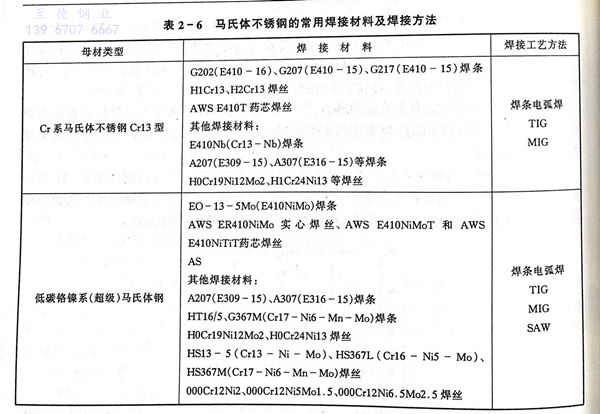

熔化焊各種方法均可用來焊接鉻系馬氏體不銹鋼管(guan),但最常用的方法是手工焊條電弧焊和鎢極氬弧焊。當采用手工焊條電弧焊時應盡可能采用低氫、超低氫焊條,焊前經過300~350℃的高溫烘烤以減少擴散氫的含量,降低冷裂紋的敏感性。鎢極氬弧焊(GTAW)主要使用于薄壁構件和管道焊件,以及重要部件的根部封底。GTAW焊的特點是焊接質量高,焊縫成型美觀,可單面焊,雙面成型,保證管子內焊縫的成型質量。焊接時為防止背面氧化,封底焊通常采取氬氣背面保護的措施。Ar+CO2或Ar+O2的富氬混合氣體保護焊也常用于焊接馬氏體不銹鋼,具有焊接效率高,焊縫質量較好以及焊縫金屬具有較高抗氫致(冷)裂紋的特點。表2-6是已標準化的Cr13型馬氏體及低碳鉻鎳系馬氏體不銹鋼管常用焊材。

鉻系馬(ma)氏體(ti)不銹鋼管,因焊(han)(han)(han)(han)(han)(han)接性較差,采(cai)用(yong)與(yu)(yu)母材(cai)成分(fen)相同的(de)焊(han)(han)(han)(han)(han)(han)材(cai)時,通(tong)常均應(ying)采(cai)取焊(han)(han)(han)(han)(han)(han)前(qian)預熱,焊(han)(han)(han)(han)(han)(han)后(hou)(hou)熱處(chu)理。但(dan)當(dang)焊(han)(han)(han)(han)(han)(han)件(jian)的(de)拘束度大,且(qie)難于(yu)進行預熱和(he)焊(han)(han)(han)(han)(han)(han)后(hou)(hou)熱處(chu)理時,也可(ke)以(yi)采(cai)用(yong)奧氏體(ti)型焊(han)(han)(han)(han)(han)(han)接材(cai)料(見(jian)表2-6),以(yi)提高焊(han)(han)(han)(han)(han)(han)接接頭的(de)塑韌性,防(fang)止裂紋(wen)的(de)發生(sheng)。但(dan)奧氏體(ti)或(huo)以(yi)奧氏體(ti)為主焊(han)(han)(han)(han)(han)(han)縫(feng)金屬的(de)強度低于(yu)馬(ma)氏體(ti)母材(cai),而且(qie)由于(yu)焊(han)(han)(han)(han)(han)(han)縫(feng)金屬化(hua)學成分(fen)和(he)顯微組(zu)織與(yu)(yu)母材(cai)差別(bie)較大,焊(han)(han)(han)(han)(han)(han)接殘(can)余(yu)應(ying)力較大,對(dui)焊(han)(han)(han)(han)(han)(han)接接頭的(de)使(shi)用(yong)性能(neng)產(chan)生(sheng)不利(li)影響,特別(bie)是對(dui)接頭的(de)疲勞(lao)蠕變性能(neng)和(he)應(ying)力腐蝕破裂不利(li)。因此采(cai)用(yong)奧氏體(ti)焊(han)(han)(han)(han)(han)(han)材(cai)時應(ying)根(gen)據使(shi)用(yong)條件(jian)嚴(yan)格選擇和(he)進行工(gong)藝評定。有(you)時還可(ke)采(cai)用(yong)鎳(nie)基合金焊(han)(han)(han)(han)(han)(han)材(cai),使(shi)焊(han)(han)(han)(han)(han)(han)縫(feng)的(de)膨脹系數與(yu)(yu)母材(cai)接近,盡量降低焊(han)(han)(han)(han)(han)(han)接殘(can)余(yu)應(ying)力和(he)高溫熱應(ying)力。