大部分常用鎳鉻系奧氏體不(bu)銹(xiu)鋼(gang)自高溫奧氏體狀態冷至室溫獲得的奧氏體基體組織都是亞穩定的,當繼續冷卻到室溫以下更低的溫度,或者經受冷變形,其中的一部分或大部分奧氏體會發生馬氏體轉變,變成馬氏體組織。不銹鋼中馬氏體有兩種形態:體心立方的a'馬氏體,呈鐵磁性;六方結構的ε馬氏體,為非鐵磁性。由于ε馬氏體總是與a'馬氏體伴隨而出現,有人認為ε馬氏體是γ→a'過程中的一種過渡相,也有人認為ε馬氏體是一種獨立相。

馬氏體轉變(bian)(bian)受鋼的化學成分、溫度(du)、冷變(bian)(bian)形量及(ji)變(bian)(bian)形速(su)率的影響。

曾對不(bu)(bu)同成(cheng)分(fen)的(de)Fe-Mn-Cr-Ni合(he)金的(de)馬(ma)氏體相(xiang)(xiang)變(bian)(bian)(bian)(bian)進行(xing)過研(yan)究(含0.03%C、0.01%~0.03%Si、0.006%~0.019%N、0.012%~0.10%Al):含20%Mn的(de)Fe-Mn合(he)金自(zi)1050℃水(shui)冷(leng)(leng)(leng)(leng)(leng)至(zhi)室(shi)(shi)(shi)溫(wen)(wen)(wen),發(fa)生(sheng)(sheng)γ→E轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian),相(xiang)(xiang)約(yue)(yue)(yue)為(wei)(wei)40%,再冷(leng)(leng)(leng)(leng)(leng)卻至(zhi)-196℃,y相(xiang)(xiang)幾(ji)乎全部轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian)為(wei)(wei)ε相(xiang)(xiang),只生(sheng)(sheng)成(cheng)少(shao)量的(de)α'相(xiang)(xiang)。成(cheng)分(fen)為(wei)(wei)Fe-5%Mn-15%Cr-9%Ni合(he)金自(zi)1050℃水(shui)冷(leng)(leng)(leng)(leng)(leng)至(zhi)室(shi)(shi)(shi)溫(wen)(wen)(wen),10min后(hou)(hou)冷(leng)(leng)(leng)(leng)(leng)至(zhi)-196℃,不(bu)(bu)發(fa)生(sheng)(sheng)馬(ma)氏體相(xiang)(xiang)變(bian)(bian)(bian)(bian),仍為(wei)(wei)100%的(de)y相(xiang)(xiang);冷(leng)(leng)(leng)(leng)(leng)至(zhi)室(shi)(shi)(shi)溫(wen)(wen)(wen),再在20℃下施(shi)以(yi)40%冷(leng)(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing)(xing),將發(fa)生(sheng)(sheng)γ→ε+α'的(de)轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian),轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian)量約(yue)(yue)(yue)為(wei)(wei)20%,其中約(yue)(yue)(yue)2/3為(wei)(wei)ε相(xiang)(xiang),1/3為(wei)(wei)α'相(xiang)(xiang);如(ru)果自(zi)1050℃水(shui)冷(leng)(leng)(leng)(leng)(leng)至(zhi)室(shi)(shi)(shi)溫(wen)(wen)(wen)后(hou)(hou),再在-196℃下施(shi)以(yi)40%的(de)冷(leng)(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing)(xing),發(fa)生(sheng)(sheng)γ→e+α'的(de)轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian),轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian)量近90%,其中約(yue)(yue)(yue)1/4為(wei)(wei)ε相(xiang)(xiang),3/4為(wei)(wei)a'相(xiang)(xiang)。成(cheng)分(fen)為(wei)(wei)Fe-20%Cr-12%Ni的(de)合(he)金自(zi)1050℃水(shui)冷(leng)(leng)(leng)(leng)(leng),10min后(hou)(hou)冷(leng)(leng)(leng)(leng)(leng)至(zhi)-196℃,不(bu)(bu)發(fa)生(sheng)(sheng)馬(ma)氏體相(xiang)(xiang)變(bian)(bian)(bian)(bian),冷(leng)(leng)(leng)(leng)(leng)至(zhi)室(shi)(shi)(shi)溫(wen)(wen)(wen)在20℃下施(shi)以(yi)40%的(de)冷(leng)(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing)(xing),僅發(fa)生(sheng)(sheng)γ→E轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian),相(xiang)(xiang)約(yue)(yue)(yue)為(wei)(wei)10%;如(ru)果冷(leng)(leng)(leng)(leng)(leng)至(zhi)室(shi)(shi)(shi)溫(wen)(wen)(wen)后(hou)(hou)再在-196℃下施(shi)以(yi)40%的(de)冷(leng)(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing)(xing),將發(fa)生(sheng)(sheng)γ→ε+α轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian),轉(zhuan)(zhuan)(zhuan)(zhuan)變(bian)(bian)(bian)(bian)量約(yue)(yue)(yue)為(wei)(wei)55%,15%為(wei)(wei)ε相(xiang)(xiang),40%為(wei)(wei)α'相(xiang)(xiang)。

對(dui)于奧氏體不(bu)銹鋼(gang)的馬氏體轉變(bian)的臨(lin)界溫度(du)M3,已建立起(qi)若干Ms,點(dian)(a')與(yu)合金成(cheng)分關系的經驗(yan)公式,下面是其中的一個(ge)表達(da)式:

上面兩個(ge)公(gong)式說明,奧氏體(ti)不(bu)銹鋼中合金元素含量越高(gao),馬氏體(ti)點就越低,馬氏體(ti)轉變就越不(bu)容易發生。

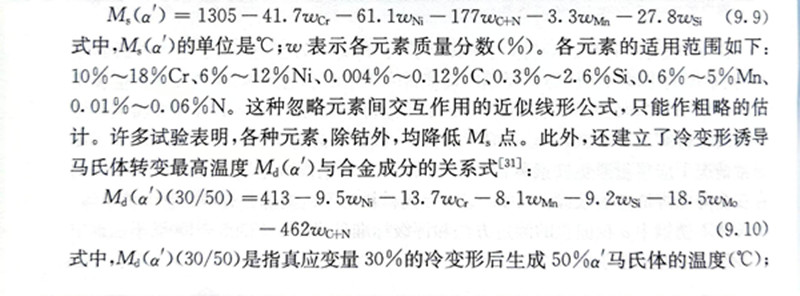

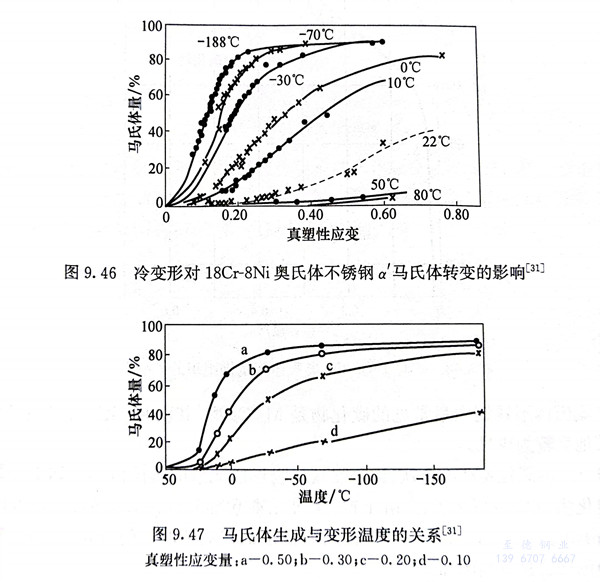

在18Cr-8Ni奧氏體不銹鋼中,α'馬氏體形成量隨冷變形量加大和變形溫度降低而增多,如圖9.46和圖9.47所示。可以看出,在每一變形溫度下,α'馬氏體含量隨冷變形量加大而增長到一定數值后將趨于飽和。隨變形溫度的降低,在同樣變形量的條件下,α'馬氏體的生成量增加,其增加也有一個飽和值,亦即無論采取什么措施,不可能完全轉變為馬氏體。這種奧氏體穩定化受多種因素影響,除合金成分和晶粒度等內在因素外,還有奧氏體化溫度、冷卻速率等外界因素。

變(bian)(bian)形速率對馬(ma)氏體(ti)轉變(bian)(bian)的影響主要(yao)是變(bian)(bian)形發(fa)熱導致材(cai)料溫(wen)度上升的作用,即(ji)變(bian)(bian)形速率越(yue)高,材(cai)料溫(wen)度也(ye)越(yue)高,因而α'馬(ma)氏體(ti)的生(sheng)成量也(ye)越(yue)少。