)開(kai)發(fa)中,其(qi)核(he)心機(ji)理是通過(guo)(guo)(guo)引入適當氧化(hua)物和(he)析出相(xiang)(xiang)實(shi)現(xian)(xian)釘扎熱(re)(re)影(ying)響(xiang)區奧氏(shi)體(ti)(ti)晶(jing)界并(bing)促進晶(jing)內鐵(tie)(tie)素(su)體(ti)(ti)形(xing)(xing)成,進而(er)細化(hua)相(xiang)(xiang)變(bian)(bian)組(zu)(zu)織(zhi),改善熱(re)(re)影(ying)響(xiang)區組(zu)(zu)織(zhi)性能(neng)。顯然,這種熱(re)(re)影(ying)響(xiang)區內的(de)(de)(de)(de)奧氏(shi)體(ti)(ti)狀(zhuang)態與不銹鋼管(guan)高(gao)溫(wen)(wen)形(xing)(xing)變(bian)(bian)下(xia)的(de)(de)(de)(de)粗大(da)奧氏(shi)體(ti)(ti)組(zu)(zu)織(zhi)十分(fen)吻合。因此,第(di)二相(xiang)(xiang)誘導(dao)相(xiang)(xiang)變(bian)(bian)形(xing)(xing)核(he)成為熱(re)(re)軋(ya)(ya)(ya)(ya)(ya)無縫鋼管(guan)在(zai)線(xian)組(zu)(zu)織(zhi)性能(neng)調(diao)控(kong),特別是組(zu)(zu)織(zhi)細化(hua)和(he)提(ti)高(gao)強韌性能(neng)的(de)(de)(de)(de)一種有效途徑(jing),即可在(zai)熱(re)(re)軋(ya)(ya)(ya)(ya)(ya)不銹鋼管(guan)高(gao)溫(wen)(wen)變(bian)(bian)形(xing)(xing)的(de)(de)(de)(de)條件下(xia),實(shi)現(xian)(xian)板材領域低溫(wen)(wen)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)具(ju)備的(de)(de)(de)(de)“控(kong)制(zhi)(zhi)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)”組(zu)(zu)織(zhi)細化(hua)效果。基于這一思路以及對(dui)鋼中第(di)二相(xiang)(xiang)粒子(zi)(zi)析出行(xing)為的(de)(de)(de)(de)研究(jiu),東(dong)北大(da)學研究(jiu)團(tuan)隊(dui)進一步(bu)提(ti)出了(le)“第(di)二相(xiang)(xiang)控(kong)制(zhi)(zhi)+高(gao)溫(wen)(wen)熱(re)(re)軋(ya)(ya)(ya)(ya)(ya)+控(kong)制(zhi)(zhi)冷(leng)卻”的(de)(de)(de)(de)在(zai)線(xian)形(xing)(xing)變(bian)(bian)/相(xiang)(xiang)變(bian)(bian)一體(ti)(ti)化(hua)組(zu)(zu)織(zhi)調(diao)控(kong)路線(xian)。針對(dui)典型(xing)碳錳鋼,通過(guo)(guo)(guo)復合脫氧工(gong)藝控(kong)制(zhi)(zhi),在(zai)鋼中引入具(ju)有高(gao)熱(re)(re)穩定性的(de)(de)(de)(de)氧化(hua)物后,充(chong)分(fen)發(fa)揮第(di)二相(xiang)(xiang)粒子(zi)(zi)的(de)(de)(de)(de)誘導(dao)晶(jing)內形(xing)(xing)核(he)作用(yong),在(zai)1100℃高(gao)溫(wen)(wen)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)和(he)控(kong)制(zhi)(zhi)冷(leng)卻條件下(xia)獲(huo)(huo)得了(le)微細的(de)(de)(de)(de)晶(jing)內鐵(tie)(tie)素(su)體(ti)(ti)組(zu)(zu)織(zhi),實(shi)驗(yan)鋼的(de)(de)(de)(de)強、韌性能(neng)均顯著提(ti)高(gao)(如(ru)圖6-68所示(shi)),在(zai)不實(shi)施(shi)低溫(wen)(wen)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)的(de)(de)(de)(de)控(kong)制(zhi)(zhi)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)前(qian)提(ti)下(xia),實(shi)現(xian)(xian)了(le)類同(tong)于“控(kong)軋(ya)(ya)(ya)(ya)(ya)控(kong)冷(leng)”的(de)(de)(de)(de)良好組(zu)(zu)織(zhi)細化(hua)效果。

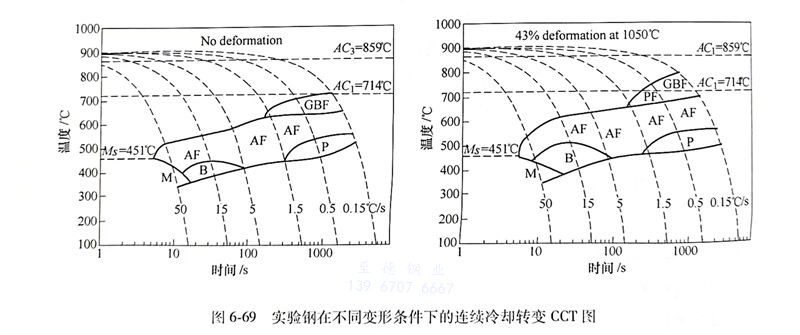

針對“第(di)二(er)(er)相(xiang)(xiang)控制(zhi)+高(gao)(gao)溫熱軋+控制(zhi)冷(leng)卻”工藝下(xia)的(de)(de)(de)低碳(tan)鋼組織(zhi)演變行為進(jin)行了(le)系統(tong)研究。采用質量分數為0.07C-0.06Si-1.5Mn-0.01P-0.006S成分的(de)(de)(de)實驗鋼,進(jin)行鈦(tai)脫氧處理,引(yin)入氧化(hua)鈦(tai)型(xing)第(di)二(er)(er)相(xiang)(xiang)粒子,考察(cha)了(le)不同(tong)變形和(he)冷(leng)速條件下(xia)的(de)(de)(de)連續冷(leng)卻轉變行為,如圖6-69和(he)圖6-70所示(shi)。結果表(biao)明,含氧化(hua)鈦(tai)實驗鋼在1.5~15℃/s冷(leng)速范圍內(nei)可獲(huo)得明顯(xian)的(de)(de)(de)針狀鐵素體組織(zhi),并且在1050℃以(yi)上高(gao)(gao)的(de)(de)(de)變形溫度下(xia)有利(li)于組織(zhi)的(de)(de)(de)細(xi)化(hua)。根(gen)據實驗結果,為了(le)達(da)到(dao)組織(zhi)細(xi)化(hua)的(de)(de)(de)目(mu)的(de)(de)(de),在不銹鋼管高(gao)(gao)溫變形條件下(xia),需(xu)結合控制(zhi)冷(leng)卻技術進(jin)行鋼管軋后(hou)冷(leng)卻路徑的(de)(de)(de)控制(zhi),從而發揮細(xi)晶組織(zhi)對強度和(he)韌性同(tong)時改善的(de)(de)(de)作用。

目前,控制冷卻技術在熱軋不銹鋼管中的工業應用研究尚處于起步階段,特別是結合管材成分特點的組織性能在線調控機理機制研究還落后于板帶材等領域。熱軋鋼管形變/相變在線組織一體化調控技術研究取得一定進展,后續依據“第二相控制+高溫熱軋+控制冷卻”的組織調控思路,深入研究變形一冷卻一相變的協同控制機制,實現鋼管領域產品的“控軋控冷”組織調控工藝效果,構建基于在線控制冷卻工藝的全新熱軋不銹(xiu)鋼管組織性能調控平臺。基于形變/相變在線組織調控技術,進一步地通過成分設計一熱軋成型一控制冷卻一熱處理的全流程工藝一體化控制,實現細晶強化、相變強化及析出強化的綜合強韌化,開發出高品質、低成本的熱軋不銹鋼管產品是進一步研發的重點。這對促進我國鋼鐵行業以“資源節約型、節能減排型”等綠色制造為特征的熱軋不銹(xiu)鋼管產品的開發與生產,具有重要意義。