不銹(xiu)鋼管立式穿(chuan)孔(kong)機具有各種不同的(de)結構,采用何種結構取決(jue)于其不同的(de)用途。

若用于實心坯料穿(chuan)孔(kong)(kong)(kong)的穿(chuan)孔(kong)(kong)(kong)機,通(tong)常具有安(an)(an)裝(zhuang)在同(tong)一導(dao)向(xiang)裝(zhuang)置上(shang)的兩個活動橫(heng)梁(liang)(liang)(liang),其中一個橫(heng)梁(liang)(liang)(liang)安(an)(an)裝(zhuang)有鐓(dui)粗(cu)坯料用的鐓(dui)粗(cu)桿,也(ye)稱為鐓(dui)粗(cu)梁(liang)(liang)(liang);另一個活動橫(heng)梁(liang)(liang)(liang)上(shang)安(an)(an)裝(zhuang)有穿(chuan)孔(kong)(kong)(kong)桿,即稱穿(chuan)孔(kong)(kong)(kong)梁(liang)(liang)(liang)。兩個橫(heng)梁(liang)(liang)(liang)可(ke)以(yi)同(tong)時或(huo)者單獨地工(gong)作(zuo)或(huo)移(yi)動。

若采用擴孔(kong)(kong)工藝時(shi),沒有(you)(you)鐓粗工序,則可以簡(jian)化(hua)穿(chuan)孔(kong)(kong)機(ji)的結構(gou),兩個動(dong)梁并(bing)為一個,僅作為擴孔(kong)(kong)頭在穿(chuan)孔(kong)(kong)筒中的對中,即具有(you)(you)短(duan)行程的附加動(dong)梁。

一般最為常用的不銹鋼(gang)管穿孔機用于分別完成穿孔和擴孔兩個工序。

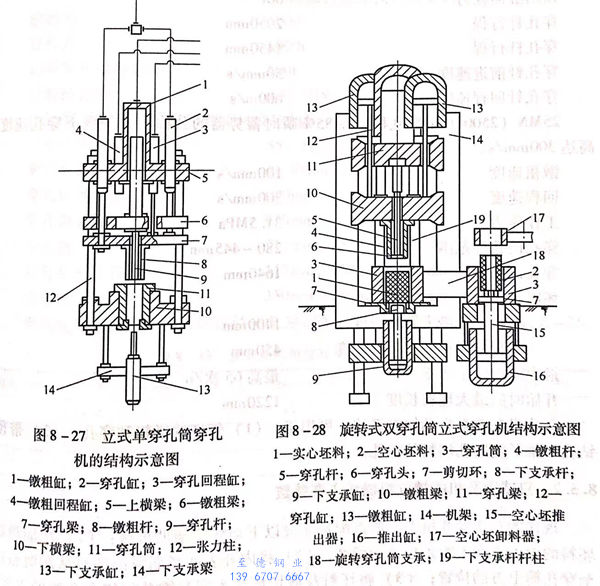

穿(chuan)(chuan)孔(kong)(kong)機(ji)(ji)(ji)按其結構(gou)形式(shi)可以分為三類:有(you)(you)一個固(gu)定穿(chuan)(chuan)孔(kong)(kong)筒的(de)(de)(de)(de)(de)穿(chuan)(chuan)孔(kong)(kong)機(ji)(ji)(ji);有(you)(you)一個移(yi)動穿(chuan)(chuan)孔(kong)(kong)筒的(de)(de)(de)(de)(de)穿(chuan)(chuan)孔(kong)(kong)機(ji)(ji)(ji)和(he)具有(you)(you)多(duo)(duo)工位的(de)(de)(de)(de)(de)旋轉或(huo)移(yi)動穿(chuan)(chuan)孔(kong)(kong)筒座(zuo)的(de)(de)(de)(de)(de)多(duo)(duo)穿(chuan)(chuan)孔(kong)(kong)筒形式(shi)的(de)(de)(de)(de)(de)穿(chuan)(chuan)孔(kong)(kong)機(ji)(ji)(ji)。日本的(de)(de)(de)(de)(de)神戶制(zhi)鋼還安裝(zhuang)了有(you)(you)3個穿(chuan)(chuan)孔(kong)(kong)筒的(de)(de)(de)(de)(de)多(duo)(duo)穿(chuan)(chuan)孔(kong)(kong)筒結構(gou)的(de)(de)(de)(de)(de)穿(chuan)(chuan)孔(kong)(kong)機(ji)(ji)(ji)。

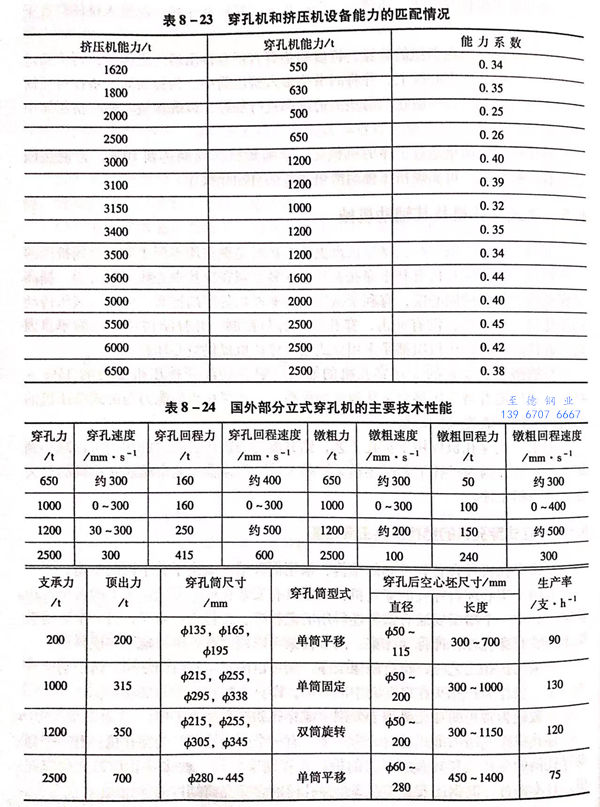

表8-23為穿孔機(ji)的能力(li)與擠(ji)壓機(ji)能力(li)的匹配(pei)情況,表8-24為國(guo)外(wai)部分立(li)式(shi)穿孔機(ji)的主要(yao)技術性能。

圖8-27所示為(wei)立式單筒固(gu)定式穿(chuan)孔機(ji)(ji)的結構示意圖,此(ci)種(zhong)穿(chuan)孔機(ji)(ji)設備高度高,裝出(chu)料間(jian)隙時間(jian)長,被認為(wei)是一種(zhong)陳舊的結構。

近代(dai)也有采(cai)用4工(gong)位雙穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)筒(tong)移(yi)動式(shi)或旋轉式(shi)立(li)式(shi)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)機(ji)結構(圖8-28)。這種結構的(de)立(li)式(shi)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)機(ji),采(cai)用2個穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)筒(tong)交替作業,裝出料和穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)筒(tong)內襯的(de)清理都在(zai)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)中心線之外(wai)進行。因此(ci),不(bu)僅使(shi)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)機(ji)的(de)高(gao)度(du)降(jiang)低,同時降(jiang)低了(le)廠房(fang)設施(shi)的(de)高(gao)度(du),而且(qie)也提(ti)高(gao)了(le)設備的(de)使(shi)用效(xiao)率(lv)。但是,隨之穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)筒(tong)的(de)快速和精(jing)確(que)定(ding)位及固定(ding)比較困難,搞得(de)不(bu)好會(hui)影(ying)響穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)后空心坯(pi)壁厚的(de)精(jing)度(du)。

雙(shuang)穿孔(kong)(kong)筒(tong)結構的穿孔(kong)(kong)機,穿孔(kong)(kong)筒(tong)具有4個工(gong)(gong)位(wei)(wei),在這些(xie)工(gong)(gong)位(wei)(wei)上依次完成以下工(gong)(gong)序:把(ba)穿孔(kong)(kong)坯(pi)料裝入(ru)穿孔(kong)(kong)筒(tong),進行坯(pi)料的鐓(dui)粗和穿孔(kong)(kong),從穿孔(kong)(kong)筒(tong)中頂出(chu)空心坯(pi),進行穿孔(kong)(kong)筒(tong)內(nei)襯的清理。

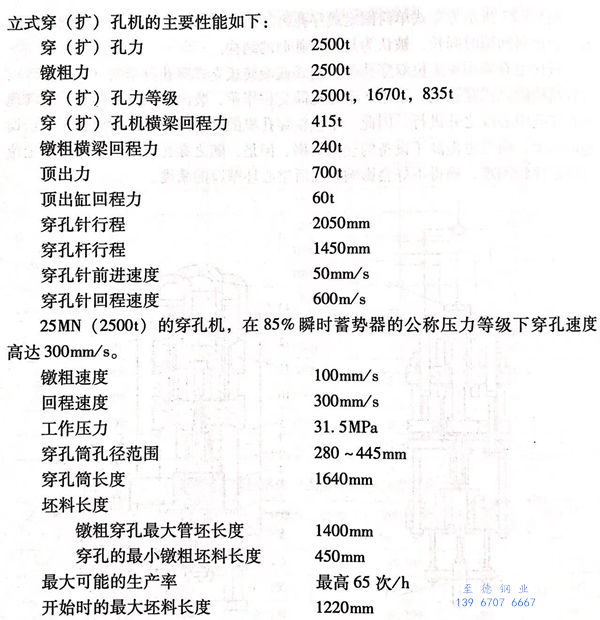

美國 Lone Star鋼(gang)廠55MN(5500t)臥式鋼(gang)管擠壓機(ji)相配套的25MN(2500t)立式穿孔機(ji)的主要性能(neng)如下:

穿(chuan)孔機配置有自(zi)動控制系統(tong),可(ke)用于:(1)管坯(pi)的鐓(dui)粗和穿(chuan)孔;(2)帶預鉆孔和錐形輔(fu)助孔坯(pi)料的擴孔。